Patents

Literature

33results about How to "Easy to remove manually" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

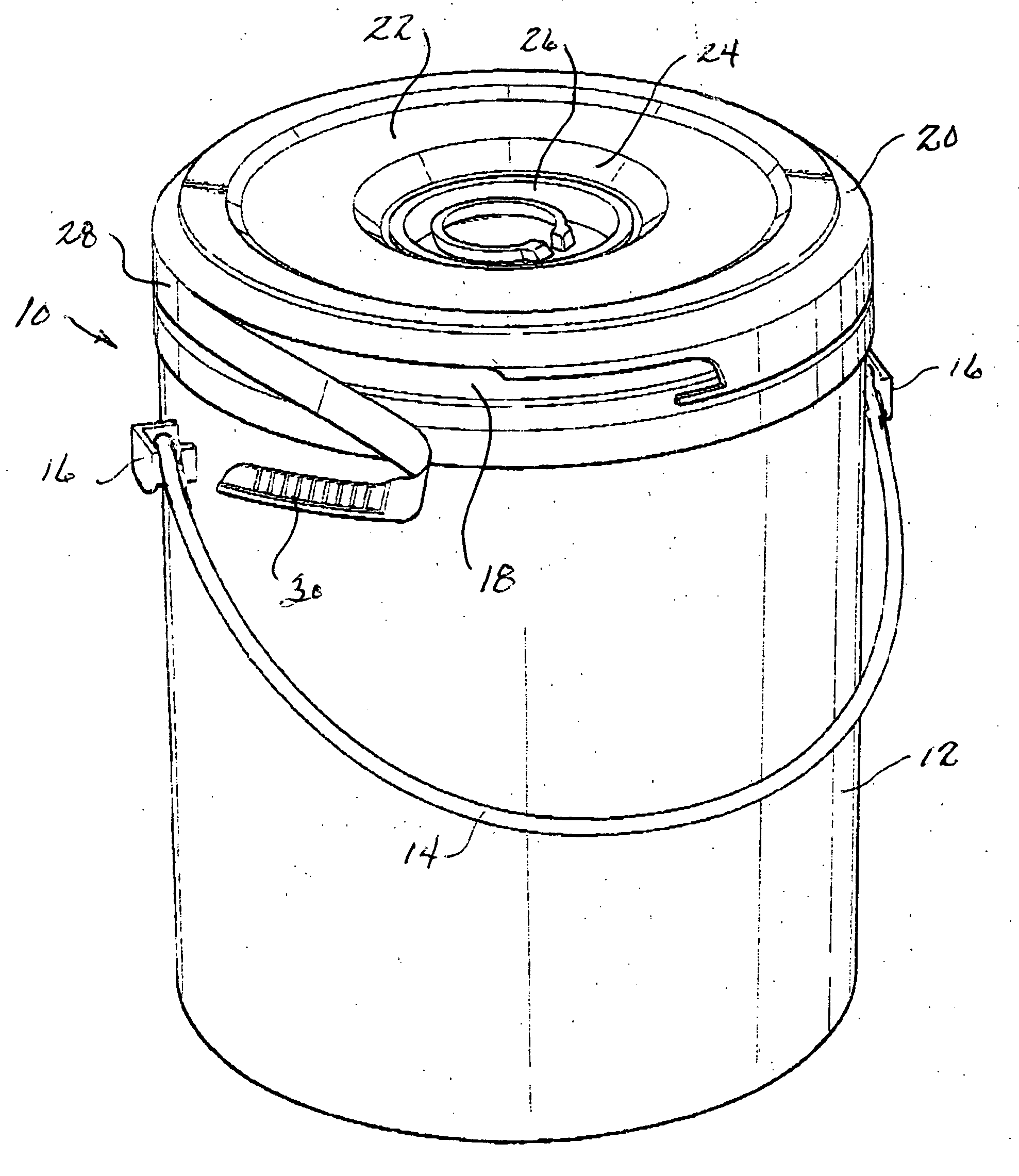

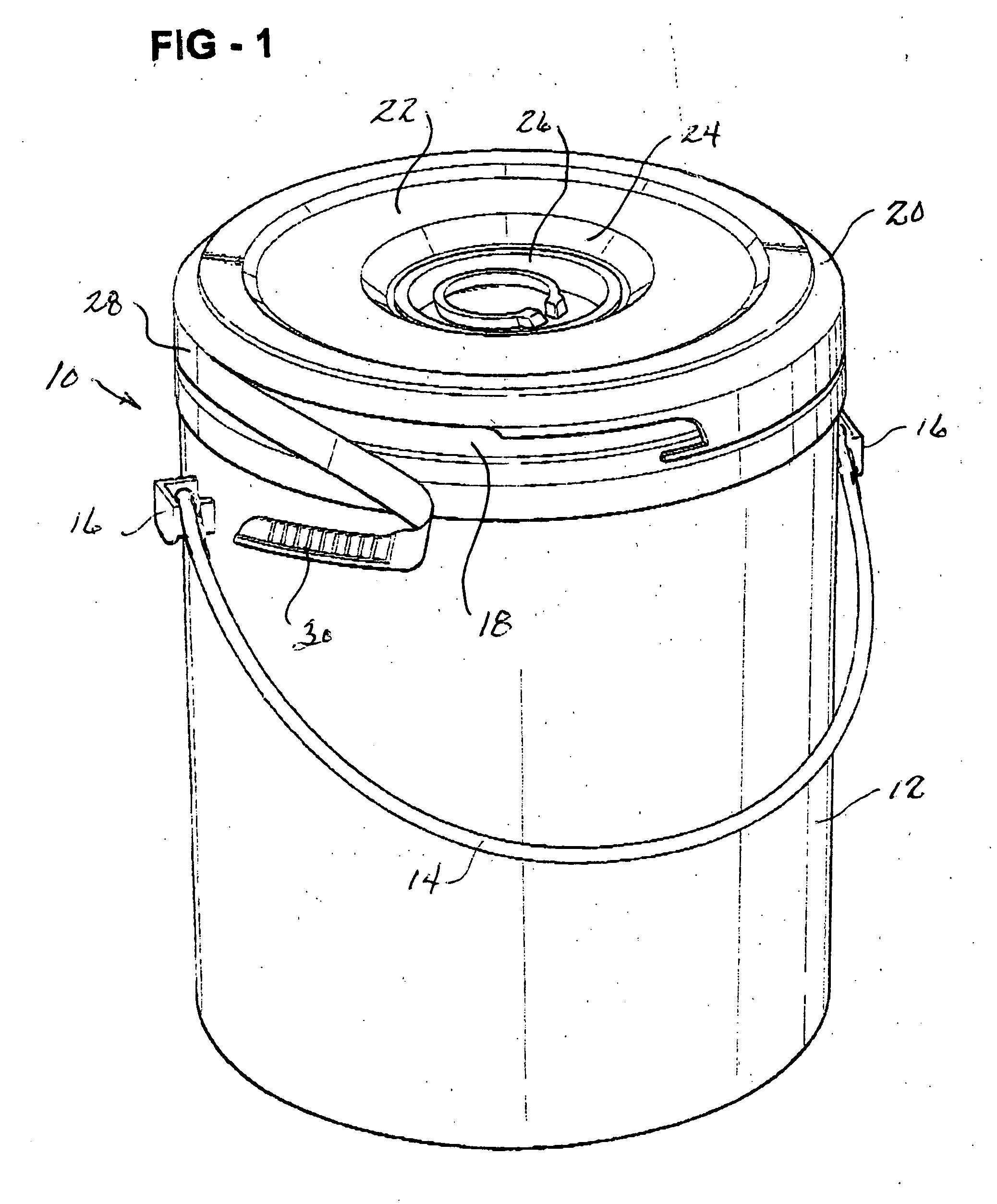

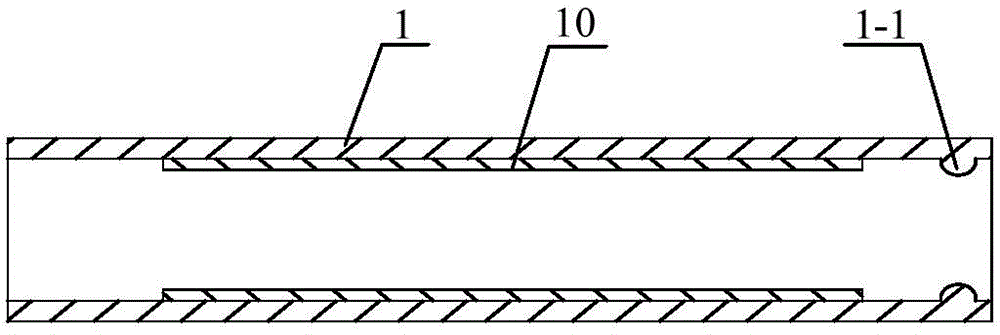

All plastic paint container

InactiveUS20080029559A1Easy to remove manuallyLevel of securityClosuresClosure using stoppersLacquerEngineering

An all plastic paint container comprising the combination of a cylindrical pail, a separate snap-on pouring spout ring and a separate snap on lid having a tear band which must be removed before manual access to the edge of the lid for removal purposes can be realized. The mechanical attachments between the pouring ring and the pail and between the lid and the pouring ring are achieved by inverted U-shaped channels and under cuts which provide the snap on mechanical associations.

Owner:LETICA

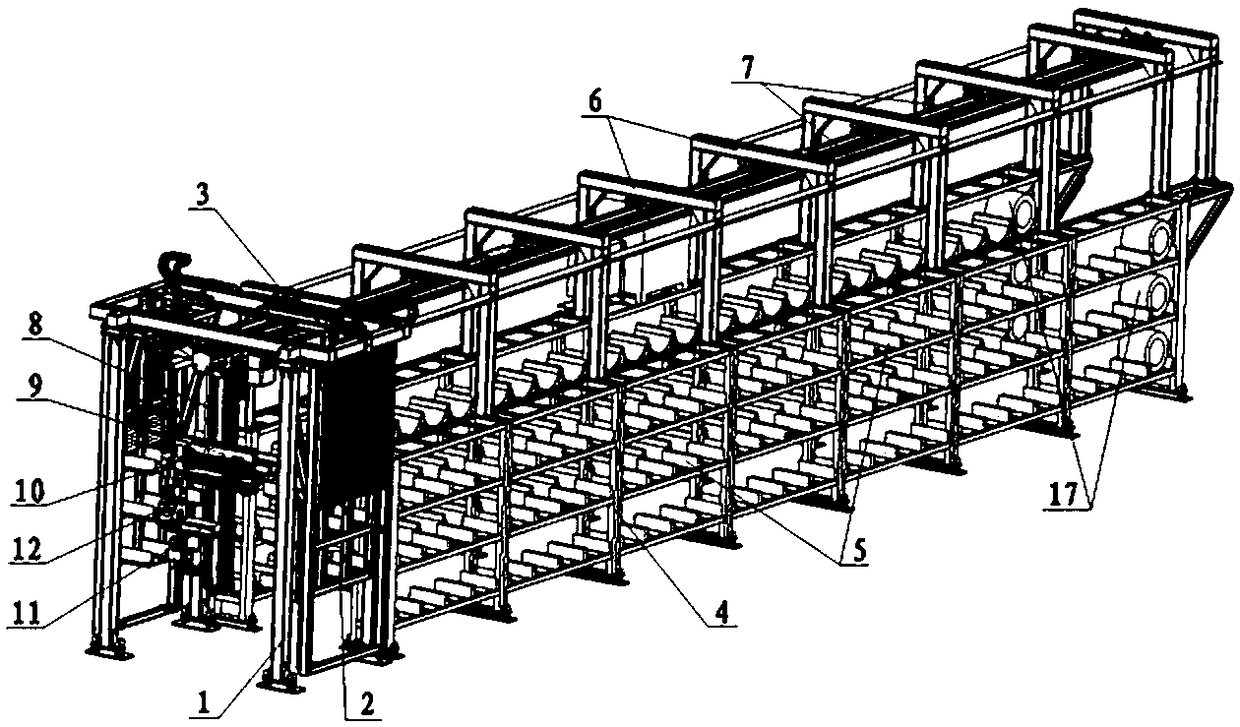

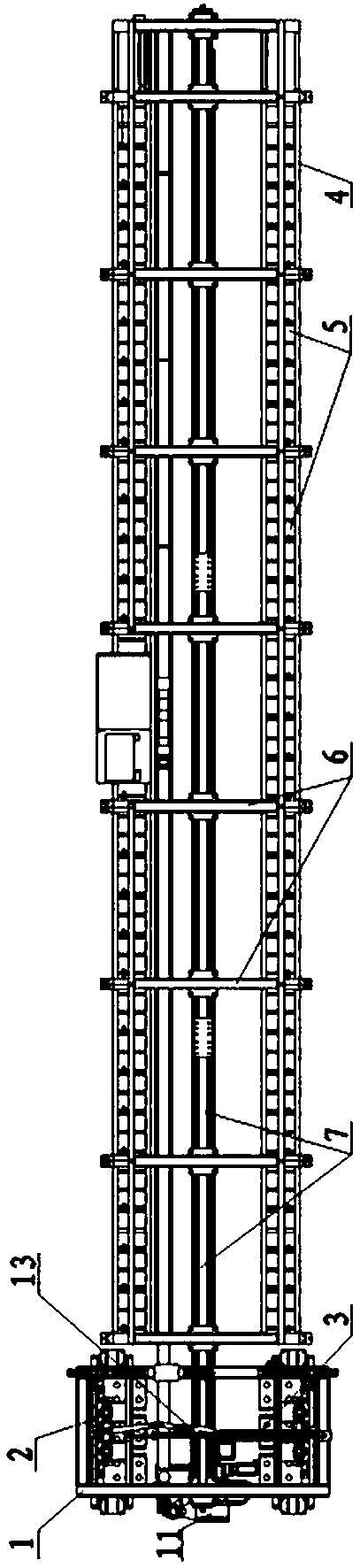

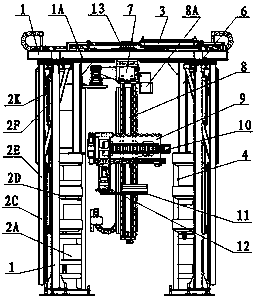

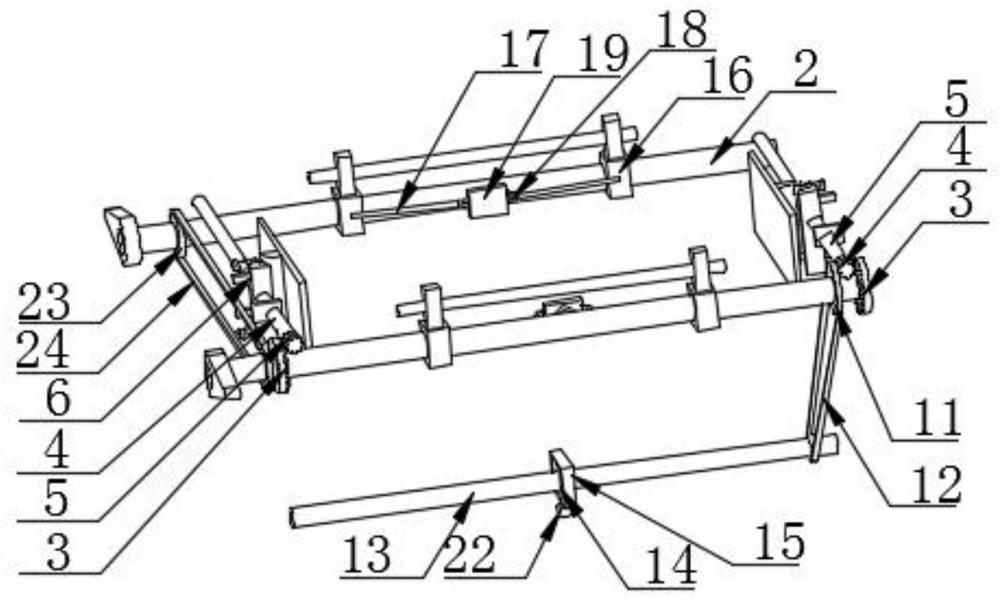

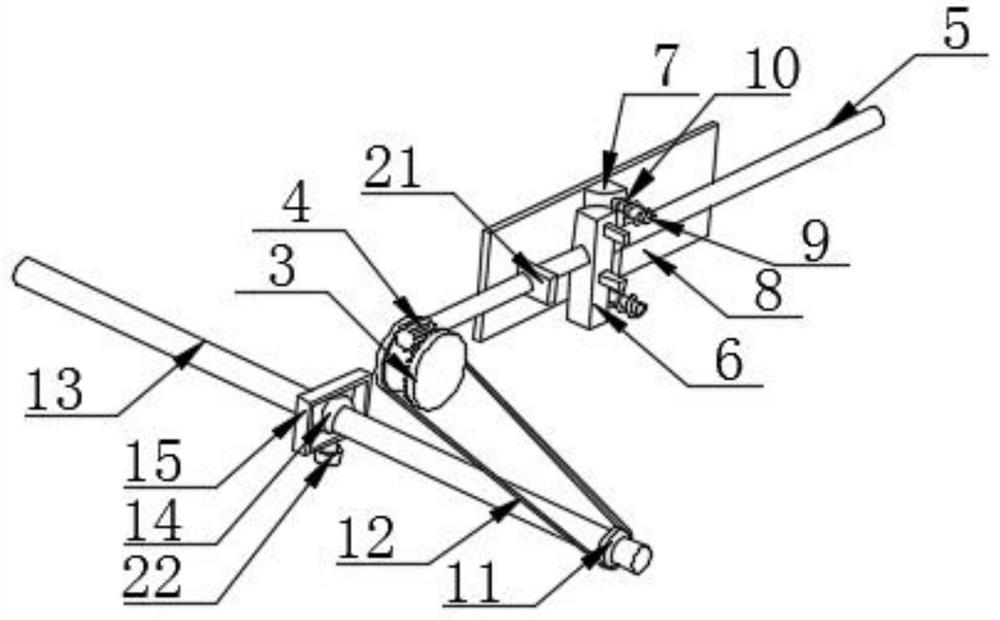

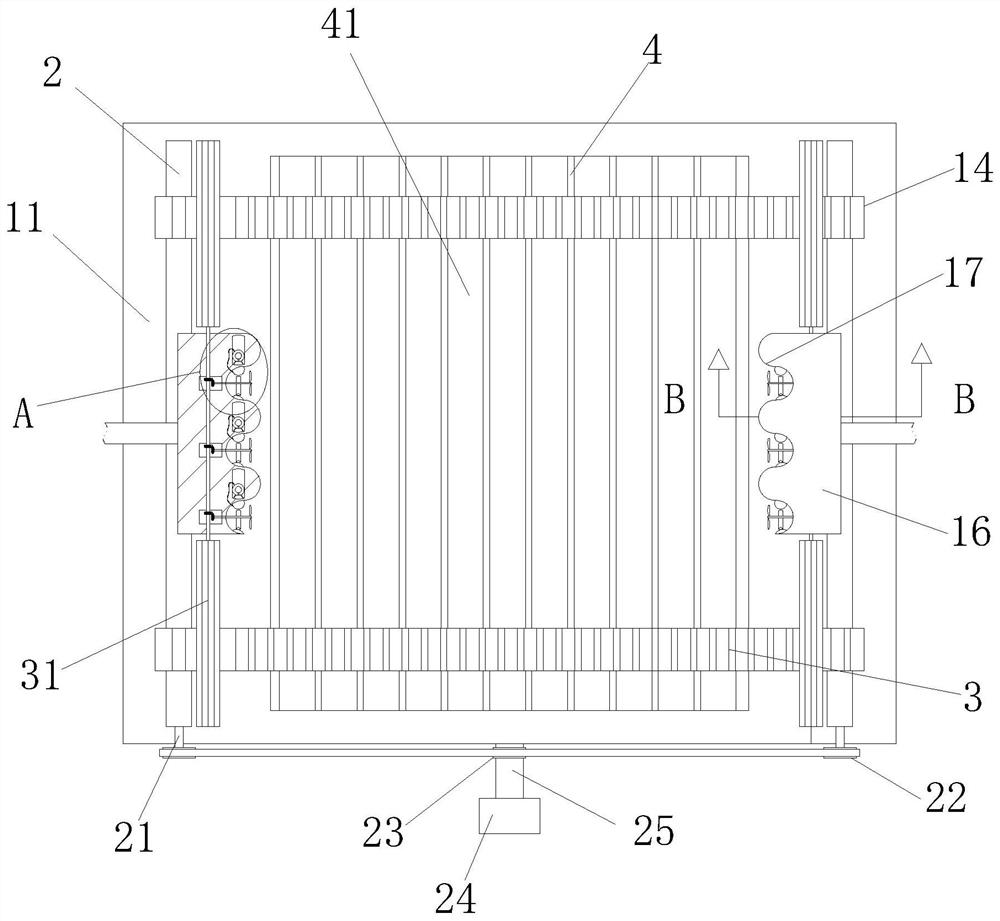

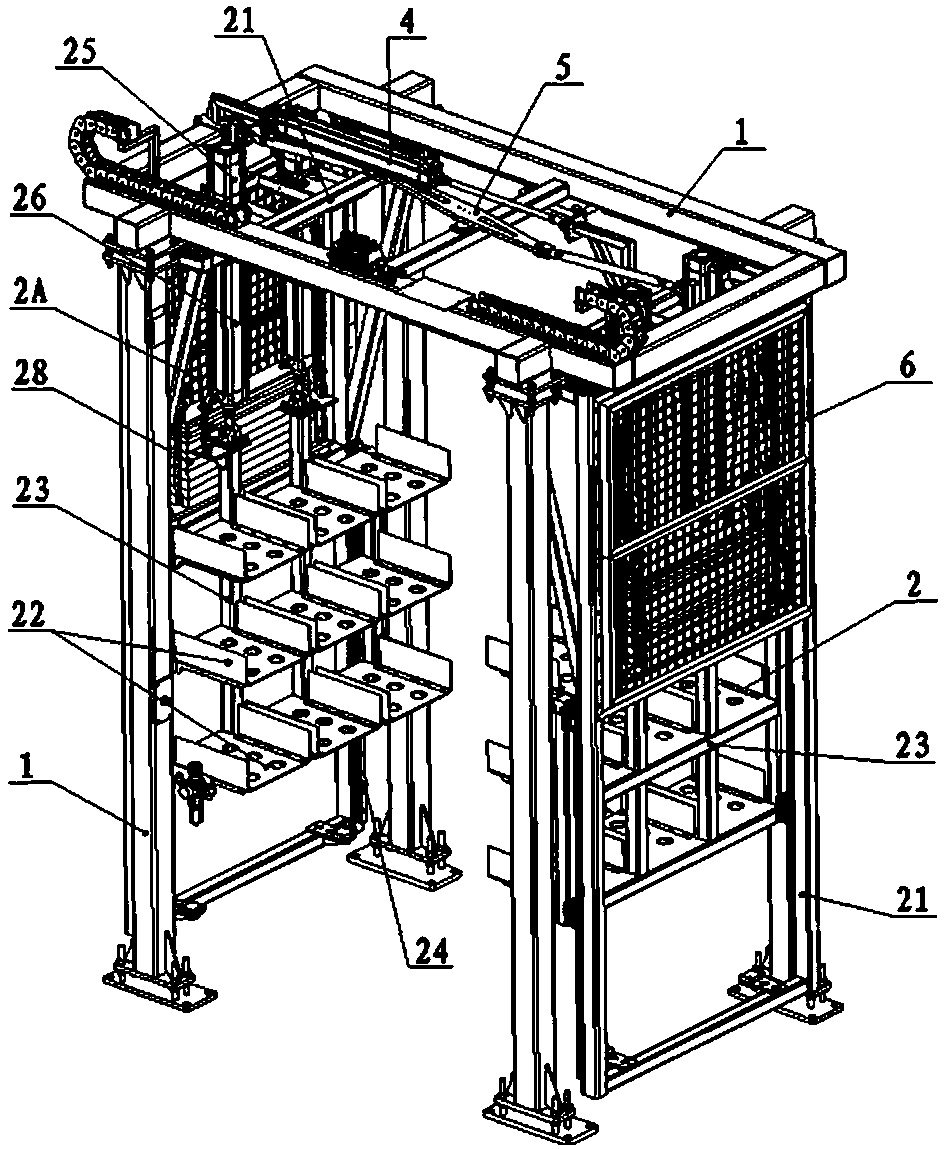

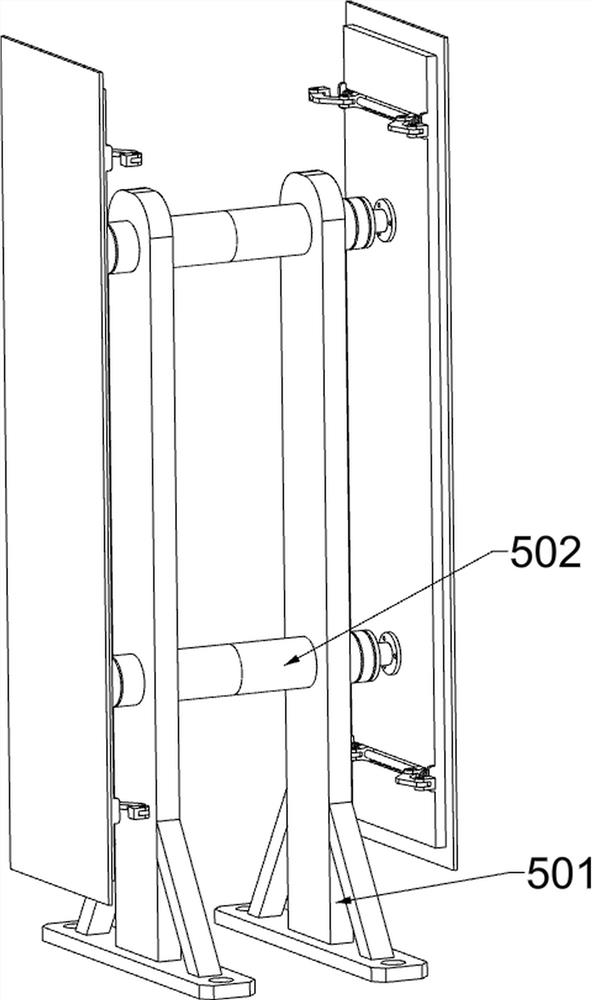

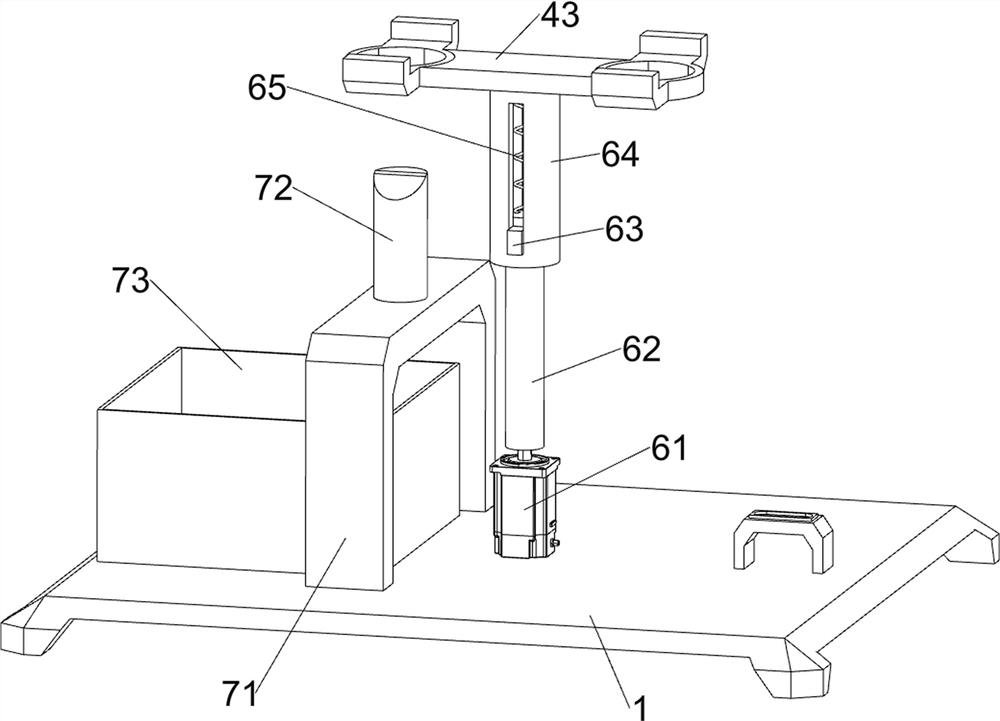

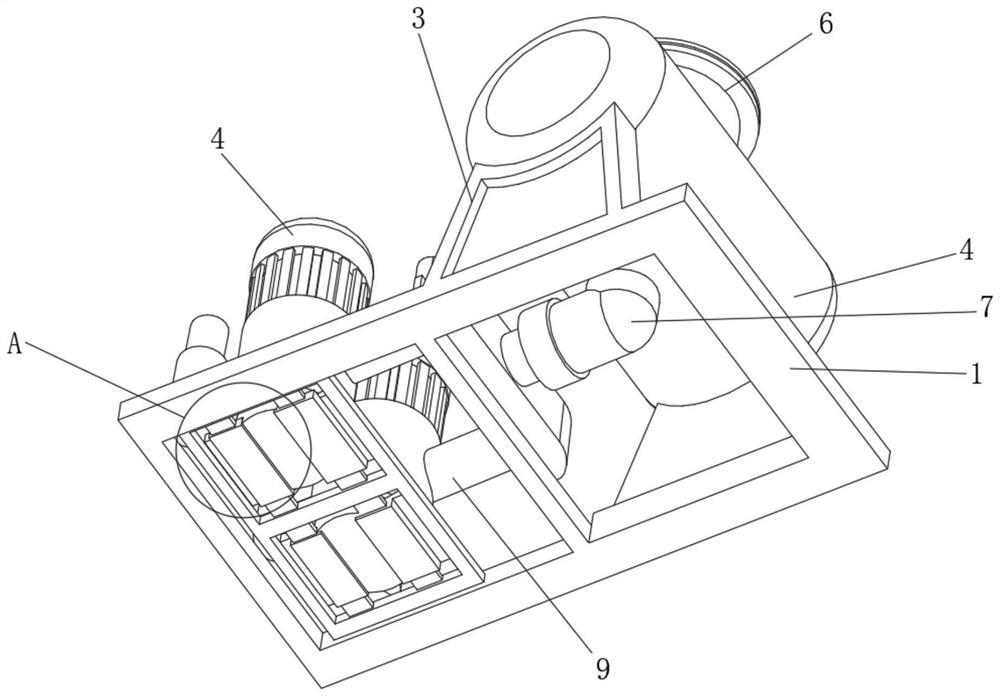

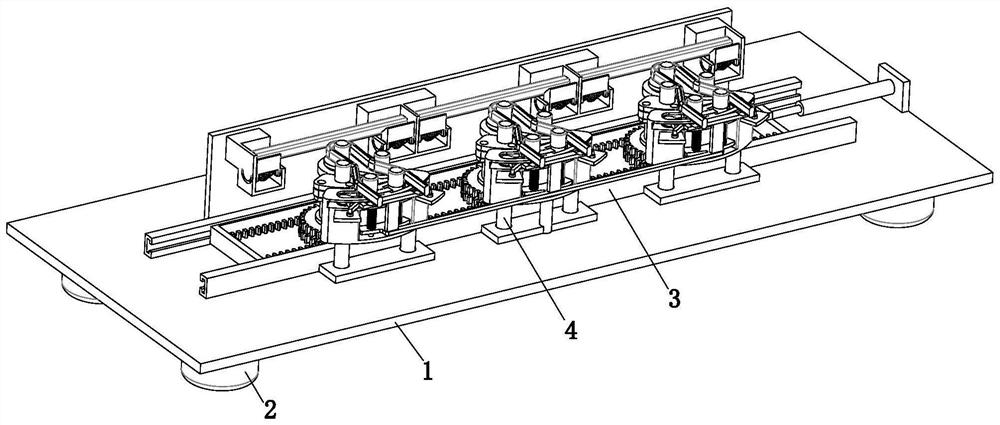

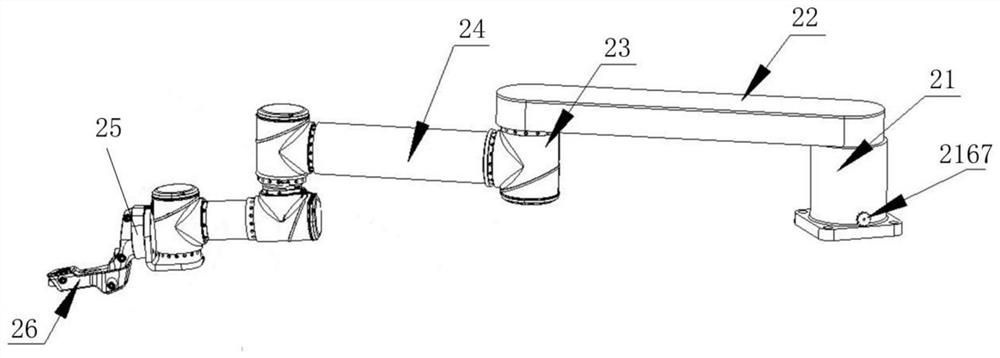

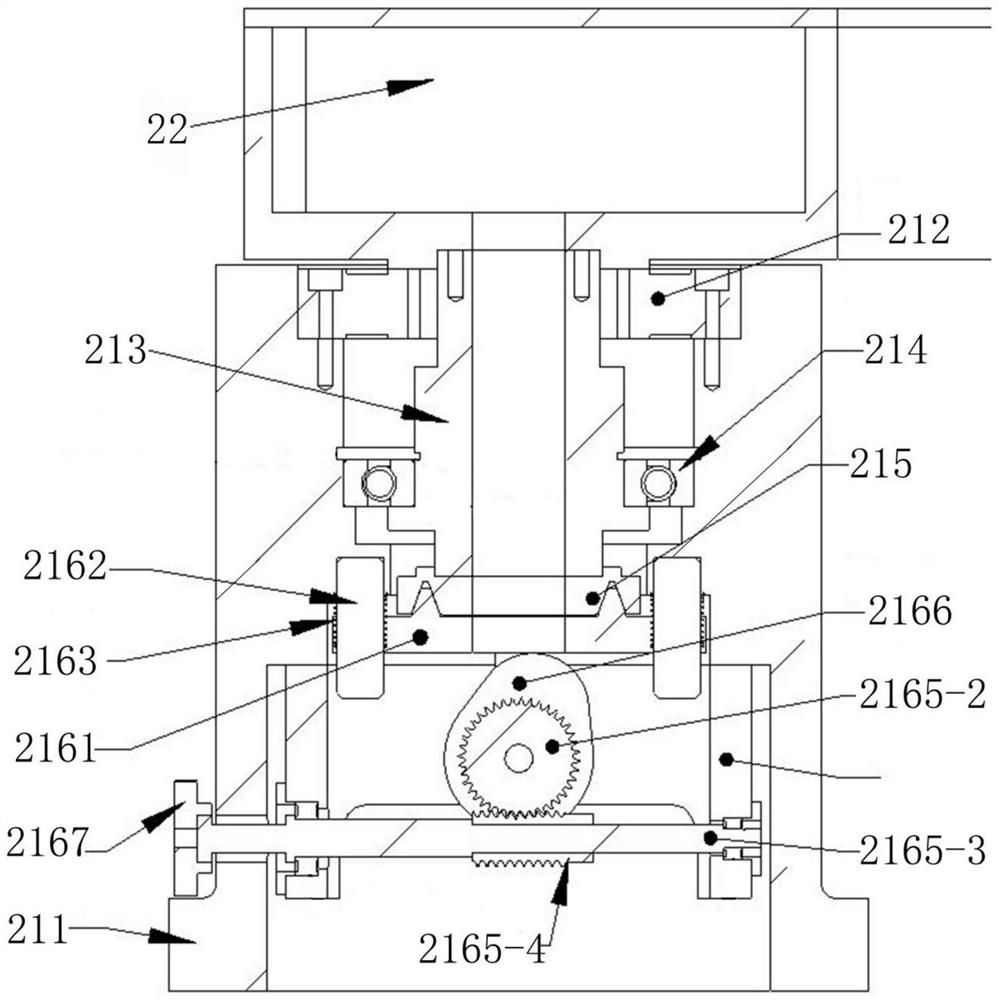

Intelligent yarn discharging and rectangular coordinate robot automatic yarn supplementing system

ActiveCN108190646AImprove efficiencyReduce labor intensityFilament handlingYarnRectangular coordinates

The invention discloses an intelligent yarn discharging and rectangular coordinate robot automatic yarn supplementing system. According to the system, yarn discharging mechanisms are perpendicularly arranged on one side or two sides of a yarn discharging support, the two ends of a yarn discharging horizontal-driving device are fixedly connected or are hinged to the yarn discharging support and theyarn discharging mechanisms so as to drive the yarn discharging mechanisms to horizontally move, each yarn discharging mechanism is provided with a plurality of yarn discharging brackets and a firstperpendicular linear driving device, wherein the yarn discharging brackets are perpendicular to the yarn discharging mechanism, and the first perpendicular linear driving device drives the yarn discharging brackets to vertically move; a yarn storage rack is fixedly provided with a plurality of yarn storage grooves in the direction perpendicular to the moving direction of the yarn discharging mechanisms; yarn supplementing supports are fixedly arranged on the ground or the yarn storage rack along the X axis; an X-axis cross beam is fixedly arranged on the yarn supplementing supports along the Xaxis; one end of a Z-axis vertical shaft is in perpendicular sliding driving connection with the X-axis cross beam; a Y-axis longitudinal beam is in sliding driving connection with a Z-axis guide rail; an A-axis mounting base is in perpendicular sliding driving connection with the Y-axis longitudinal beam; and a clamp rotating driving device is fixedly arranged on the A-axis mounting base and isperpendicularly and fixedly connected to the driving end of the clamp rotating driving device. The system has the advantages that the automation degree is high, the yarn discharging and supplementingefficiency is high, and a yarn roll is not liable to deform.

Owner:云南柔控科技有限公司 +1

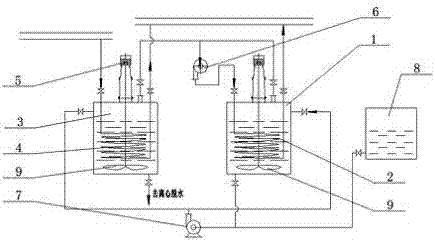

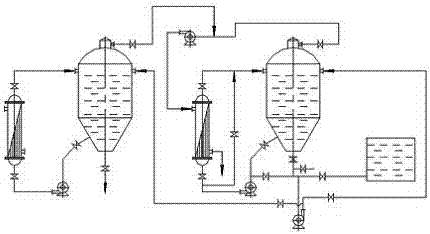

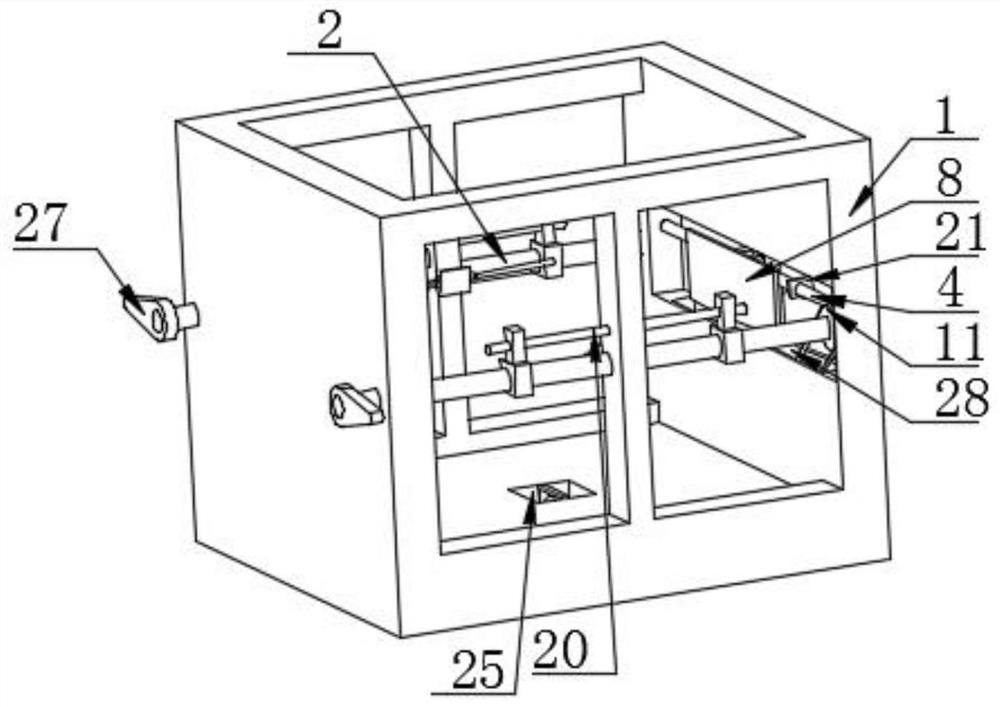

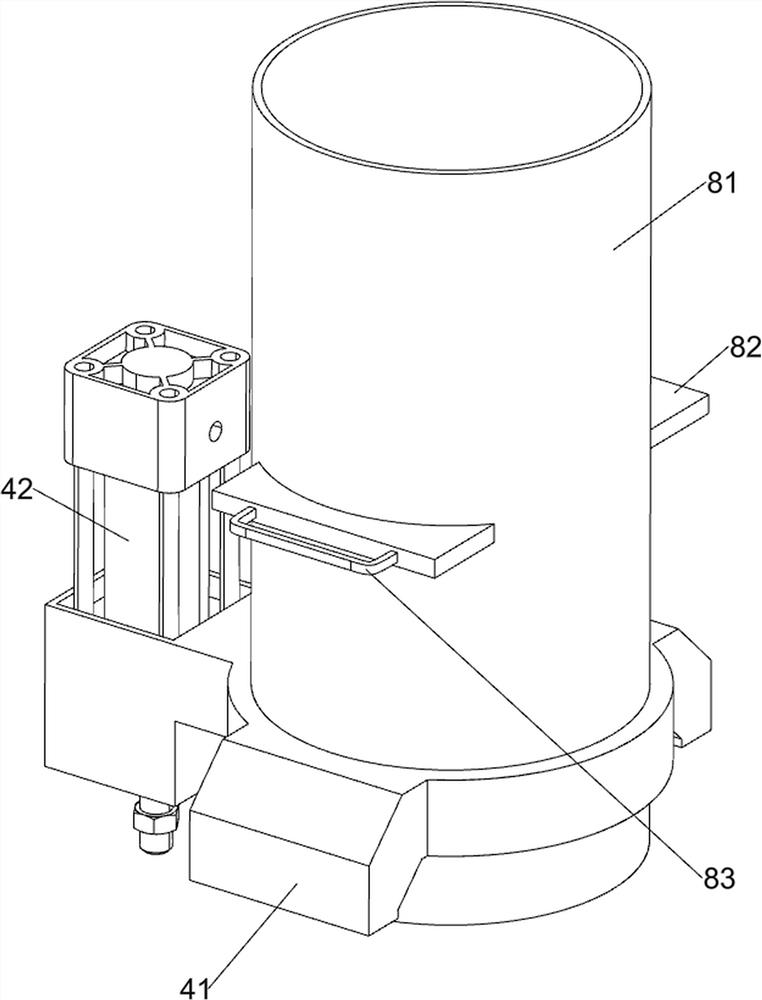

MVR evaporation crystallizer suitable for high salt concentration and crystallization and production process of MVR evaporation crystallizer

InactiveCN106964169ASolve the problem that the MVR evaporator cannot be appliedChange processEvaporation with vapour compressionCrystallization by component evaporationSalt depositBoiling point

The invention discloses an MVR evaporation crystallizer suitable for high salt concentration and crystallization and production process of the MVR evaporation crystallizer, relates to industrial energy-saving equipment, and particularly relates to an evaporation crystallizer suitable for high salt concentration. A first heat exchanger and a second heat exchanger are respectively arranged in a first evaporation chamber and a second evaporation chamber, wherein a steam inlet end of the second evaporation chamber is connected with a steam main pipe; a steam outlet end of the second evaporation chamber is connected with a steam inlet of the first evaporation chamber by a compressor; the steam outlets of the first evaporation chamber and the second evaporation chamber are connected with a condensed water main pipe; a liquid delivery pump is connected between a liquid storage tank and each of the first evaporation chamber and the second evaporation chamber; stirring power devices are arranged on the first evaporation chamber and the second evaporation chamber; stirring devices are arranged in the first evaporation chamber and the second evaporation chamber. In the invention, the evaporation chamber and the heat exchanger of the traditional MVR evaporation crystallizer are changed from a split type to an integrated structure, i.e., the heat exchanger is arranged inside the evaporation chamber, so that the equipment is more compact; a surface of the heat exchanger is exposed in a large space, to facilitate the subsequent crystallization and removal of salt deposits. In a process flow of the scheme, a boiling point of the materials is increased due to precipitation of crystals, so the process flow of a first issue solution is still adopted.

Owner:刘向东

New energy automobile battery bundling and locking device

The invention provides a new energy automobile battery bundling and locking device, and relates to the technical field of new energy automobiles. The new energy automobile battery bundling and locking device comprises a fixing frame, a fixing assembly is arranged in the fixing frame, the fixing assembly comprises two first lead screws, the two first lead screws penetrate through the fixing frame and are rotationally connected with the fixing frame, first bevel gears are fixedly connected to the outer sides of the two first lead screws, one side of each first bevel gear is in engaged connection with a second bevel gear. According to the new energy automobile battery bundling and locking device, the second bevel gears rotate to drive second lead screws to rotate, the second lead screws rotate to drive first protruding blocks to move rightwards, the first protruding blocks move rightwards to extrude second protruding blocks to move outwards, the second protruding blocks move outwards to drive limiting plates to move outwards, so that a new energy battery is fixed; With the above structure adopted, new energy batteries with different sizes can be quickly fixed. The device is simple in structure, convenient to operate, time-saving and labor-saving.

Owner:邓宏朝

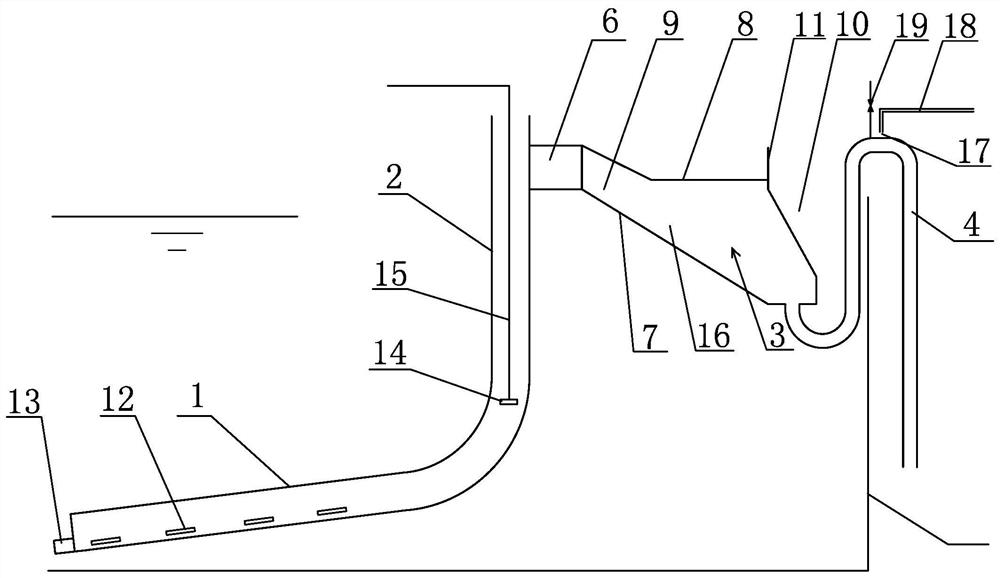

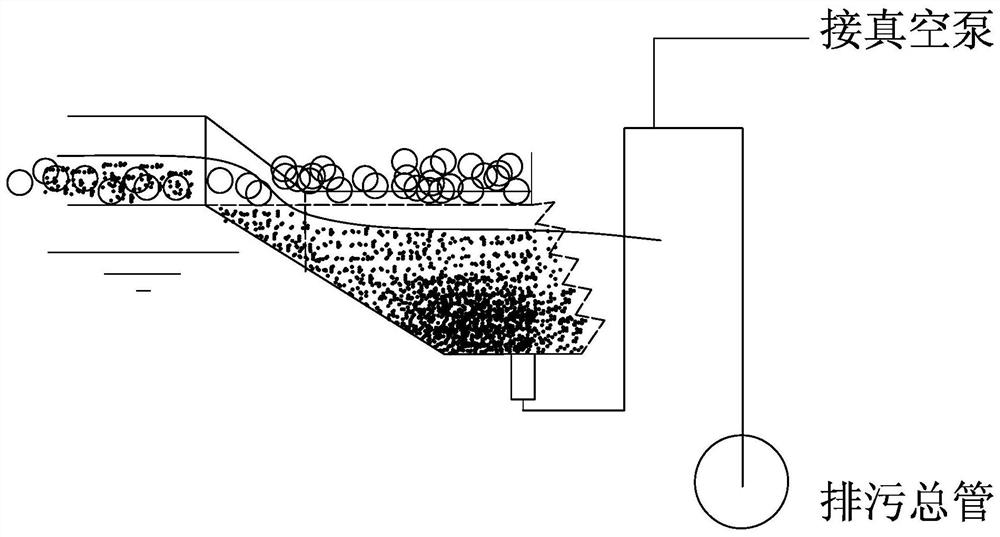

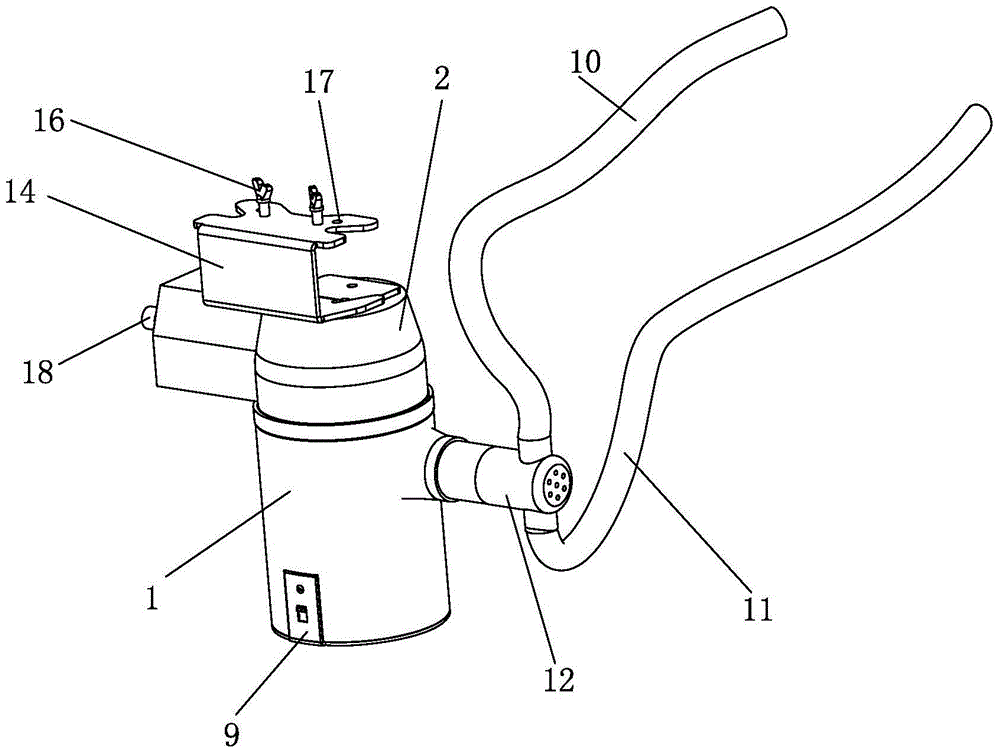

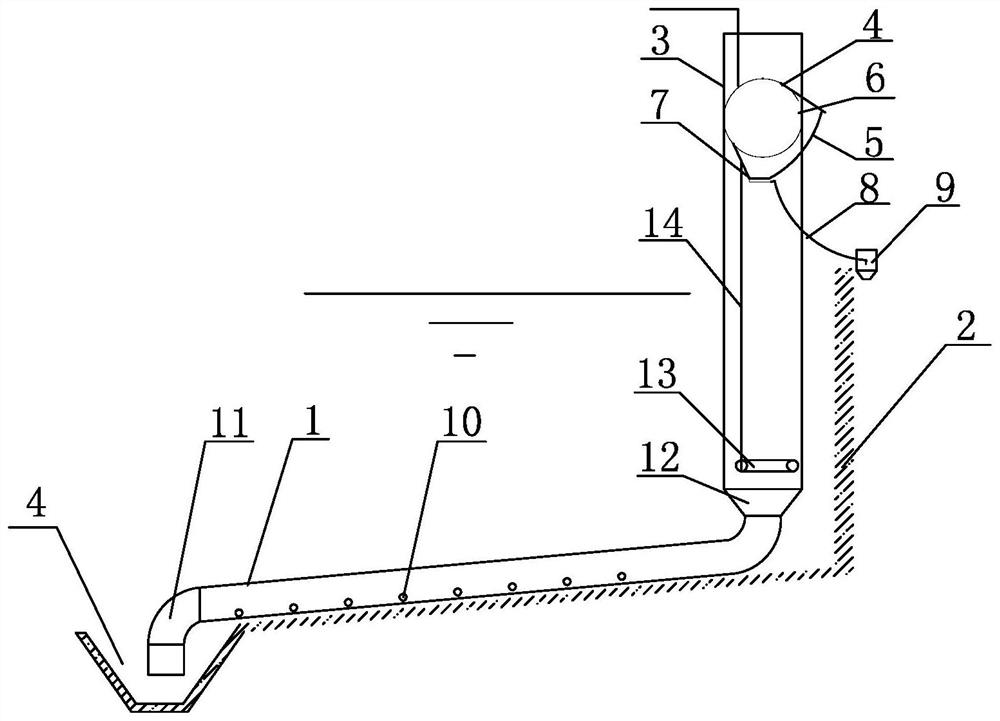

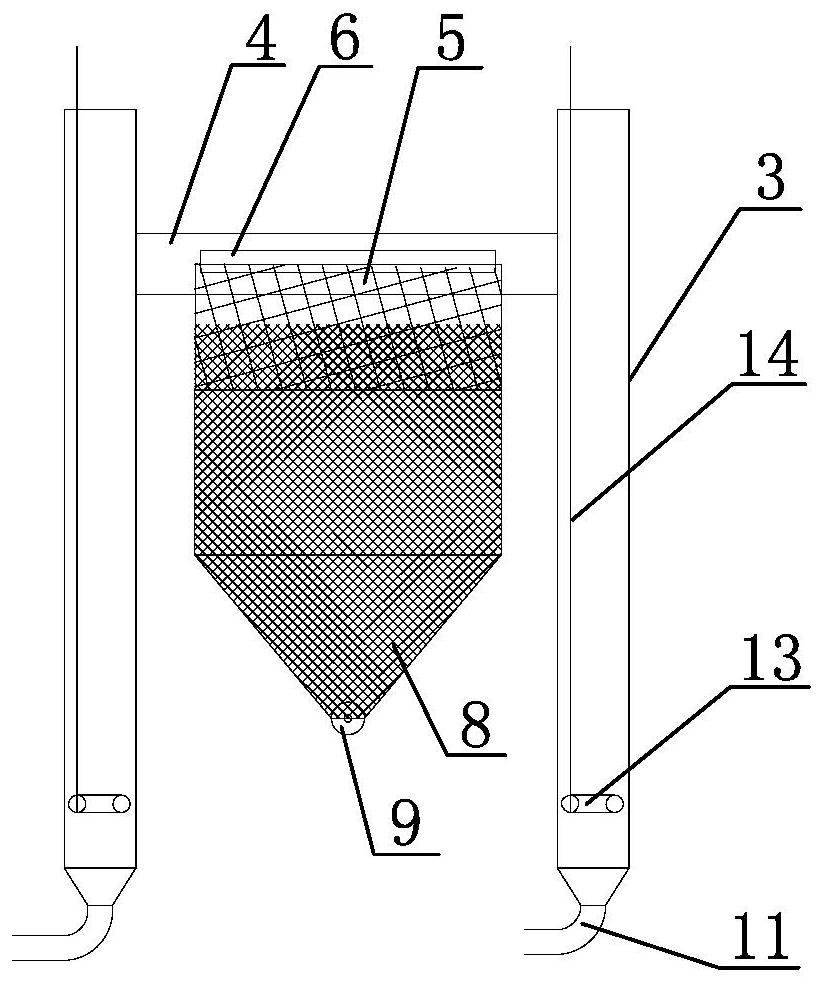

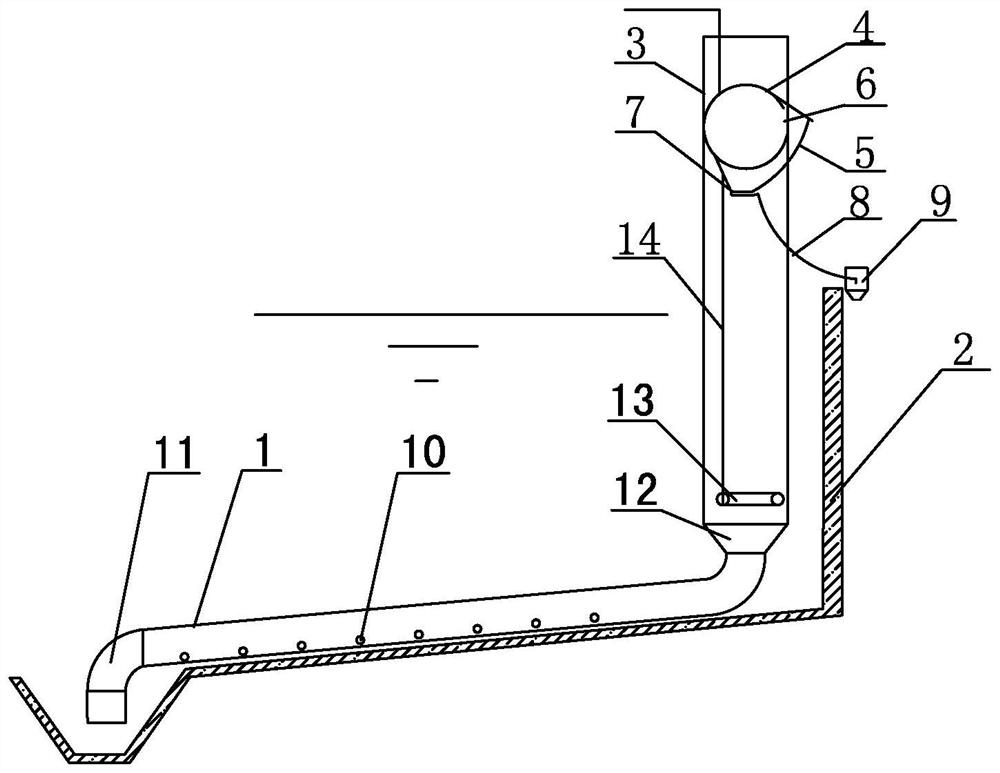

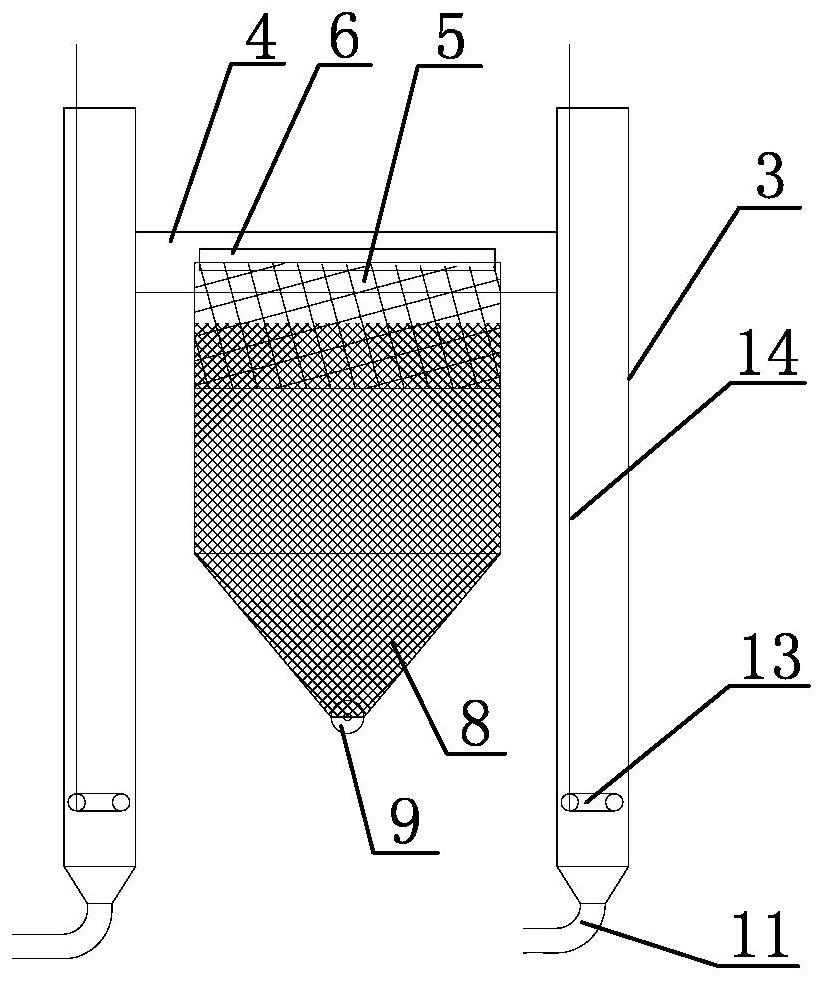

Continuous concentration and sewage discharge device and method for shrimp farming system

PendingCN112715471ASolve the disadvantages of easy blockageEasy to remove manuallyClimate change adaptationPisciculture and aquariaEnvironmental geologyMechanical engineering

The invention discloses a continuous concentration and sewage discharge device and method for a shrimp farming system. The continuous concentration and sewage discharge device is characterized by comprising a sewage collecting pipe, an air lift pipe, a sewage storage bin and a sewage discharge pipe, wherein the opening end of the sewage collecting pipe is located in the center of the bottom of a culture pond, the other end of the sewage collecting pipe communicates with the air lift pipe, and the air lift pipe communicates with the sewage storage bin through a sewage suction pipe; the sewage storage bin is defined by a bottom plate arranged obliquely downwards, side baffles symmetrically arranged on two sides of the bottom plate, a detachable coarse filter screen and a detachable fine filter screen, the coarse filter screen is horizontally arranged between the two side baffles, the fine filter screen is obliquely or vertically arranged between the two side baffles, and the two ends of the coarse filter screen are connected with the sewage suction pipe and the fine filter screen respectively; and the bottom of the fine filter screen is connected with the bottom plate, the top of the bottom plate is connected with the bottom of the sewage suction pipe, the lowest position of the bottom plate communicates with the sewage discharge pipe in a butt joint mode, and a positive baffle is vertically arranged at the joint of the coarse filter screen and the fine filter screen. The continuous concentration and sewage discharge device has the advantages that shrimp shells, dead shrimps, and sick shrimps with poor vitality can be separated in time, residual bait and feces are concentrated and then discharges, and the water consumption is low for sewage discharge.

Owner:NINGBO UNIV

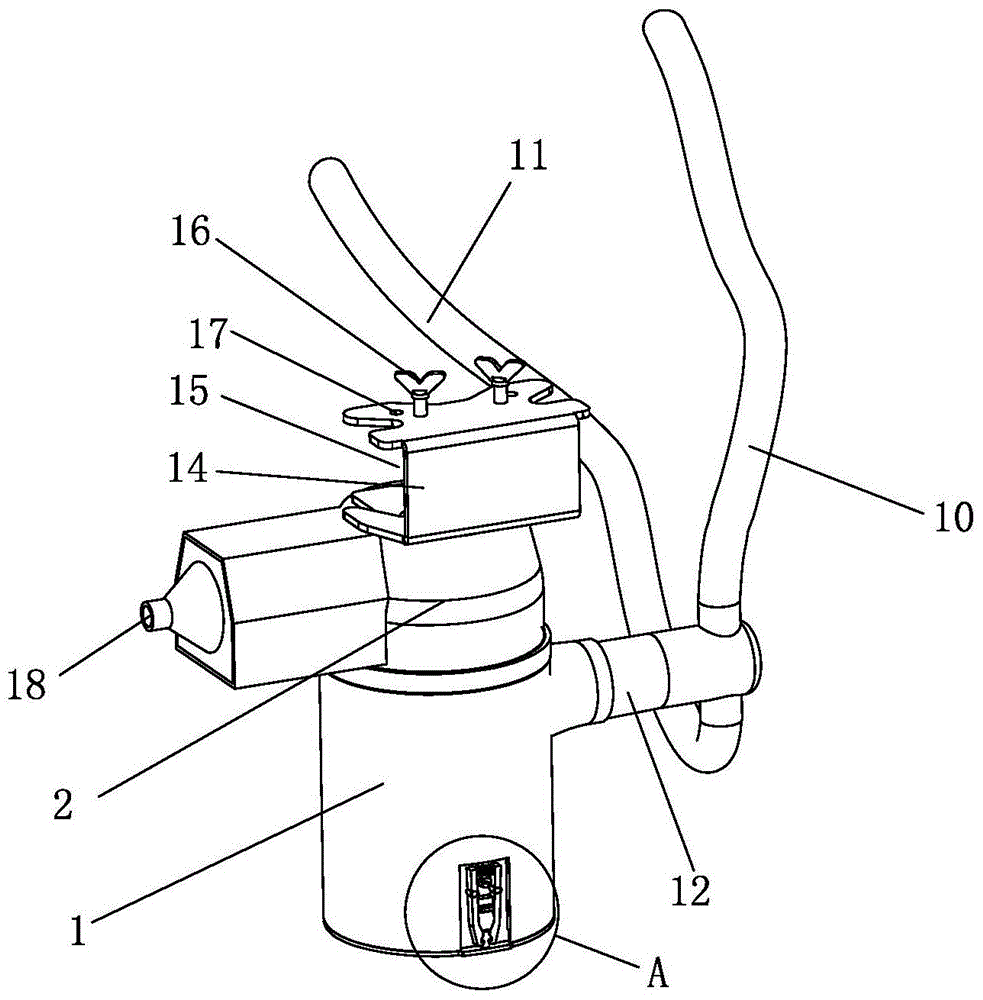

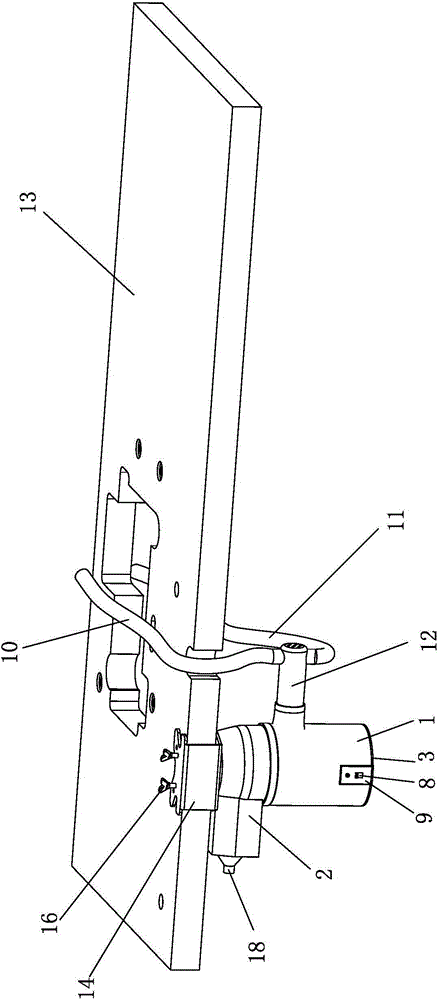

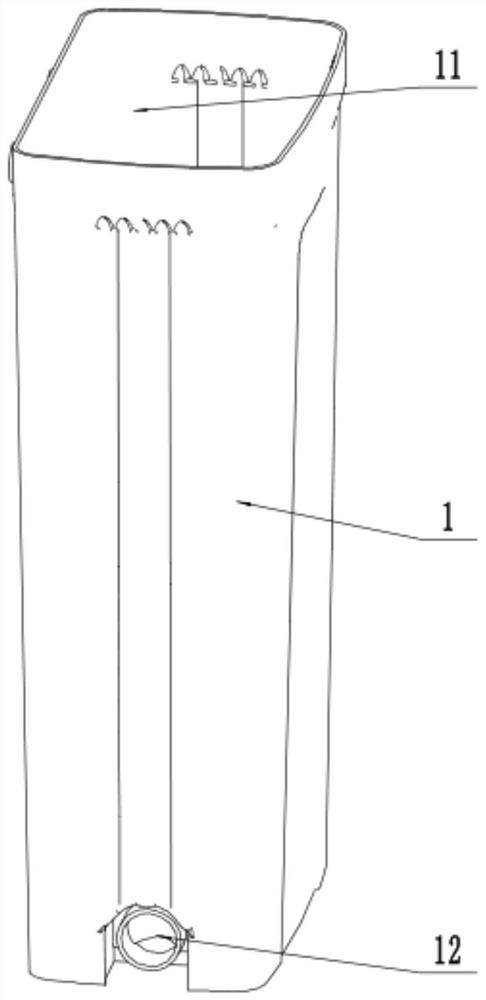

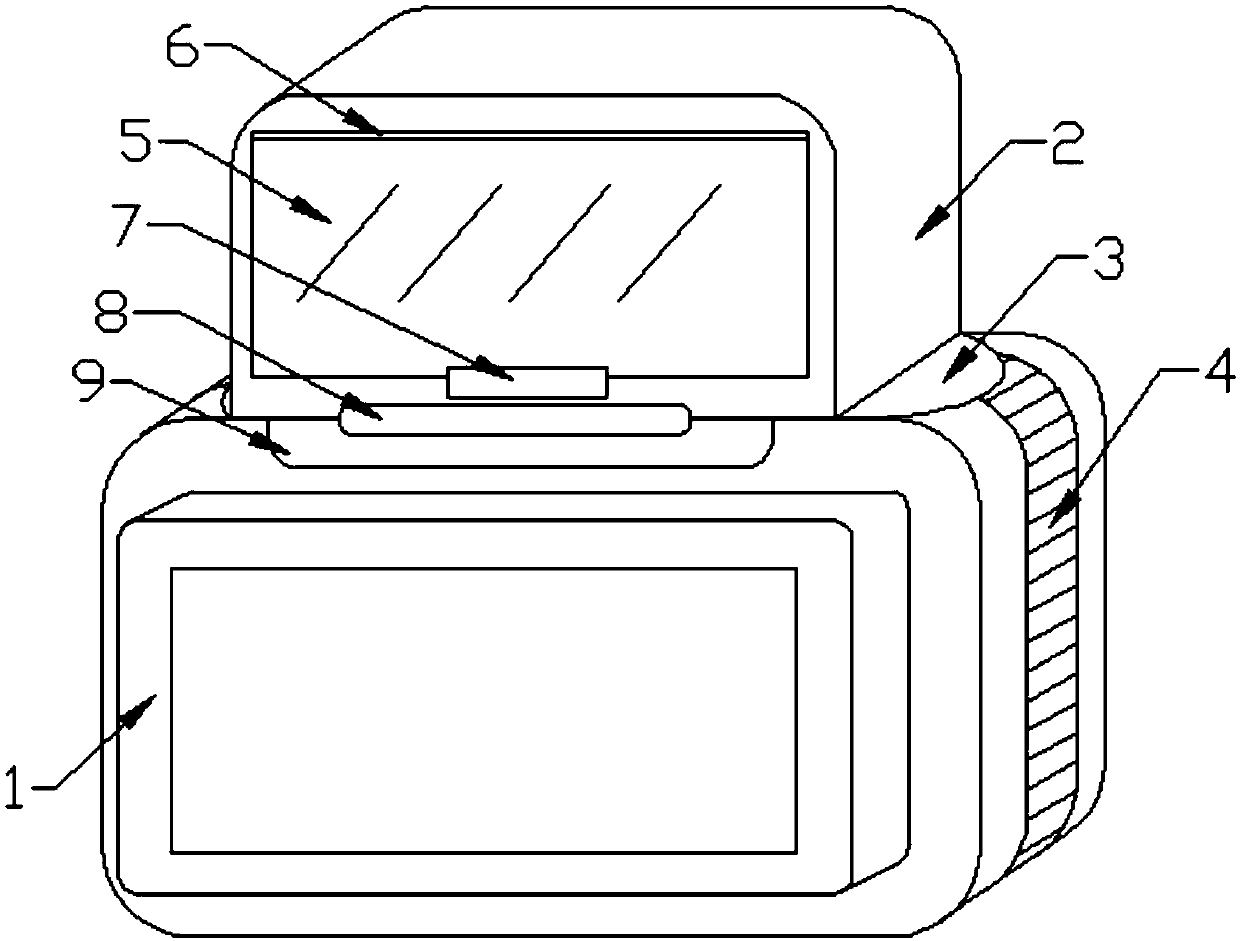

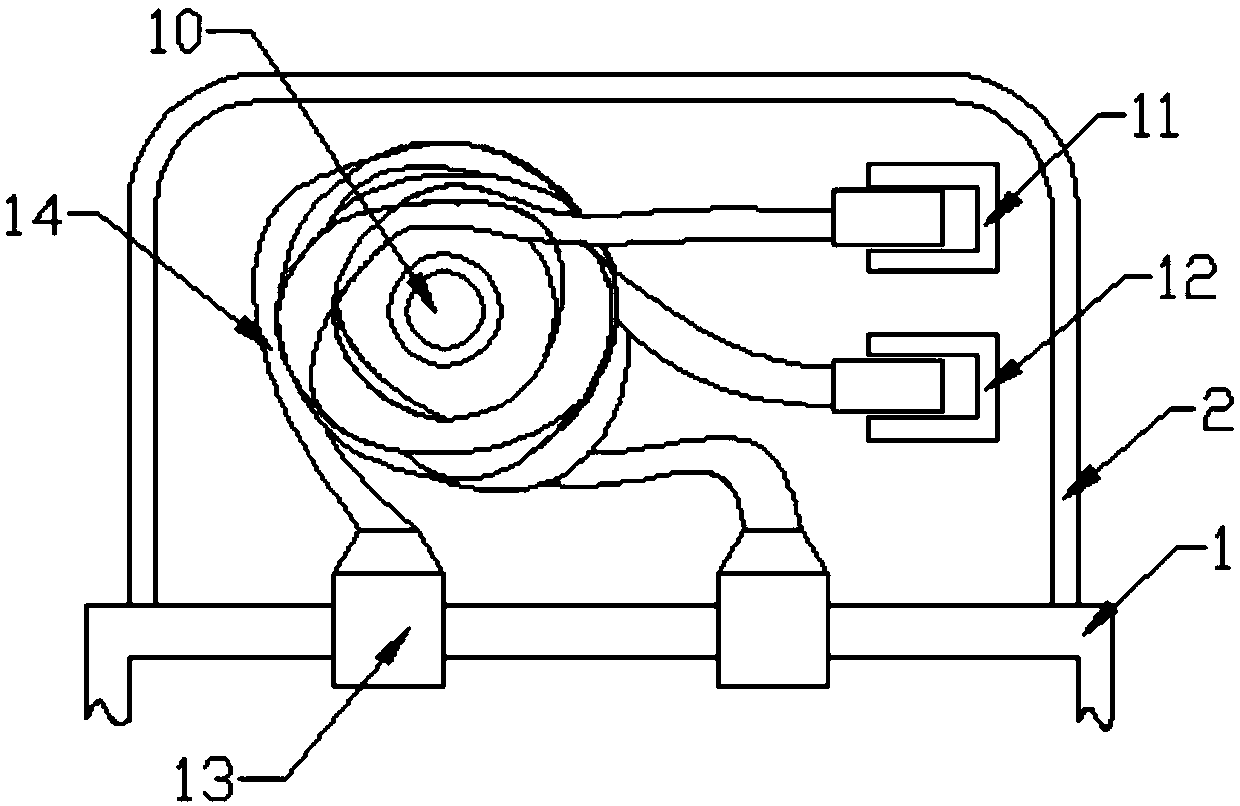

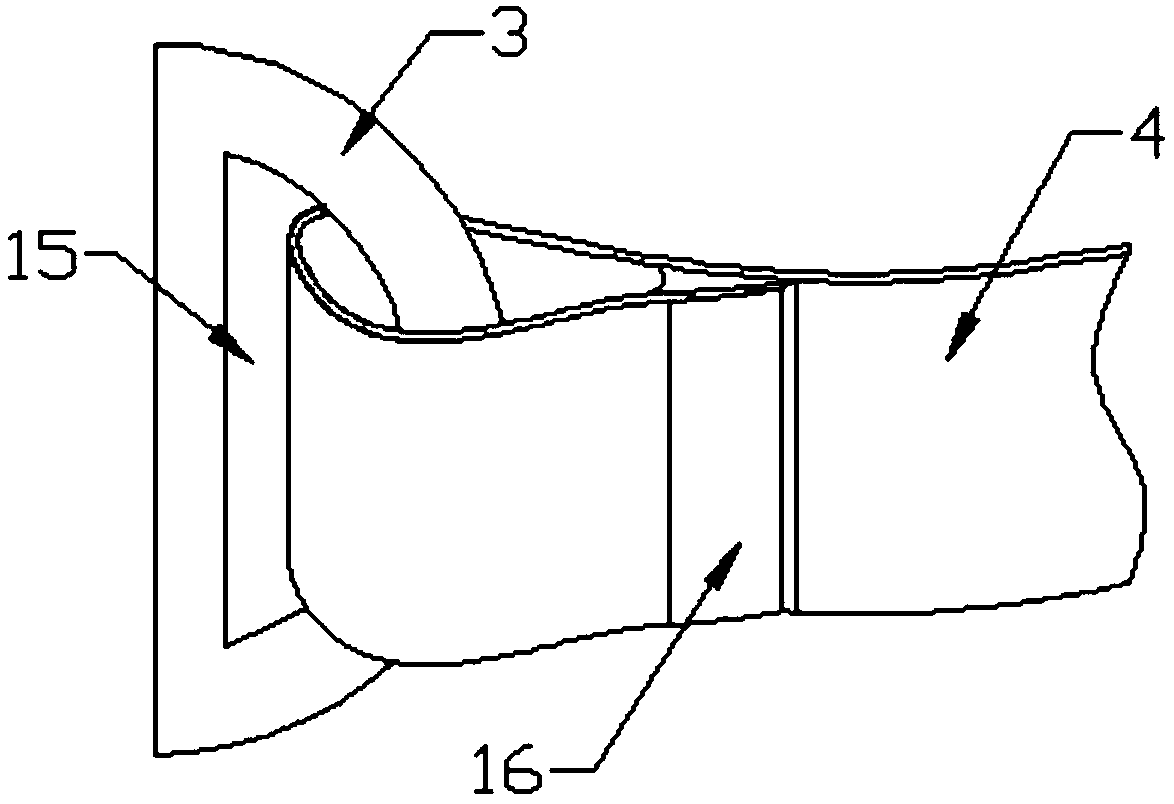

Electric dust suction device on sewing machine

The invention belongs to the technical field of sewing machines, and particularly relates to an electric dust suction device on a sewing machine. The electric dust suction device comprises a waste collecting barrel, the upper end of the waste collecting barrel is provided with an air suction motor hood, the waste collecting barrel is communicated with an inner cavity of the air suction motor hood, an air suction motor is arranged in the air suction motor hood, an air suction opening is arranged in the waste collecting barrel, and an air suction tube is arranged on the air suction opening. Cost and complexity for mounting a large air pump are omitted to a great extent, an air suction and dust removal mechanism and mounting are simplified, and the mechanism is more convenient and practical and convenient to operate; as the handheld air suction tube is arranged, when the machine is unused, fabric clippings at a front door sheet and teeth are cleaned manually, and the handheld air suction tube can hung on a fixing hook under a bedplate when the machine is operated; by the principle, the problem that trimming influence is affected by accumulation of thread chains at an automatic thread trimmer of an overedger is solved more conveniently, the process of manually cleaning the fabric clippings is facilitated as well, and the electric dust suction device is simple to operate, attractive in complete-machine effect and practical.

Owner:JACK SEWING MASCH CO LTD

Positioning device for power electronic component production

InactiveCN113547256AShorten positioning timeImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderProcess engineering

The invention belongs to the technical field of power electronic component production, and particularly relates to a positioning device for power electronic component production. The positioning device comprises a workbench, a welding unit is mounted on the workbench, a placement seat is fixedly connected to the workbench, the placement seat is located right below the welding unit, a protective cover is fixedly connected to the workbench, the protective cover is arranged around the placement seat, hydraulic cylinders are fixedly connected to the side walls of the two sides of the protective cover, and the end parts of hydraulic rods of the hydraulic cylinders penetrate through the protective cover and are fixedly connected with positioning plates. The invention provides the positioning device for power electronic component production, and aims to solve the problems that when a square power electronic component is automatically welded by an intelligent welding machine, the component needs to be fixed at the center of a workbench by a positioning mechanism, then a welding program is input, automatic welding is carried out through the welding machine, however, an existing positioning mechanism is tedious, the positioning time is long, and the welding efficiency of the welding machine is affected.

Owner:江苏众利达自动化设备有限公司

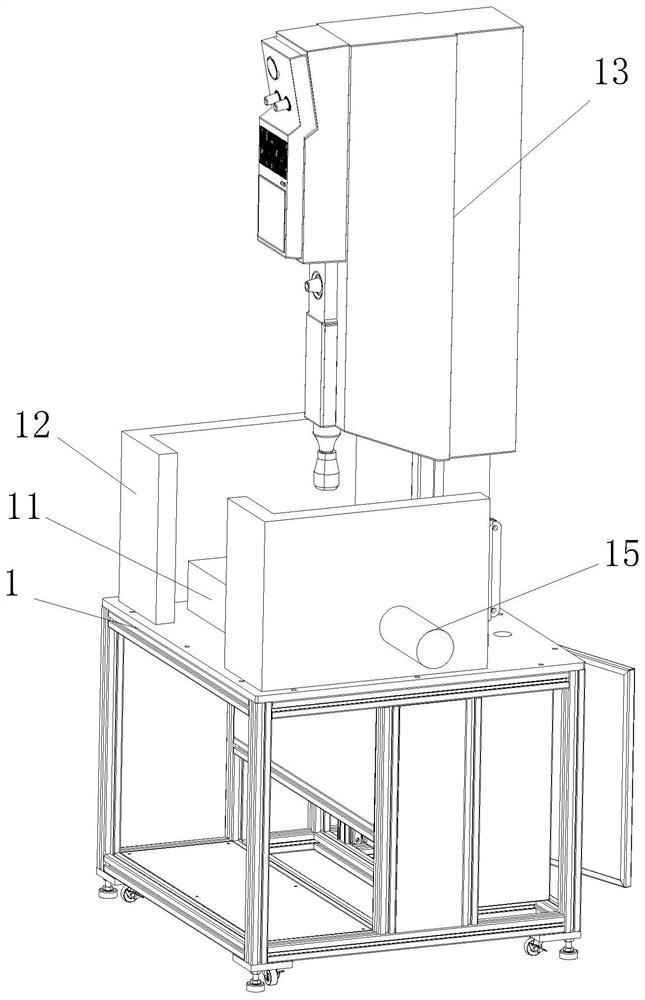

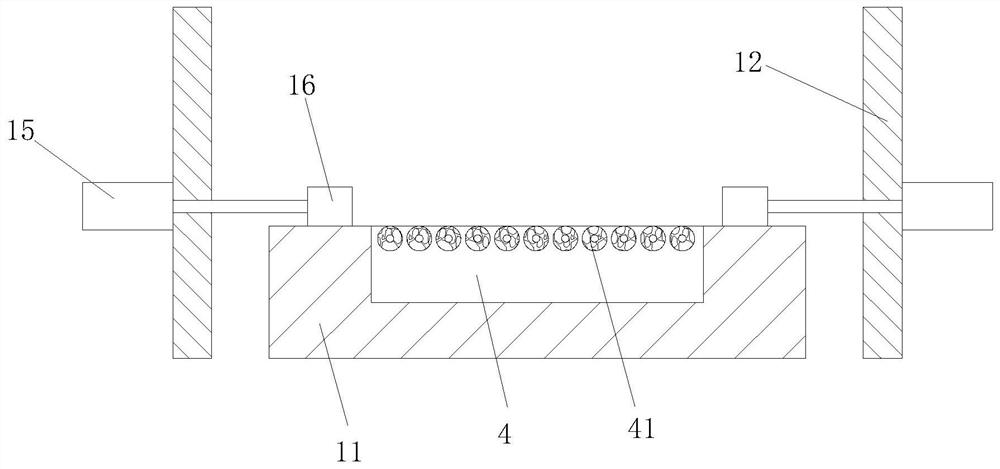

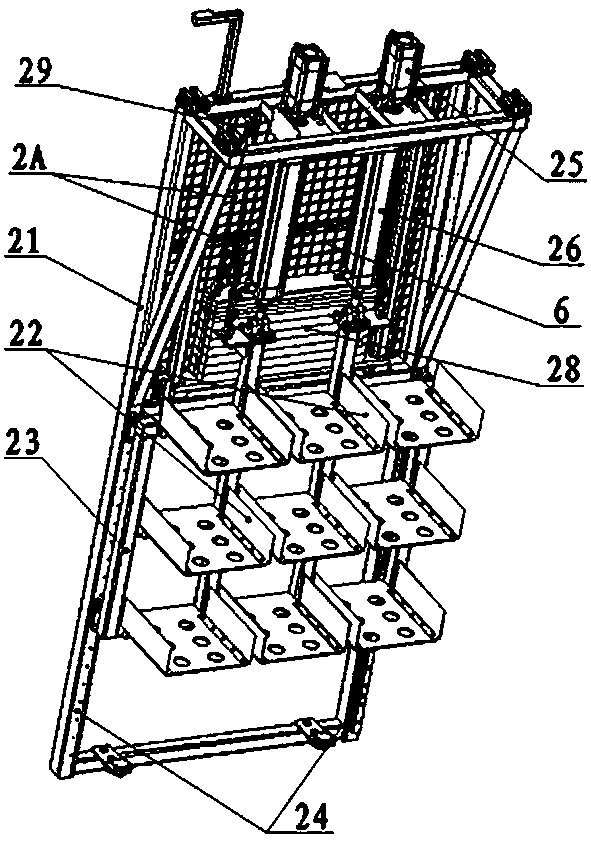

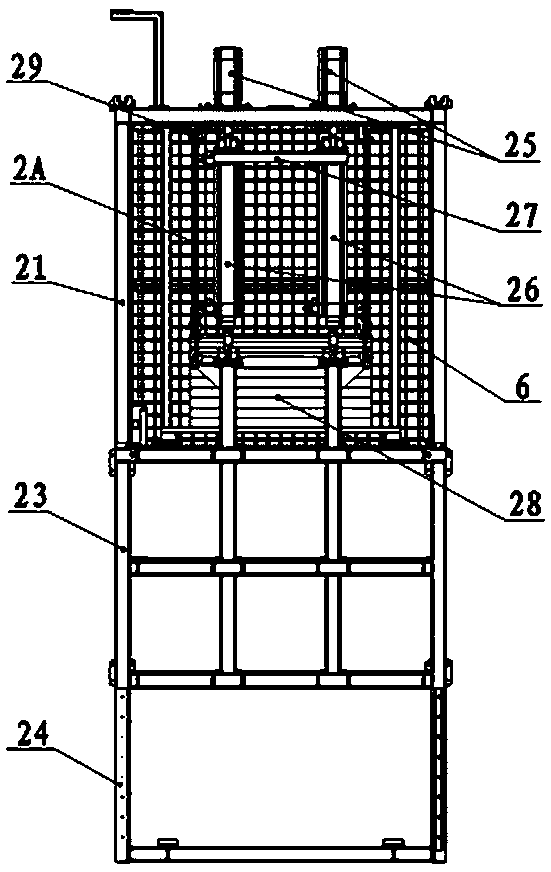

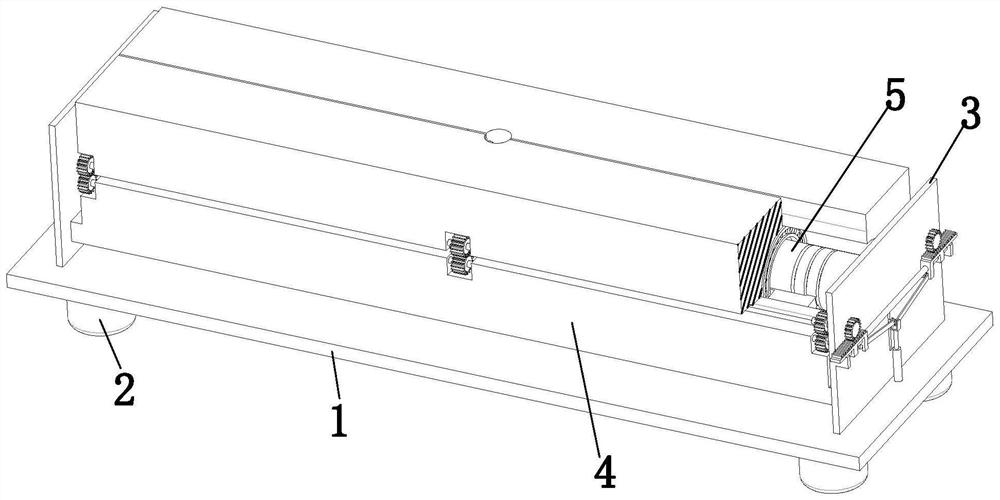

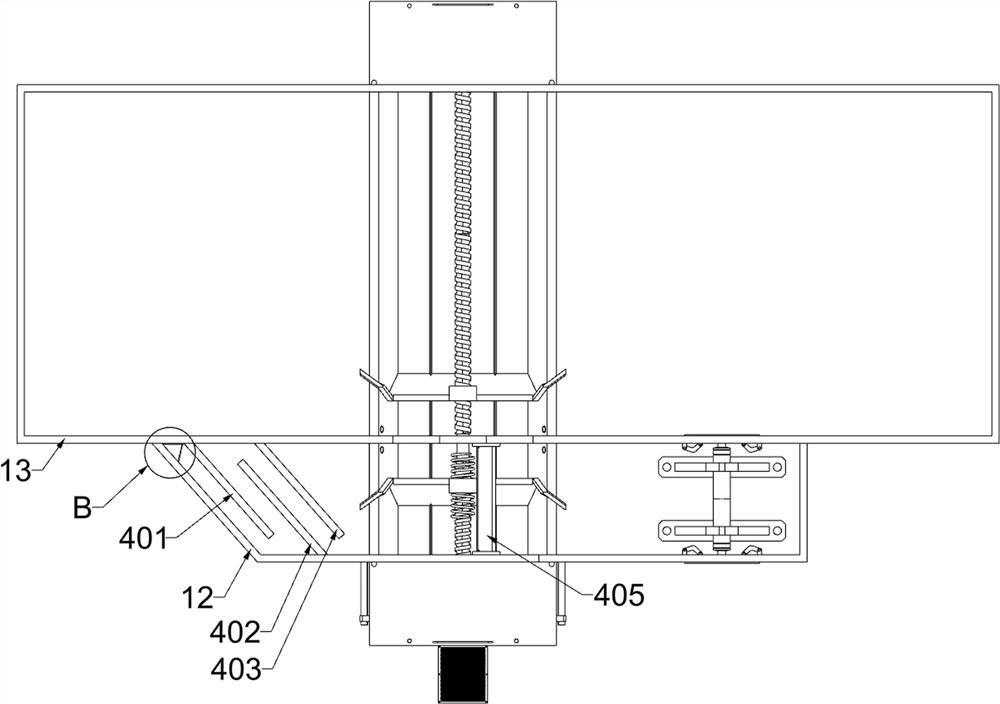

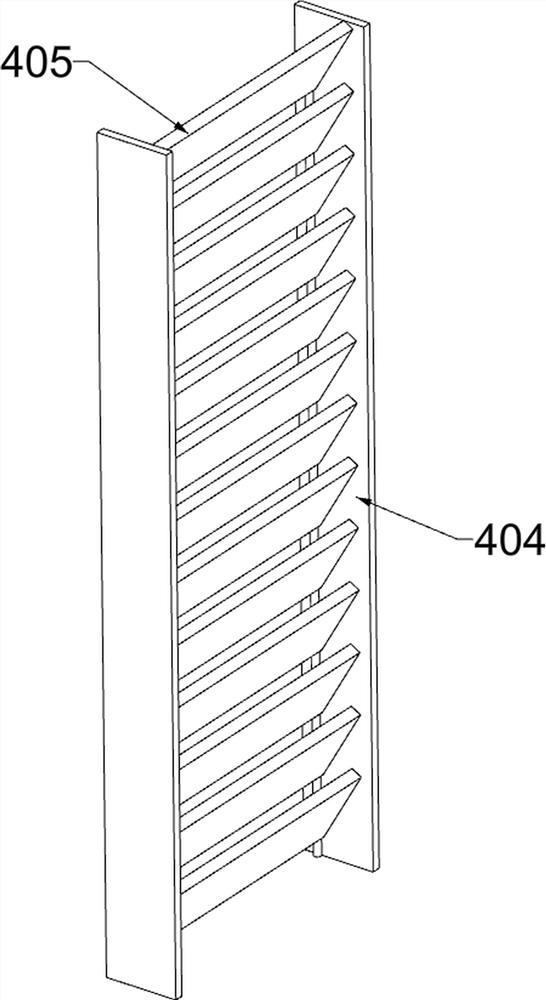

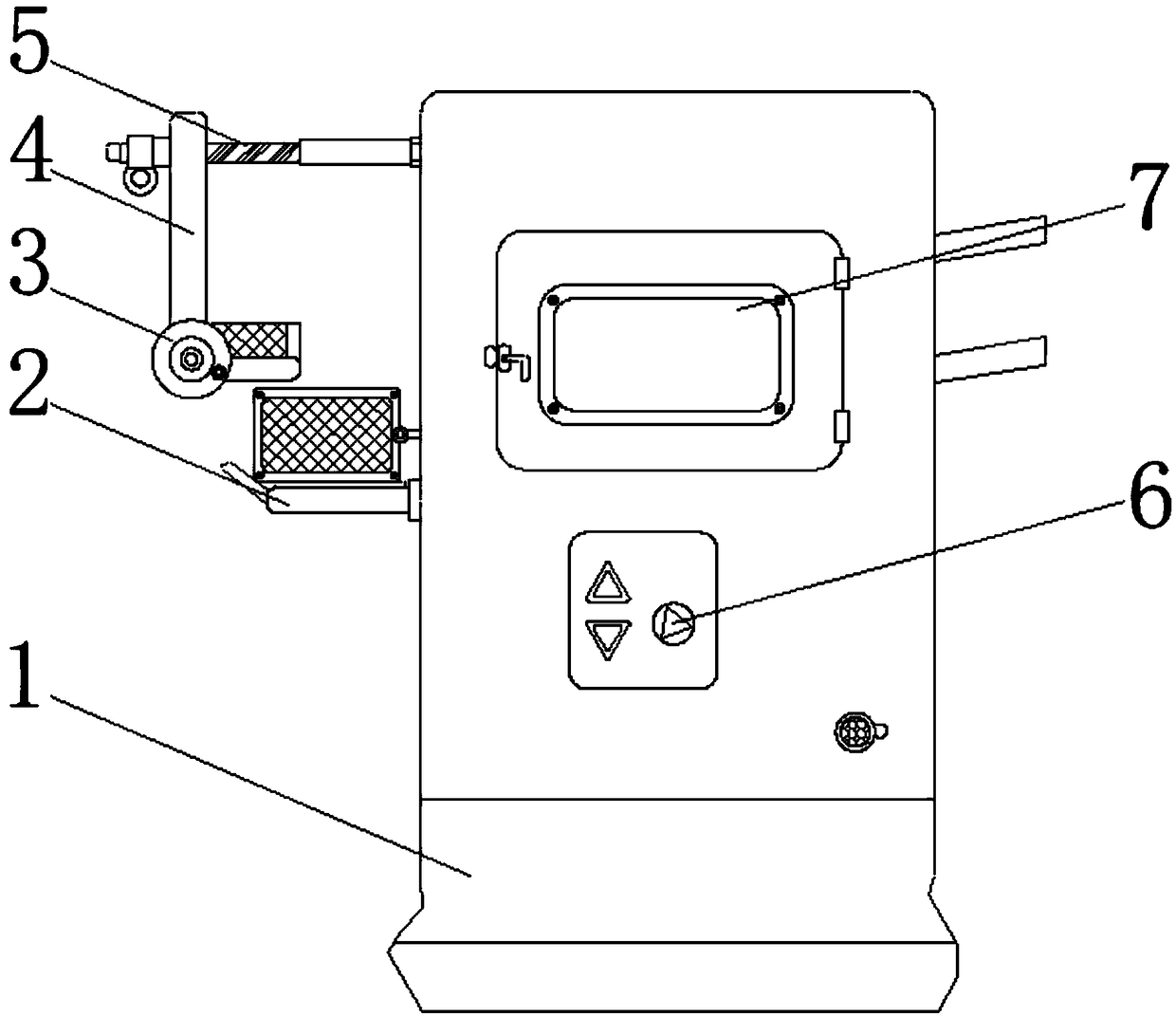

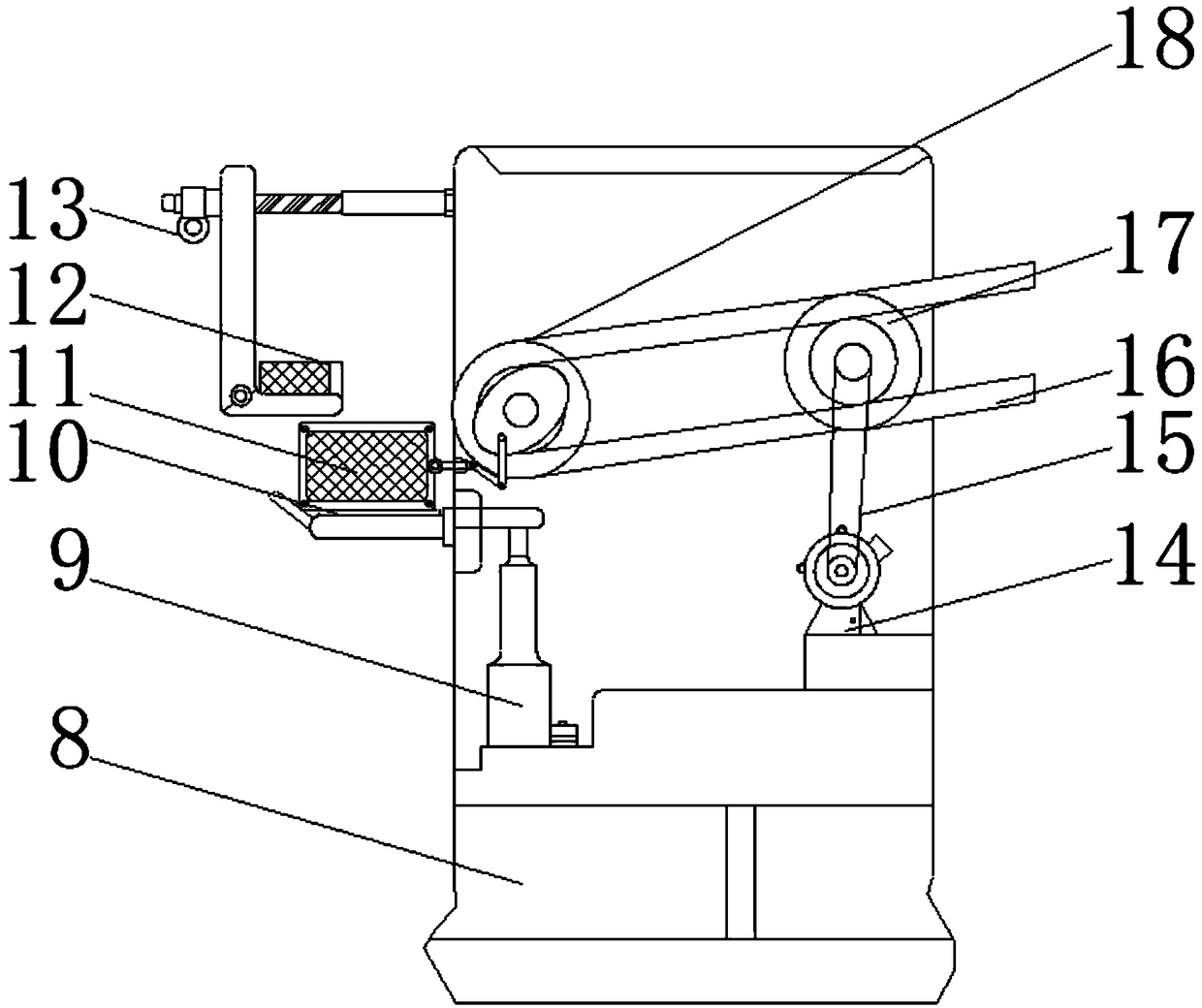

Efficient and reliable automatic yarn discharging machine

ActiveCN108190647AIncrease yarn unloading efficiencyReduce labor intensityFilament handlingTextile disintegration and recoveryYarnEngineering

The invention discloses an efficient and reliable automatic yarn discharging machine including a gantry support, a yarn discharging mechanism, a horizontal guide rail and a horizontal linear drive device, the top portion of the gantry support is fixedly provided with the horizontal guide rail, and the yarn discharging mechanism is vertically arranged at one side of the gantry support; the horizontal linear drive device and the gantry support are connected in a fixed or hinged mode, the yarn discharging mechanism includes a yarn discharging frame, yarn discharging brackets, a yarn discharging seat, vertical guide rails and a first vertical linear drive device, the yarn discharging frame is vertically arranged, and the top portion of the yarn discharging frame is slidably connected with thehorizontal guide rail and connected with an active end of the horizontal linear drive device in a fixed or hinged mode; two sides of one surface of the yarn discharging frame are fixedly provided withthe vertical guide rails, two sides of the yarn discharging seat are separately and slidably connected with the vertical guide rails, and one surface, facing the interior of the gantry support, of the yarn discharging seat is fixedly provided with a plurality of yarn discharging brackets which are perpendicular to the yarn discharging seat; and the first vertical linear drive device is verticallyand fixedly connected with the top portion of the yarn discharging frame and a moving end is connected with the yarn discharging seat in a fixed or hinged mode. The efficient and reliable automatic yarn discharging machine has the characteristics of compact and reliable structure, high efficiency of yarn discharging, difficult-to-deform yarn roll and high adaptability.

Owner:云南昆船电子设备有限公司 +1

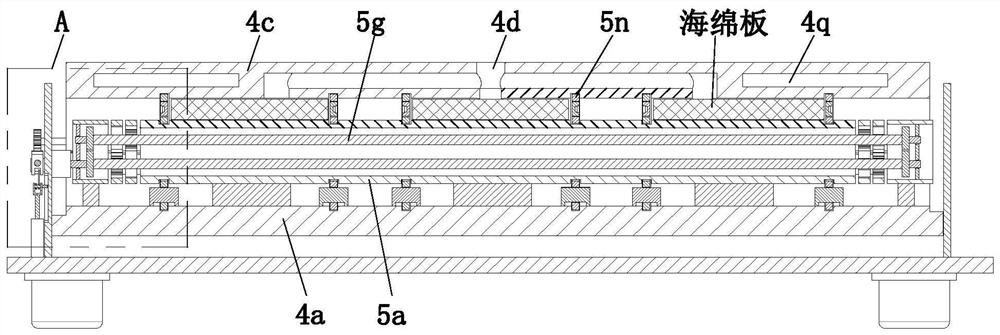

Polyurethane heat preservation sponge plate forming and manufacturing process

InactiveCN112549418AEasy to remove manuallyImprove work efficiencyFlat articlesProcess engineeringMaterials science

The invention provides a polyurethane heat preservation sponge plate forming and manufacturing process, which comprises a mounting bottom plate, supporting legs, a supporting plate, a positioning mechanism and a distance adjusting mechanism, and can solve the problems that in the polyurethane heat preservation sponge plate forming and manufacturing process, a mold for forming operation needs to bemanually positioned and sealed; in addition, the number of polyurethane heat preservation sponge plates which usually need to be machined is large, a plurality of sponge plates are difficult to machine at the same time in traditional forming machining operation, the labor intensity of manual operation is high, the working efficiency of machining operation is reduced, and the size of a sealing cavity used for forming operation is difficult to adjust in real time according to actual production requirements, it is guaranteed that the sponge plates of different shapes can be machined, gaps in theforming cavity are difficult to effectively seal in the forming process, and the problems that excessive burrs are generated due to the fact that the gaps are too large, and the forming cavity is more difficult to open automatically after forming operation are solved.

Owner:南京中鑫知网络科技有限公司

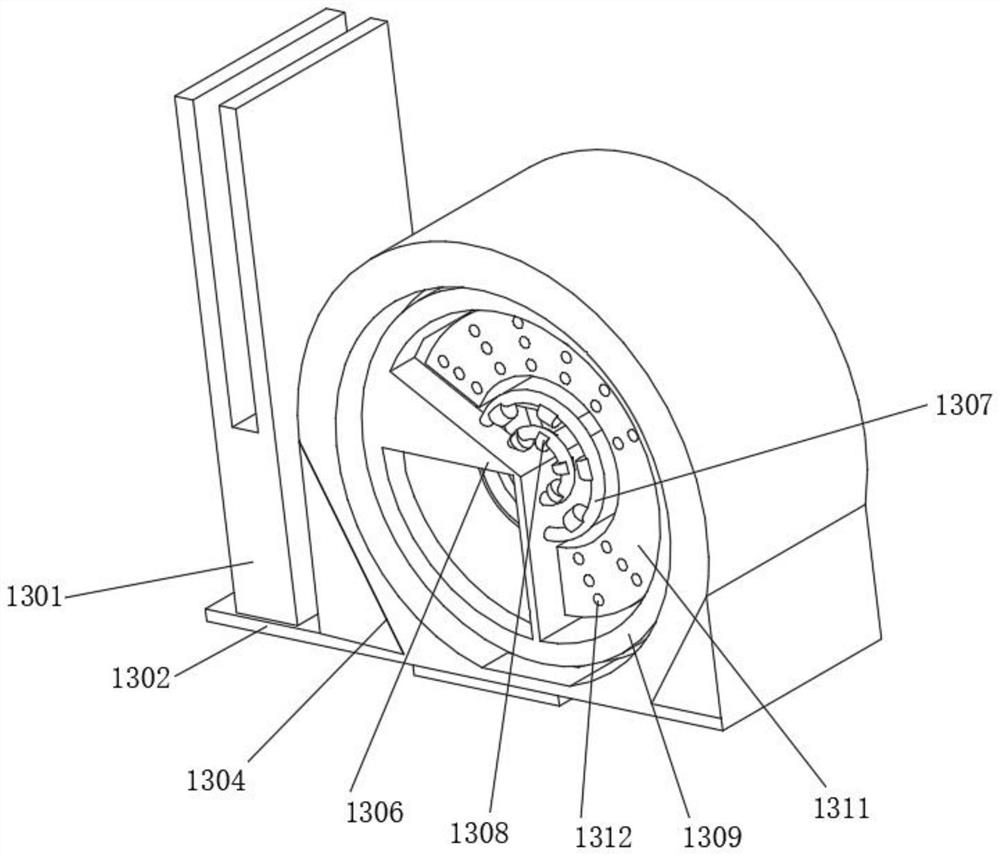

Explosion-proof and dust-proof ventilation equipment for underground engineering

PendingCN114592897AIgnite won'tReduce concentrationDust removalFire preventionEnvironmental engineeringGas explosion

The invention relates to the field of underground engineering, in particular to explosion-proof and dust-proof ventilation equipment for underground engineering. The technical problems that the concentration of gas in underground air in a ventilation pipeline can be gradually increased, when the concentration reaches a gas explosion concentration limit value, the danger of gas explosion exists, and dust in the underground air can pollute equipment due to the fact that the dust is not treated in time after settling are solved. According to the technical scheme, the explosion-proof and dust-proof ventilation equipment for the underground engineering comprises an adapter pipe, a fan and the like; the right side of the adapter communicates with a fan. Air with gas is intermittently injected into the closed space, and then the gas is ignited, so that the concentration of the gas in the underground air is reduced, and a large amount of gas cannot be ignited; and after the dust is sprayed and settled, the dust settles again in turbid liquid, so that the dust is accumulated and collected, and manual removal is facilitated.

Owner:冼志华

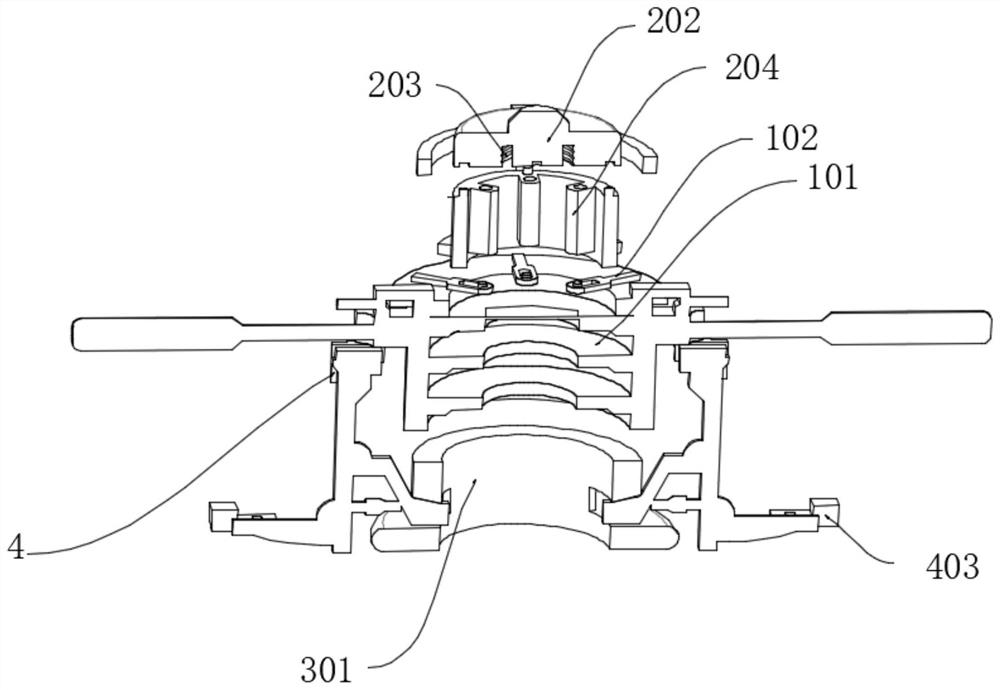

Long shaft tapping quick-change threading die guide frame

ActiveCN114211062ACases that do not skewNot misplacedThread cutting machinesStructural engineeringDrill

The invention discloses a long-shaft tapping quick-change threading die guide frame, and particularly relates to the technical field of tapping, the long-shaft tapping quick-change threading die guide frame comprises a positioning auxiliary clamping frame, guide frame outer frames are connected to the two sides of the positioning auxiliary clamping frame in a clamped mode, the positioning auxiliary clamping frame comprises a tapping twisting column frame, and a fixing clamping column is fixedly connected to the outer side of the tapping twisting column frame; a first sliding groove is formed in the outer surface of the guide frame outer frame, the first sliding groove of the guide frame outer frame and the tapping twisting column frame are arranged in a synchronous distance adjusting state, the lower side of the tapping twisting column frame is rotationally connected with a sliding block frame, and the two sides of the positioning auxiliary clamping frame are rotationally connected with rotating rods. The end guide frame and the guide frame outer frame are in a detachable clamping shape, so that the end guide frame can be conveniently and manually disengaged, a worker can clean the end guide frame, and therefore, external machining residues are prevented from entering the equipment to cause mounting deformation of the tapping drill while the tapping drill is clamped.

Owner:东台市双厦工具有限公司

High-end manufacturing automatic metal column tapping equipment

InactiveCN112808907AEasy to remove manuallySave human effortScrew-threads articlesMechanical engineeringIndustrial engineering

The invention relates to tapping equipment, in particular to high-end manufacturing automatic metal column tapping equipment. The technical aim to be achieved by the invention is to provide the high-end manufacturing automatic metal column tapping equipment capable of automatically tapping and taking down a metal column. In order to achieve the technical aim, the high-end manufacturing automatic metal column tapping equipment provided by the invention comprises a top plate connected with a support plate, a tapping assembly connected to the top plate, and a downward pressing assembly connected to the support plate. Through cooperation of the tapping assembly and the downward pressing assembly, downward pressing and tapping are conducted on the metal column, and through a clamping assembly, it is not needed to manually pull a sliding rod to move rightwards to conduct tapping on the metal column.

Owner:盐城市千钧贸易有限公司

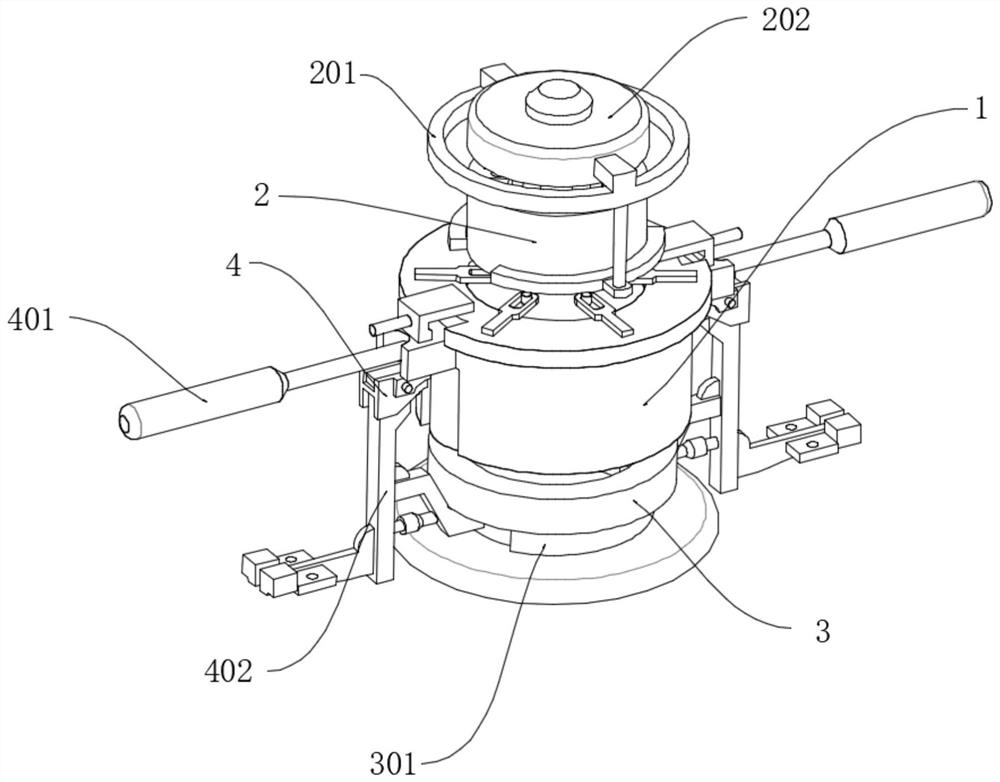

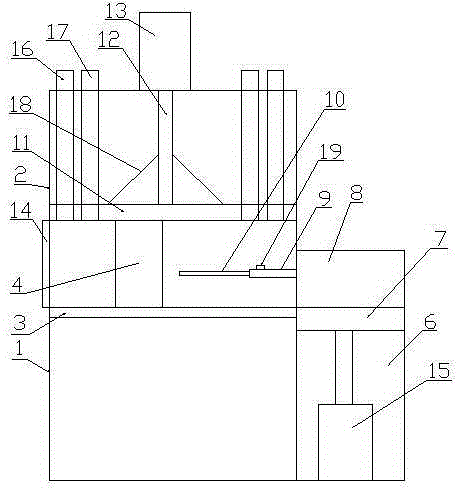

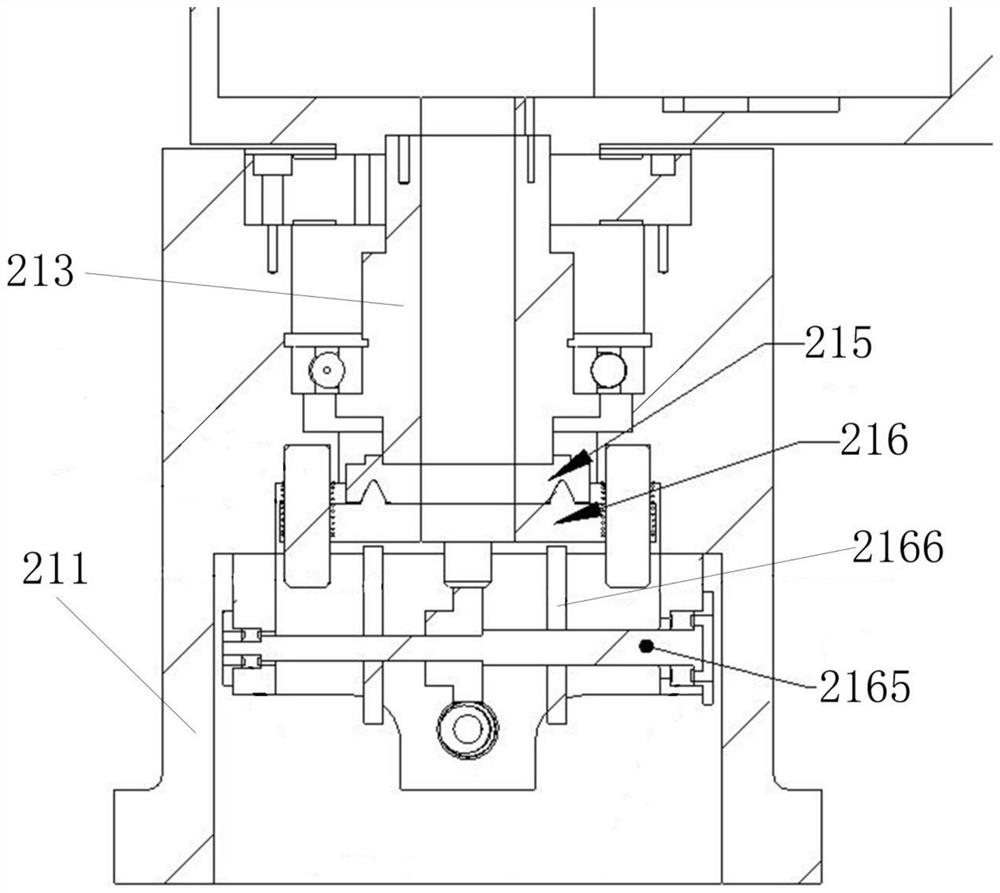

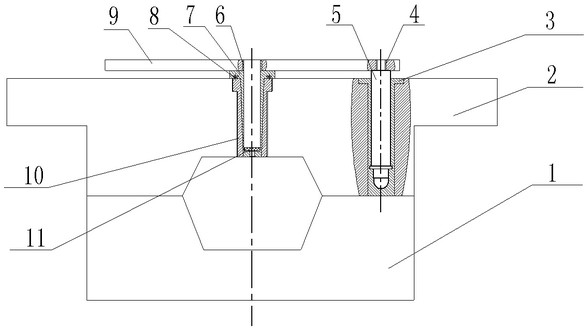

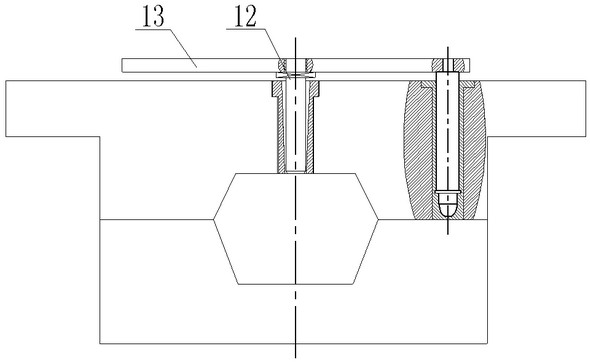

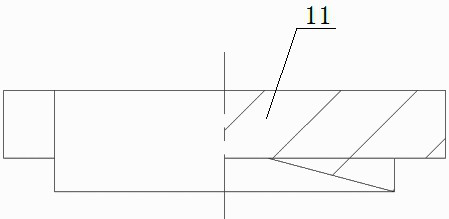

Power cell needling testing device

InactiveCN105352695AEasy to remove manuallyEasy to installShock testingStrength propertiesElectrical batteryEngineering

The invention aims to provide a power cell needling testing device. A sliding track is arranged on a base in an explosion-proof glass frame, a cell placing box provided with through holes in a side surface is arranged on the sliding track, a pressing plate is arranged to tightly press the cell placing box, and then a needling hydraulic machine drives steel needles to needle cells in the cell placing box; an open door is arranged, the cell placing box can be conveniently and manually taken out, and cells are installed and taken out; in addition, the explosion-proof glass frame is internally provided with an air exhaust pipe and a water spraying pipe, and temperature reduction and poison gas exhausting are carried out to prevent the cells from exploding in the needling process. The power cell needling testing device is simple in structure, easy to operate, capable of efficiently and safety carrying out needling testing on the power cells and applicable to production.

Owner:WUHU KAIER ELECTRICAL TECH

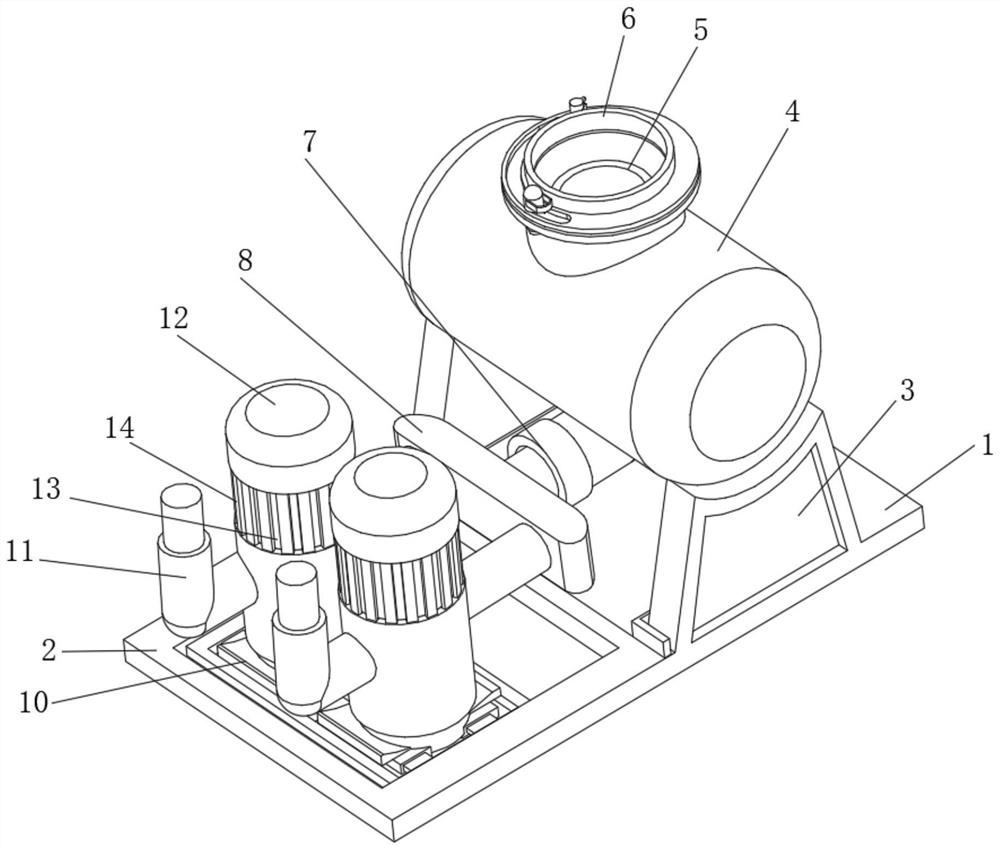

Intelligent negative pressure water supply system for water affairs

PendingCN114775737ANo need to worry about wasteNo need to worry about breedingService pipe systemsWater mainsWater volumeWater source

The invention discloses a negative pressure water supply system for intelligent water affairs, and relates to the technical field of water supply systems. Comprising a bottom fixing frame, the left side of the bottom fixing frame is fixedly connected with a connecting frame body, and the left side and the right side of the top of the bottom fixing frame are both fixedly connected with inclined plane supporting frames. As the equipment needs to provide a large amount of water, and a plurality of water pumps are additionally arranged in the equipment, the problems of large noise and water accumulation can be caused, the inclination angle of the pressurizing tank body can be adjusted at any time, and a noise removal mechanism for reducing noise is additionally arranged in the pressurizing tank body, so that the noise generated when the equipment is used is reduced to a great extent; and the position where water is easy to accumulate at the lower part can be upwards extracted by adjusting the pressurization angle, so that the waste of water sources and the breeding of a large number of bacteria are not needed. And when the water flow is large, the pump body is not opened.

Owner:马志杰

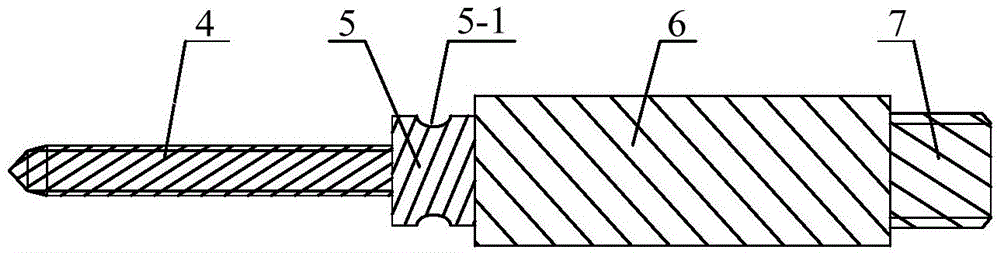

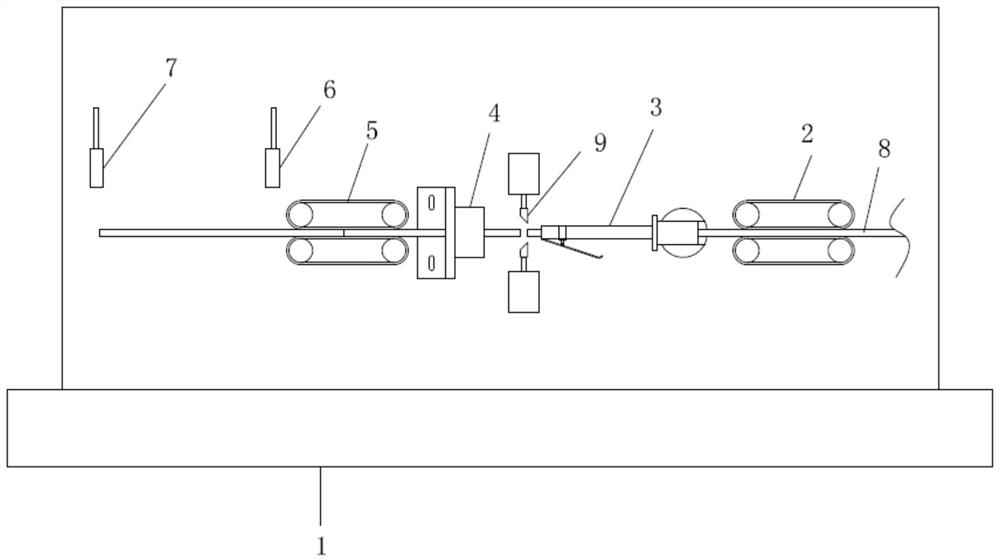

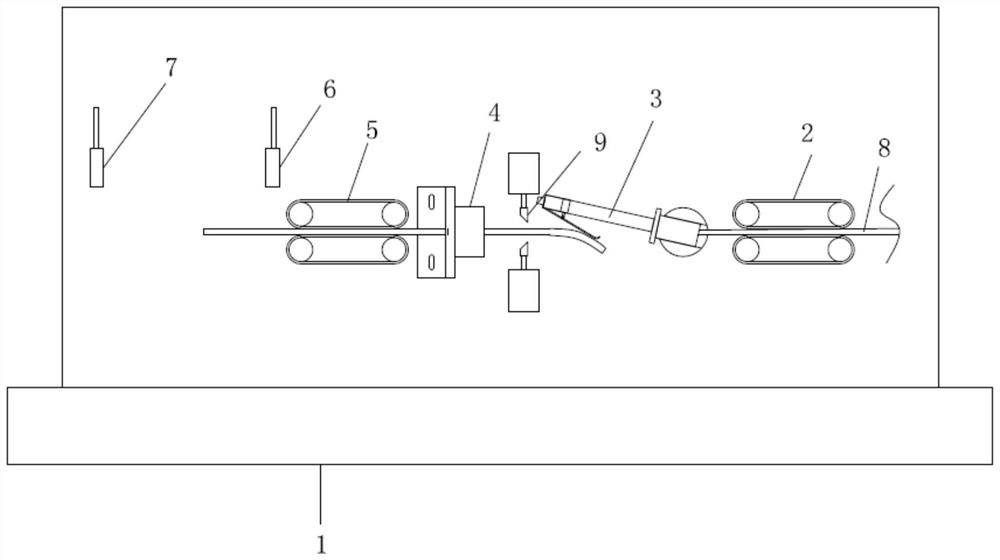

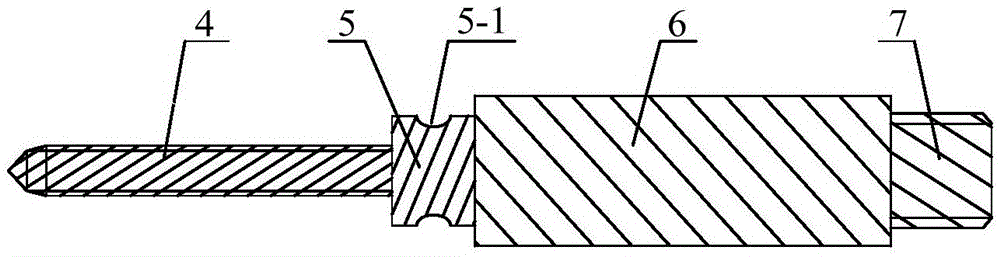

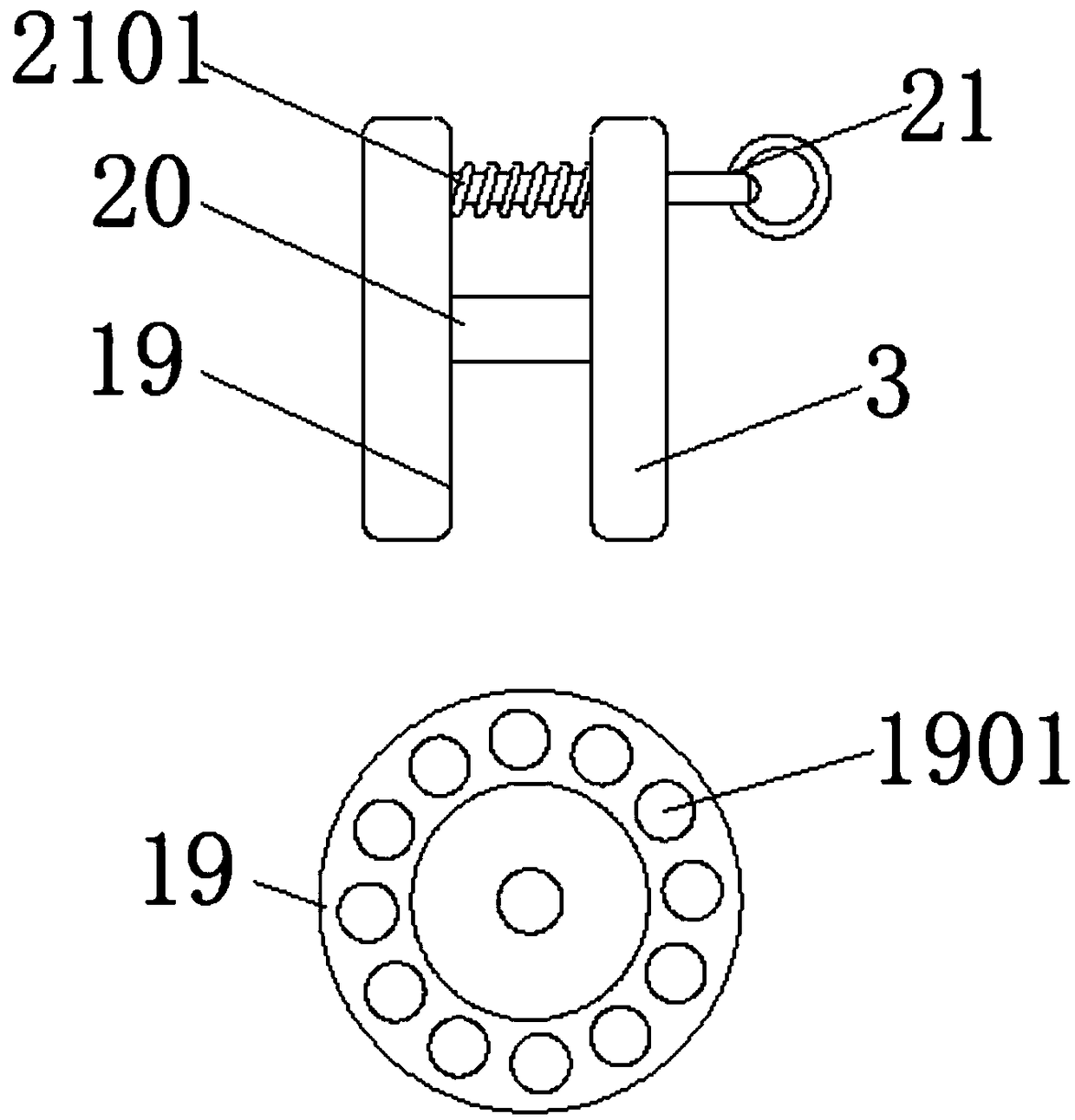

Cigarette defect simulator

ActiveCN103983648AEasy to remove manuallyAvoid mixingOptically investigating flaws/contaminationControl systemSimulation

The invention discloses a cigarette defect simulator which is characterized in that the simulator contains a casing pipe and a simulation inner-core arranged inside the casing pipe; and the simulation inner-core contains a hollow-head simulation inner-core (2) which is provided with an electronic transponder (3). The cigarette defect simulator has advantages of simple structure and low cost, and can be used to simulate cigarette defects so as to verify sensitivity and accuracy of a cigarette packer's cigarette defect detection and rejection unit and simultaneously detect the cigarette defect simulator which hasn't been accurately detected and rejected. Thus, it brings convenience in manually rejecting the cigarette defect simulator (or automatically rejecting the simulator by a packer through a correlation with a central control system of the packer); the cigarette defect simulator is prevented from being mixed in normal cigarettes; a verification effect is guaranteed; and production efficiency can be raised. Thus, the cigarette defect simulator is suitable for popularization and usage.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

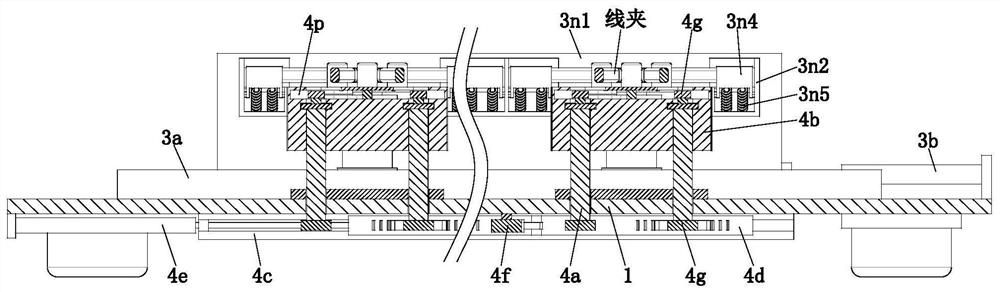

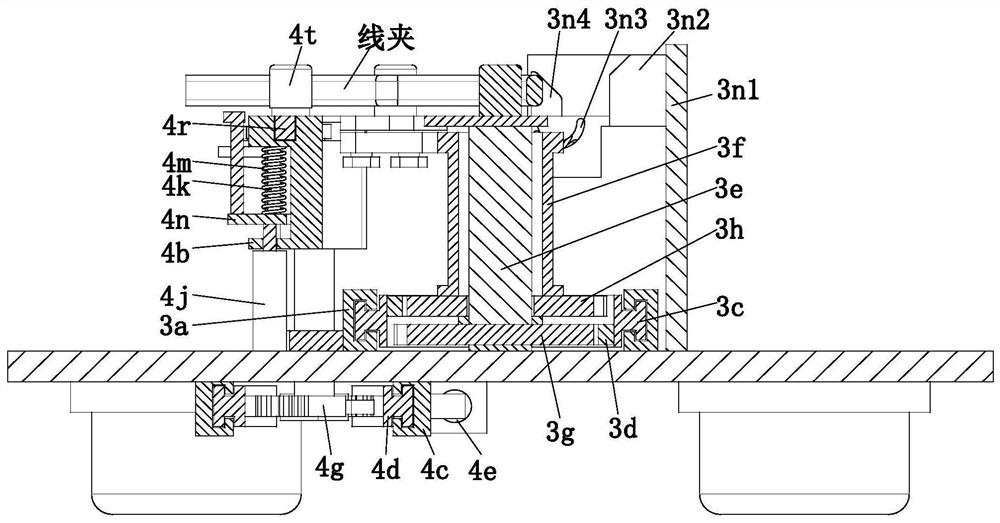

Power line clamp processing production system

InactiveCN112496113AImprove work efficiencyEasy to take outMetal-working feeding devicesPositioning devicesPress brakeElectrical and Electronics engineering

The invention relates to a power line clamp processing production system. The power line clamp processing production system comprises a mounting bottom plate, supporting columns, a bending mechanism and a distance adjusting mechanism, wherein the supporting columns are uniformly arranged at the lower end of the mounting bottom plate, the bending mechanism is arranged at the upper end of the mounting bottom plate, and the distance adjusting mechanism is arranged on the mounting bottom plate located on one side of the bending mechanism. A plurality of power line clamps to be bent can be placed at the same time through positioning sliding frames arranged at multiple stations, so that the operation efficiency of forming machining operation is improved. Under pushing of the power line clamps, positioning sliding seats begin to rotate downwards through sliding fit between positioning sliding rods and positioning sliding grooves, and receding is conducted for movement of the power line clamps. After the power line clamps completely rotate out of the positioning sliding frames, a bending shaft pushes the power line clamp to rotate to a certain angle, and then the power wire clamps begin tobend under the blocking and limiting action of a distance adjusting sliding rod, so that the required bending effect is achieved.

Owner:许子隆

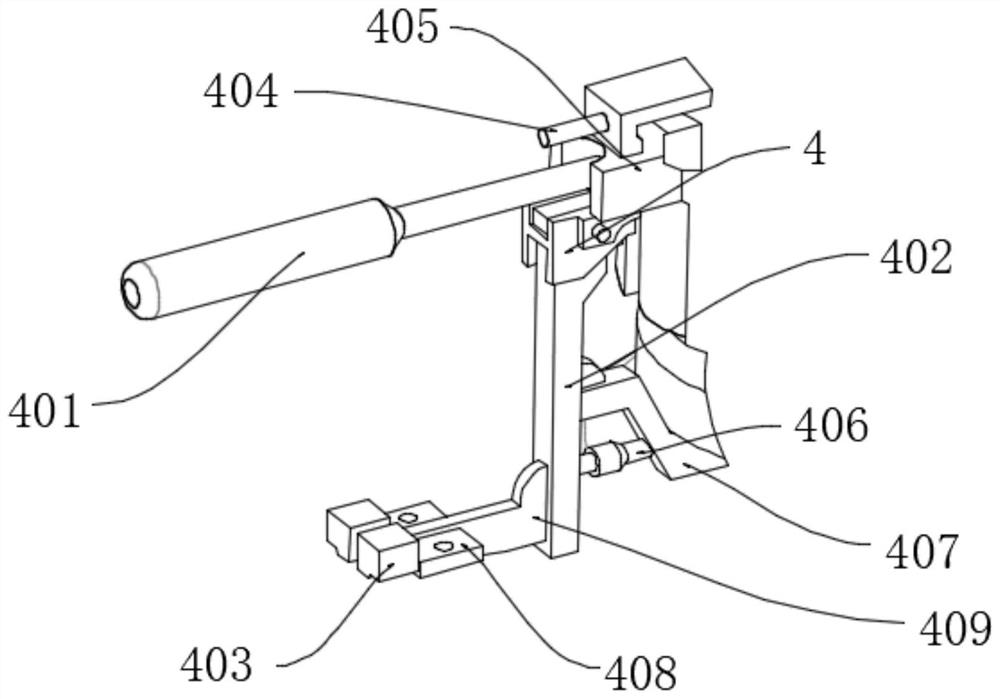

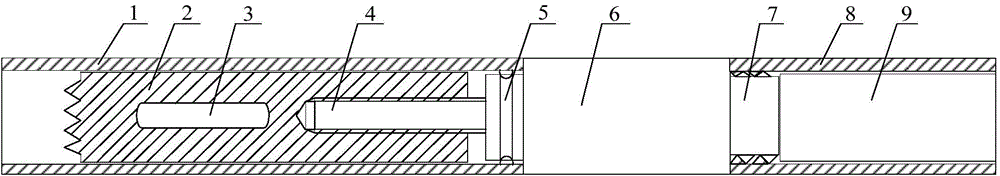

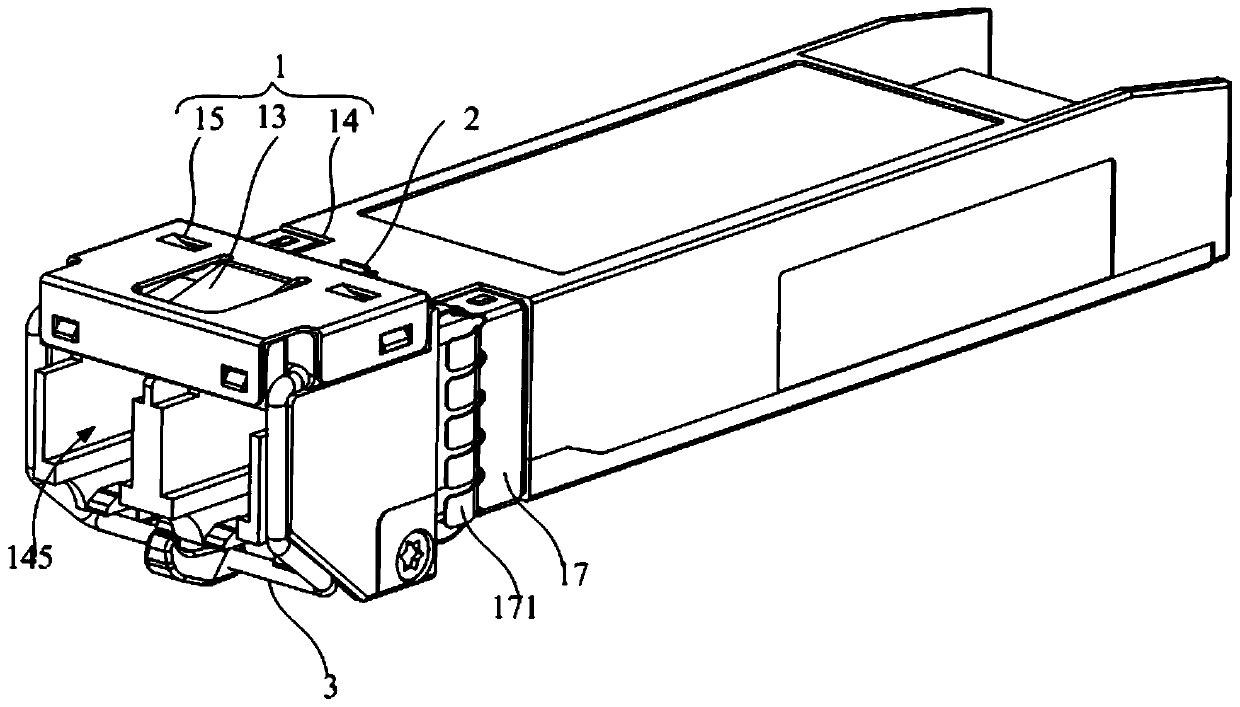

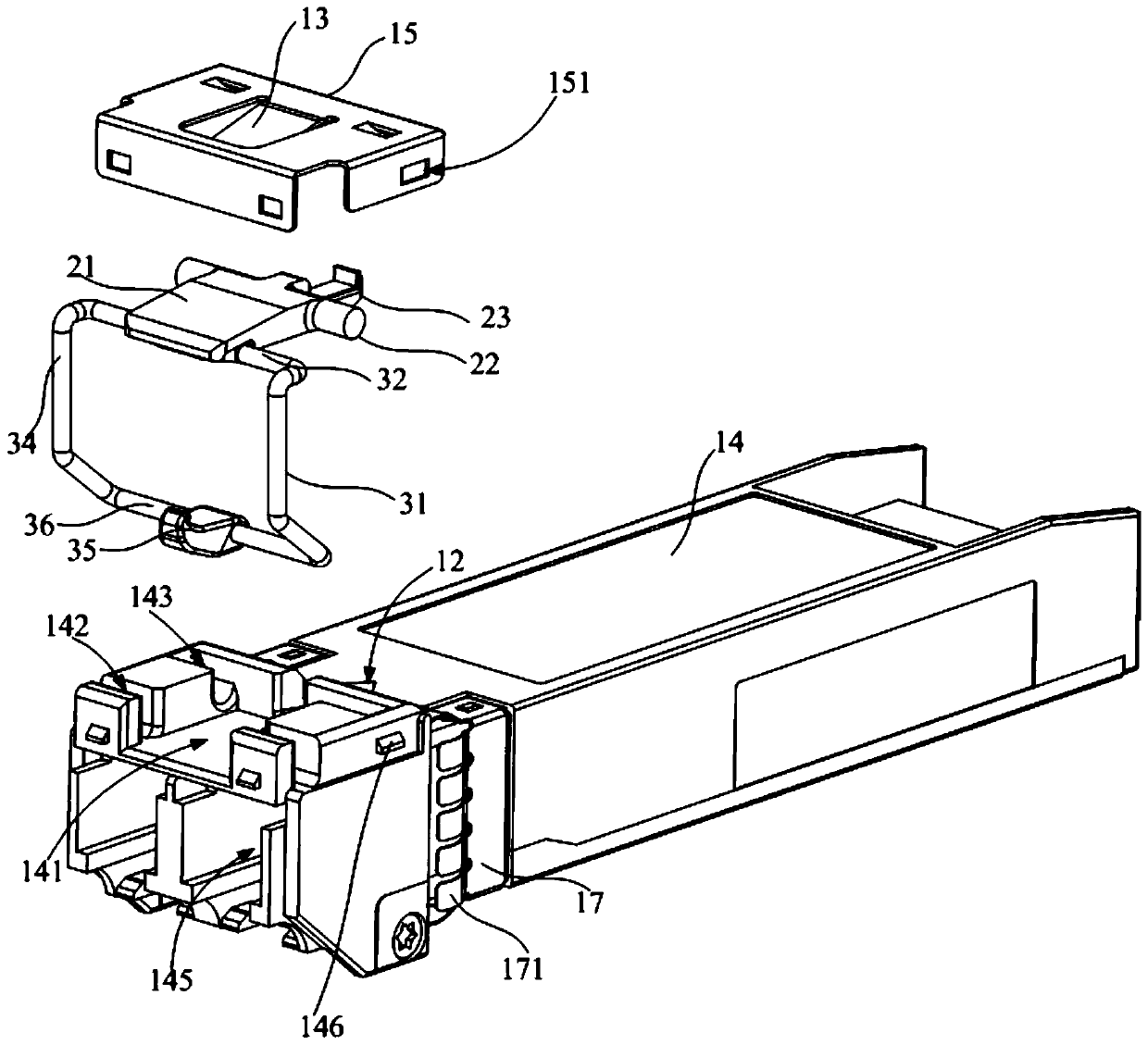

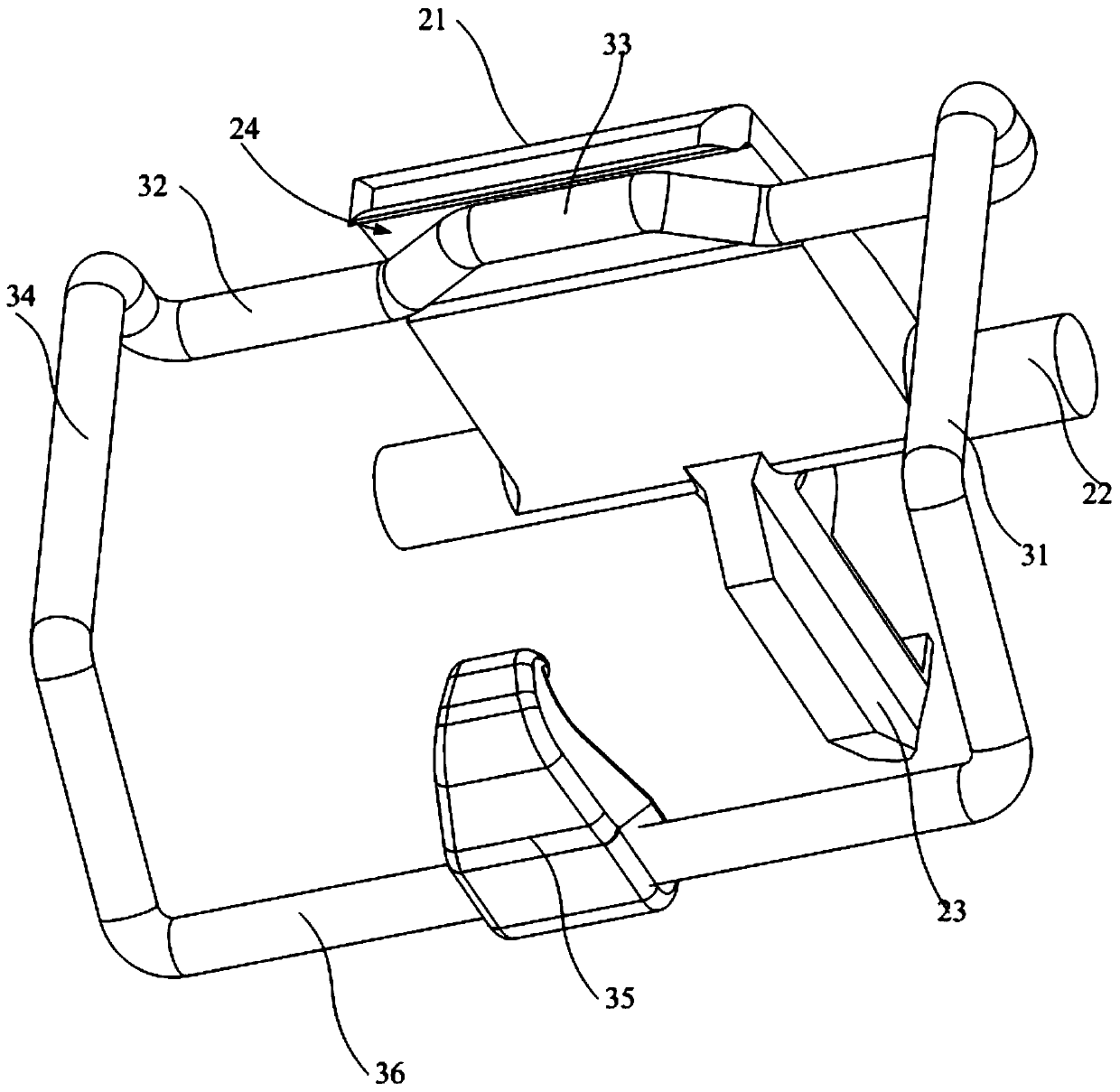

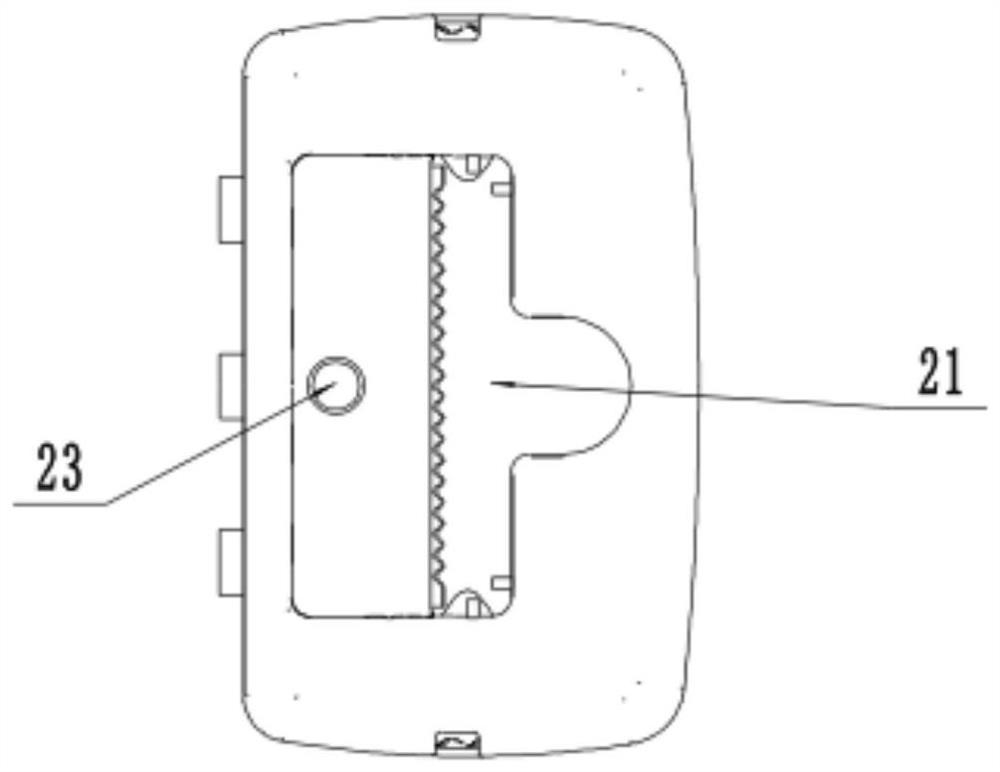

Unlocking structure and optical module

PendingCN111338036AEasy extractionSimple structureCoupling light guidesOptical ModuleMechanical engineering

The invention discloses an unlocking structure and an optical module. The unlocking structure comprises a base, a locking piece and a rotating piece. The base is provided with a containing cavity anda locking groove communicated with the containing cavity; the base is provided with an elastic piece arranged by corresponding to the containing cavity; the locking piece comprises a pressing plate, arotating shaft and a locking block which are connected in sequence, the pressing plate and the locking block are rotatably arranged on the base through the rotating shaft, the pressing plate is arranged in the containing cavity, the locking block is arranged in the locking groove, and the pressing plate is abutted against the elastic piece; the rotating piece is arranged on the base in a rotatable mode. According to the unlocking structure, the structure of the optical module is simplified and the efficiency of plugging and unplugging the optical module is improved.

Owner:APAT OPTOELECTRONICS COMPONENTS

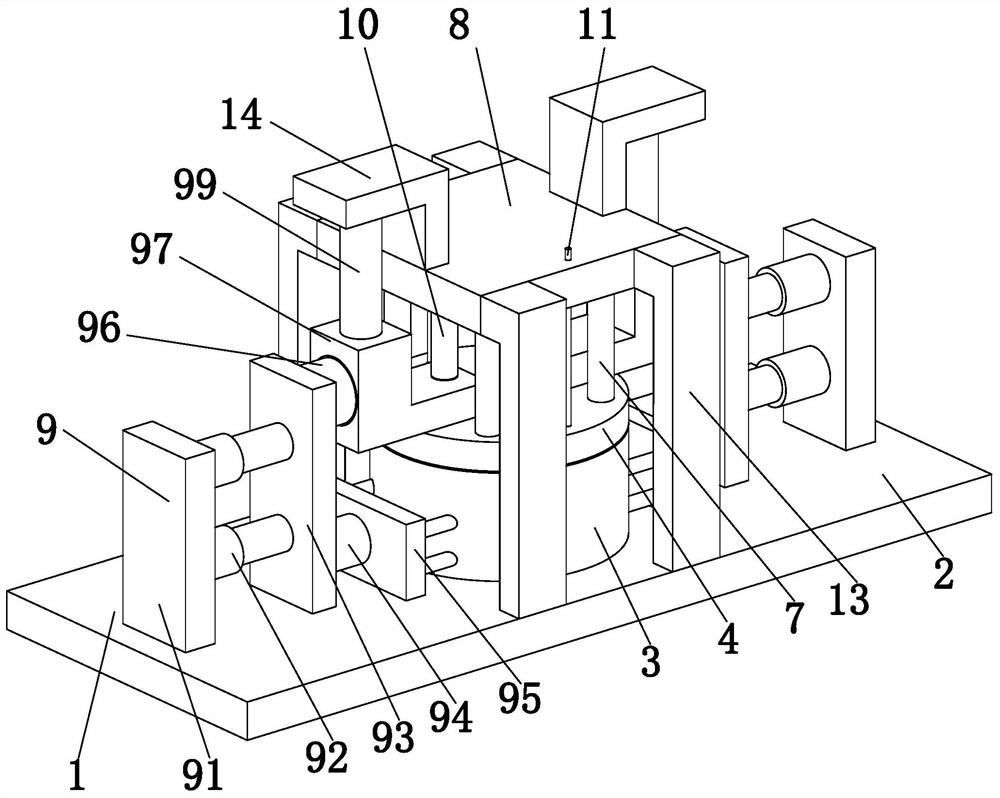

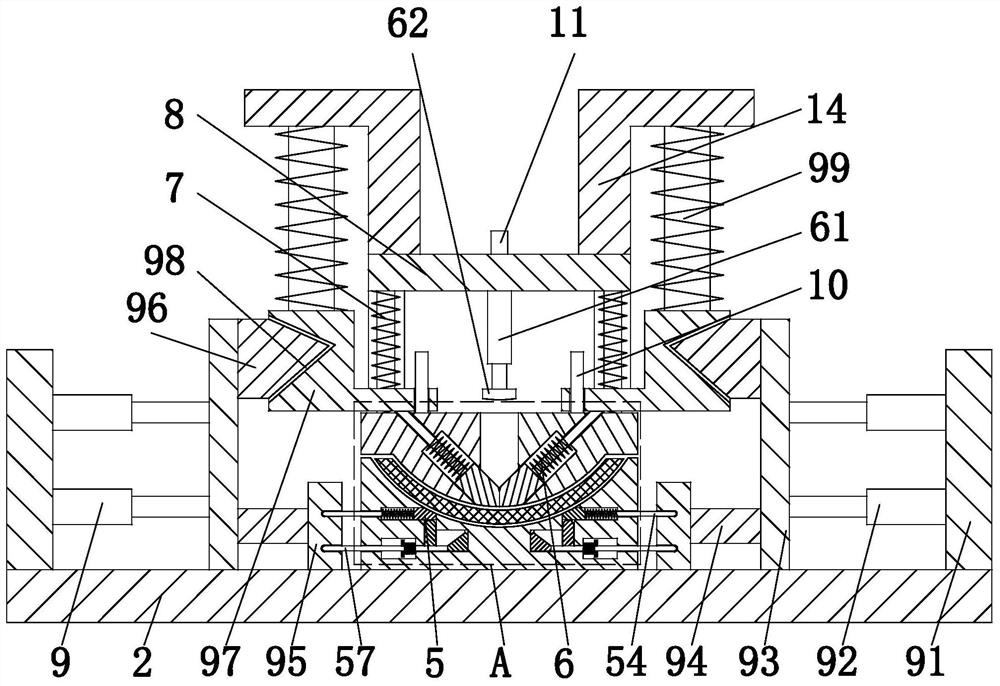

Pressure container end cover machining and forming method

The invention provides a pressure container end cover machining and forming method. Pressure container end cover machining and forming equipment is used in the method and comprises a casting and forming device. The pressure container end cover machining and forming method can solve the following problems existing in the pressure container end cover machining and forming process that a, for a pressure container end cover machining and forming mode, a traditional mode is that a machine tool is adopted for punching, a plate is punched to be in an end cover shape, for some thick end cover punching, the mode cannot be taken, the requirement for the device is high, punching defects exist, and the requirement cannot be met; and b, another mode is a casting and forming mode, according to an existing casting and forming device, an end cover formed in a cavity needs to be taken out manually through a tool, the end cover and the cavity are in solidification connection, the end cover cannot be taken out manually easily, and the formed end cover cannot be automatically taken out through the device.

Owner:杭州临安伊卡顿智能科技有限公司

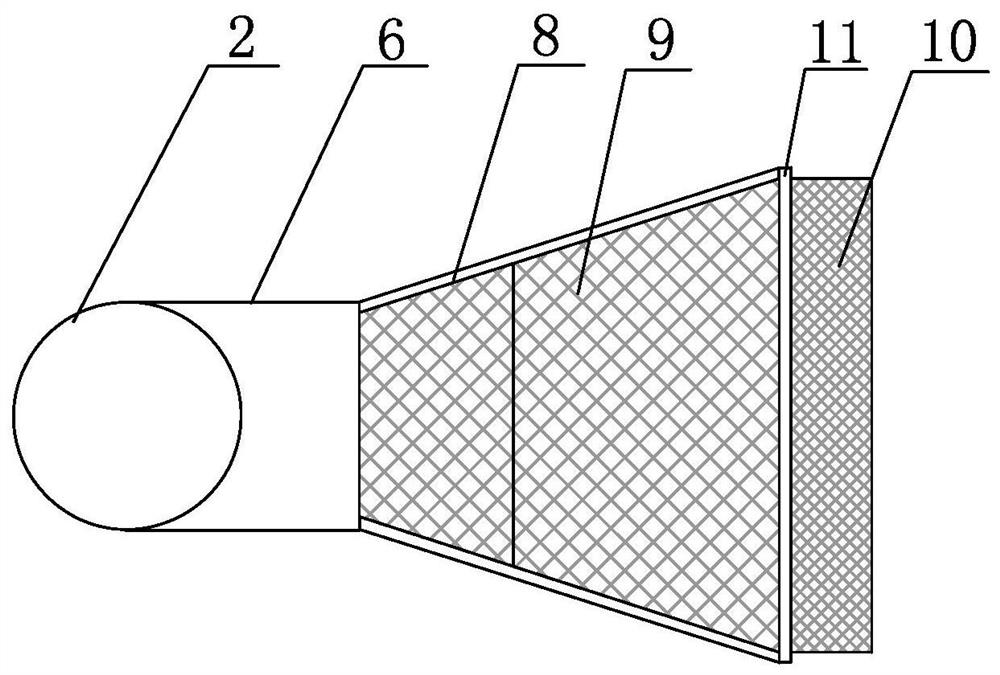

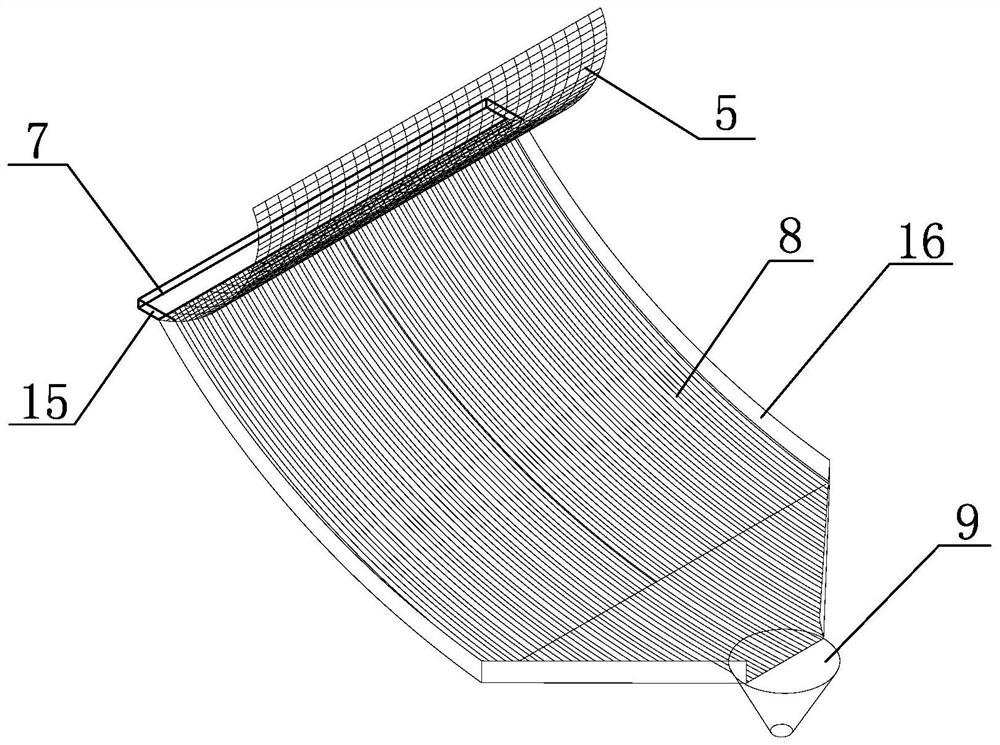

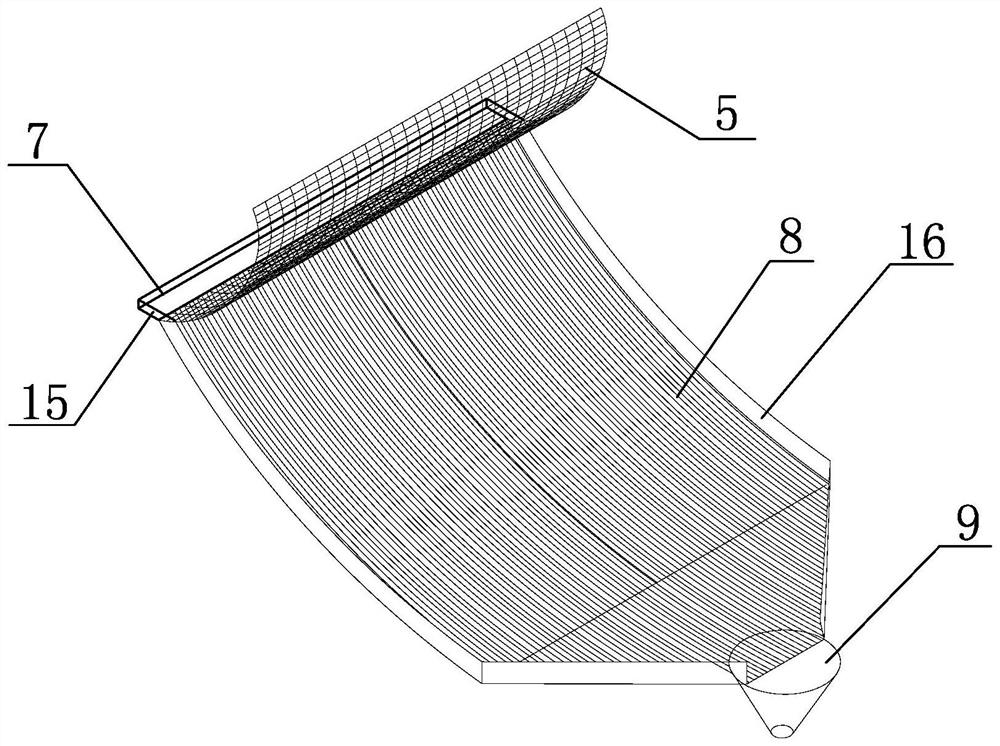

Double-arc continuous concentration and sewage discharge device and method for shrimp farming system

ActiveCN112715466ASolve the disadvantages of easy blockageEasy to remove manuallyClimate change adaptationPisciculture and aquariaWater filterEngineering

The invention discloses a double-arc continuous concentration and sewage discharge device and method for a shrimp farming system. The device is characterized by comprising at least two symmetrically-arranged sewage collecting pipes, the opening ends of the sewage collecting pipes are located in the center of the bottom of a culture pond, and one end, close to the wall of the culture pond, of each sewage collecting pipe communicates with the bottoms of gas stripping pipes; a transverse pipe communicating with the gas stripping pipes is arranged between the two gas stripping pipes and located on the water surface of the culture pond, a detachable thick arc-shaped screen cloth bent towards the transverse pipe is arranged on the side, close to the wall of the culture pond, of the outer wall of the transverse pipe, and a long-strip-shaped hole is formed in the pipe wall of the transverse pipe and located in the area of the thick arc-shaped screen cloth; and a collecting tank is arranged between the bottom of the thick arc-shaped screen cloth and the bottom of the transverse pipe, a detachable thin arc-shaped screen cloth used for filtering water filtered by the thick arc-shaped screen cloth is arranged below the thick arc-shaped screen cloth, and a collecting hopper is arranged at the triangular bottom of the thin arc-shaped screen cloth. The device has the advantages that shrimp shells, dead shrimps, and diseased shrimps with poor vitality can be separated in time, residual feeds and excrement are concentrated and then discharged, and the sewage discharge water consumption is greatly reduced.

Owner:NINGBO UNIV

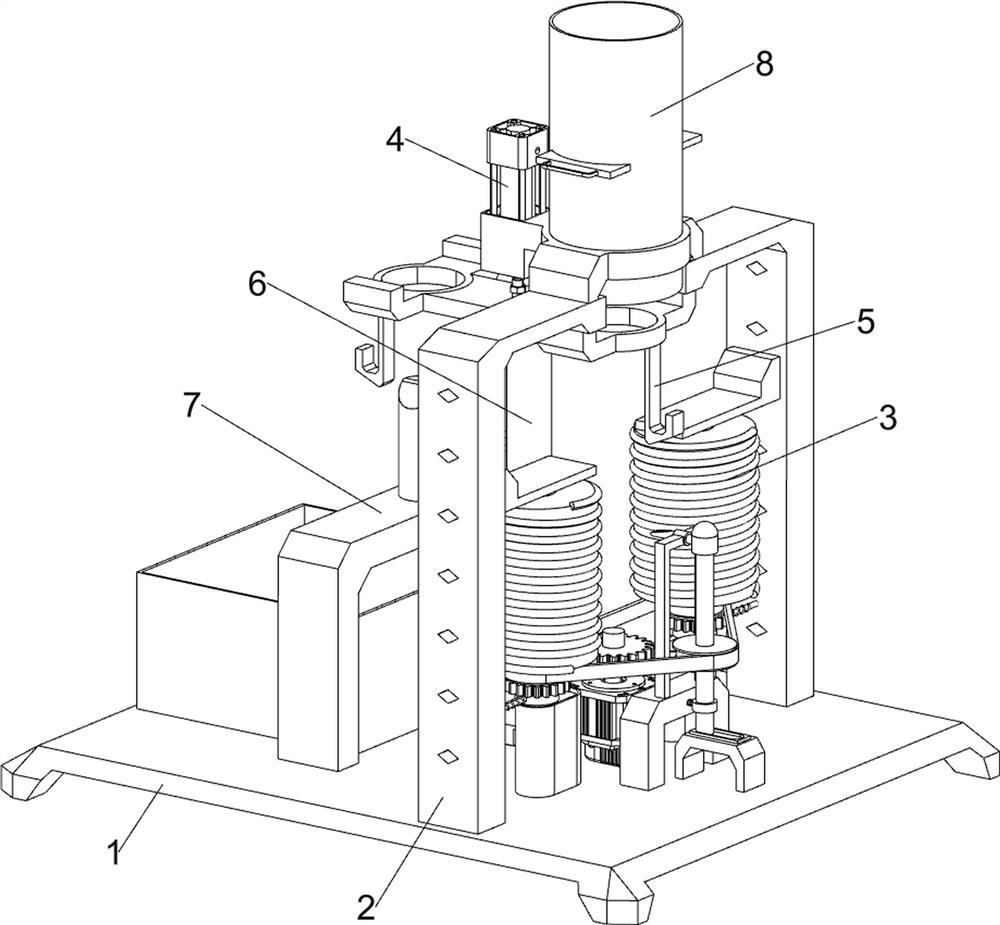

Mechanical arm and surgical navigation positioning system

PendingCN113855246ASimple structureReduce weightSurgical navigation systemsComputer-aided planning/modellingSurgical ManipulationRotational axis

The invention discloses a mechanical arm and a surgical navigation and positioning system. The mechanical arm comprises: a base joint; a driven arm which is rotationally mounted on the base joint; and connecting rods which are sequentially connected in a matched mode through joints, wherein the first connecting rod is connected with the driven arm in a matched mode through joints. The base joint comprises a hollow base and a rotating shaft rotationally mounted in the base, and the driven arm is fixedly connected with the rotating shaft; and a braking assembly matched with the end face of the rotating shaft to achieve braking is installed in the base and located below the rotating shaft. According to the mechanical arm, self-locking of the mechanical arm can be achieved, and the problems that an existing brake is large in power-off self-locking vibration and short in service life and needs to be frequently replaced are solved. According to the invention, the occupied space of the trolley in the operation can be reduced, a doctor can conveniently carry out the operation in the operation, the information interaction of each device can be reduced, the operation efficiency of the doctor is improved, and the operation time is shortened.

Owner:NANJING TUODAO MEDICAL TECHNOLOGY CO LTD

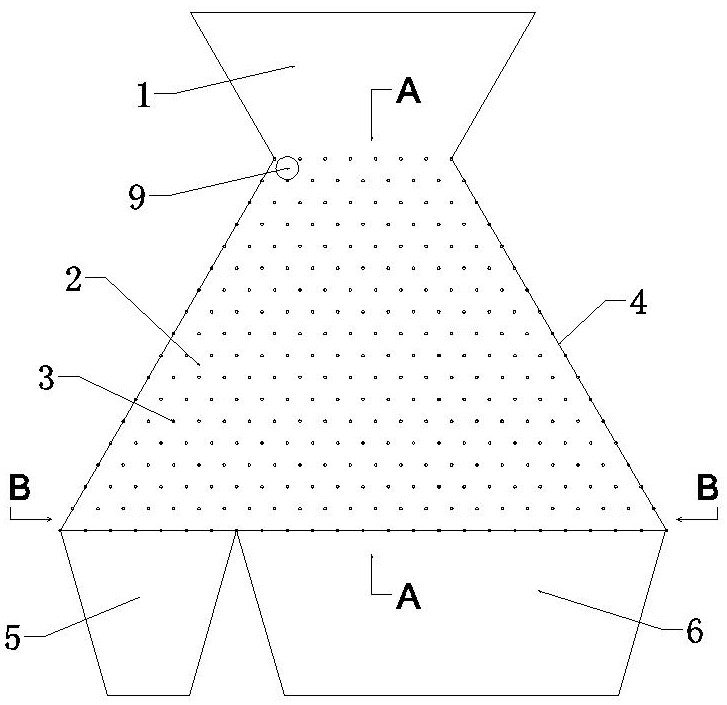

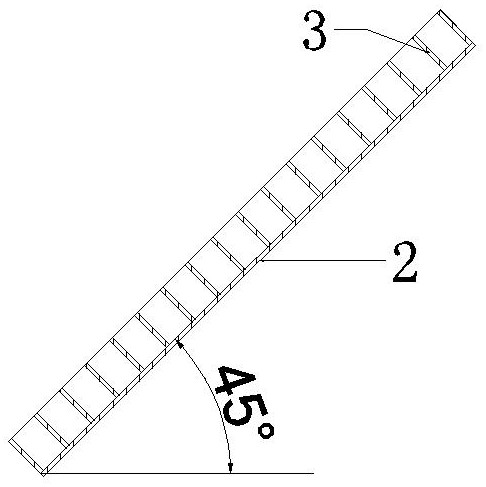

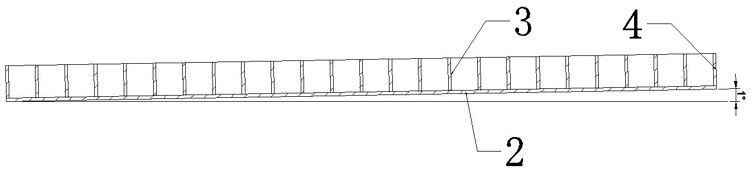

Needle plate ball screening machine

The invention discloses a needle plate ball screening machine, and relates to the field of ball screening equipment. The needle plate ball screening machine comprises a feeding chute, a screening area and a discharging chute. The screening area comprises a bottom plate, firing pins and side plates, the bottom plate is of a trapezoidal structure, the firing pins are evenly fixed to the upper surface of the bottom plate, and the two side edges of the bottom plate are fixedly connected with the side plates correspondingly; the upper end of the bottom plate is connected with the feeding chute, and the lower end of the bottom plate is connected with the discharging chute; and the bottom plate is obliquely arranged in the vertical direction and the left-right direction, and a supporting frame is arranged on the lower end face of the bottom plate. According to the needle plate ball screening machine, precise screening of balls is carried out through the inclination angle of a needle plate, and finished balls with a certain specific particle size are obtained through screening, so that the screening precision of the balls is improved, the needle plate ball screening machine is suitable for secondary fine screening of the balls, and the grinding effect of a ball mill is improved.

Owner:唐山冀东启新水泥有限责任公司

Core box

PendingCN113042683AEasy to remove manuallyReduce dosageMoulding machinesEnvironmental geologyStructural engineering

Owner:XINXING HEAVY IND HUBEI 3611 MECHANICAL

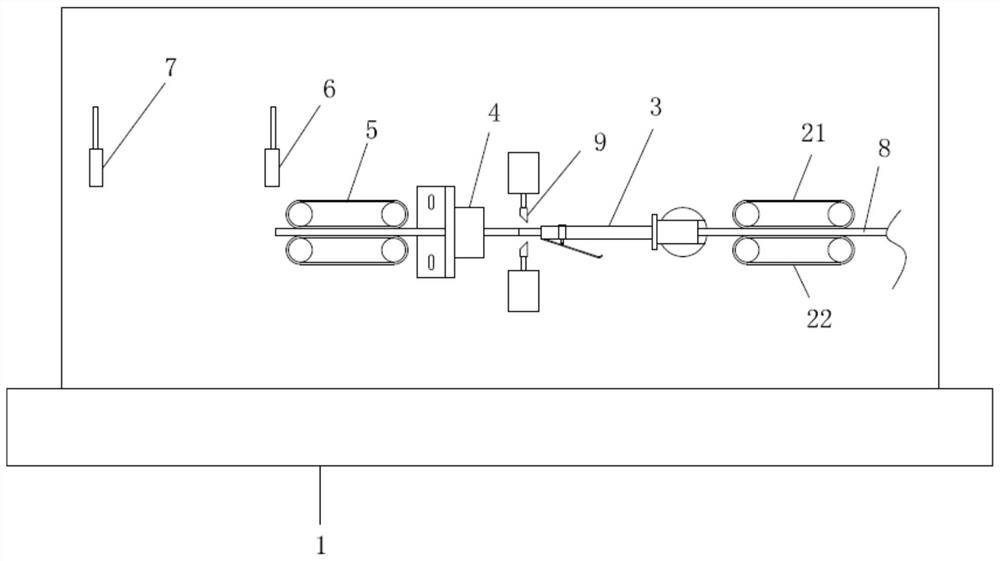

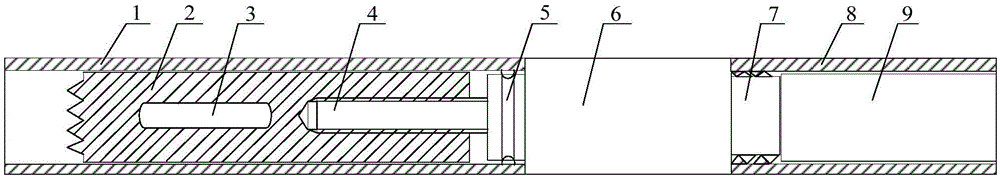

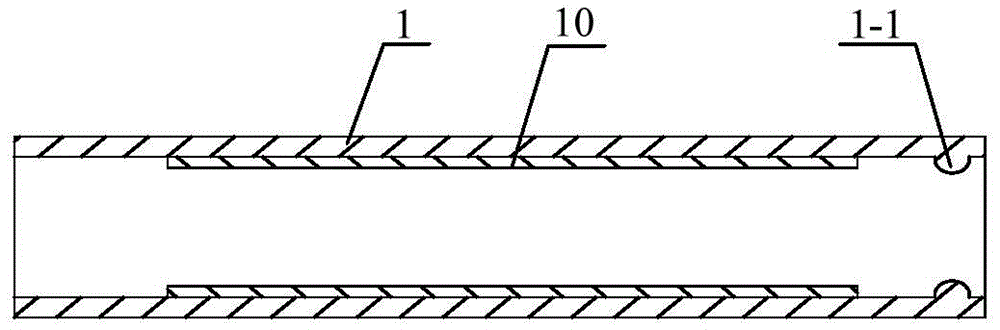

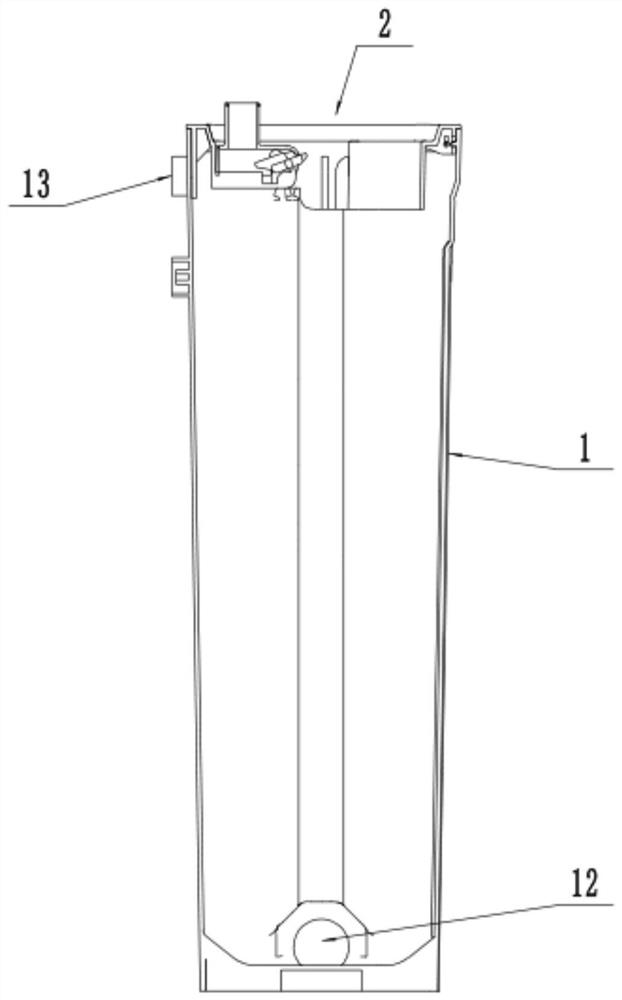

Wire cutting machine capable of improving stripping efficiency of wire harness protective sleeve

PendingCN114378223AFully control the lengthEasy to remove manuallyMetal working apparatusWire cuttingStructural engineering

The invention discloses a wire cutting machine capable of improving stripping efficiency of a wire harness protective sleeve, which comprises a rack, and the rack is provided with a first traction belt group, a first guide piece, a cutter structure, a second guide piece, a second traction belt group, a first position sensor and a second position sensor which are arranged along a straight line, a wire harness sequentially penetrates through the first traction belt set, the first guide piece, the cutter structure, the second guide piece and the second traction belt set, the first traction belt set comprises a first upper traction belt and a first lower traction belt, the wire harness is clamped between the first upper traction belt and the first lower traction belt, the first guide piece is rotatably installed on the rack, and the cutter structure is installed on the rack. The cutter structure comprises wire cutters symmetrically arranged on the two sides of the wire harness, the first position sensor is correspondingly arranged on the portion, above the wire harness, of the rack, and the second position sensor is parallel to the first position sensor. Compared with the prior art, fixed-length cutting of the wire harness is achieved, and the stripping efficiency of the wire harness protection sleeve is effectively improved.

Owner:苏州旗强电气有限公司

Cigarette Defect Simulator

ActiveCN103983648BEasy to remove manuallyAvoid mixingOptically investigating flaws/contaminationControl systemSimulation

The invention discloses a cigarette defect simulator which is characterized in that the simulator contains a casing pipe and a simulation inner-core arranged inside the casing pipe; and the simulation inner-core contains a hollow-head simulation inner-core (2) which is provided with an electronic transponder (3). The cigarette defect simulator has advantages of simple structure and low cost, and can be used to simulate cigarette defects so as to verify sensitivity and accuracy of a cigarette packer's cigarette defect detection and rejection unit and simultaneously detect the cigarette defect simulator which hasn't been accurately detected and rejected. Thus, it brings convenience in manually rejecting the cigarette defect simulator (or automatically rejecting the simulator by a packer through a correlation with a central control system of the packer); the cigarette defect simulator is prevented from being mixed in normal cigarettes; a verification effect is guaranteed; and production efficiency can be raised. Thus, the cigarette defect simulator is suitable for popularization and usage.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

A double-arc continuous concentrated sewage discharge device and method for a shrimp farming system

ActiveCN112715466BSolve the disadvantages of easy blockageEasy to remove manuallyClimate change adaptationPisciculture and aquariaFecesPrawn

The invention discloses a double-arc continuous concentrated sewage discharge device and method for a shrimp farming system, which is characterized in that it comprises at least two symmetrically arranged sewage collection pipes, the open end of the sewage collection pipes is located at the center of the bottom of the culture pond, and the sewage collection pipes are close to the cultivation One end of the pool wall communicates with the bottom of the airlift pipe, and a horizontal pipe connected to the airlift pipe is arranged between the two airlift pipes and on the water surface of the culture pond. A detachable thick arc-shaped screen with curved horizontal tubes. Long holes are arranged on the tube wall of the horizontal tube and located in the area of the thick arc-shaped screen. Slot, under the thick curved screen, there is a detachable thin curved screen for filtering the water filtered by the thick curved screen. Shrimp shells, dead shrimp, and sick shrimp with poor vitality are discharged after concentrating residual bait and feces, and greatly reducing the water consumption of sewage.

Owner:NINGBO UNIV

Automatic cutting and receiving auxiliary device for labels

PendingCN108818723AConvenient for practical useRealize the vibration effectMetal working apparatusPlastic recyclingEngineeringMechanical engineering

The invention discloses an automatic cutting and receiving auxiliary device for labels. The automatic cutting and receiving auxiliary device comprises a main shell, a movable frame and a hanging plate; a thread barrel is welded to one side surface of the main shell; a screw rod is arranged in the thread barrel by a thread body; the bottom end of the hanging plate is provided with a baffle plate bya rotating shaft; a limiting chute is formed in the top end of the movable frame; an electric pushing rod is fixedly arranged in the main shell; a power motor is fixedly arranged in the main shell atone side of the electric pushing rod; a drive roller is arranged in the main shell above the power motor by a bearing; a driven roller is arranged in the main shell at one side of the drive roller bya bearing; and the surface of the driven roller and the surface of the drive roller are sleeved and connected with a conveying belt. According to the automatic cutting and receiving auxiliary devicedisclosed by the invention, by installing a series of structures, when being received by the device, the cut labels can be helped to evenly fall into a receiving component; shutdown operation can be avoided, which is convenient for continuous receiving to be realized.

Owner:苏州利通印刷有限公司

Flat mop cleaning barrel and cleaning tool

PendingCN112438671AEasy to remove manuallyEasy to removeCarpet cleanersFloor cleanersWater flowEngineering

The invention discloses a flat mop cleaning barrel and a cleaning tool, and relates to the technical field of cleaning tools. The barrel comprises a barrel cover, the barrel cover is provided with aninsertion port and a water distribution tank, the water distribution tank is located at the side part of the insertion port, the upper part of the water distribution tank is provided with a water inlet pipe, and a water flushing hole is formed in one side, facing the insertion port, of the water distribution tank; and a strip-shaped window is further arranged on the side, facing the insertion opening, of the water distribution tank and located on the upper side of the water flushing hole, a scraping strip is arranged in the window and can swing up and down along with in and out of a mop head,and a plurality of scraping teeth are arranged on the side, facing the insertion port, of the scraping strip and evenly distributed in the length direction of the scraping strip. When the mop head isinserted into the insertion port, the scraping strip plays a role in removing hair, floccules and other sundries, when the wiped object is flushed, water flow can directly flush the wiping object, andthe problem that due to the fact that the sundries block water, flushing is not thorough is solved. When the mop head is pulled out, the wiped object can be extruded by the scraping strip, so that the barrel has a dehydration function.

Owner:张树晴

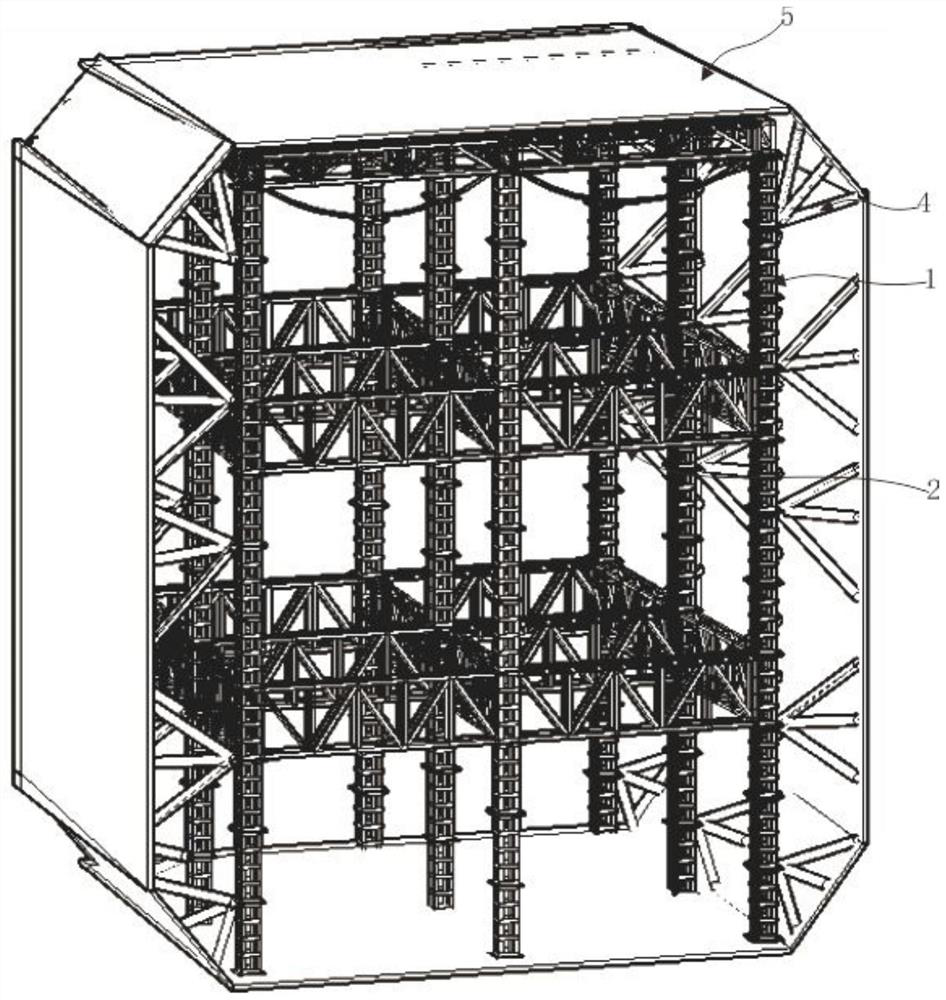

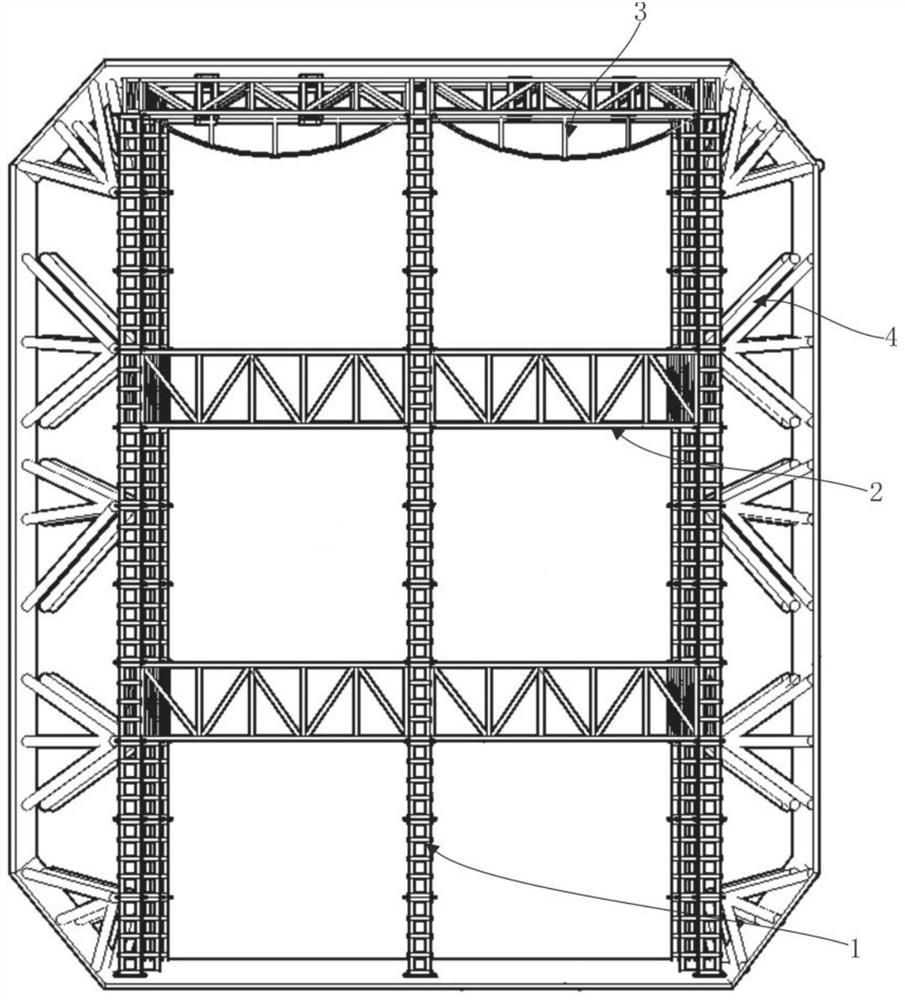

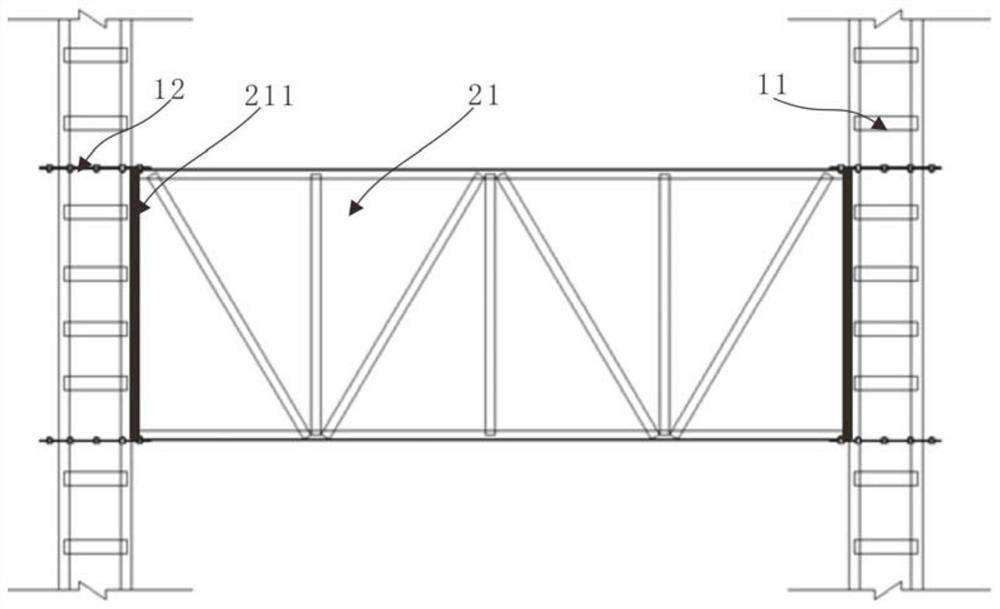

Assembled formwork support device for special-shaped concrete cavity

InactiveCN109339436BLight weightMeet the requirements of construction precision control indicatorsForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksStructural engineeringMechanical engineering

The invention discloses a fabricated mold plate supporting device of a shaped concrete tunnel body. The fabricated mold plate supporting device comprises a plurality of lattice columns, one or more layers of plane truss beams are arranged on a square columnar support composed of all lattice columns in the height direction, and the plane truss beams include a plurality of transverse truss beams fixedly connected between two adjacent lattice columns and a plurality of longitudinal truss beams connected between two adjacent and parallel transverse truss beams; tension chord truss beams are fixedly installed between the lattice columns at the edge of the top end of the columnar support, the plane truss beams are installed at the top ends of the lattice columns located in the space enclosed byall tension chord truss beams, and the plane truss beams at the top ends of the lattice columns and the tension chord truss beams are fixedly connected through the transverse truss beams and the longitudinal truss beams; and a plurality of supporting mechanisms for supporting the side faces of mold plates are arranged on the two lines of the lattice columns which are parallel to the longitudinal truss beams and located at the outermost layer in the height direction.

Owner:SOUTHWEAT UNIV OF SCI & TECH

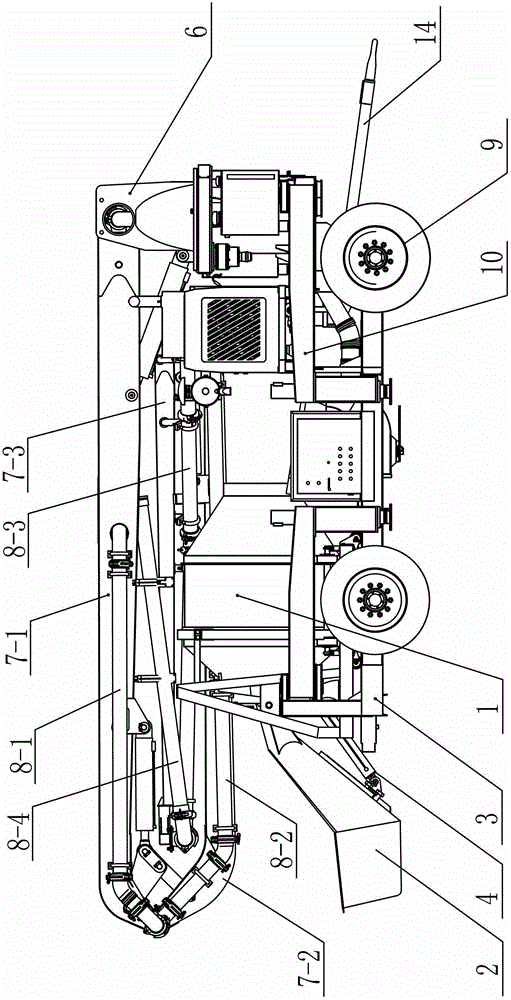

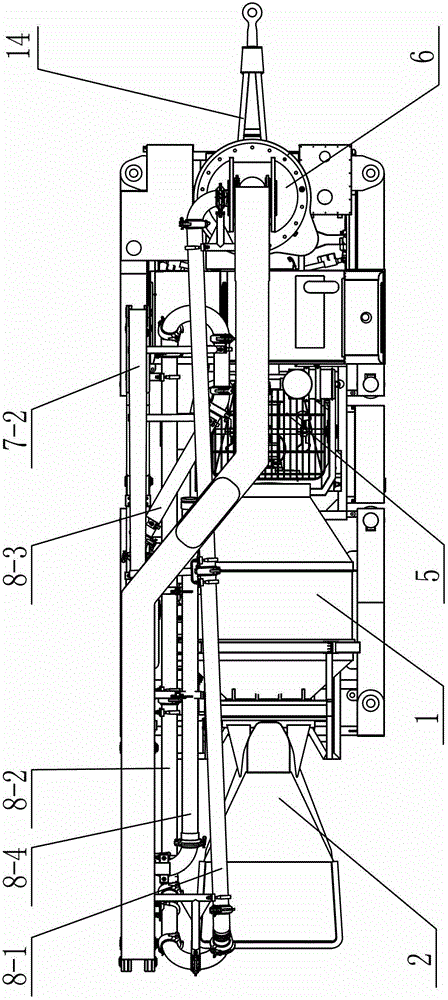

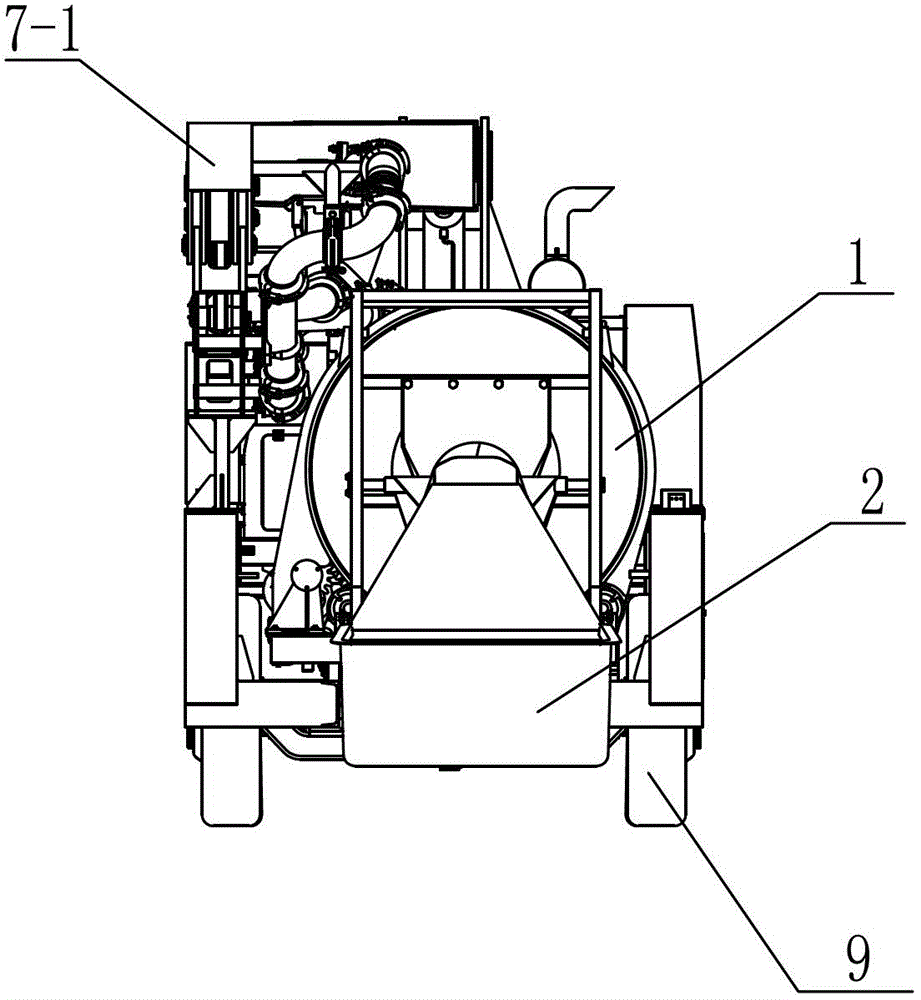

Concrete mixer truck

The invention provides a concrete mixing distributing vehicle capable of fabricating concrete on site and carrying out distribution in to-be-poured positions. The concrete mixing distributing vehicle comprises a frame assembly, a stirring assembly and a distributing assembly, wherein the stirring assembly and the distributing assembly are arranged on the frame assembly; the stirring assembly comprises a stirring barrel and a feed hopper; the feed hopper is hinged with a frame; the feed hopper is provided with a hydraulic lifting mechanism capable of driving the feed hopper to rotate and enabling the end part of the feed hopper to extend into the stirring barrel in a limiting position; and a pumping hopper with grids and a pumping mechanism for conveying the concrete in the pumping hopper to the distributing assembly are arranged between the stirring assembly and the distributing assembly. The concrete mixing distributing vehicle provided by the invention has the advantageous effects of realizing operations of stirring, pumping and distributing the concrete through a set of device, saving time and labor, and largely reducing equipment cost and labor cost; and a feeding mechanism capable of being flexibly lifted is arranged in the position in which the inlet of the stirring barrel is positioned, so that the requirements of fabricating the concrete on site are met.

Owner:ZHEJIANG TRUEMAX ENG

A special coil box for an ignition transformer

InactiveCN109103829AFully fixedSimple structureTransformers/inductances coils/windings/connectionsTransformerEngineering

The invention discloses a special coil box for an ignition transformer, which includes a coil box, an ignition transformer is arranged at the bottom of the coil box, a positioning plate is arranged onboth side of the coil box, a fastening belt is installed on the outside of the positioning plate, the fastening belt is made of elastic rubber tape, a positioning edge is installed on the bottom of the coil box, a detection cover is installed on the surface of the coil box, a winding column is installed inside the coil box, and an input end clasp and an output end clasp are installed inside the coil box. The coil box can be fully fixed on the ignition transformer by the cooperation of the positioning edge protector and the fastening belt, the transparent detection cover enables people to visually observe the condition of the signal cable, and can be opened and closed conveniently with the snap fastener, so that the signal cable is convenient to arrange and the simple quality inspection operation is carried out, the coil box is simple in structure but complete in function, can effectively protect the circuit, and the cost is relatively low, the process is simple and convenient to produce, and has the popularization value.

Owner:SUZHOU HUANYAN ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com