Core box

A core box and top core technology, used in casting and molding equipment, metal processing equipment, molding machines, etc., can solve the problems of too many sand particles and trouble, and achieve the effect of reducing the cost of sand cores, saving consumption, and facilitating manual removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

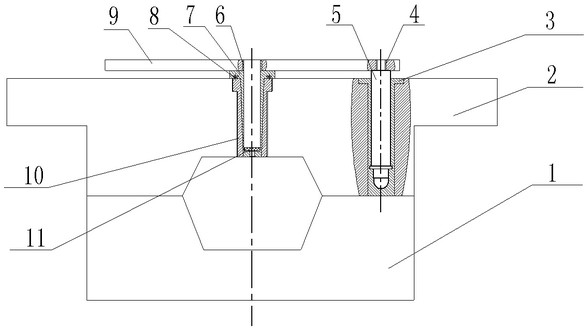

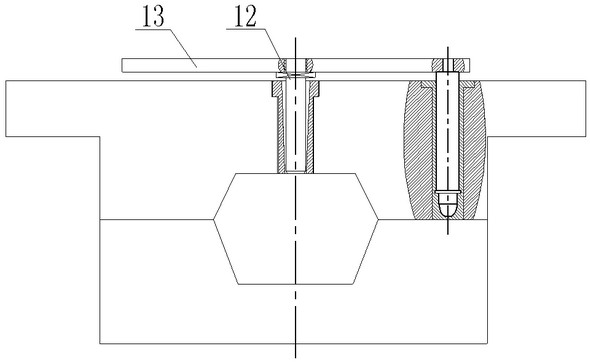

[0026] figure 1 , figure 2 Among them, the present invention includes a lower core box 1, an upper core box 2, a sand shooting device, and a core ejector device; the upper core box 2 is provided with an upper cavity, the lower core box 1 is provided with a lower cavity, and the upper core box 2. After closing the mold with the lower core box 1, the upper cavity and the lower cavity form the molding cavity of the sand core.

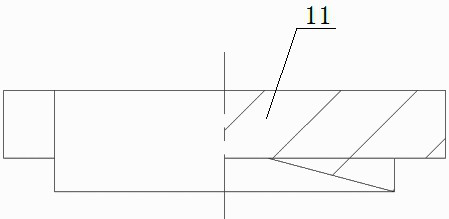

[0027] The sand-shooting device comprises a sand-shooting plate 9, a sand-shooting mouth 7 and a positioning pin one mounted on the bottom of the sand-shooting plate 9, and the inside of the sand-shooting mouth 7 is a stepped hole 14, including a large stepped hole at the upper end, a small hole connected to the lower end of the large stepped hole. Step hole, a sand retaining block 11 is housed in the large step hole, the sand retaining block 11 is a stepped cylinder with a large upper part and a smaller lower part, the diameter of the small step cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com