Concrete mixer truck

A technology for concrete and distributing trucks, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of no concrete feeding mechanism and filter device, unable to meet the needs of various working conditions, and limited applicable occasions. , to facilitate manual removal, reduce equipment and labor costs, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below in conjunction with accompanying drawing:

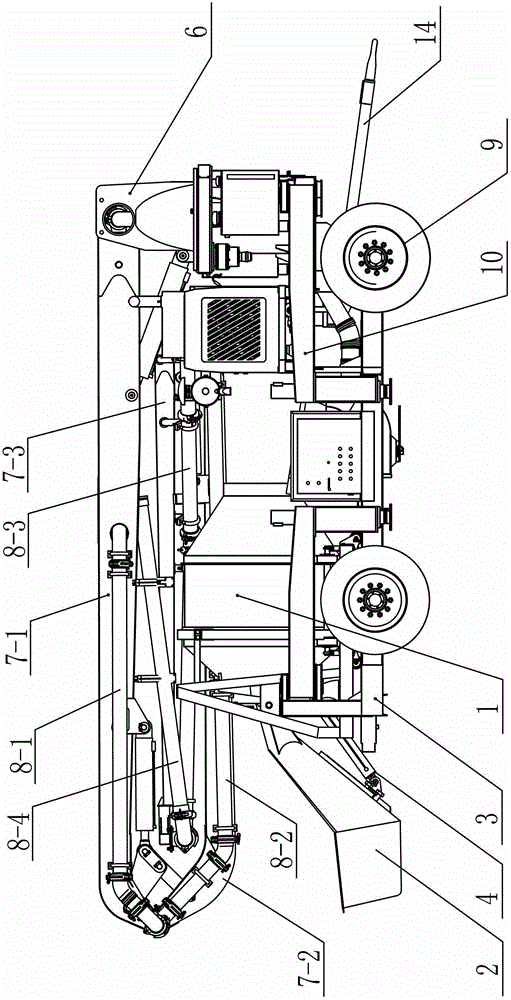

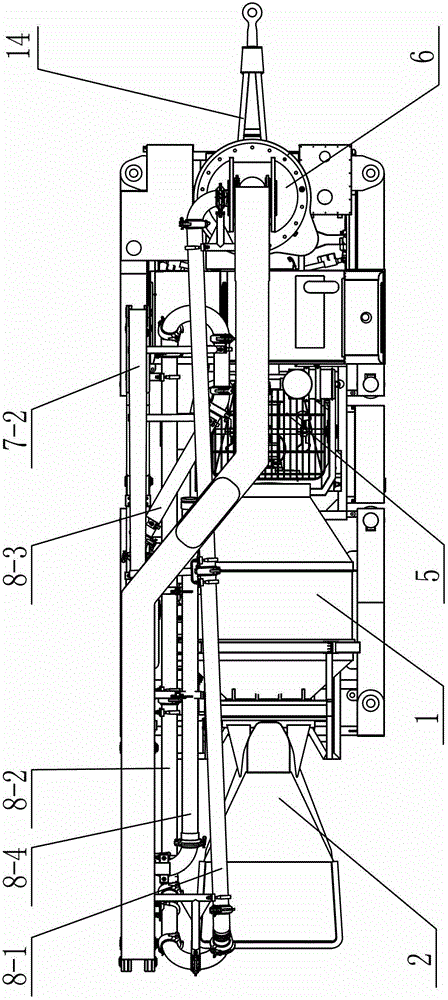

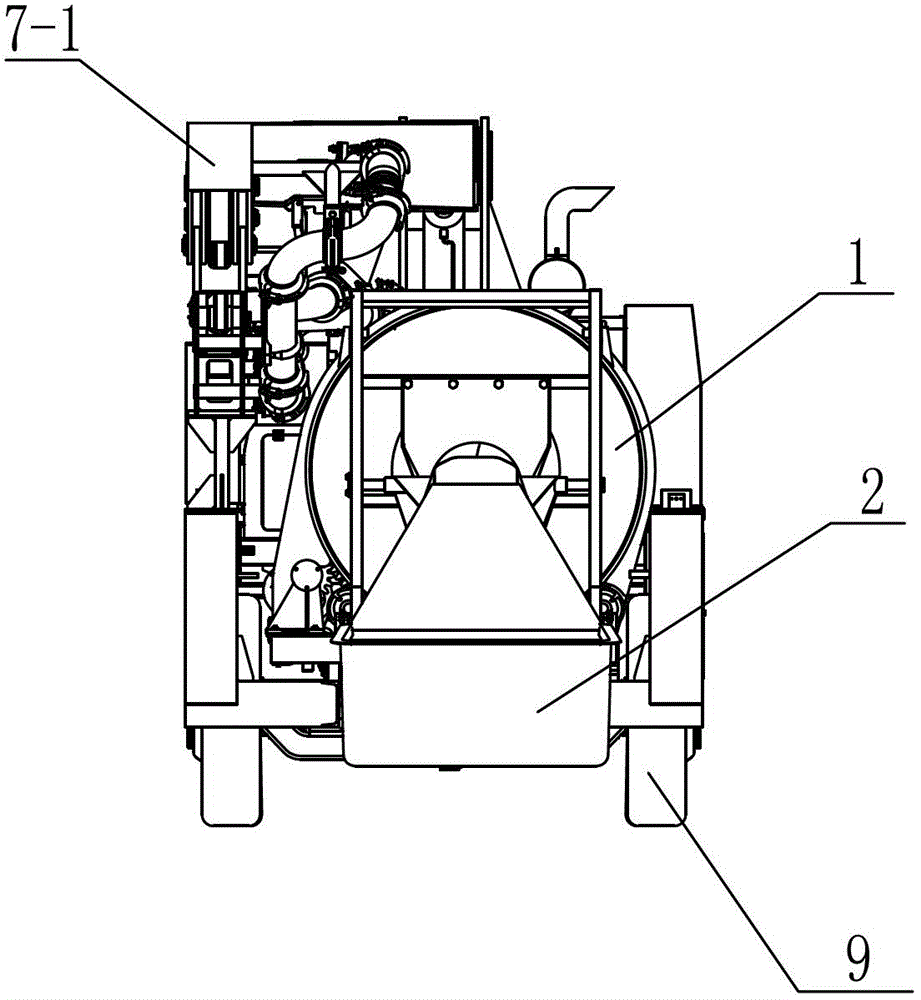

[0022] refer to Figure 1 to Figure 4 , a concrete mixing and distributing vehicle, including a frame assembly, a mixing assembly and a distributing assembly installed on the frame assembly; the mixing assembly includes a mixing bucket 1 and a feeding hopper 2, and the feeding hopper 2 is hinged to the frame 3 The feed hopper 2 is provided with a hydraulic jacking mechanism 4 that can drive the feed hopper to rotate and make the end of the feed hopper extend into the mixing barrel at the limit position. A pumping hopper 5 and a pumping mechanism for delivering the concrete in the pumping hopper 5 to the distribution assembly.

[0023] The fabric distribution assembly includes a support seat 6, an arm frame 7 and a concrete delivery pipeline. The arm frame 7 can rotate at a full angle of 360° relative to the support seat. The arm frame 7 includes a large arm 7-1, a mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com