Patents

Literature

65results about How to "Tight action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

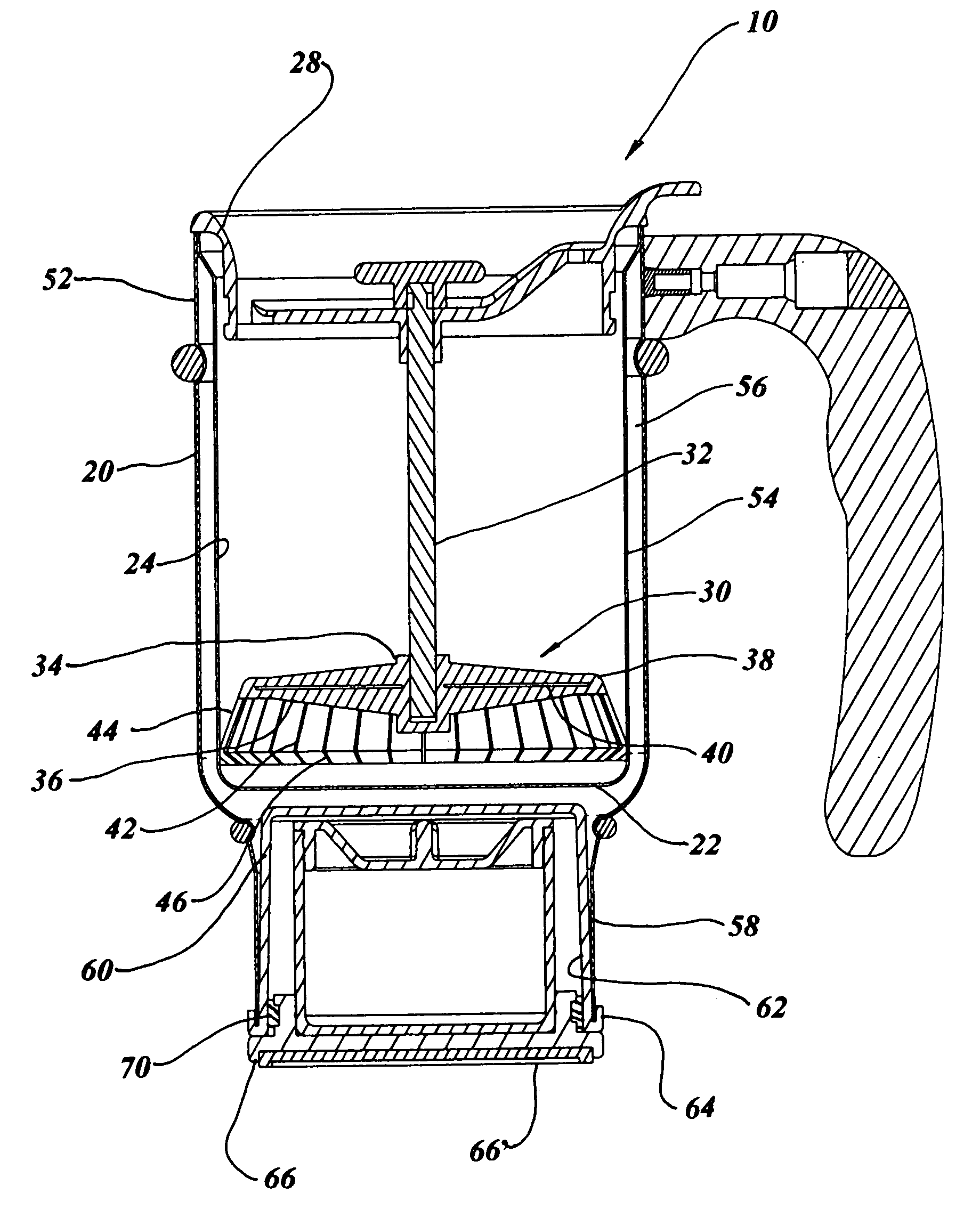

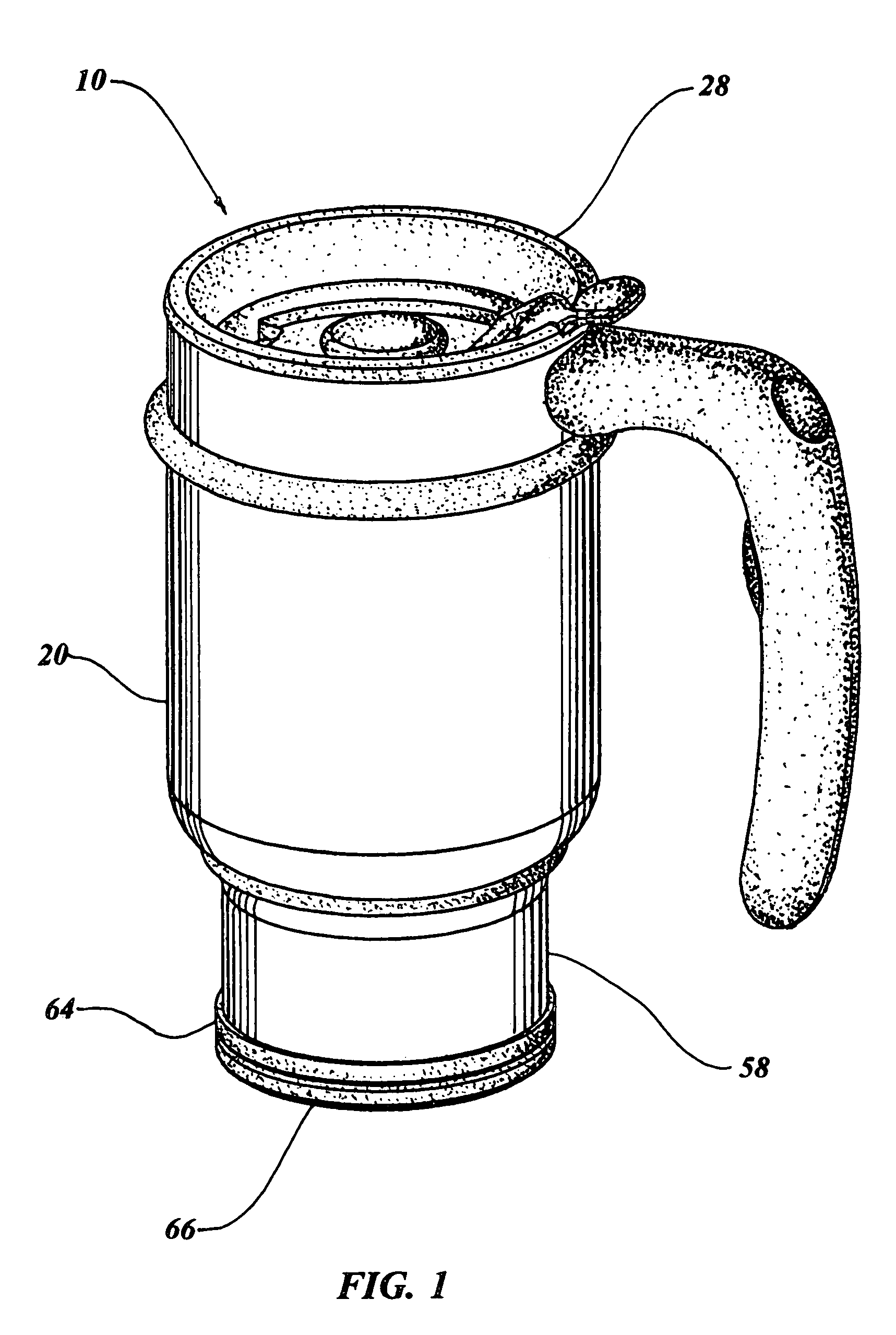

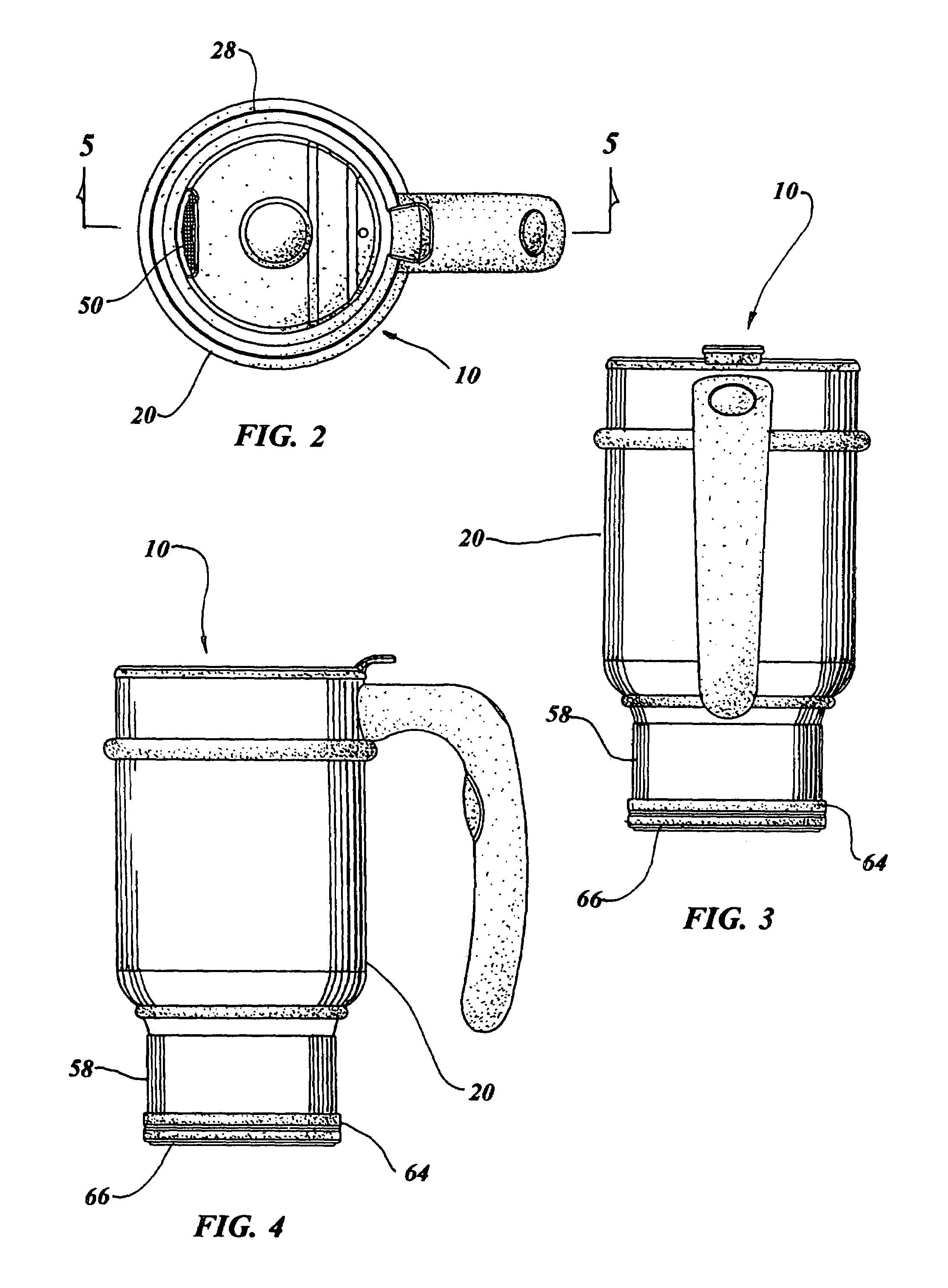

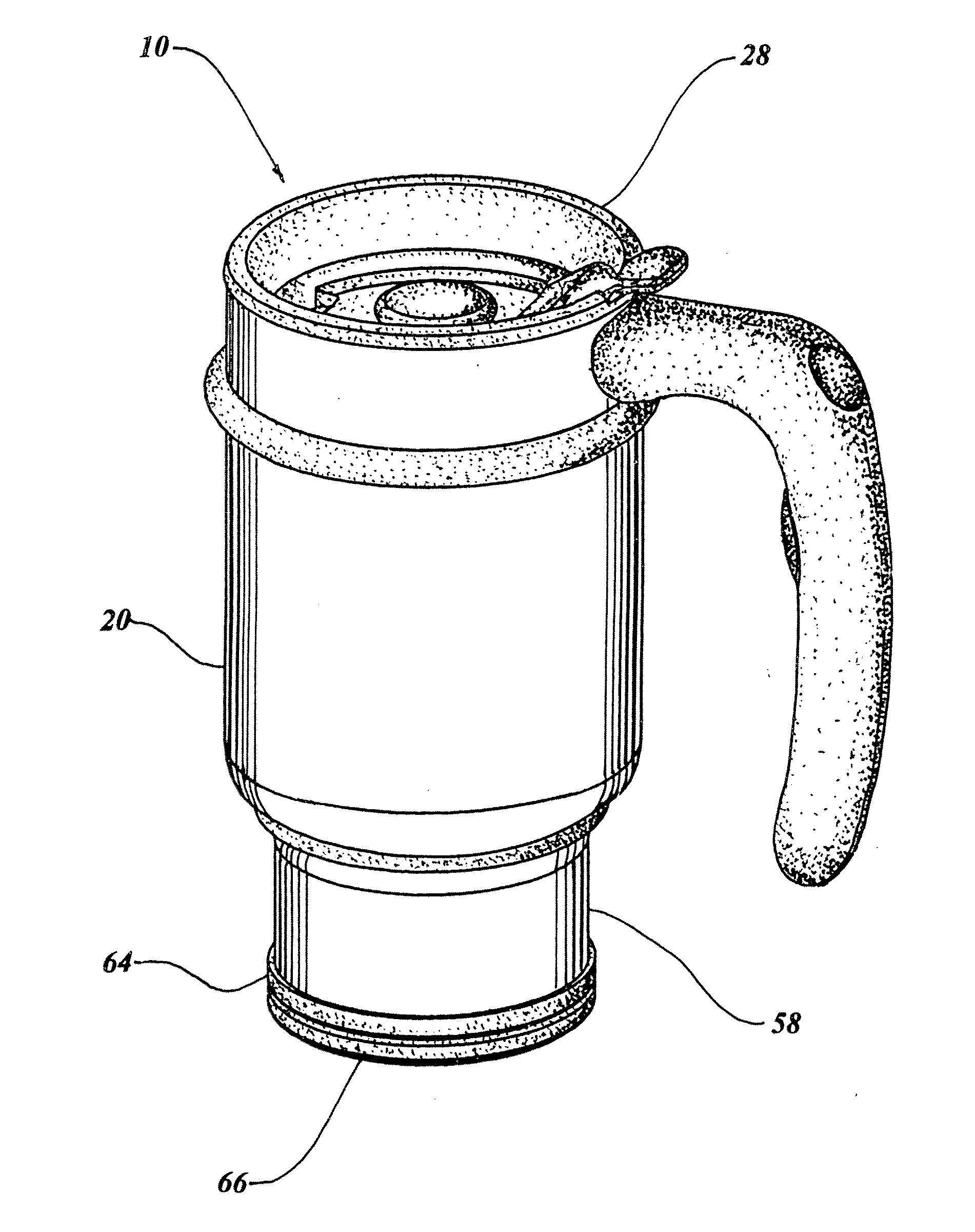

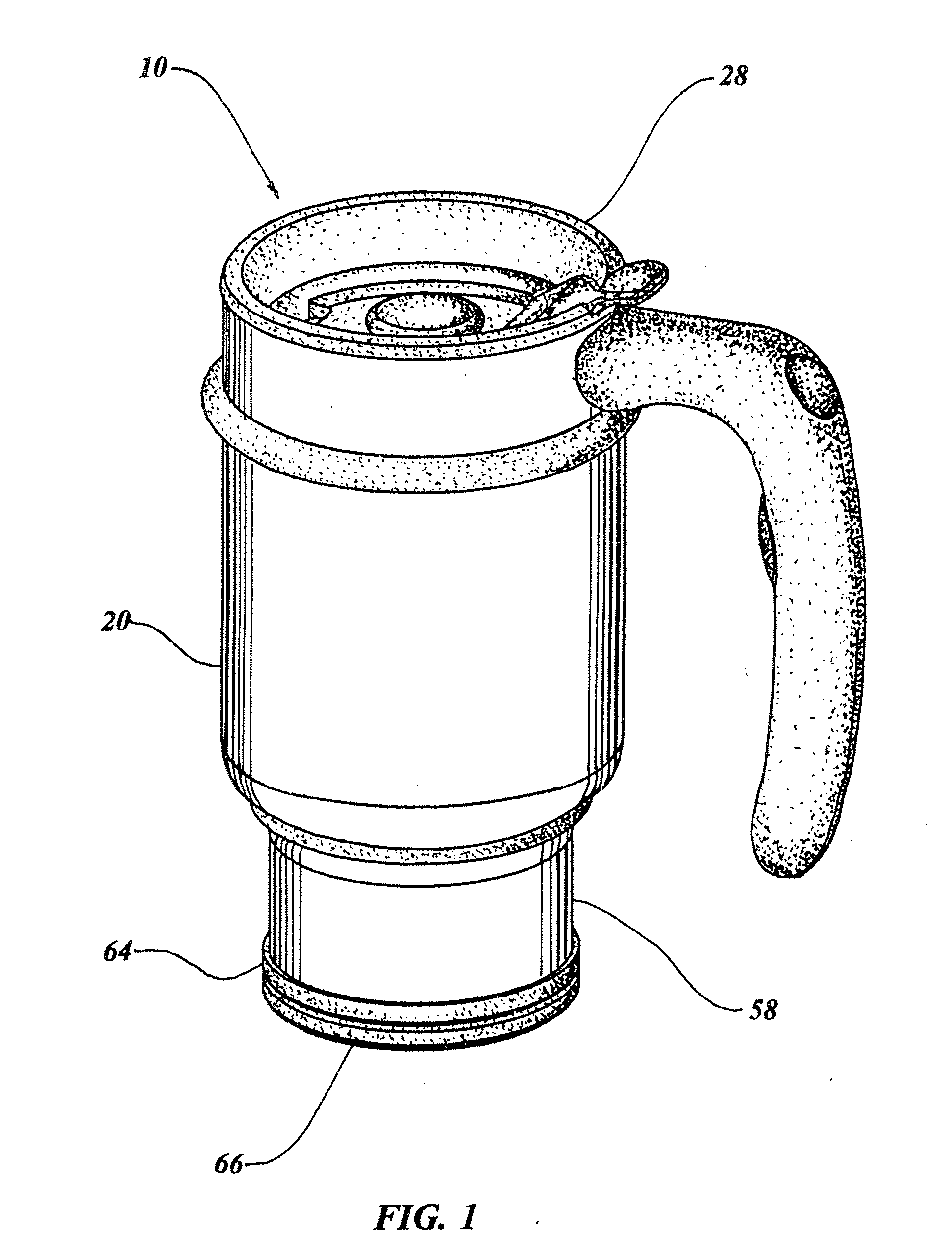

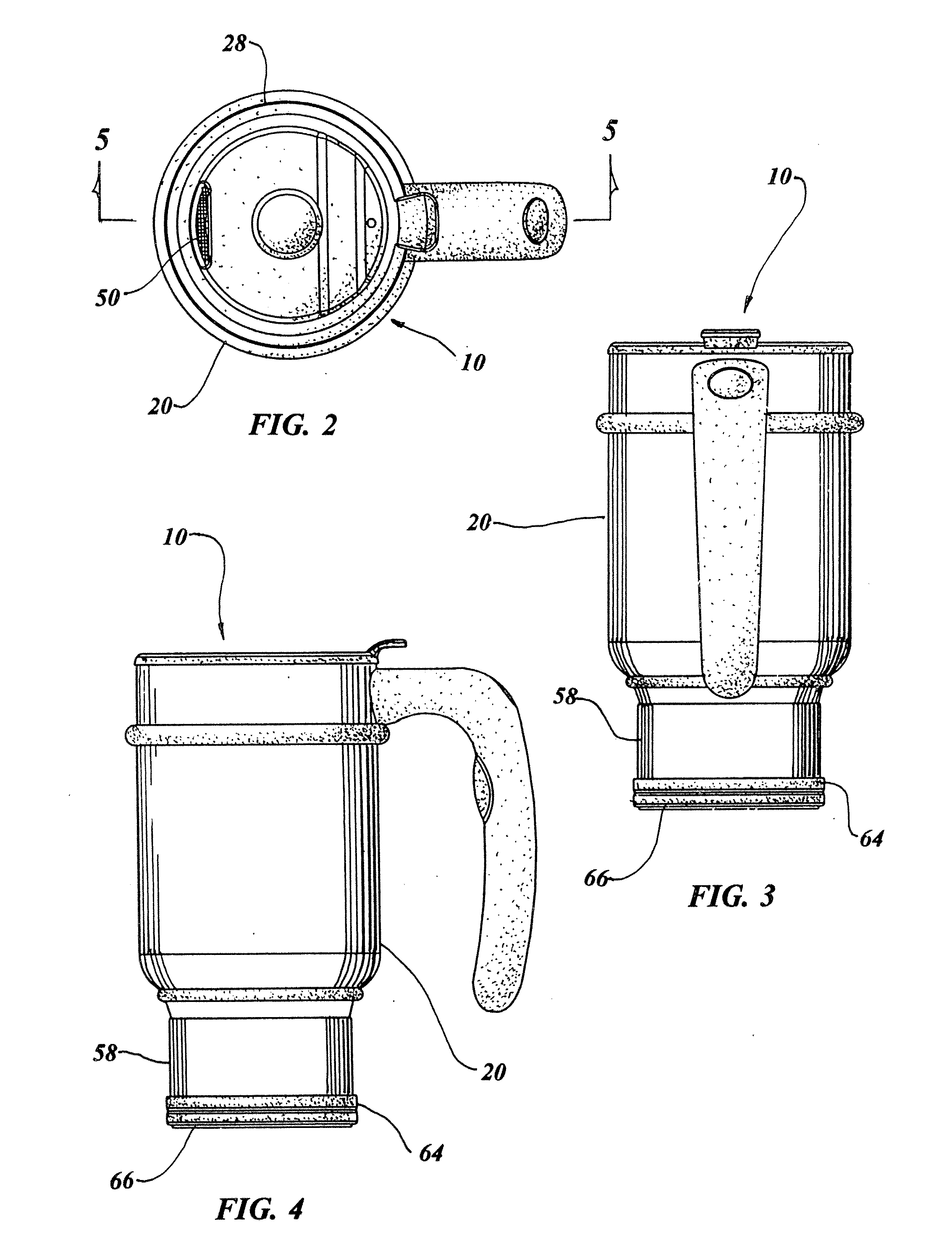

Beverage press mug with storage container

InactiveUS7194951B1Tight actionPrevent leakageBeverage vesselsRigid containersSugarMechanical engineering

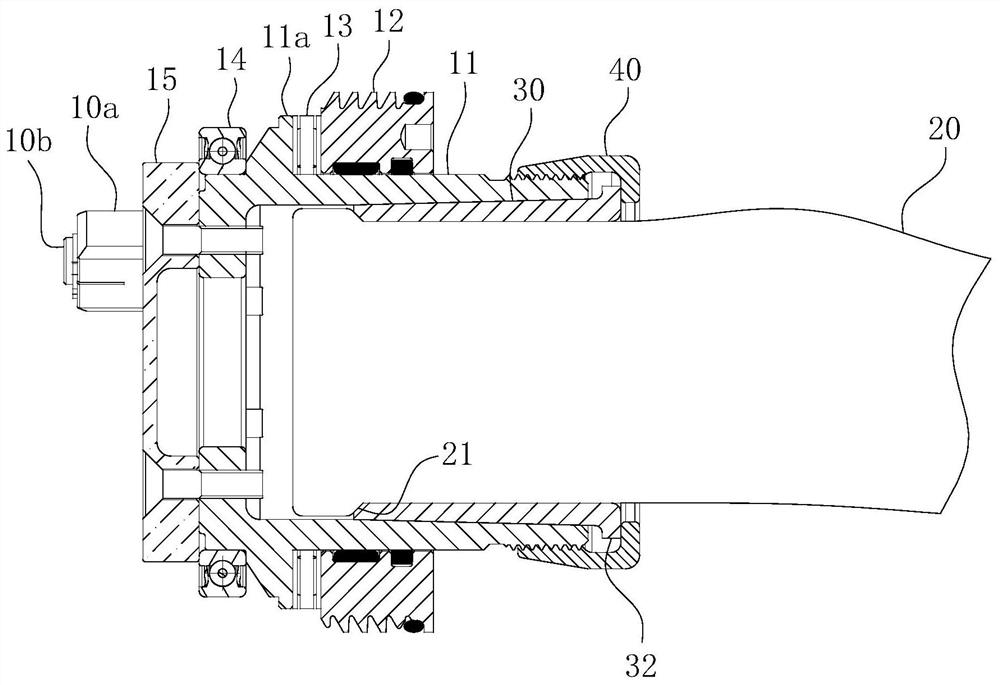

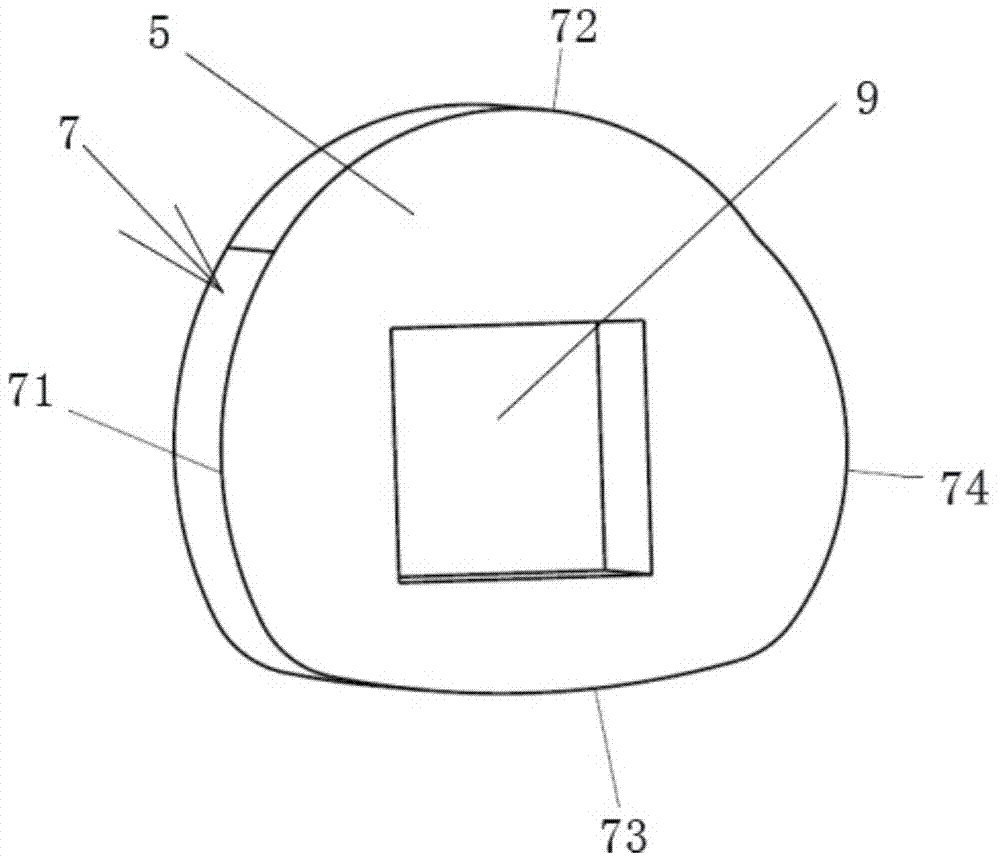

A mug (10), specifically a vessel (20) incorporating a plunger assembly (30), that includes a number of fingers (42), is improved by positioning the fingers downwardly to contact the side wall of the vessel. The improvement also includes the following; a minor diameter portion (58) of the vessel sized to fit a motor vehicle cup holder. An open distal ended liner (62) intimately embracing a storage container compartment (60) formed on an inside surface of the outer shell minor diameter portion of the vessel. A closure base (66) removably engages the liner and encloses the bottom of the vessels storage container compartment. The closure base includes a number of inwardly facing spacer legs (68) that removably retain a storage container (72) including a detachable lid (74). The storage container provides a receptacle for such items as coffee grinds, tea leaves, sugar and creamer etc. such that the items may be conveniently available with the mug.

Owner:RATTLER HLDG LLC

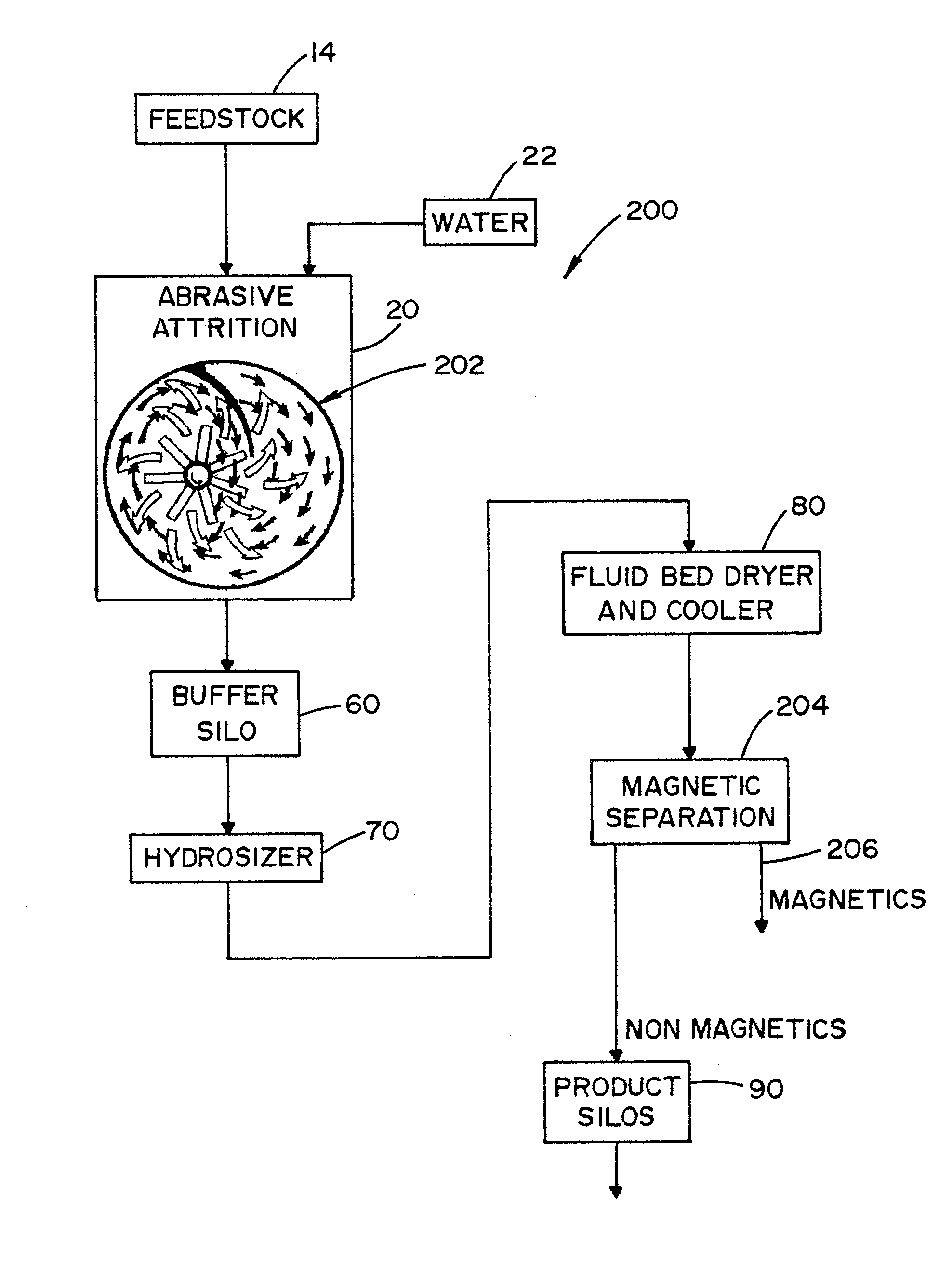

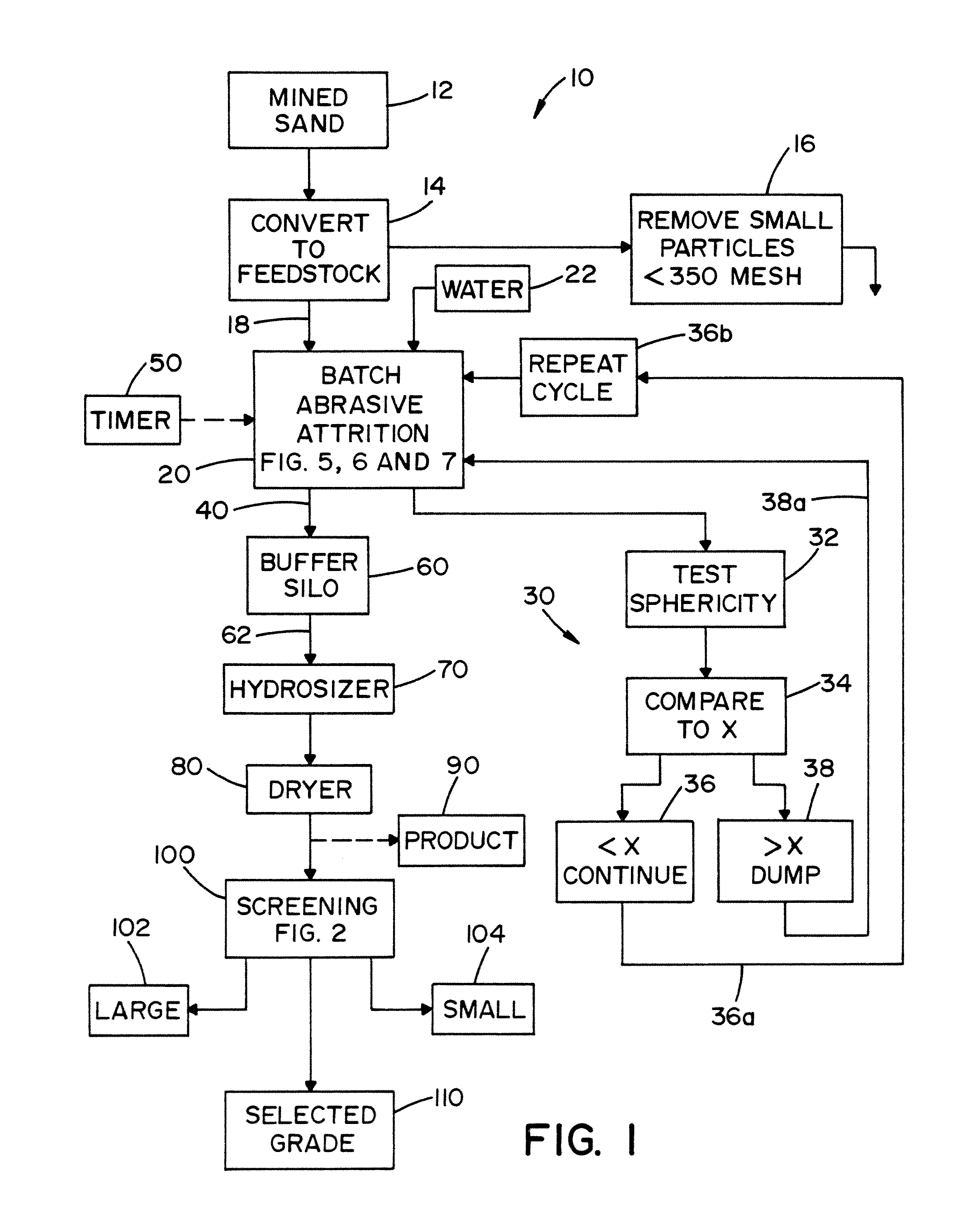

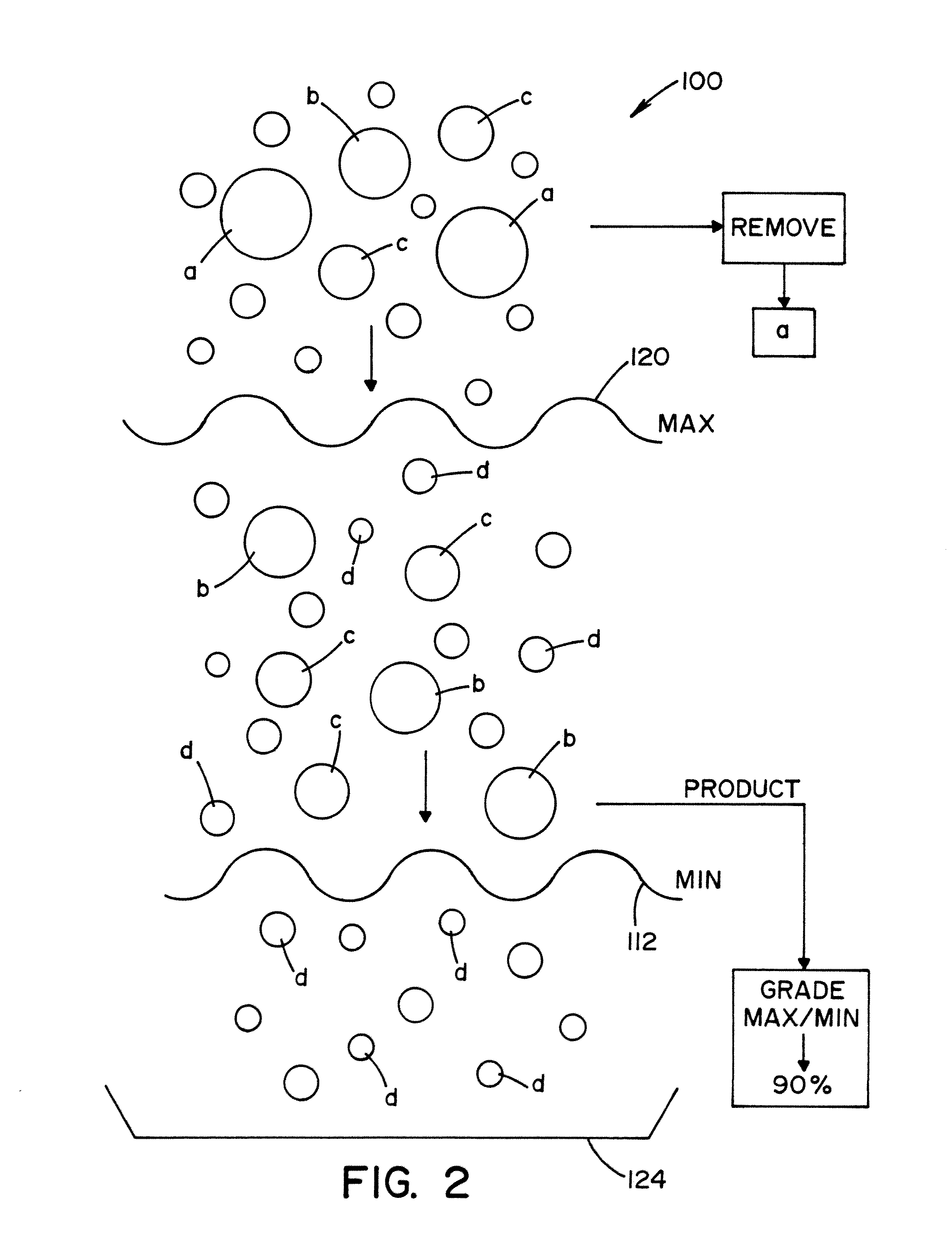

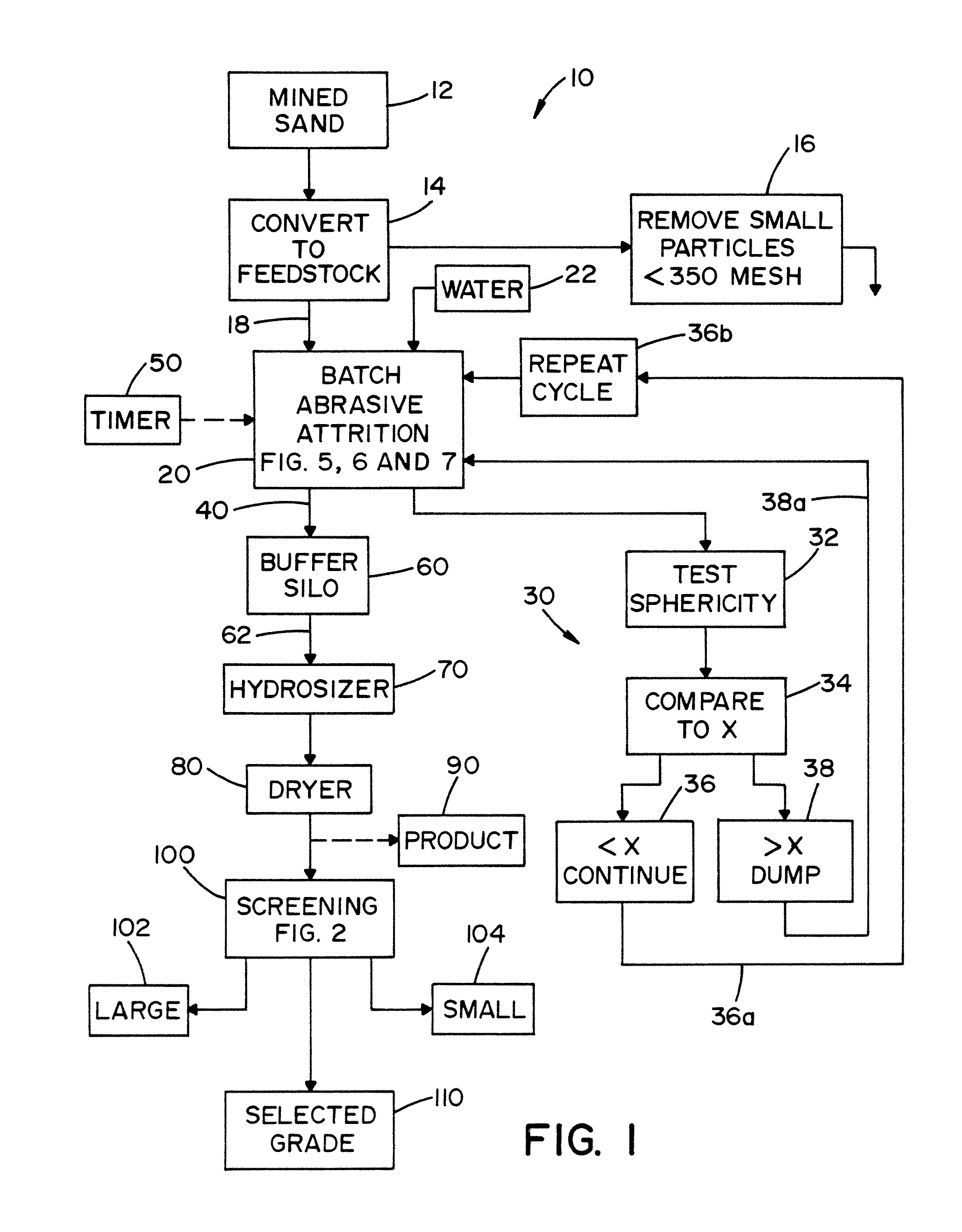

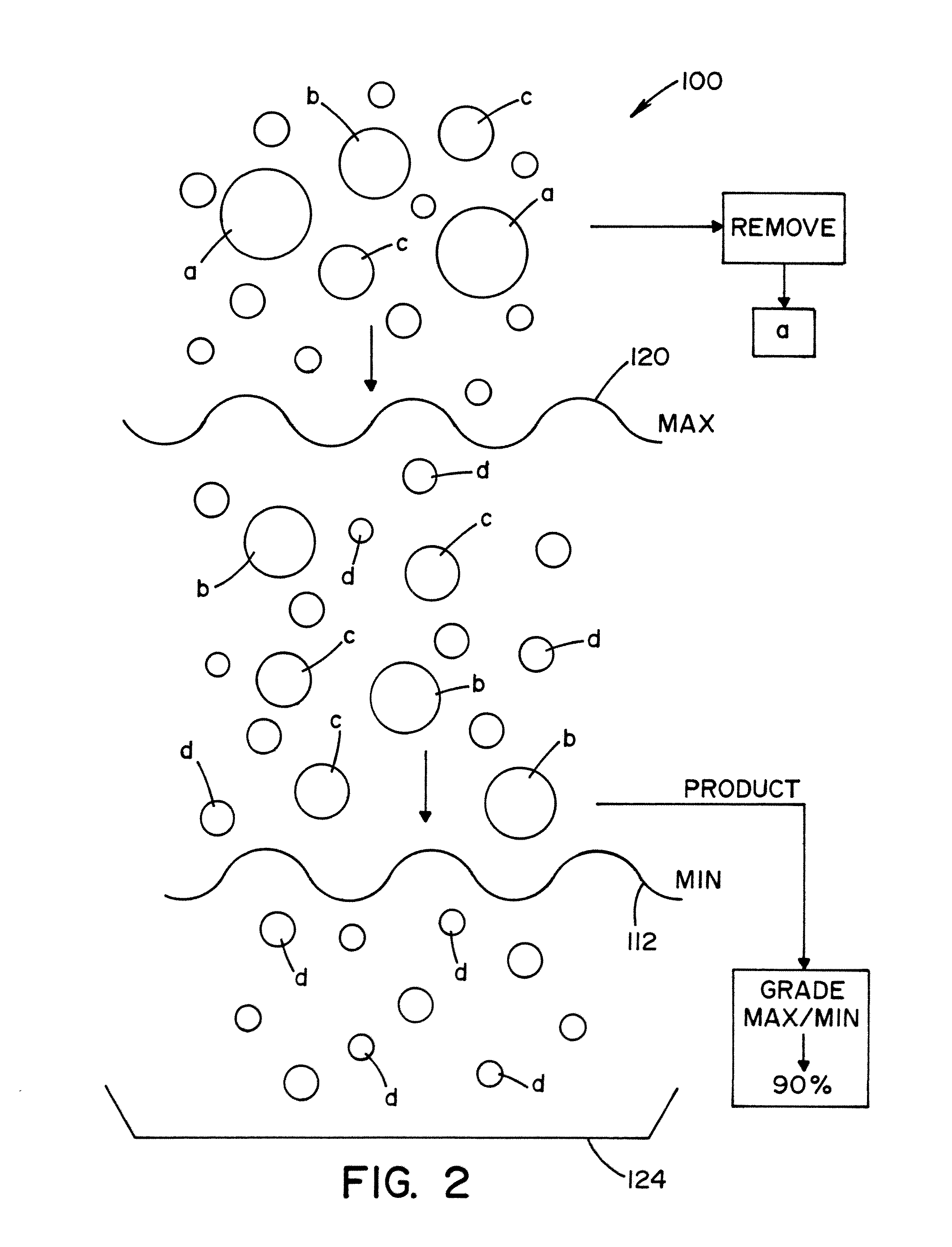

Method of making proppant used in gas or oil extraction

InactiveUS20100197532A1SatisfactoryQuality improvementGas current separationSolid waste disposalHardnessPre treatment

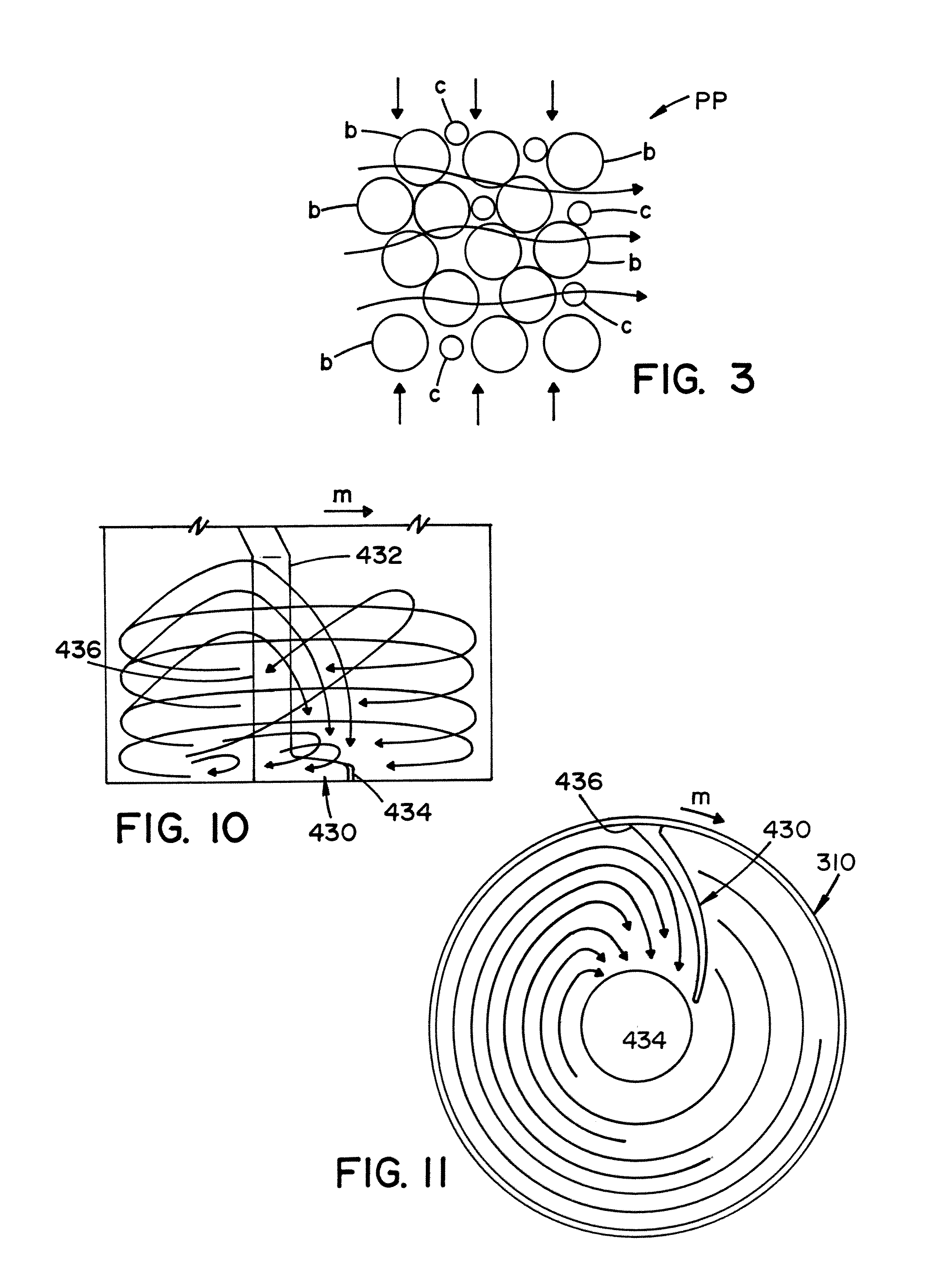

Method and system for making a spherical proppant having a selected grade from a naturally occurring mined mineral having a hardness of over 6.0 Mohs. The method and system involves preprocessing the mineral mechanically into a semi-dry feedstock comprising a mass of particles with initial sphericity values generally less than 0.60; subjecting the semi-dry feedstock to an aggressive abrasive attrition operation for a process time; and, controlling the process time to a value wherein the particles of the feedstock are converted to final processed particles having a sphericity greater than 0.60 by increasing the sphericity of the feedstock particles by at least 0.10. In addition, the processed particles are screened to obtain a proppant having a selected grade.

Owner:COVIA HLDG CORP

Method of making proppant used in gas or oil extraction

InactiveUS8022019B2Improve roundnessGood sphericitySolid waste disposalSolid separationHardnessProduct gas

Owner:COVIA HLDG CORP

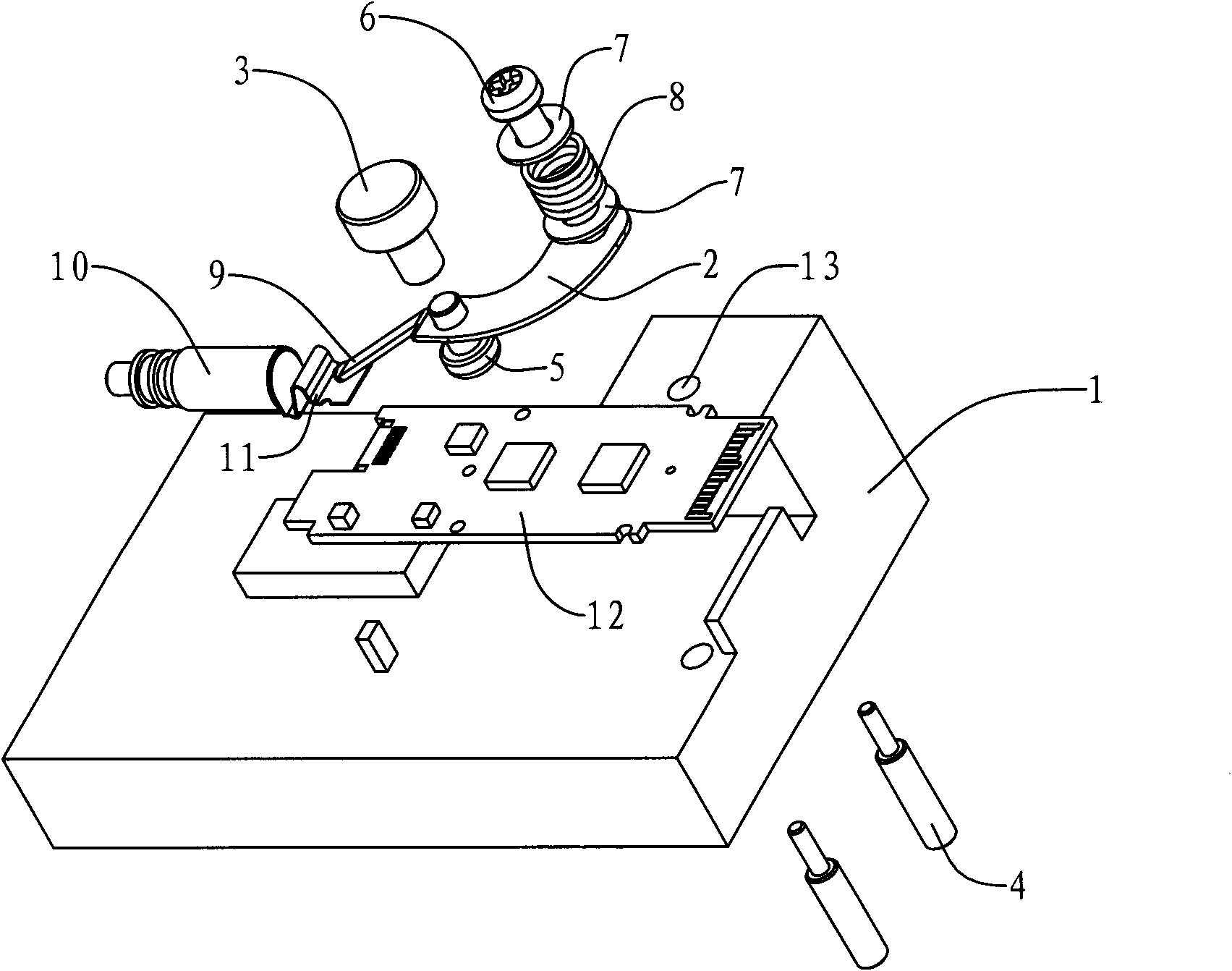

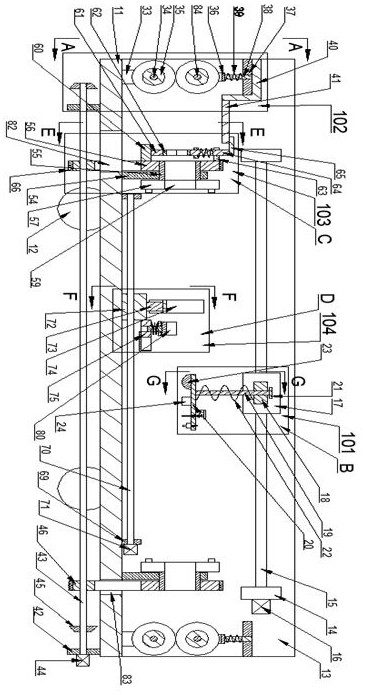

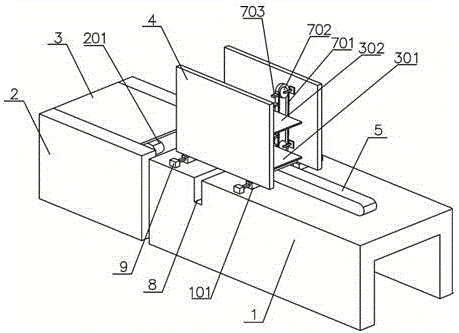

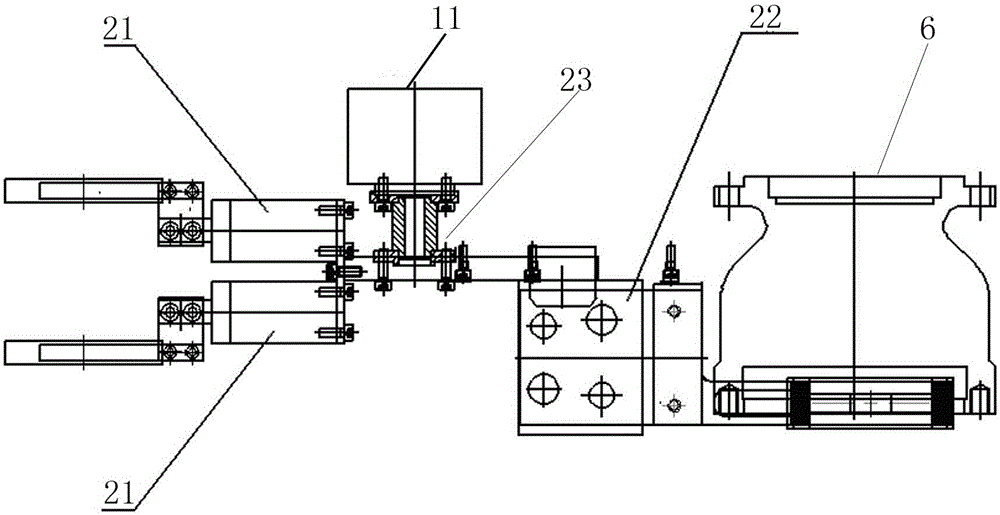

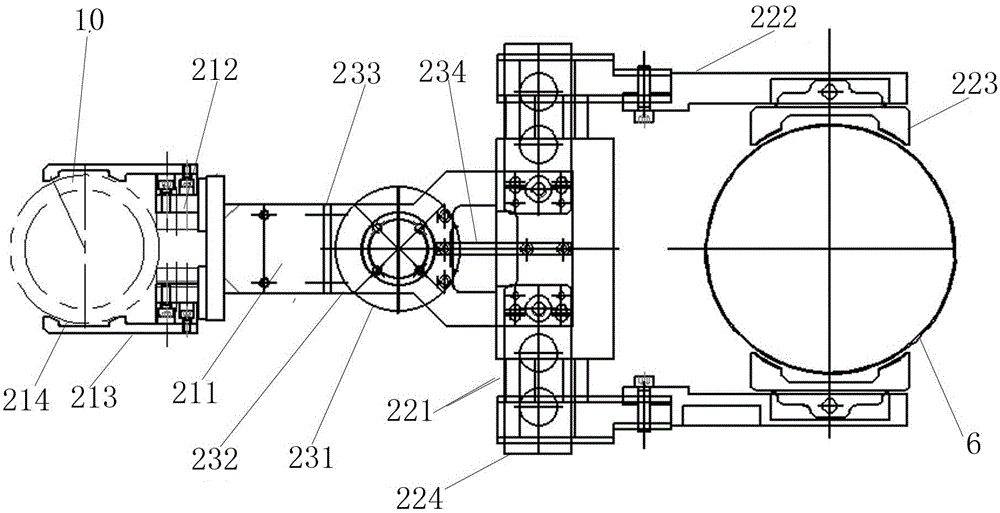

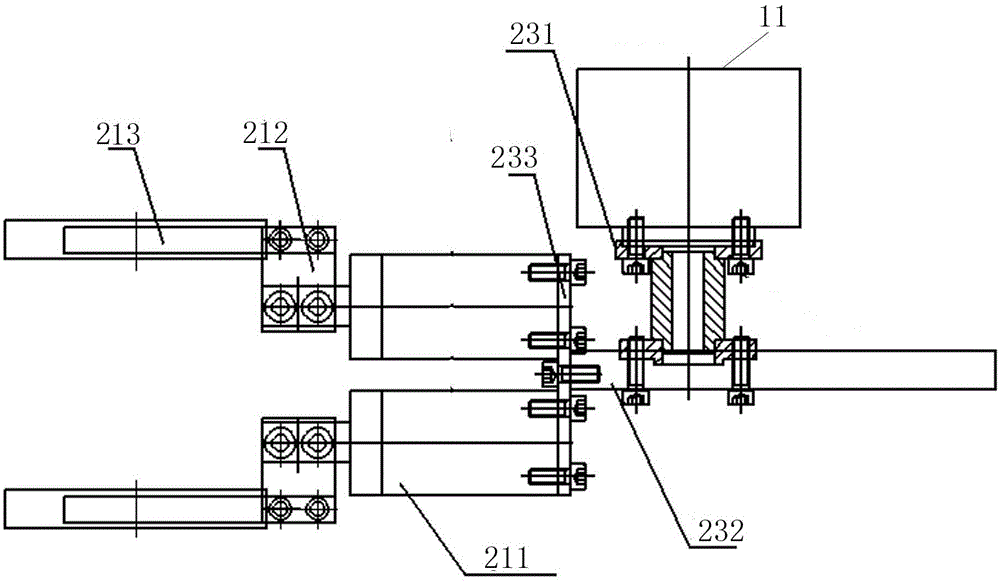

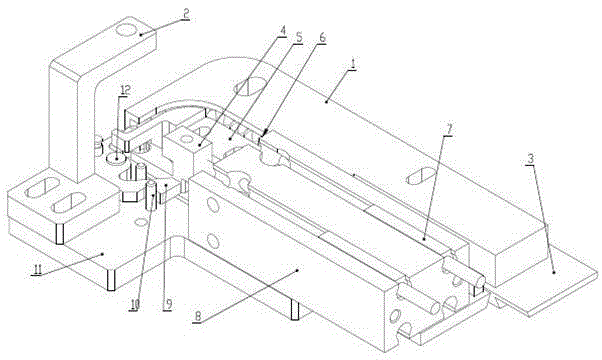

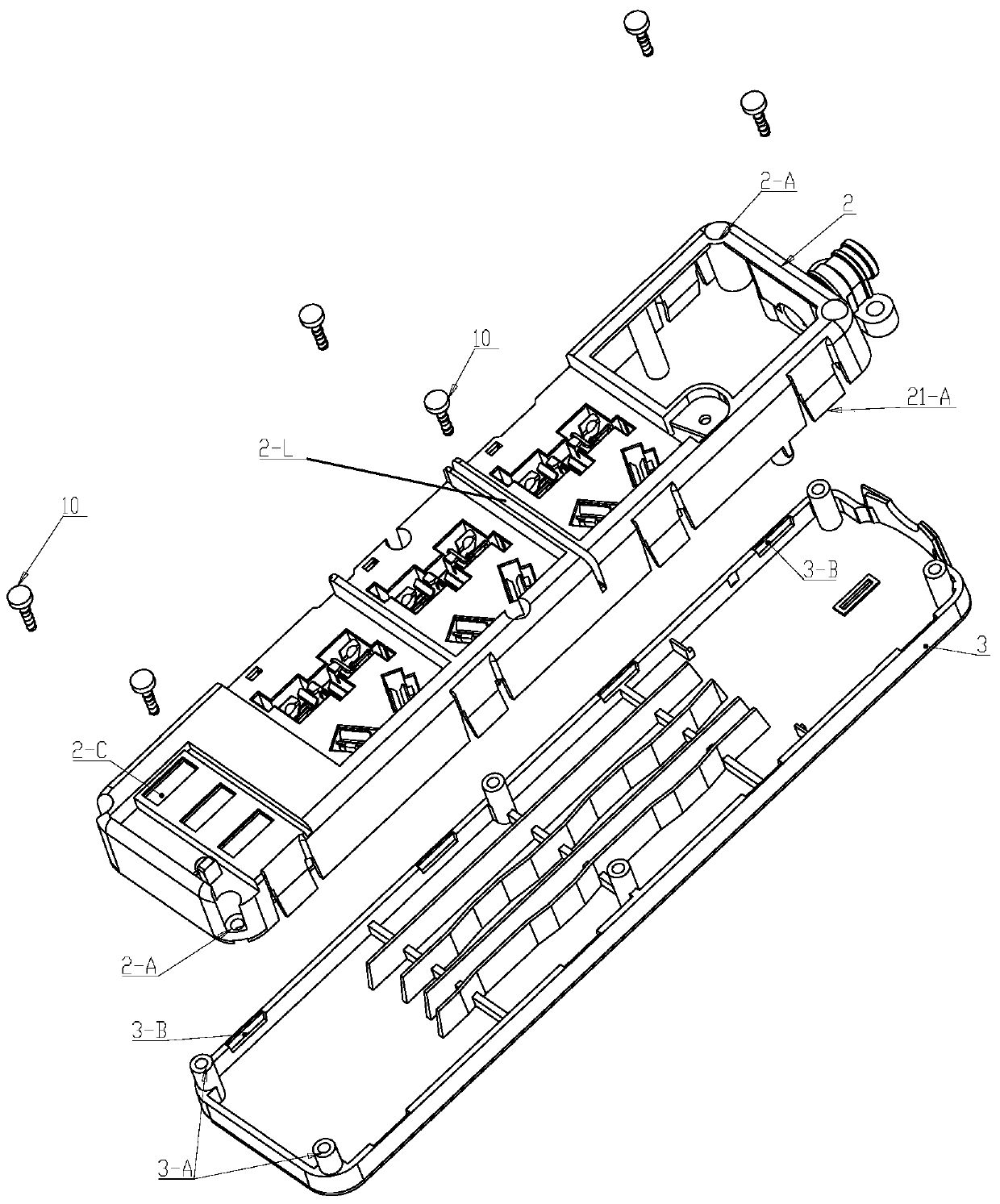

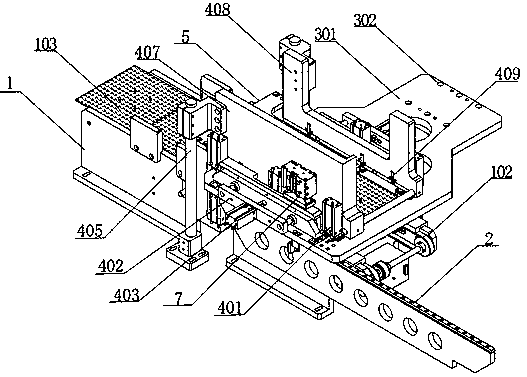

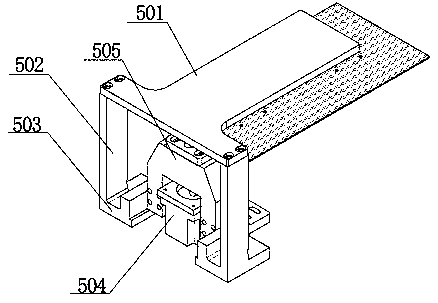

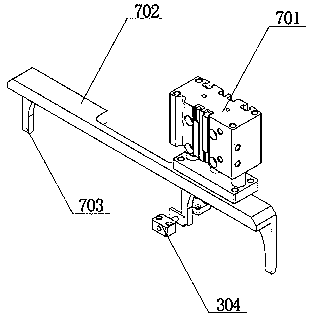

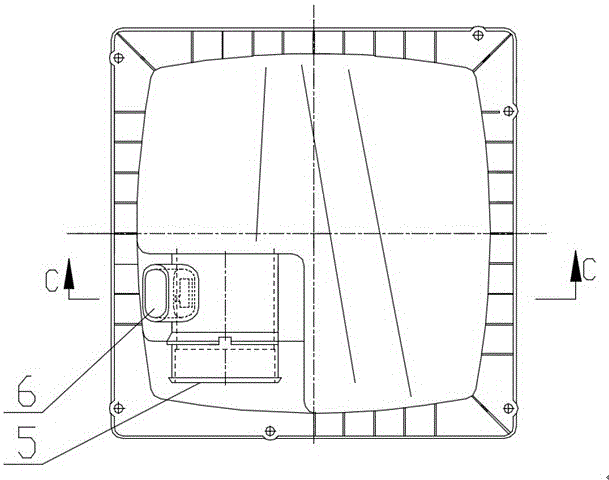

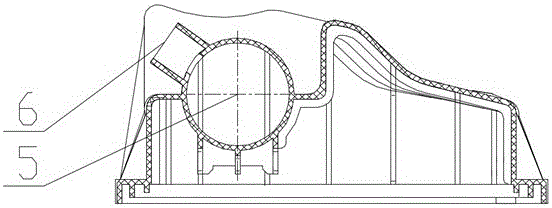

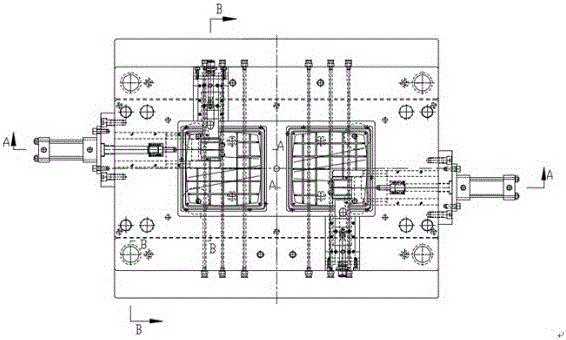

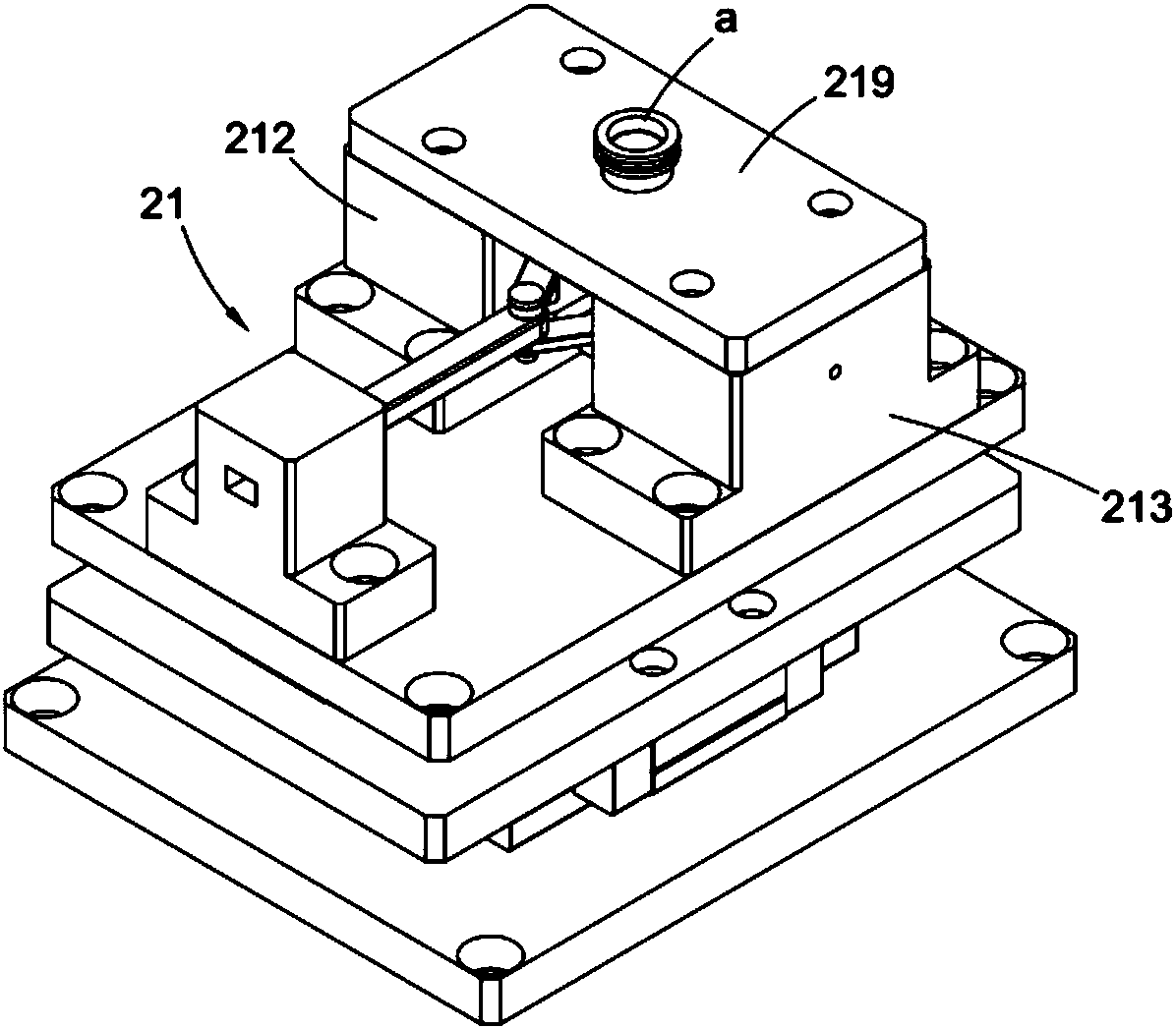

Injection mould for upper housing of car air filter

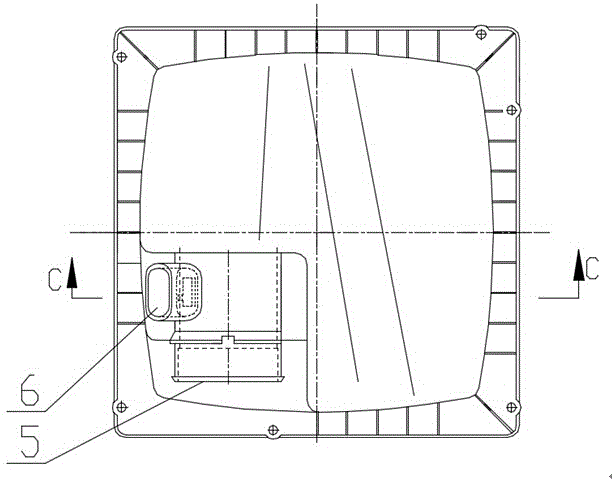

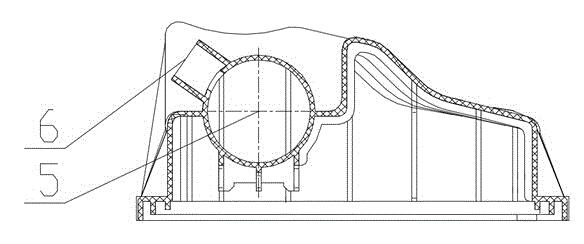

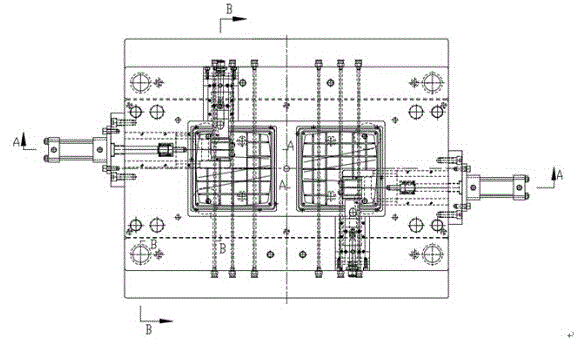

The invention discloses an injection mould for an upper housing of a car air filter. The injection mould comprises a fixed mould assembly (1), a movable mould assembly (2), a lateral loose core device (3) and an oblique loose core device (4), wherein the fixed mould assembly comprises a fixed mould seat plate (11), a fixed mould plate (12) and a cavity (13); the movable mould assembly comprises a movable mould seat plate (21), a movable mould supporting plate (22), a movable mould plate (23), a cavity (24) and a mould pushing device (25); the lateral loose core device comprises a telescopic push-pull mechanism (31), a mounting plate (32) and a lateral loose core (24); the oblique loose core device comprises a wedge-shaped supporting plate (41), a supporting baffle (42), a traction mechanism (43) and an oblique loose core (44). According to the injection mould, mutually staggered plastic parts along the loose cores can be conveniently manufactured and repaired, easily damaged parts can be conveniently replaced, the service life of the mould can be prolonged, the precision of the plastic parts can be guaranteed, and the maintenance expense of the mould can be reduced.

Owner:青岛宇信机电科技有限公司

Beverage press mug with storage container

A mug (10), specifically a vessel (20) incorporating a plunger assembly (30), that includes a number of fingers (42), is improved by positioning the fingers downwardly to contact the side wall of the vessel. The improvement also includes the following; a minor diameter portion (58) of the vessel sized to fit a motor vehicle cup holder. An open distal ended liner (62) intimately embracing a storage container compartment (60) formed on an inside surface of the outer shell minor diameter portion of the vessel. A closure base (66) removably engages the liner and encloses the bottom of the vessels storage container compartment. The closure base includes a number of inwardly facing spacer legs (68) that removably retain a storage container (72) including a detachable lid (74). The storage container provides a receptacle for such items as coffee grinds, tea leaves, sugar and creamer etc. such that the items may be conveniently available with the mug.

Owner:PLANETARY DESIGN

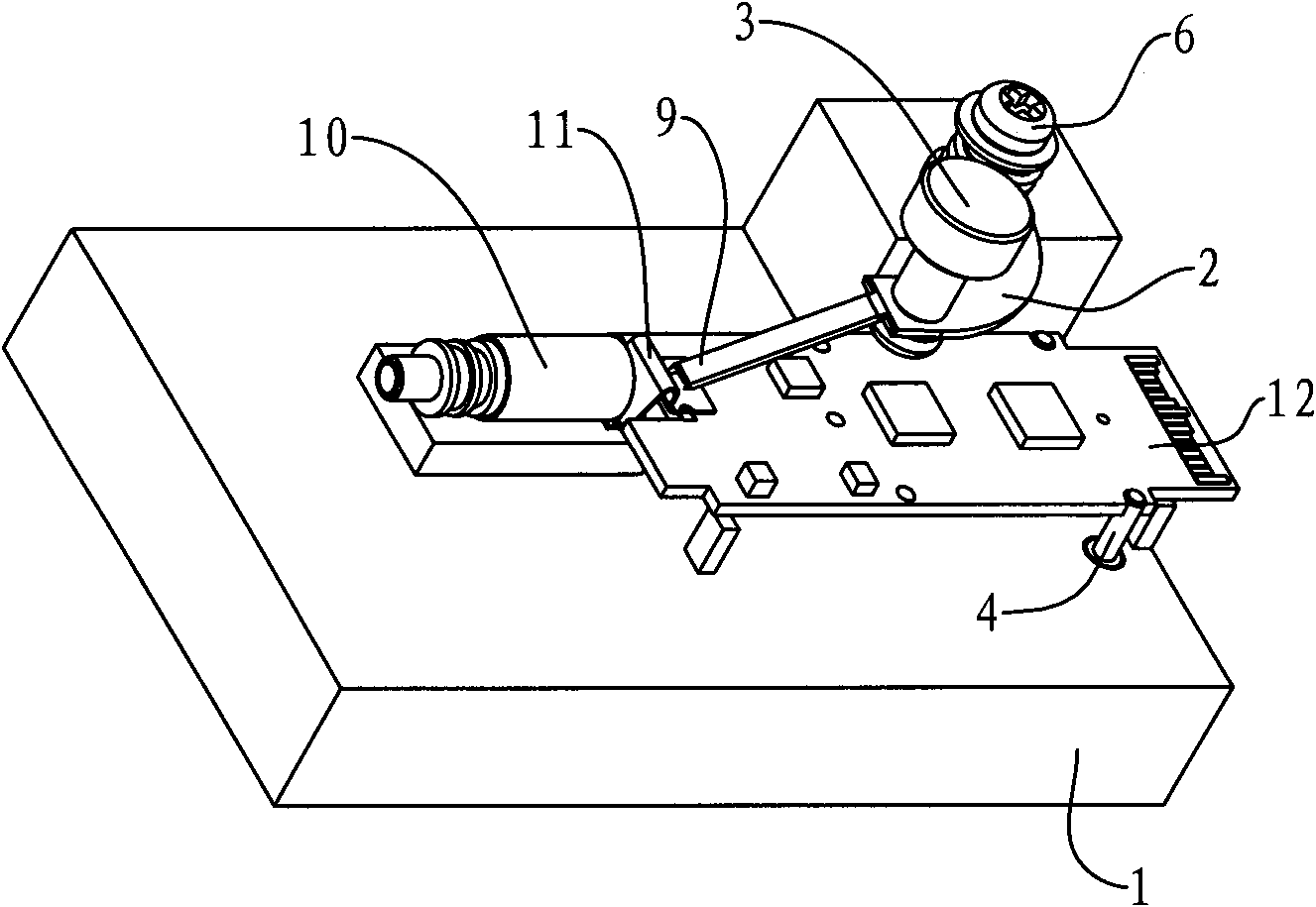

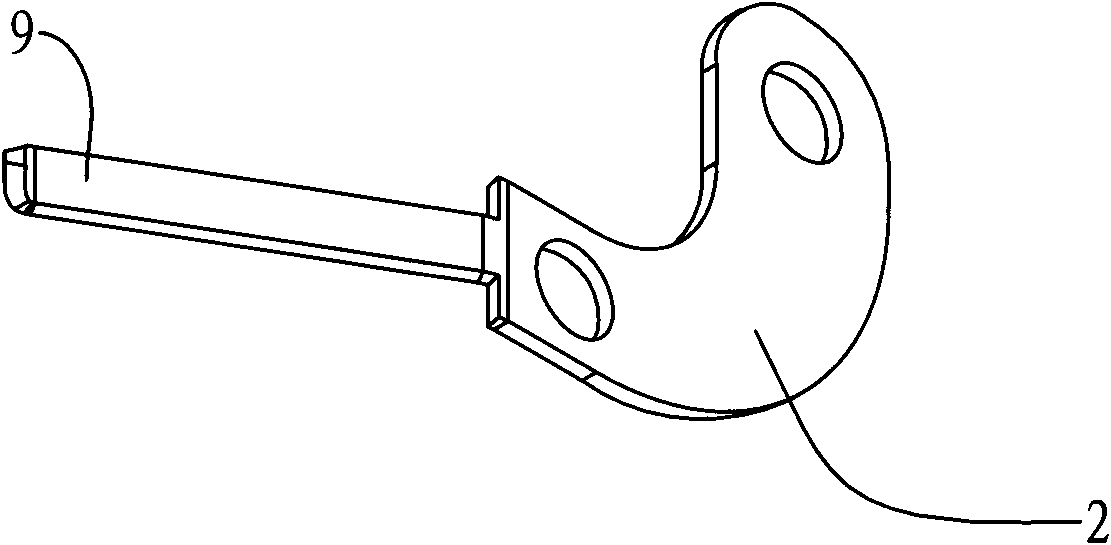

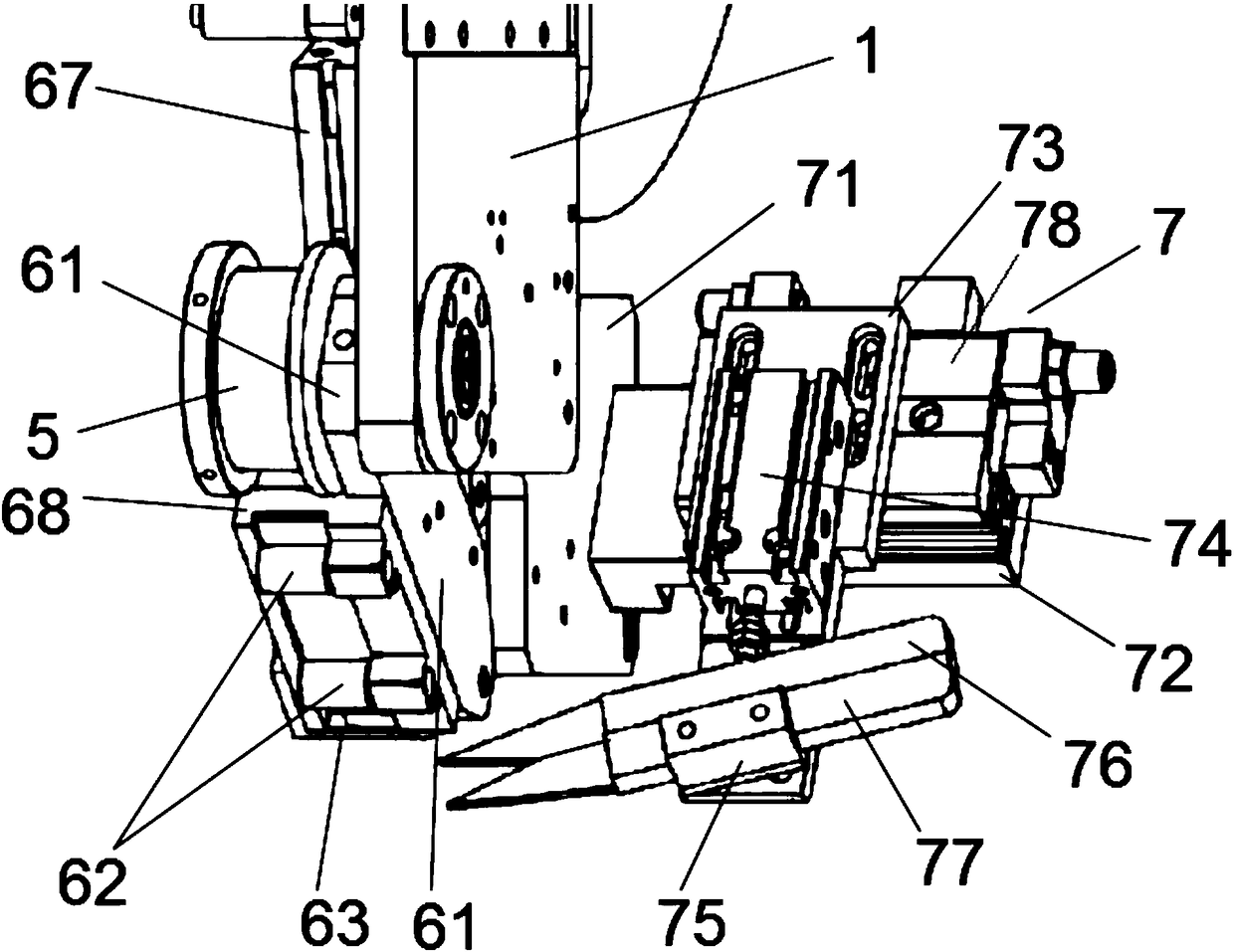

Device soft belt welding fixture

InactiveCN101913007ALight structureReasonable welding processWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention discloses a device soft belt welding fixture which comprises a base and a compression spring leaf, wherein one end of the compression spring leaf is hinged on the base through a screw, and the other end is the free end. The device soft belt welding fixture has lightweight structure, reasonable welding process step, simple and convenient use, compact actions, reliable compression and high production efficiency. The connection between a device and a circuit board completed by adopting the device soft belt welding fixture has accurate positioning, firmness, reliability and high finished product rate.

Owner:WUHAN TELECOMM DEVICES

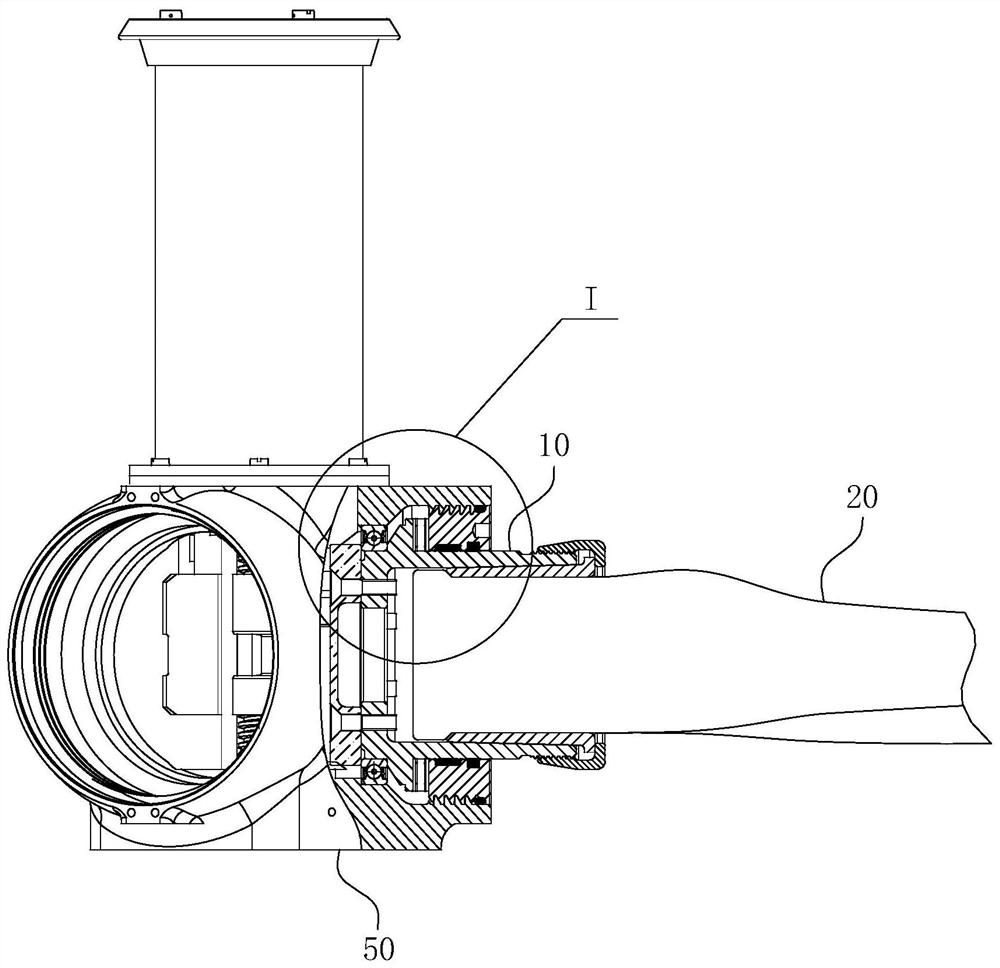

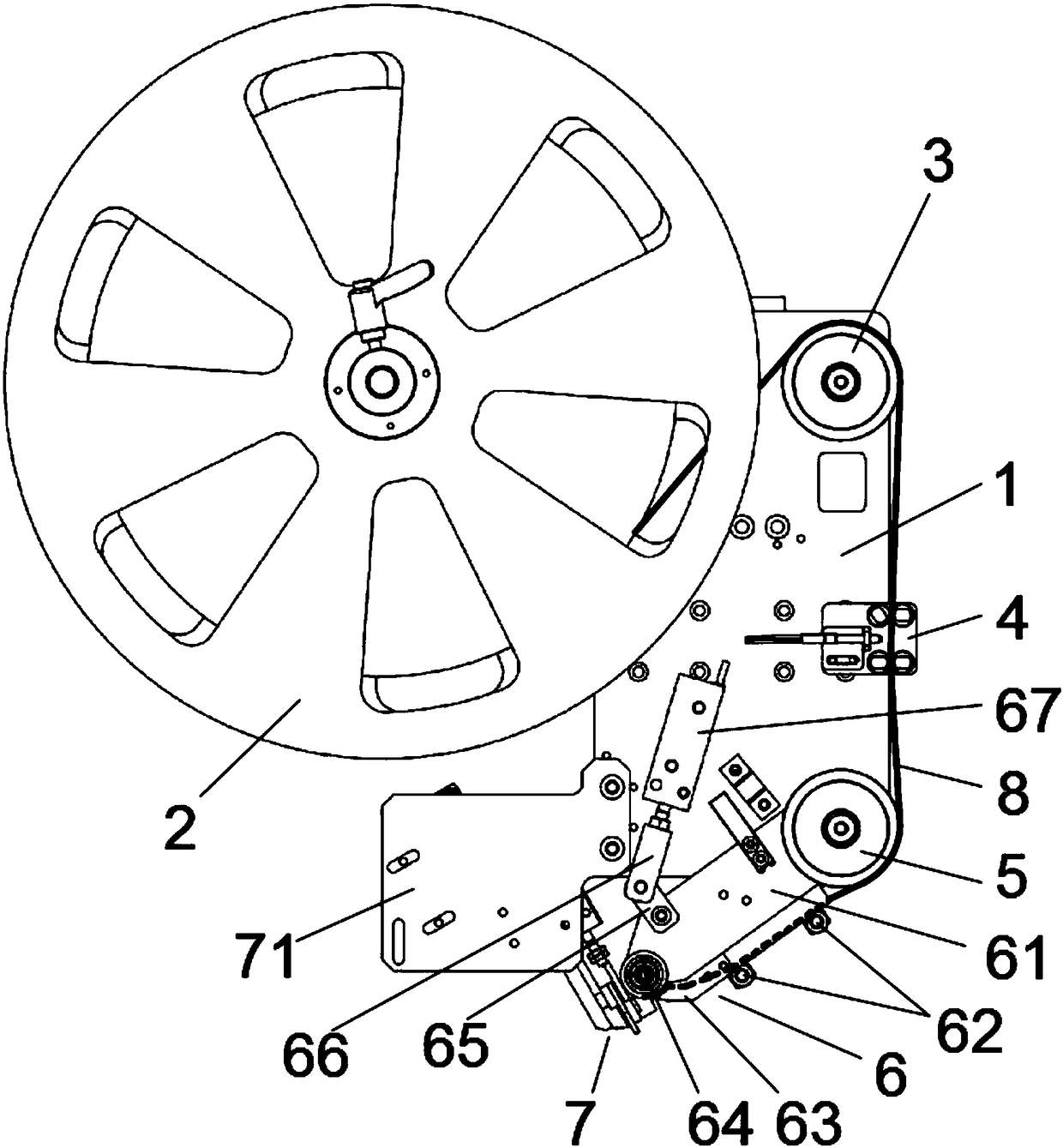

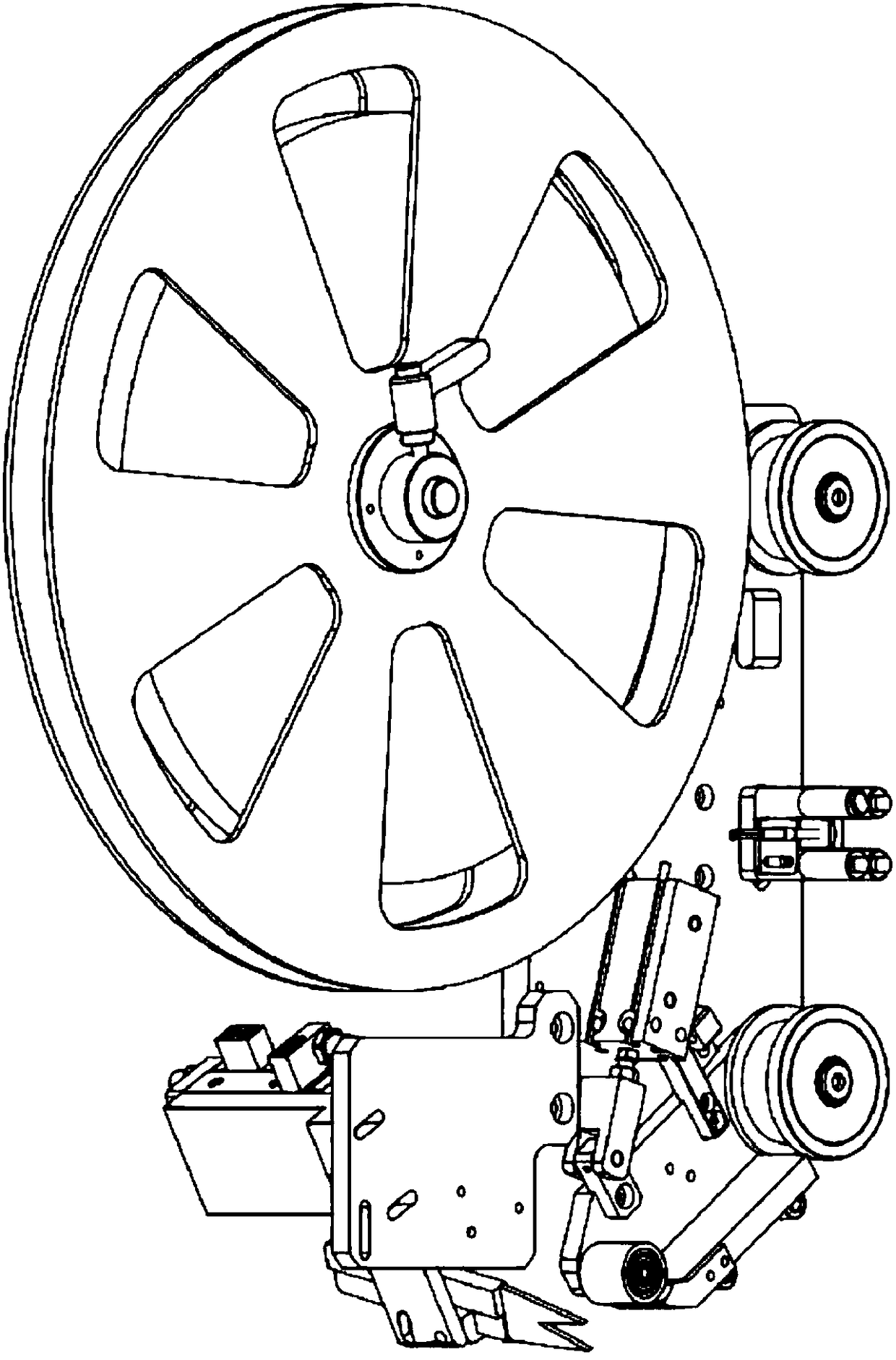

Variable pitch propeller

PendingCN112937837AMeets the requirement of a maximum of twice the centrifugal force loadGuaranteed connection strengthPropellersClassical mechanicsStructural engineering

The invention belongs to the technical field of propellers, and particularly relates to a free variable pitch propeller. The variable pitch propeller comprises a propeller hub and blades which are rotatably matched in an assembly cavity of the propeller hub through a propeller root part, and is characterized in that the propeller root part comprises a sleeve-shaped propeller root support, an annular bulge, a radial bearing and a rotary connecting seat are coaxially and sequentially arranged on the propeller root support from back to front, and the outer ring surface of the rotary connecting seat is fixed on the assembly cavity; the inner ring surface of the rotary connecting seat and the paddle root support form rotary fit with the rotary axis coaxial with the axis of the paddle root support, and the two ends of the radial bearing abut against the front side shaft shoulder of the annular protrusion and the rear side ring surface of the rotary connecting seat respectively. The connecting strength of the blades and the propeller hub can be effectively guaranteed while the normal rotation function of the blades relative to the propeller hub is guaranteed, and the propeller has the advantages of being simple and compact in structure, concise in assembly process and low in cost.

Owner:安徽羲禾航空科技有限公司

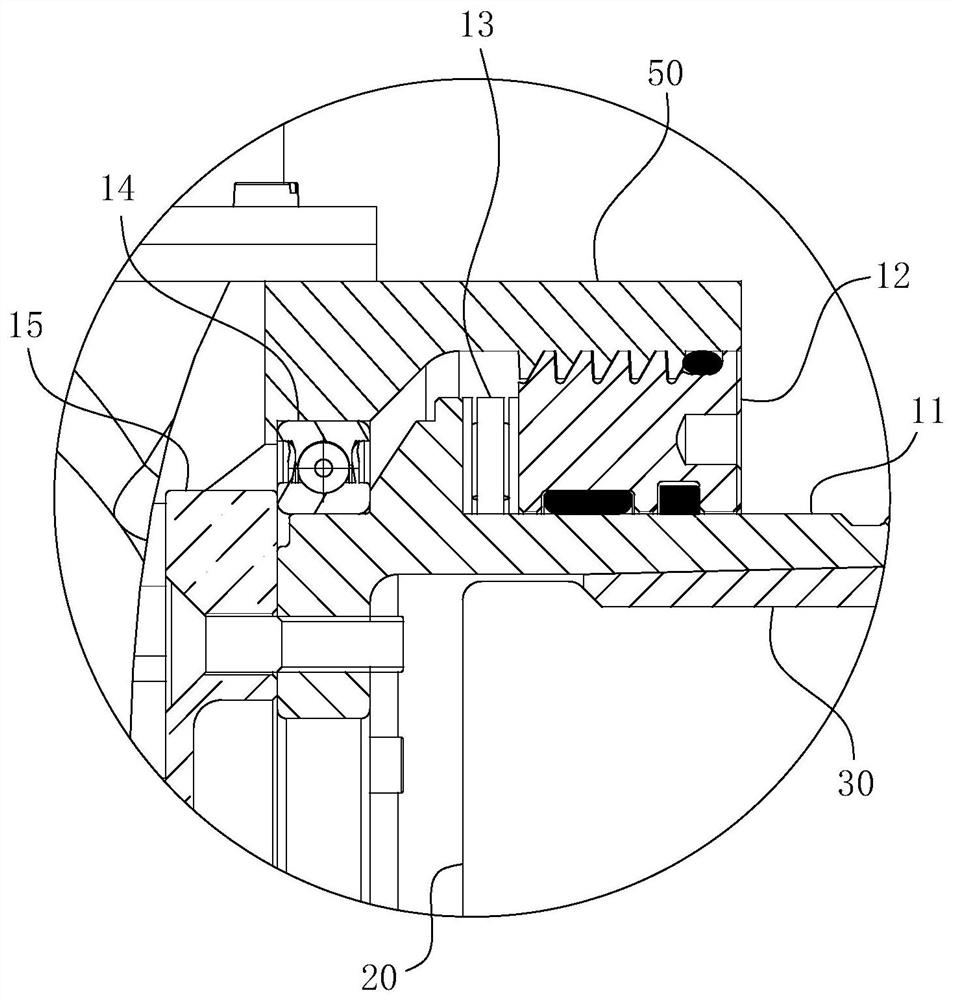

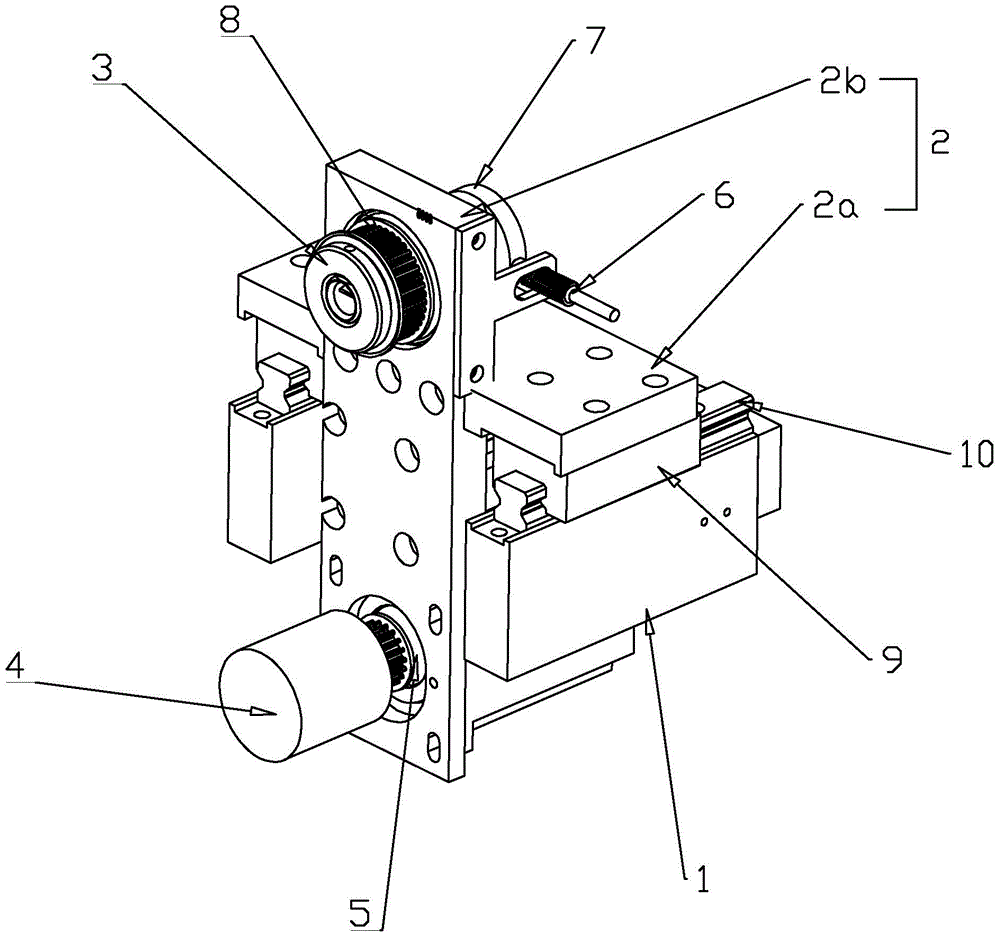

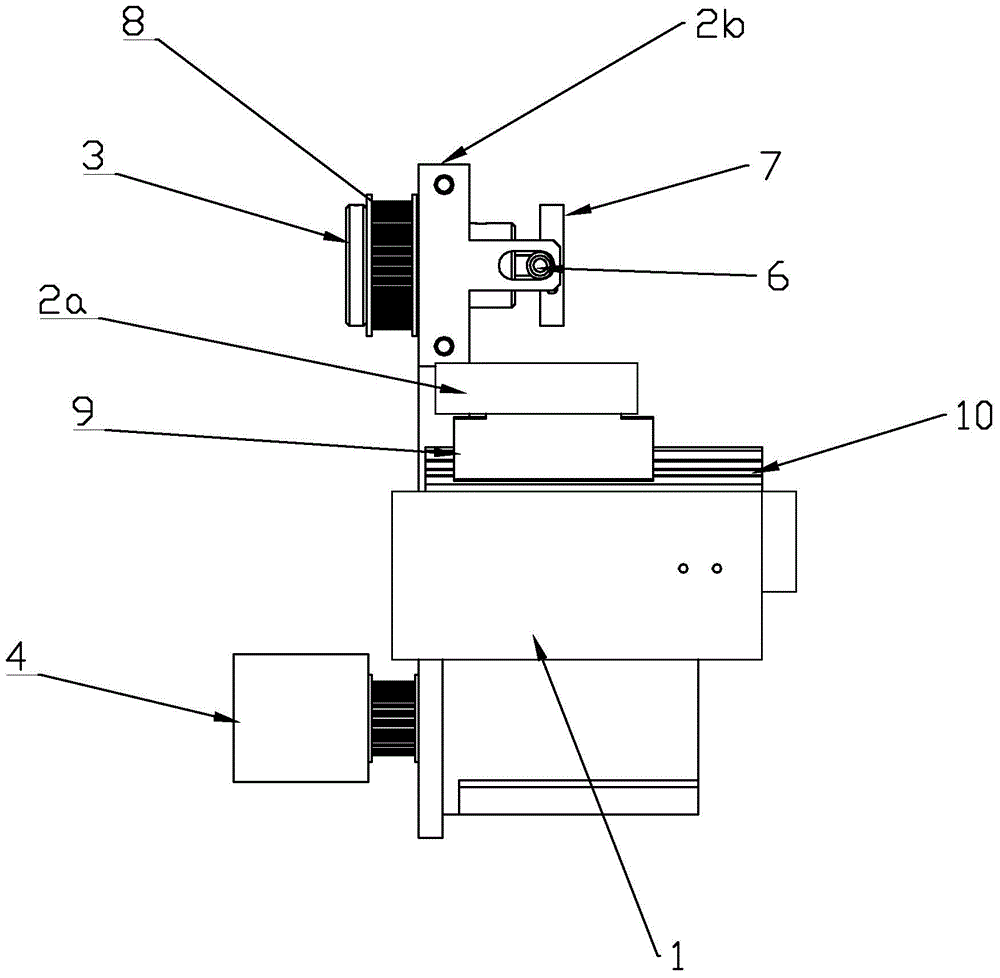

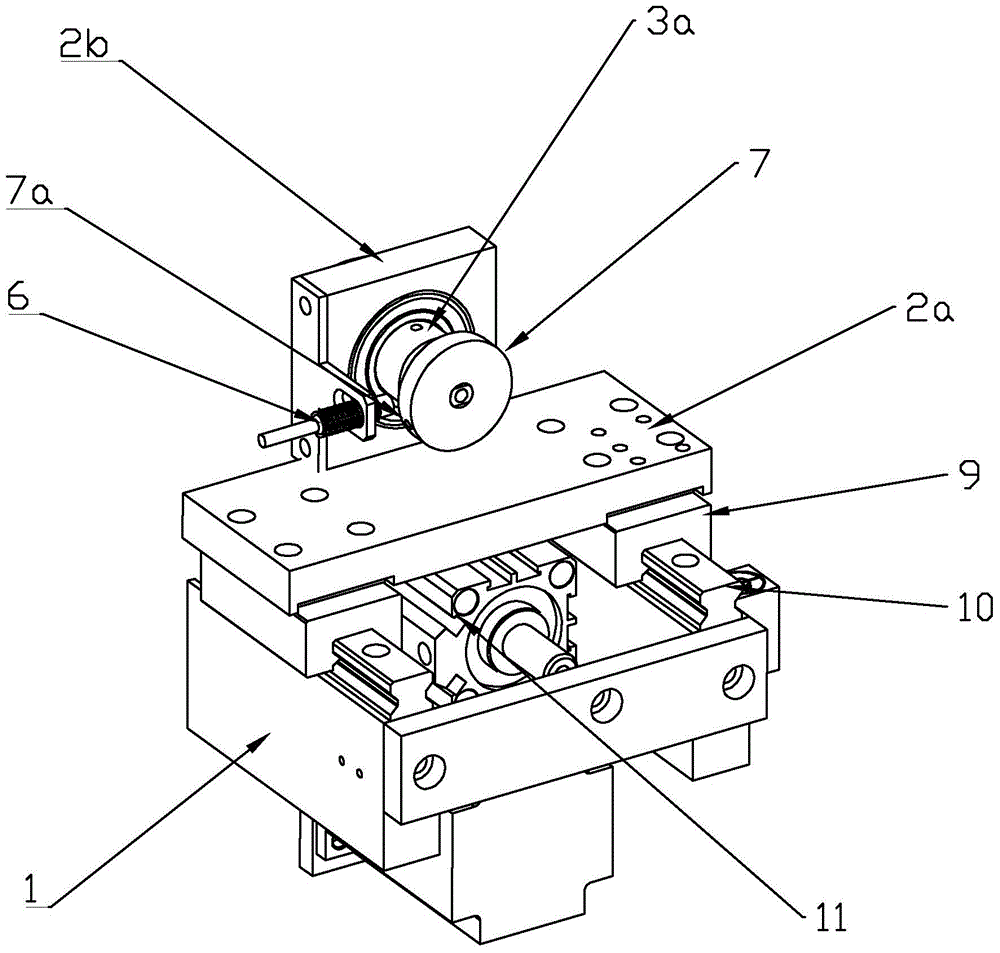

Adjustable magnetic trip and disconnector

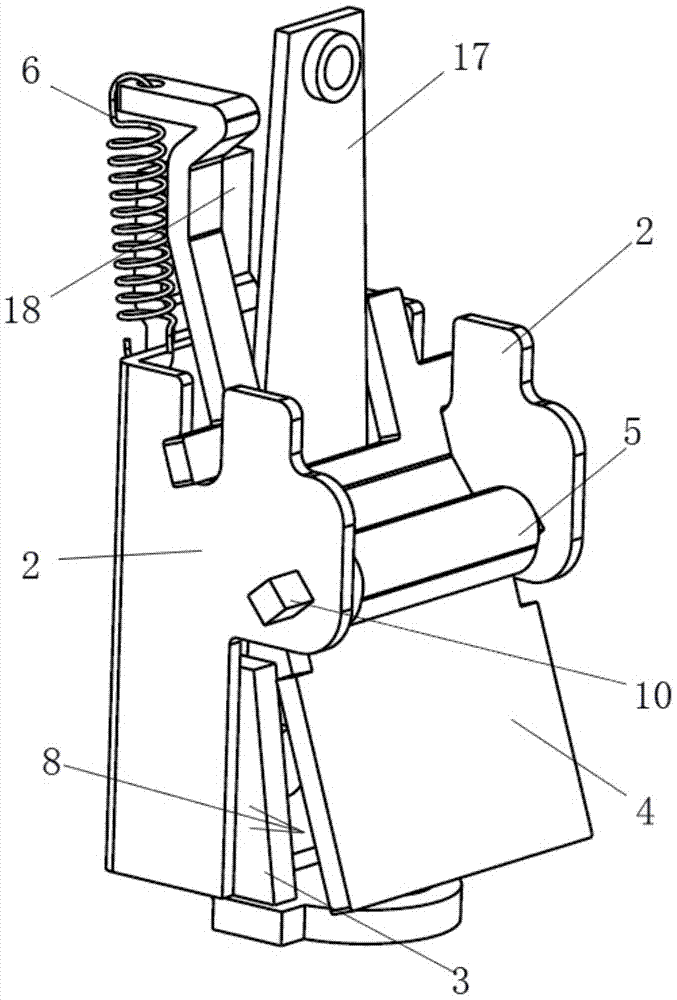

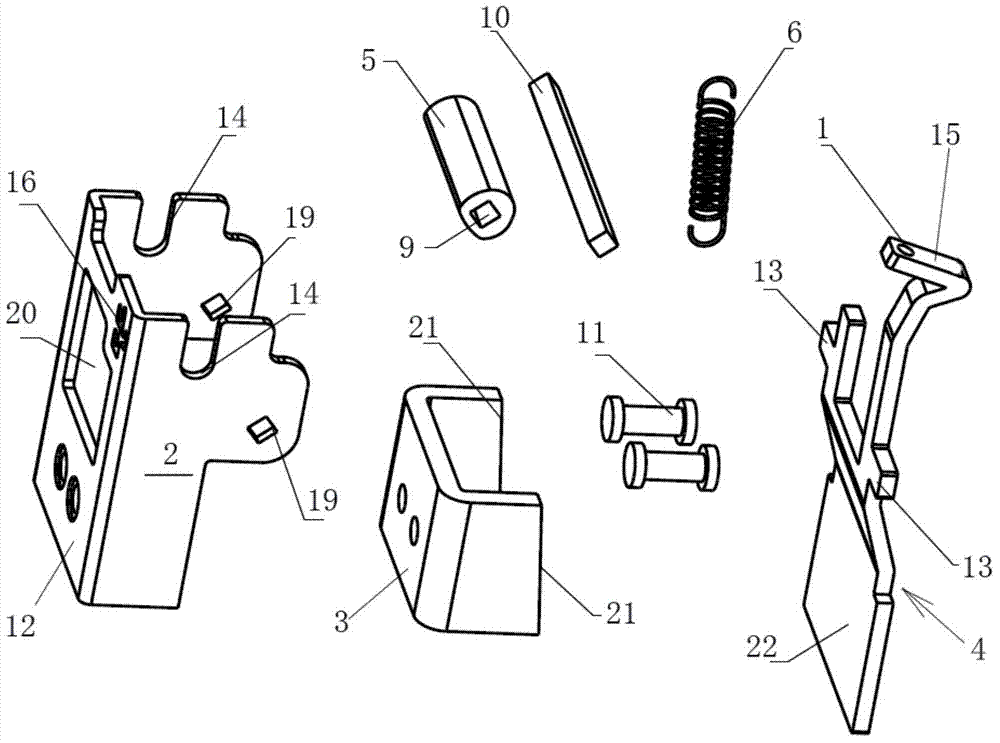

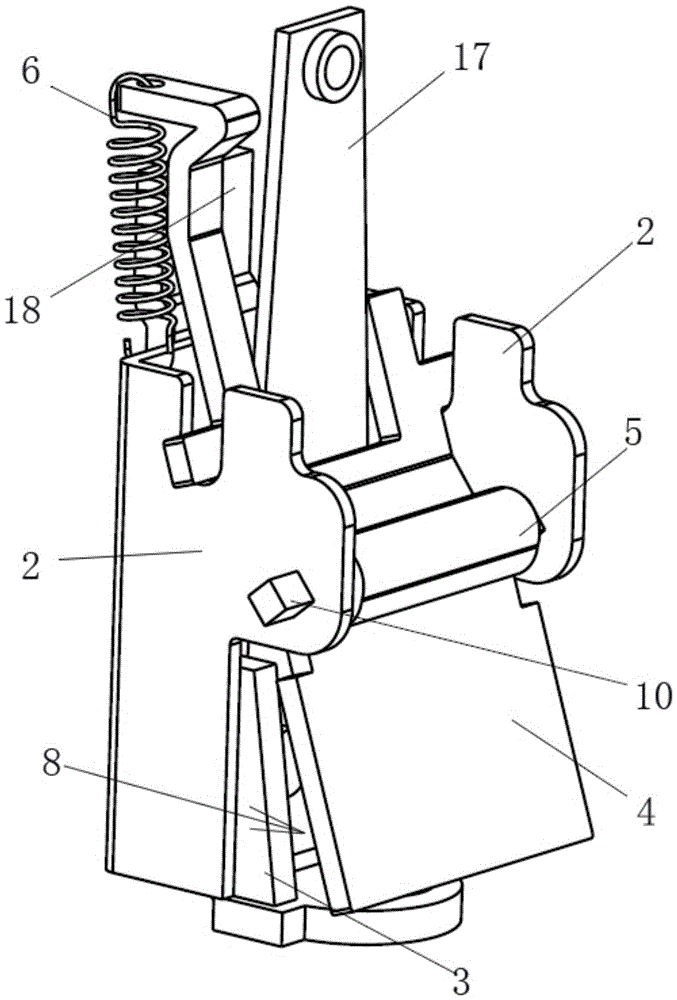

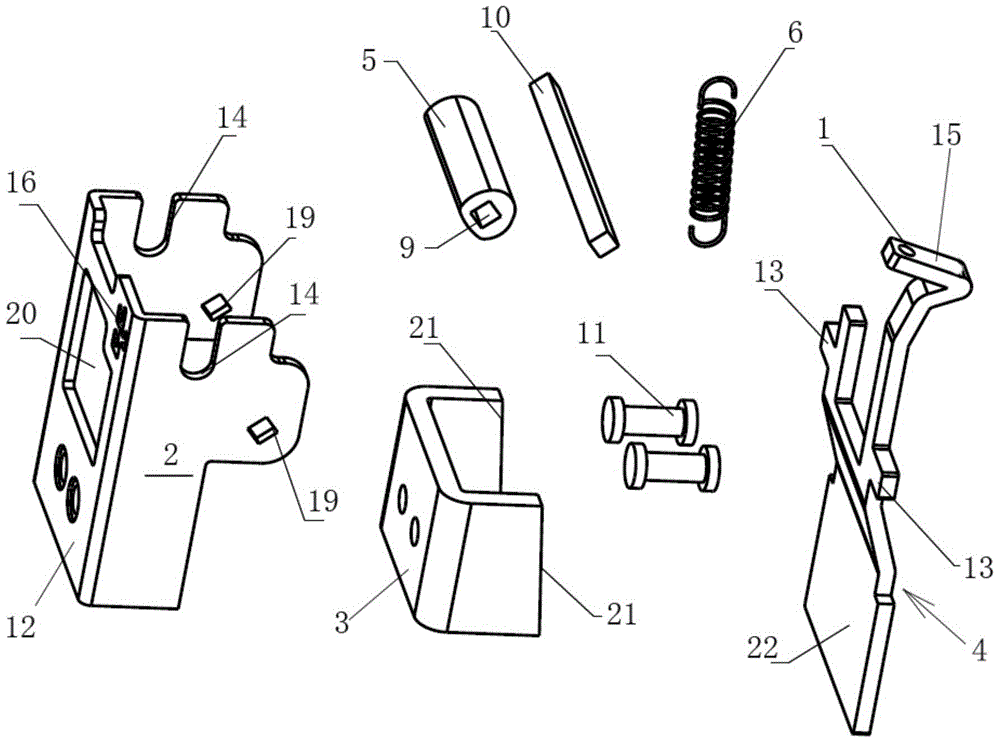

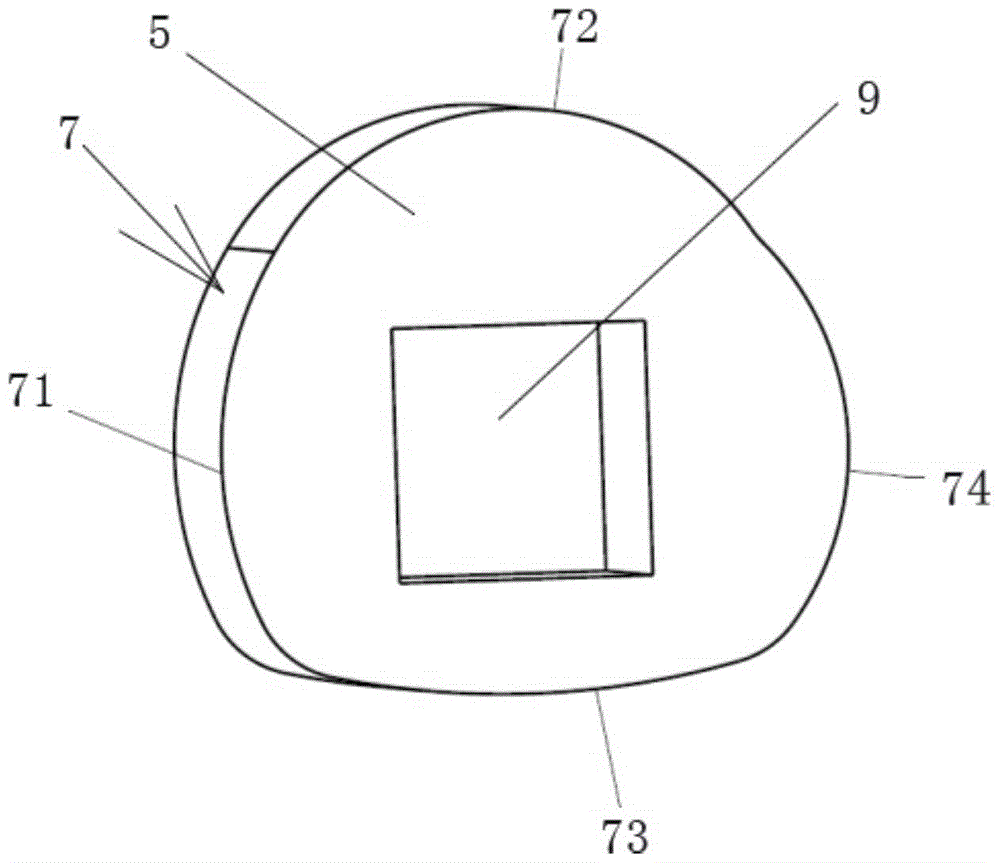

ActiveCN104779127ACompact structureThe tripping action is stable and reliableProtective switch operating/release mechanismsAdjustment of protective switch conditionsEngineeringDisconnector

The invention discloses an adjustable magnetic trip. The adjustable magnetic trip comprise a supporting frame (2), an iron core (3) fixedly connected with the supporting frame (2), an armature (4) rotationally arranged on the supporting frame (2) and keeping an electromagnetic attraction interval (8) with the iron core (3), a sleeve (5) connected with the supporting frame (2) in a position-adjustable mode, located on one side of the rotary axis of the armature (4) and pressing the armature (4) all the time, and a counter-force spring (6). One end of the counter-force spring (6) is connected with the supporting frame (2), and the other end of the counter-force spring (6) is located on the other side of the rotary axis of the armature (4) and is connected with the armature (4). An adjustment structure capable of adjusting the electromagnetic attraction interval (8) to adjust the electromagnetic attraction force between the iron core (3) and the armature (4) is formed on the adjustable magnetic trip. The adjustable magnetic trip can increase the adjustment range of the current of a disconnector, and is simple and compact in structure.

Owner:DELIXI ELECTRIC

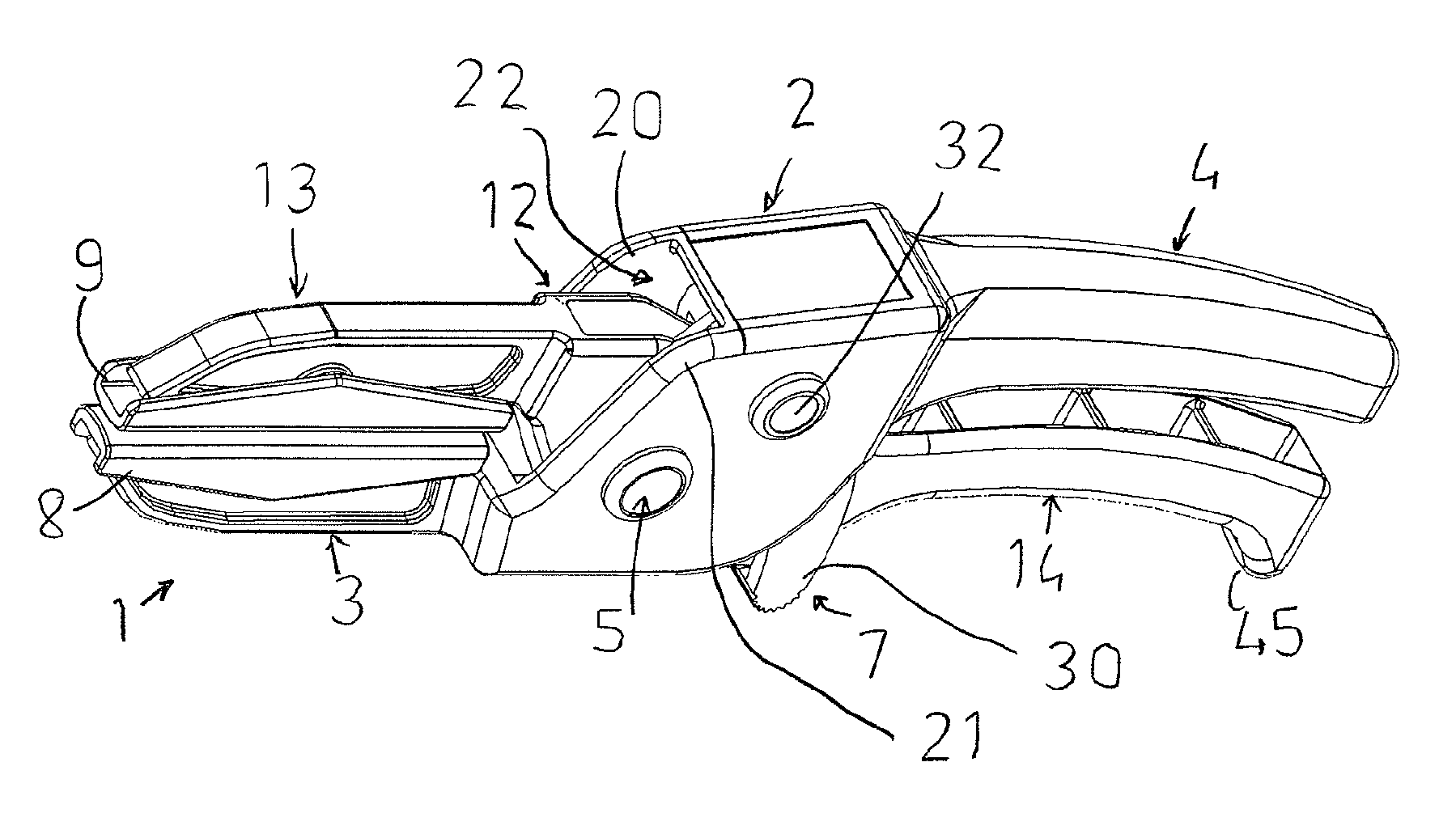

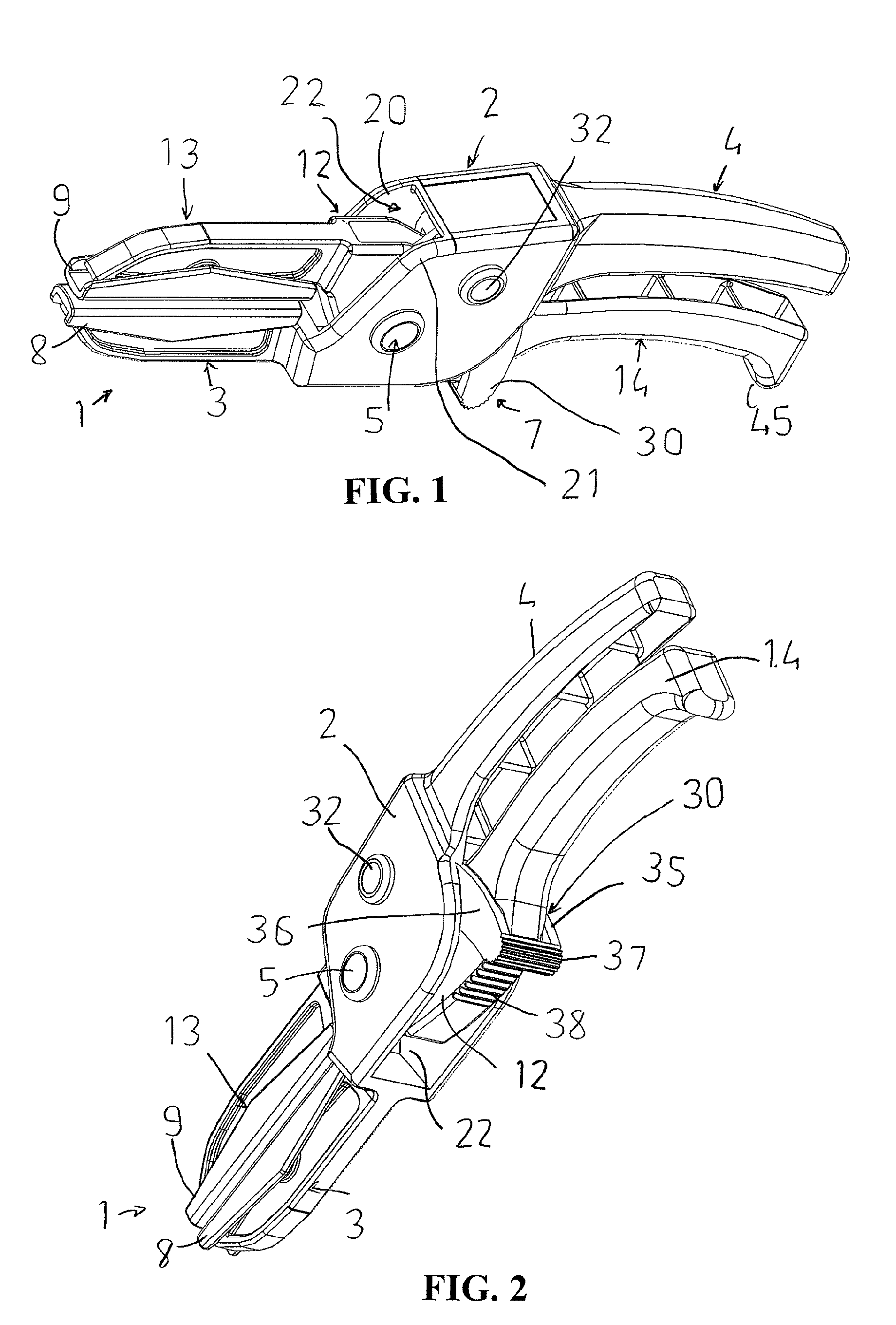

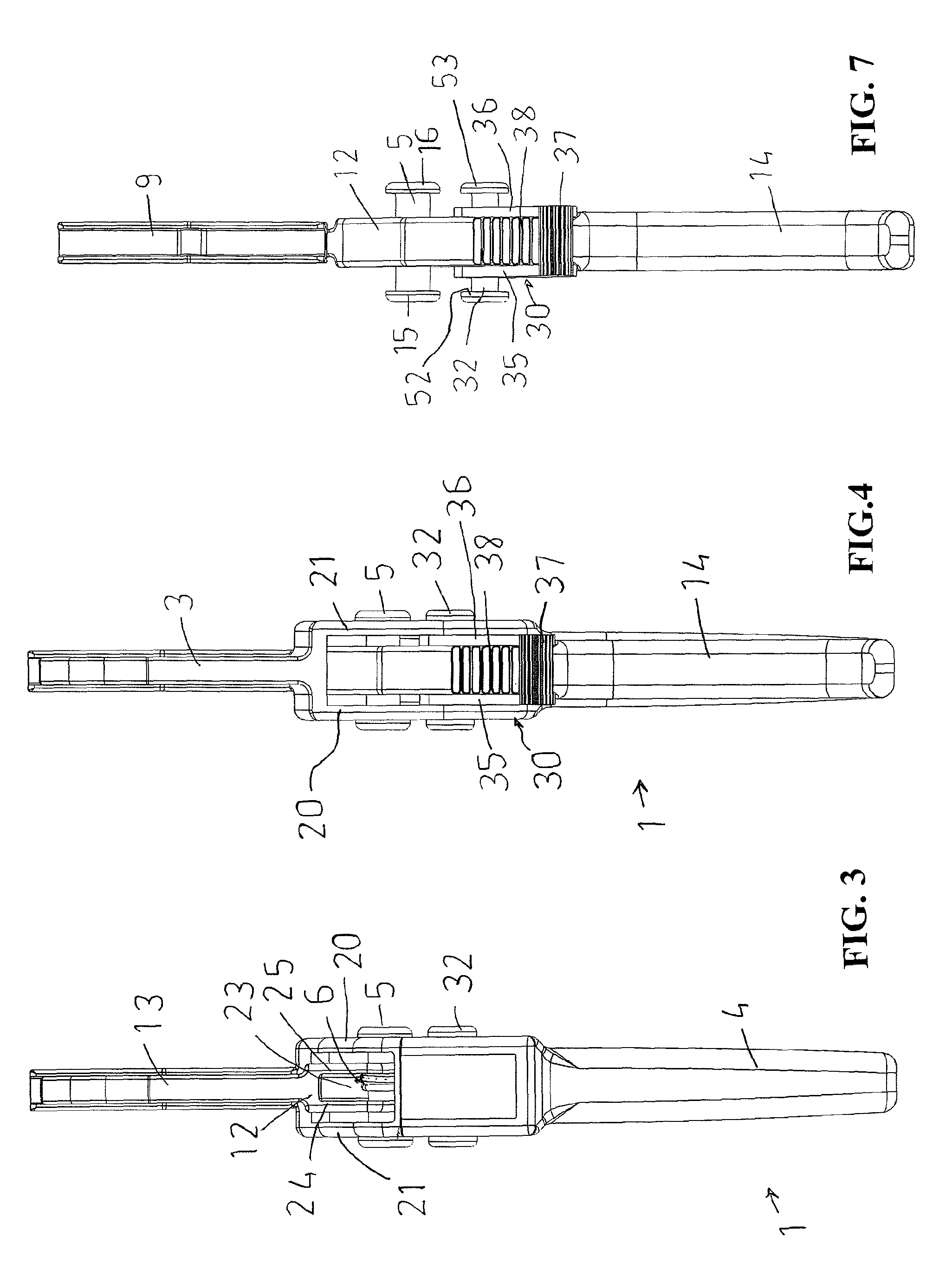

Clamping pliers

Fluid line clamping pliers include shanks, jaws, handles, a pivot connecting the shanks such that first and second jaws are opposed to one another and movable using first and second handles within a common plane between a clamping position and a non-clamping position. The pliers include a biasing mechanism, a locking mechanism, and a retainer return mechanism. A retainer is adapted to be pivoted to a locking position using an index finger of an operator of the clamping pliers while the operator's other fingers grasp the handles of the clamping pliers, and the retainer return mechanism is adapted to move the retainer from a locking position to a non-locking position when the operator squeezes the handles towards one another while the jaws are in a clamping position.

Owner:PRIVATE BRAND TOOLS AUSTRALIA

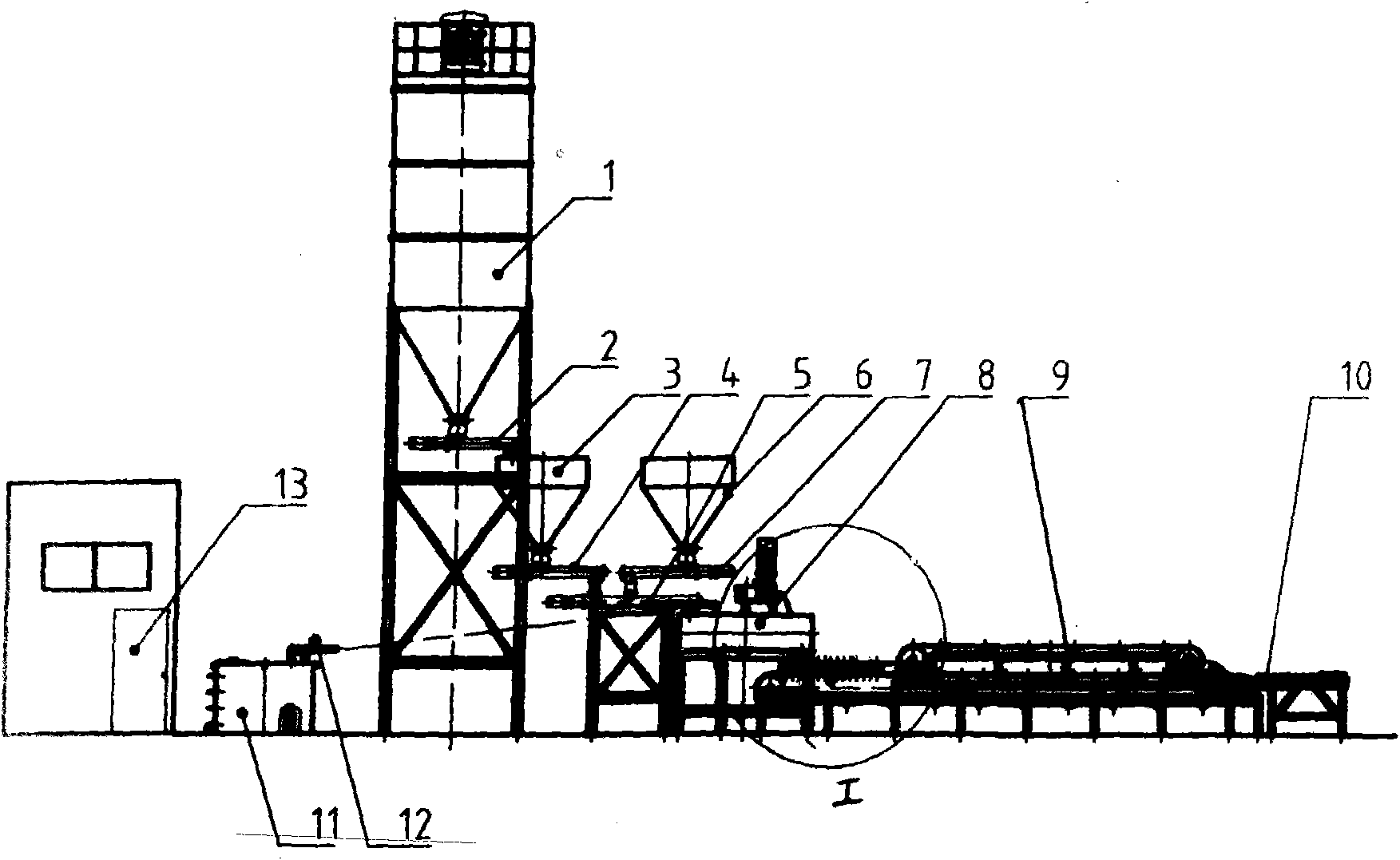

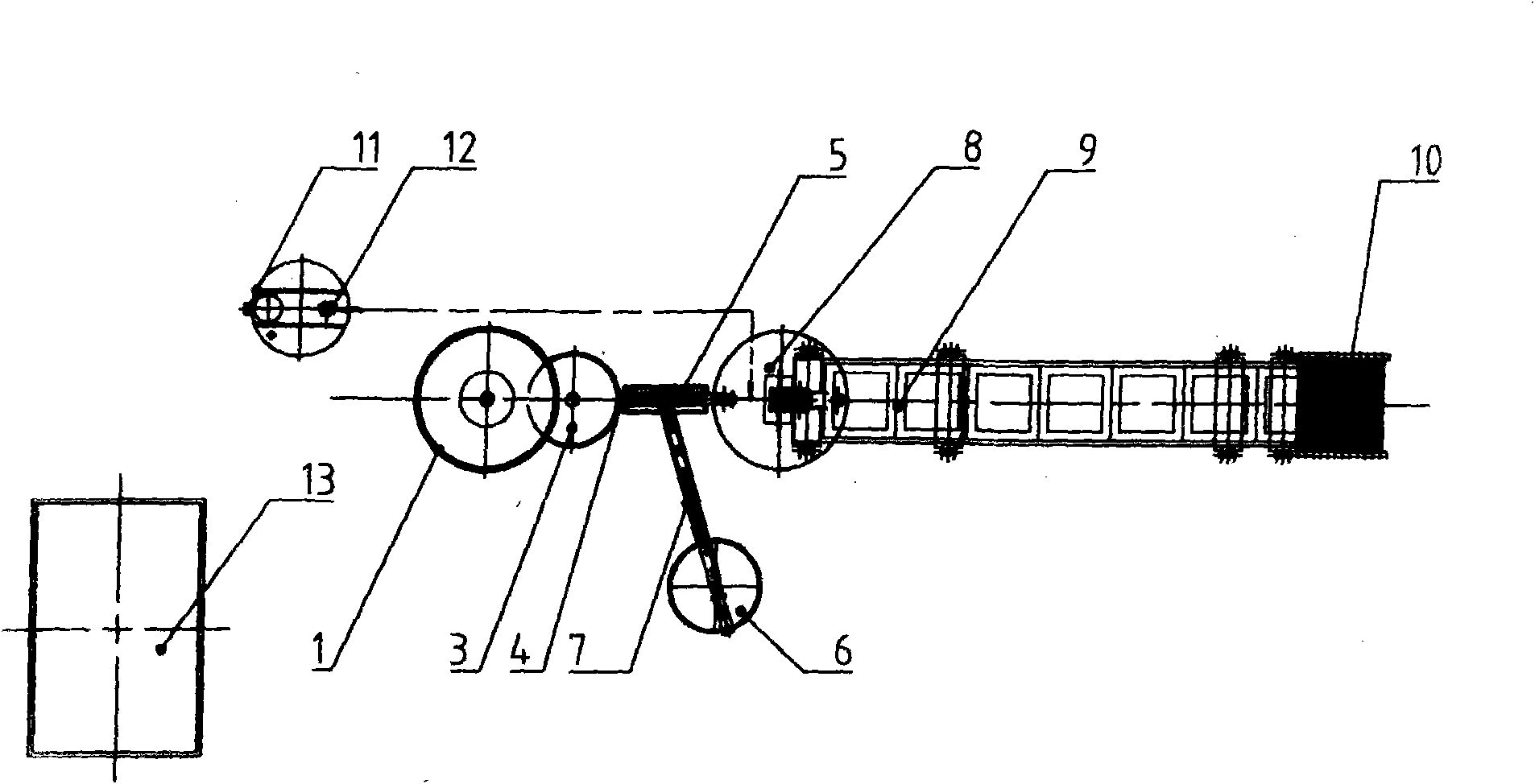

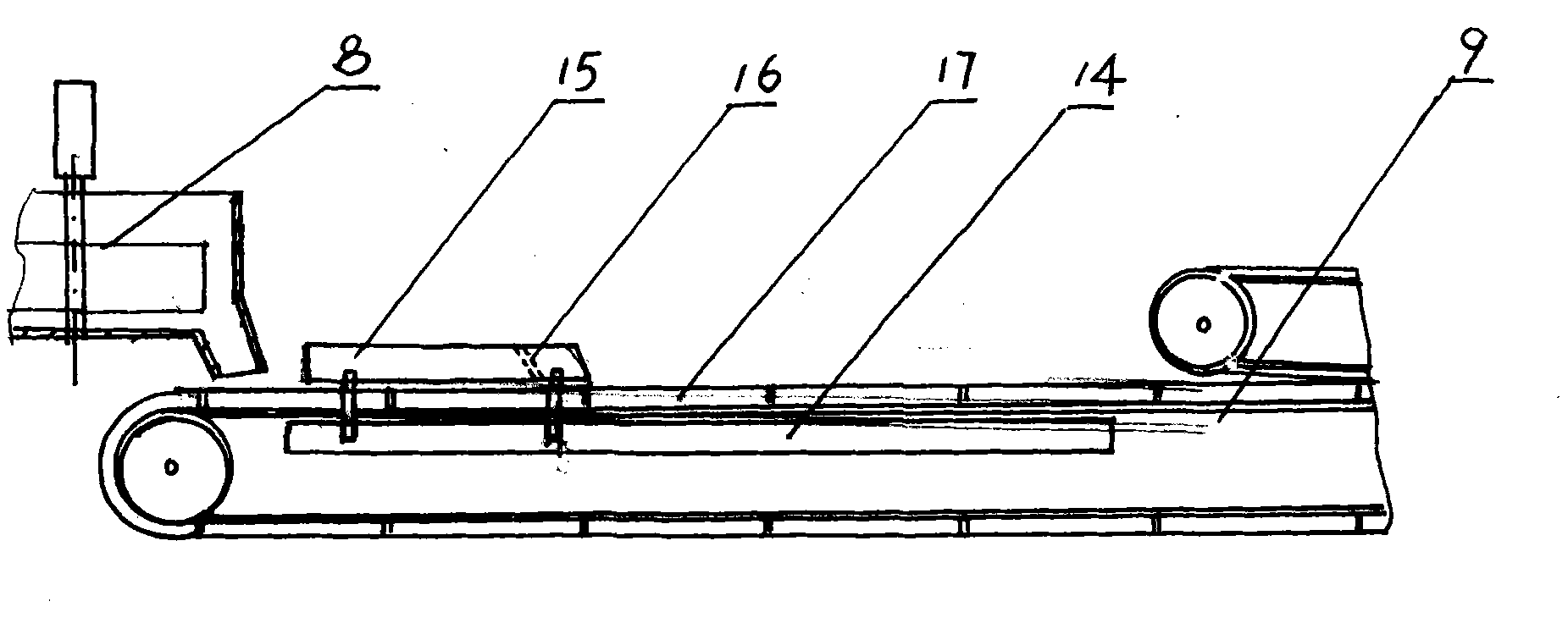

Continuous production equipment of embossed gypsum ceiling

The invention discloses continuous production equipment of an embossed gypsum ceiling, comprising a raw material conveying mechanism, a stirrer, a water tank, a finished product die assembling and disassembling mechanism, a shaking table, a material-blocking scraping plate, a finished product roller way conveyer and a distribution control tank. The continuous production equipment realizes the continuous production of the embossed gypsum ceiling by utilizing all components. The continuous production equipment has the advantages of simple structure, compact operation, single program, high production efficiency, uniform and thick grouting, high quality of finished products and attractive appearance.

Owner:宁俊岭

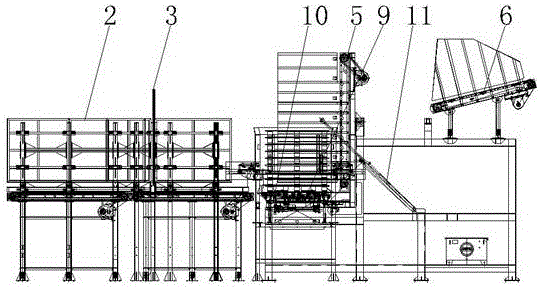

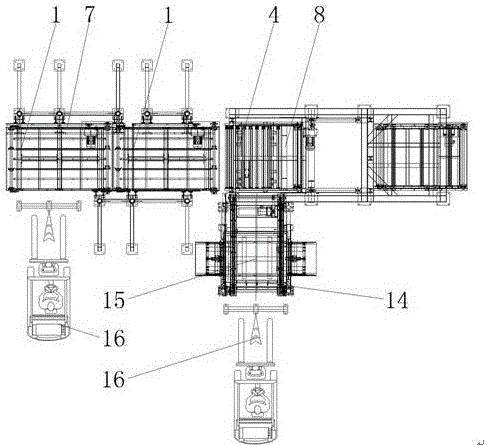

Automatic conveying and destacking system of packaging bags

InactiveCN106628919AImprove work efficiencyLong-term stable returnsConveyor partsMechanical conveyorsCollection systemEngineering

The invention discloses an automatic conveying and destacking system of packaging bags. The system is composed of an automatic conveying and detection system, a turnover discharge system and a tray collection system. The automatic conveying and detection system comprises a chain plate conveyor, a high-strength adjusting flange, an excess height and width detection device, a roller conveyor, a 90-degree turnover belt conveyor, a climbing belt conveyor, a pallet positioning machine and a tray lateral push-out mechanism. The high-strength adjusting flange is provided with a tray transverse positioning mechanism. The roller conveyor is provided with a tray longitudinal positioning mechanism, a tray fixing mechanism and a tray lateral conveying mechanism. The turnover discharge system comprises a hydraulic turnover jacking mechanism. The tray collection system comprises a chain plate conveyor and an empty tray collector. The empty tray collector is provided with a tray positioning mechanism and a hydraulic jacking mechanism. In the automatic conveying working process, stacked trays pass by the chain plate conveyor and the roller conveyor in sequence and are positioned through the transverse positioning mechanism.

Owner:JIN HOUNG FUH (CHUZHOU) CONVEYING EQUIP CO LTD

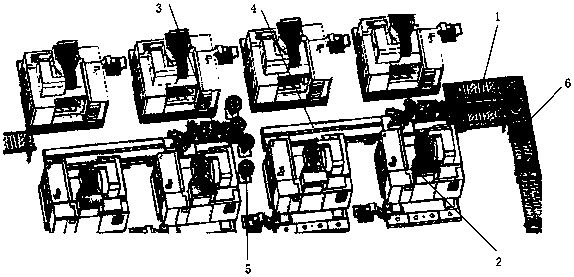

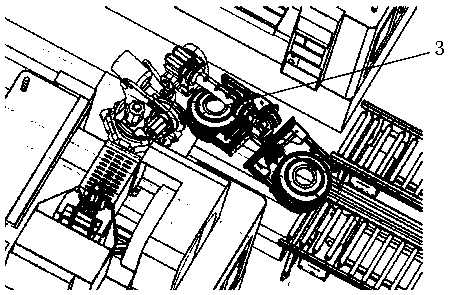

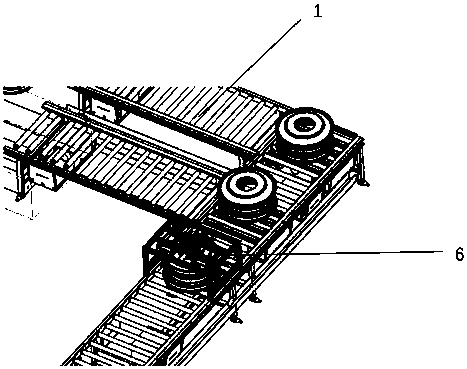

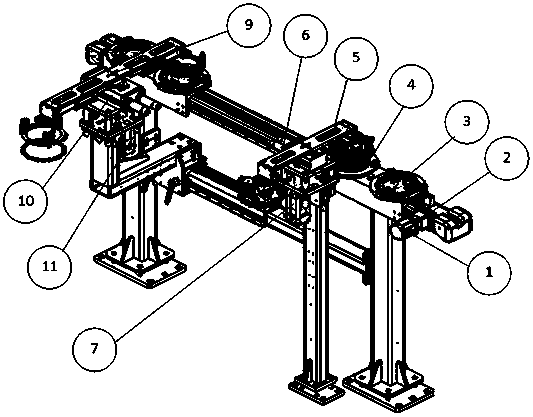

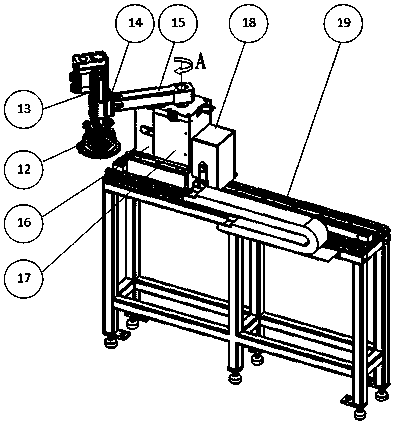

Robot hub processing center

PendingCN108000217AIncrease the level of automationReduce artificial correction of the loading position of the hubMetal working apparatusPulleyAutomation

The invention discloses a robot hub processing center. The robot hub processing center comprises a hub conveyor line, a hub processing system, a robot clamping jaw system, a robot travelling guide rail, a hub placing table and a hub judging mechanism, wherein the robot clamping jaw system comprises a robot fixing base, a mechanical arm, a robot terminal, a robot terminal connecting block, a slidewheel, a clamping air cylinder and a clamping jaw; and the robot travelling guide rail comprises a guide rail, a guide rail fixing pin and a robot travelling base. The invention aims to provide the robot hub processing center, which has classifiable and stable hub transfer, enables the robot clamping jaw to smoothly complete instructions of clamping hubs, transmitting hubs and the like, has multi-pace continuous action, and greatly improves automation degree of the processing center.

Owner:苏州康克莱自动化科技有限公司

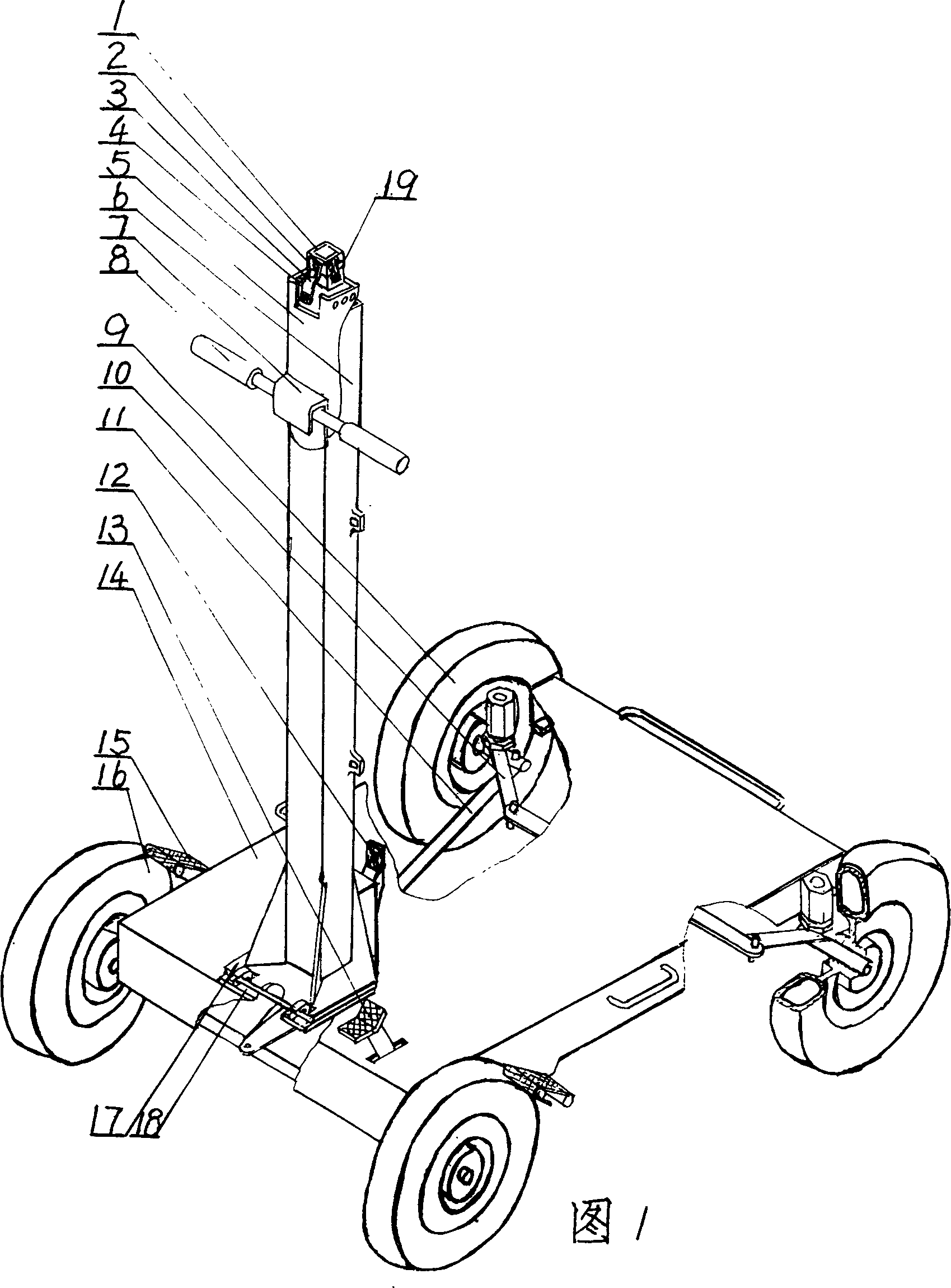

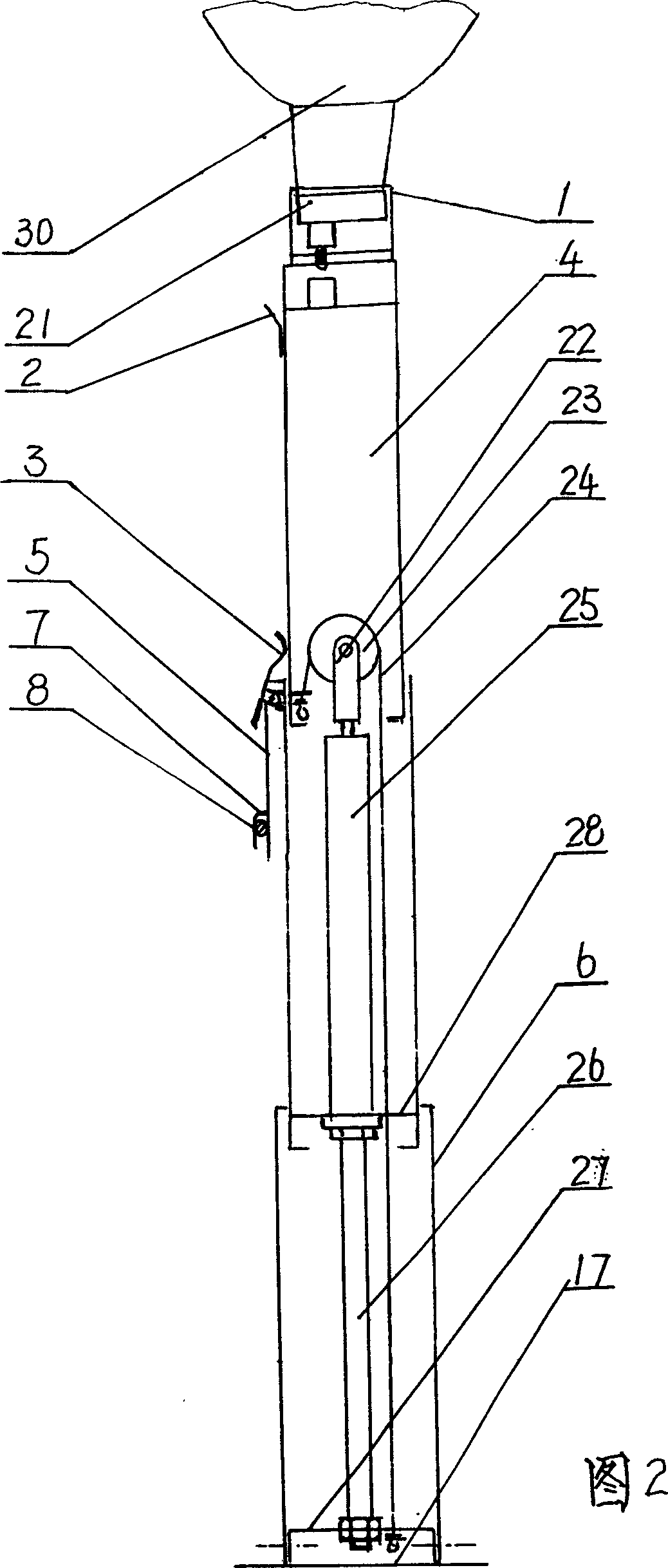

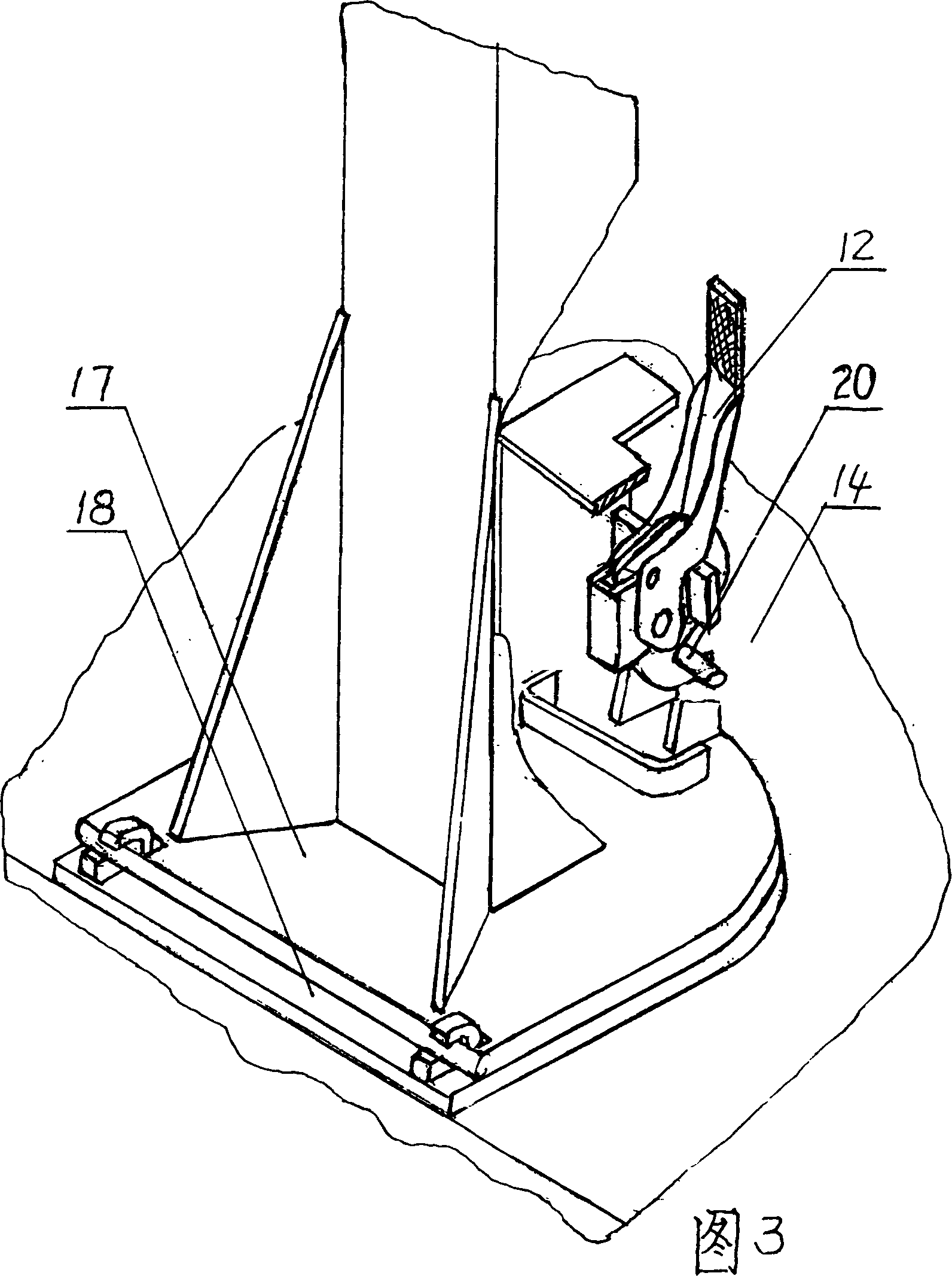

Portable vehicle for lighting

A light vehicle for the lighting purpose features that the lamp is connected to its lifting pipe via plug-socket set, its lifting pipe consisting of three segments is telescopic under the action of pneumatic spring, and the detachable lifting pipe can be turned by handle installed to it for changing the direction of lighting.

Owner:周京舟

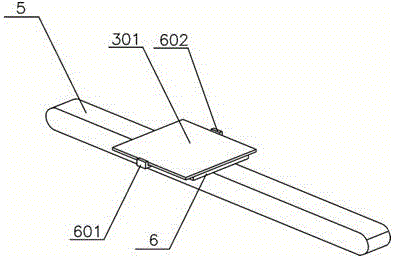

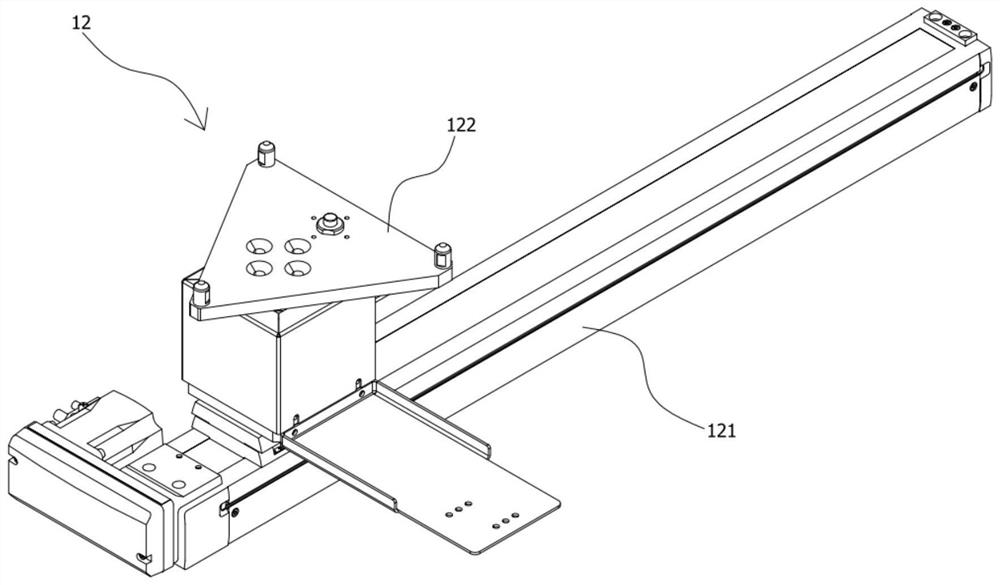

Stamping automatically loading and unloading belt device for subpackaging

PendingCN109264375ASimple structureLow costMetal-working feeding devicesControl devices for conveyorsLinear operationControl system

The invention relates to a stamping automatically loading and unloading belt device for subpackaging, which is used for automatic taking, subpackage, arrangement and placement of stamping. A conveyingand subpackaging mechanism is located at the rear part in the axial direction of a loading and unloading mechanism; the portion close to the conveying and subpackaging mechanism is provided with a peripheral equipment defective product rack platform; a peripheral equipment storage bin and a peripheral equipment good product conveyer belt are located at two sides of the loading and unloading mechanism and the conveying and subpackaging mechanism in the axial direction; a servo unit of a control system is connected with a servo motor of the peripheral equipment; the loading and unloading mechanism takes out a work blank from the peripheral equipment storage bin, conveys and puts the work blank into a stamping machine; the conveying and subpackaging mechanism takes out qualified products processed in the stamping machine from the loading and unloading mechanism, puts the qualified products into the peripheral equipment good product conveying belt, and stacks unqualified products on the peripheral equipment defective product rack platform. According to the stamping automatically loading and unloading belt device for subpackaging, the linear operation is utilized to cooperate with a rotating cylinder and a guide rod cylinder to move up and down, and the linear operation is utilized to cooperate with a rotating arm and a electric cylinder to rotate and feed, so that the actions of loading and unloading, taking out, subpackaging, arranging, placing and the like of products are completed, and the automation degree is high.

Owner:STAR SEIKI XIANGYANG

Device for automatically detecting and repairing building steel pipe crack

InactiveCN111761294ATake advantage ofImprove repair efficiencyOther manufacturing equipments/toolsArchitectural engineeringPipe

The invention discloses a device for automatically detecting and repairing a building steel pipe crack. The device for automatically detecting and repairing the building steel pipe crack comprises a base, wherein a first fixed plate is fixedly connected to the upper side end face of the base; a detecting and welding mechanism is arranged on the front side end face of the first fixed plate and is used for detecting and welding a building steel pipe; the detecting and welding mechanism comprises two left-and-right symmetrical first screw rod installation plates fixedly connected onto the front side end face of the first fixed plate; a first screw rod is rotatably connected between the two first screw rod installation plates; a feeding mechanism is arranged on the upper side end face of the base; a derusting mechanism is arranged on the right side of the feeding mechanism; and a grinding mechanism is arranged on the right side of the derusting mechanism. Therefore, the device provided bythe invention can be used for automatically detecting and repairing the building steel pipe crack, so that the building steel pipe repairing efficiency is improved, and a lot of manpower and time aresaved.

Owner:杭州圣埃蒂机械科技有限公司

Adjustable Magnetic Trip Units and Circuit Breakers

ActiveCN104779127BCompact structureThe tripping action is stable and reliableProtective switch operating/release mechanismsAdjustment of protective switch conditionsEngineeringElectric current

Owner:DELIXI ELECTRIC

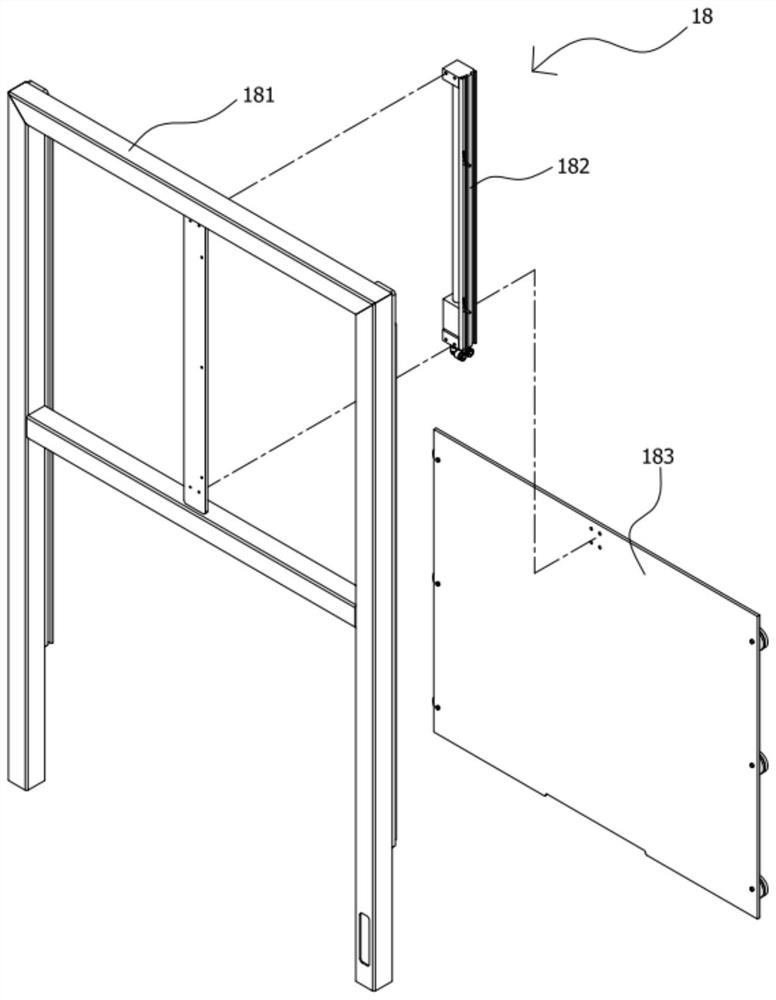

Full-automatic board sending mechanism for LED plug-in board

PendingCN105730983APush smoothMovement coordinationConveyorsConveyor partsManipulatorElectrical and Electronics engineering

The invention discloses a full-automatic board sending mechanism for an LED plug-in board. The full-automatic board sending mechanism comprises a rack, a feeding mechanism positioned at the front end of the rack, and a board sending mechanism positioned at the tail end of the feeding mechanism, the feeding mechanism comprises a conveying belt, supporting boards positioned on two sides of the rack, a sliding arm positioned on the inner sides of the supporting boards, and a clamping board slidably connected on the upper surface of the sliding arm, and a board lifting device is arranged on the inner sides of the supporting boards and used for lifting the board and then collecting the same; the full-automatic board sending mechanism further comprises a lamp board transfer manipulator which is positioned above the board lifting device and used for transferring the board. The full-automatic board sending mechanism has the advantages that by adopting the LED plug-in board sending mechanism, a conventional pushing head mechanism is improved, so that the LED plug-in board is pushed more stably; the whole board sending mechanism and a board collecting mechanism are closely matched, so that the full-automatic board sending mechanism is coordinated and compact in action, higher stability and higher orderliness in board pushing are guaranteed, production efficiency is improved, and the full-automatic board sending mechanism is accurate in control and has high market application value.

Owner:陈浩涛

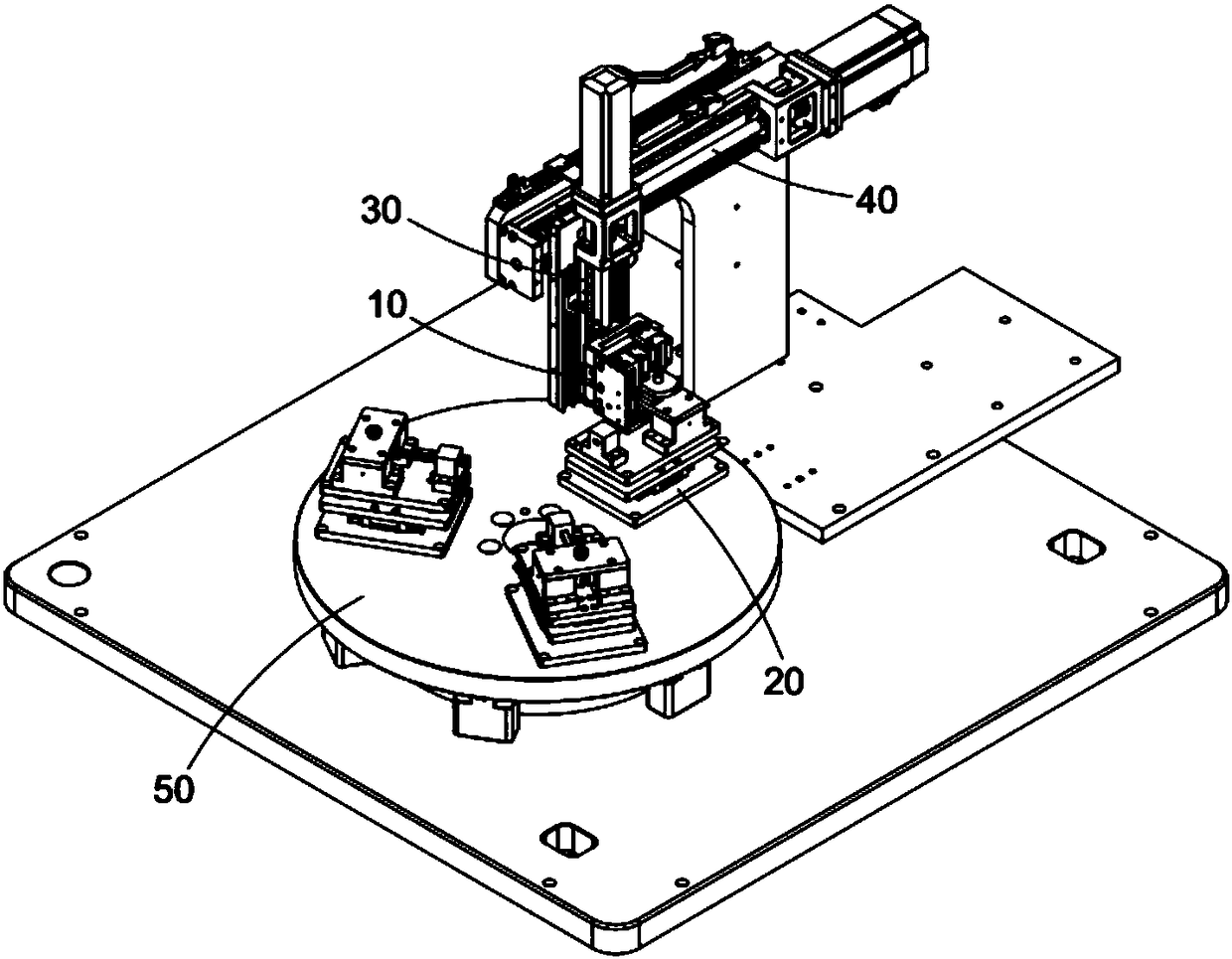

Robot workstation system for machining water pump diversion shells

InactiveCN105082147AImprove production taktIncrease productivityOther manufacturing equipments/toolsManipulatorElectrical controlManipulator

The invention relates to a robot workstation system for machining water pump diversion shells. The robot workstation system for machining the water pump diversion shells comprises a robot, a manipulator connected to an end executor of the robot, a diversion shell positioning table, a drilling machine, a tapping machine, a pair of compression ring supplying devices, a press machine and an electric control system. Diversion shells which can be machined through the robot workstation system can be 20 diversion shells and 32 diversion shells. The robot works in cooperation with the diversion shell positioning table, the compression ring supplying devices, the drilling machine, the tapping machine and the press machine, in this way, the utilization rate of the robot is increased, and the production takt is accelerated; the electric control system acts on the robot, the diversion shell positioning table, the compression ring supplying devices, the press machine, the drilling machine and the tapping machine, so that mutual cooperation and cooperative work of equipment of a whole workstation are achieved. By the adoption of the robot workstation system for machining the water pump diversion shells, drilling, tapping, ring pressing and stacking of the water pump diversion shells can be achieved automatically, production cost is reduced, high-intensity manual work is replaced, and the production efficiency and quality of products are guaranteed.

Owner:山西中圣恒磁材料有限公司

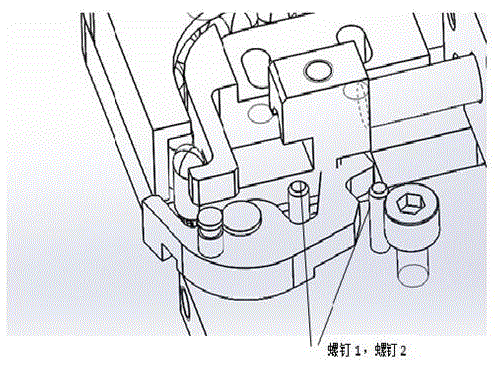

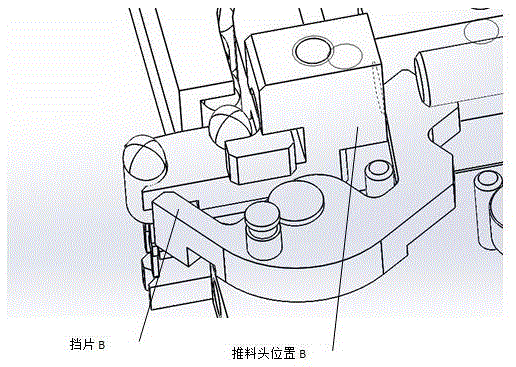

LED lamp pushing mechanism precise in linkage

The invention discloses an LED lamp pushing mechanism precise in linkage. The LED lamp pushing mechanism comprises a material blocking mechanism for controlling inputting / outputting of LED lamps and a material pushing device for conveying the LED lamps to a material feeding mechanism; the material blocking mechanism is in linkage with the material pushing device; the material blocking mechanism is provided with a blocking piece, a tension device, a limiting device for limiting the blocking piece and a rotating shaft capable of making the blocking piece rotate; the tension device is provided with a fixing piece and a screw; the fixing piece is in elastic connection with the screw; the material pushing device is provided with a material pushing head capable of fixing the LED lamps and a power source for pushing the material pushing head to move forwards. Compared with the prior art, the LED lamp pushing mechanism has the advantages that the material pushing head mechanism is improved, it is guaranteed that the LED lamps can be pushed more stably, action of the whole material pushing mechanism can be more coordinate and compact through linkage of the material pushing head and the blocking piece, stability of material pushing action is guaranteed, the lamps are pushed in sequence, production efficiency is better improved, and the LED lamp pushing mechanism is simple in structure and high in accuracy and efficiency and has good market application value.

Owner:SHENZHEN SHENGTIANDA AUTOMATION TECH CO LTD

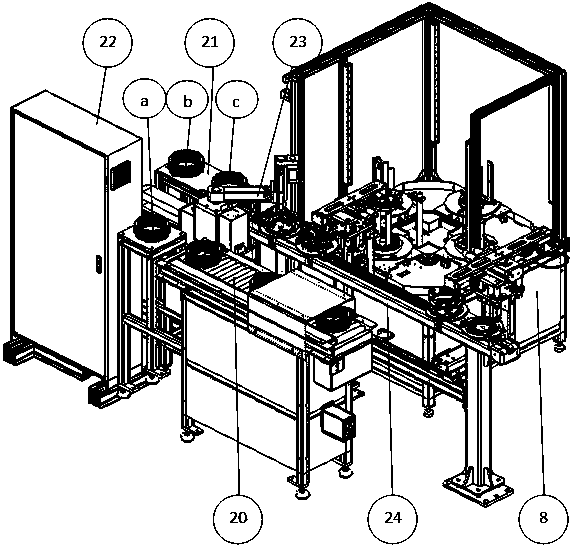

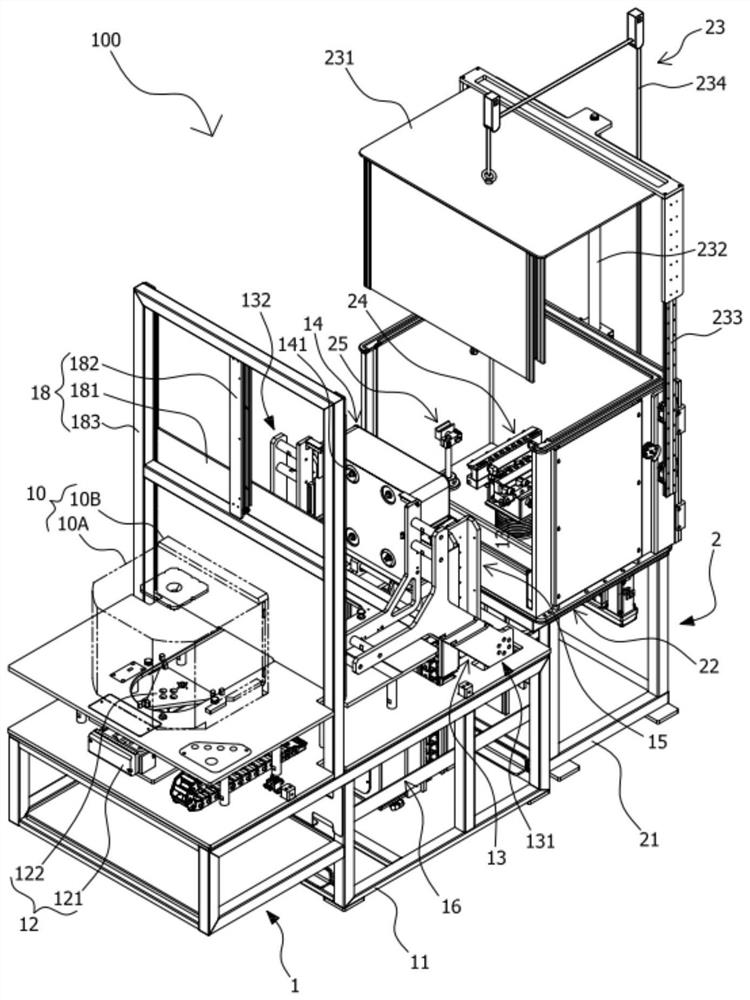

Wafer transfer box cleaning equipment and system

PendingCN113130347AAvoid stickingTight actionSemiconductor/solid-state device manufacturingParticle adhesionMechanical engineering

The invention provides wafer transfer box cleaning equipment and system which can save space, are compact in action and can avoid particle adhesion. The cleaning equipment comprises a front machine table and a rear machine table. The front machine table comprises a first frame body, a first horizontal displacement mechanism, a turnover mechanism, a suction device, a first vertical displacement mechanism, a front cleaning tank, a front cleaning device and a first isolation wall device; the rear machine table comprises a second frame body, a rear cleaning tank, a rear isolation device and a rear cleaning device; the front machine table can separate the box body from the door body, so that the door body descends, and the box body is overturned to the rear machine table for respective cleaning; the cleaning system comprises cleaning, moving, nitrogen charging and temporary storage equipment; the moving equipment can drive the wafer transfer box cleaned by the cleaning equipment to move; the nitrogen charging equipment can receive the wafer transfer box brought by the movement of the moving equipment from the cleaning equipment to charge nitrogen for the wafer transfer box; the temporary storage equipment can receive the wafer transfer box transferred by the moved equipment from the nitrogen charging equipment for temporary storage and output.

Owner:SEMTEK CORP

Fully-automatic straightening device for workpiece notch

Owner:温岭市卓一自动化设备有限责任公司

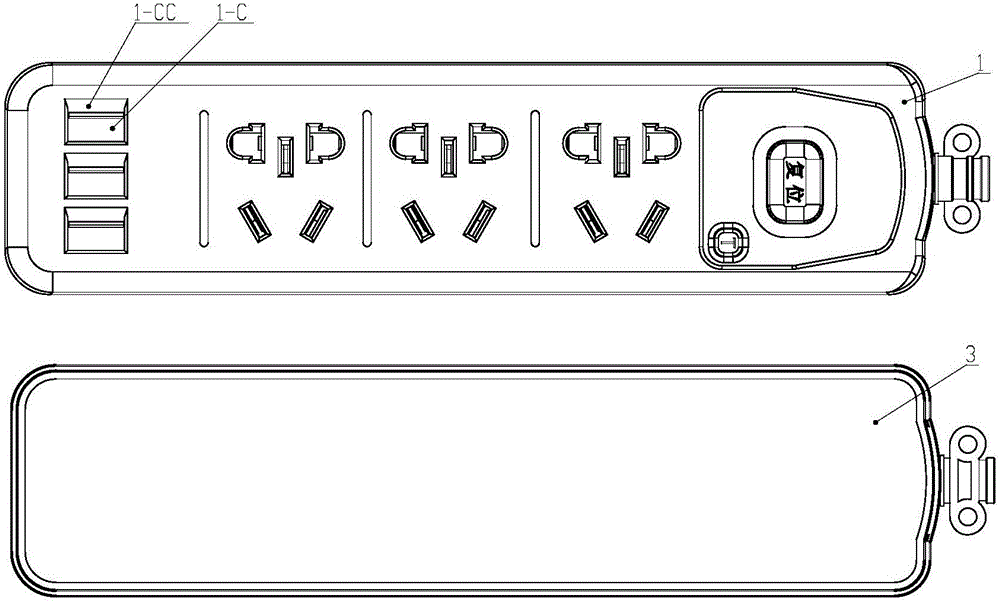

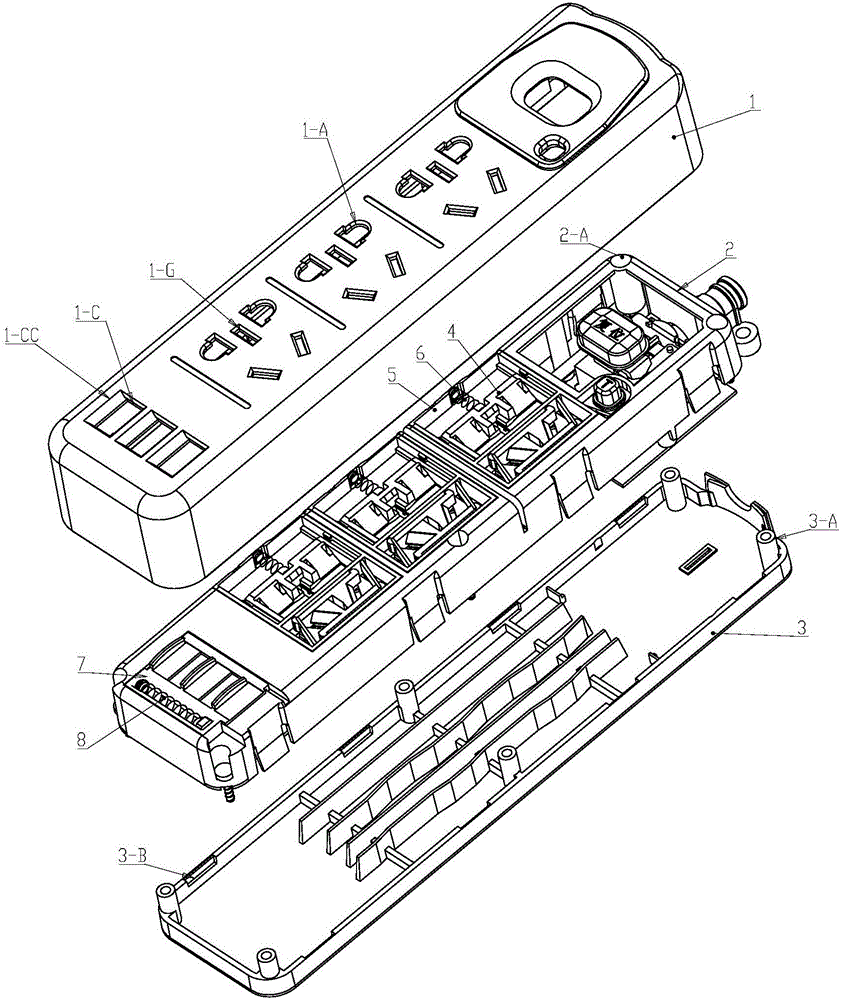

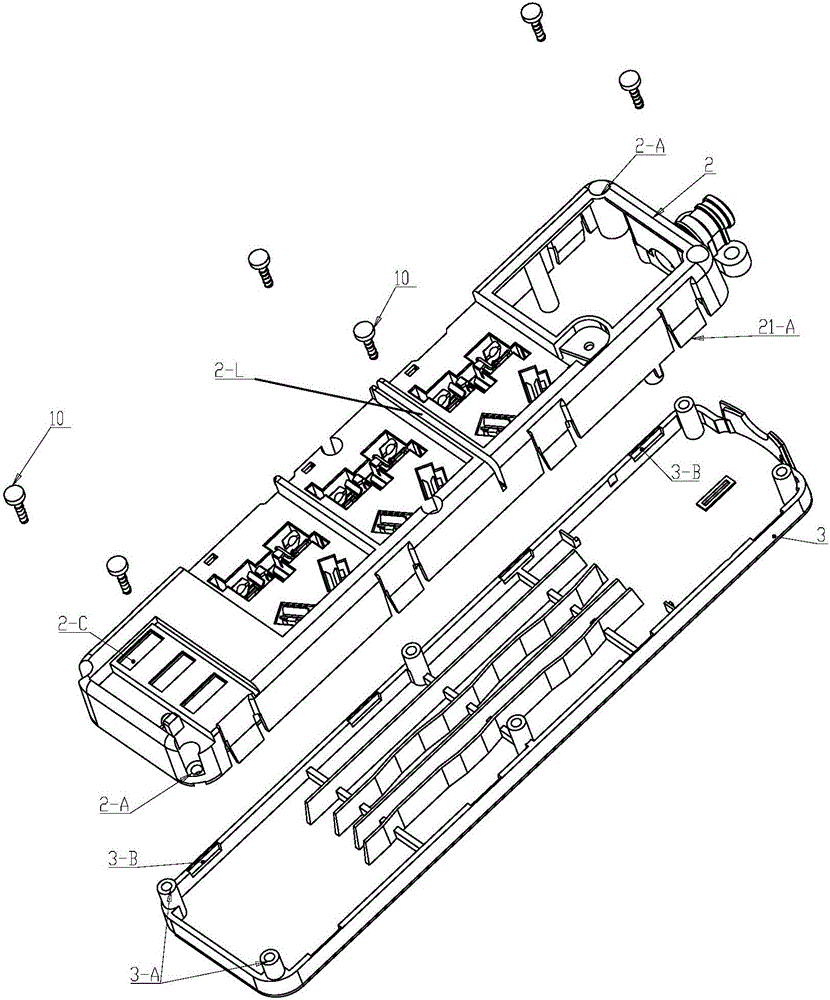

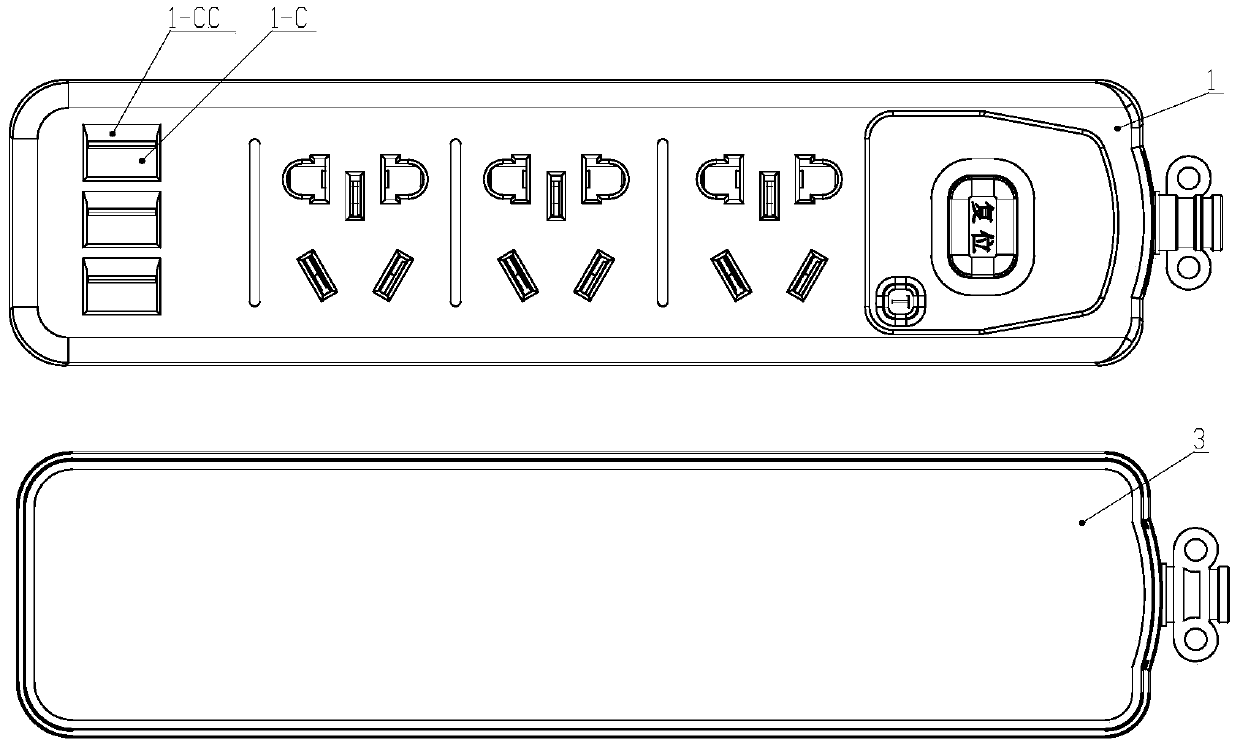

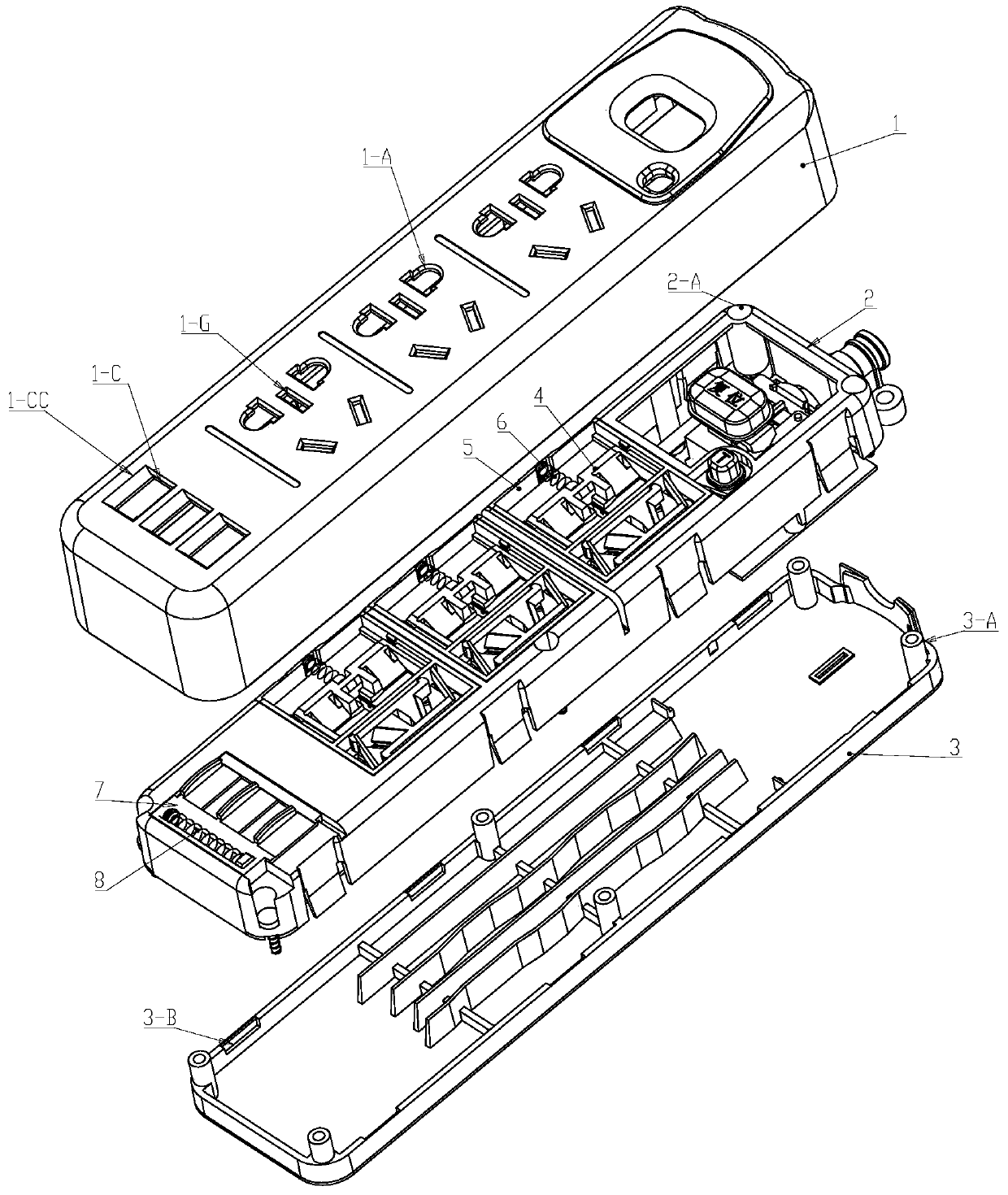

Wiring board

ActiveCN105006679AReduce resistance to movementAvoid stickingCoupling device detailsEngineeringDual purpose

The invention provides a wiring board comprising a top cover, a middle frame, and a bottom casing. The top cover is equipped with dual-purpose jacks and single jack baffle plates equipped with elastic repositioning mechanisms. Each single jack baffle plate is provided with a guiding slope on which a metallic slice is fixed. The top cover is equipped with USB sockets. One inner sidewall of each USB socket on the top cover is provided with a USB guiding slope. Each USB socket on the top cover is correspondingly provided with a USB baffle plate equipped with an elastic repositioning mechanism. Each USB baffle plate comprises a transverse sealing plate and a vertical pushing plate. The bottom casing is provided with a plurality of screw bolts. The middle frame is provided with a screw placing vertical groove. The screw placing vertical groove is provided with a screw nut stopping step. The inner sidewall of the top cover is connected with the outer sidewall of the middle frame through a buckling structure. The wiring board has beneficial effects that one baffle plate seals two jacks so as to simplify structure; each baffle plate is provided with the metallic slice so as to effectively prevent a plug from being jammed; each USB baffle plate is provided with the vertical pushing plate so as to achieve simple structure and stable and reliable operation; the middle frame is in screw connection with the bottom casing and the top cover is in buckled connection with the middle frame such that fast assembly and good firmness are achieved.

Owner:WENZHOU VAN SHEEN ELECTRIC APPLIANCE

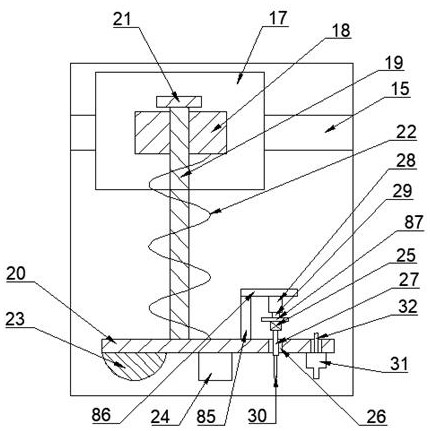

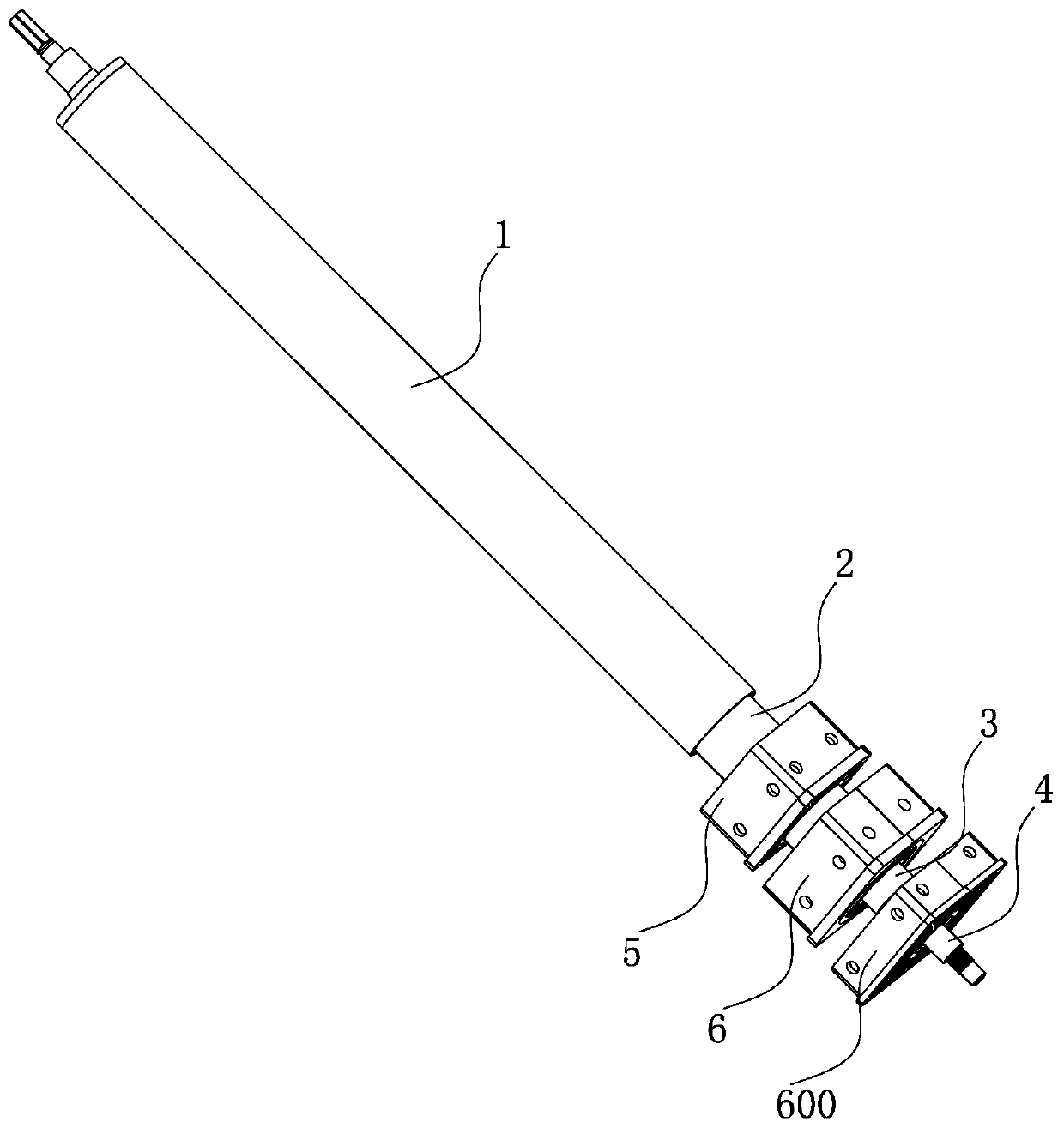

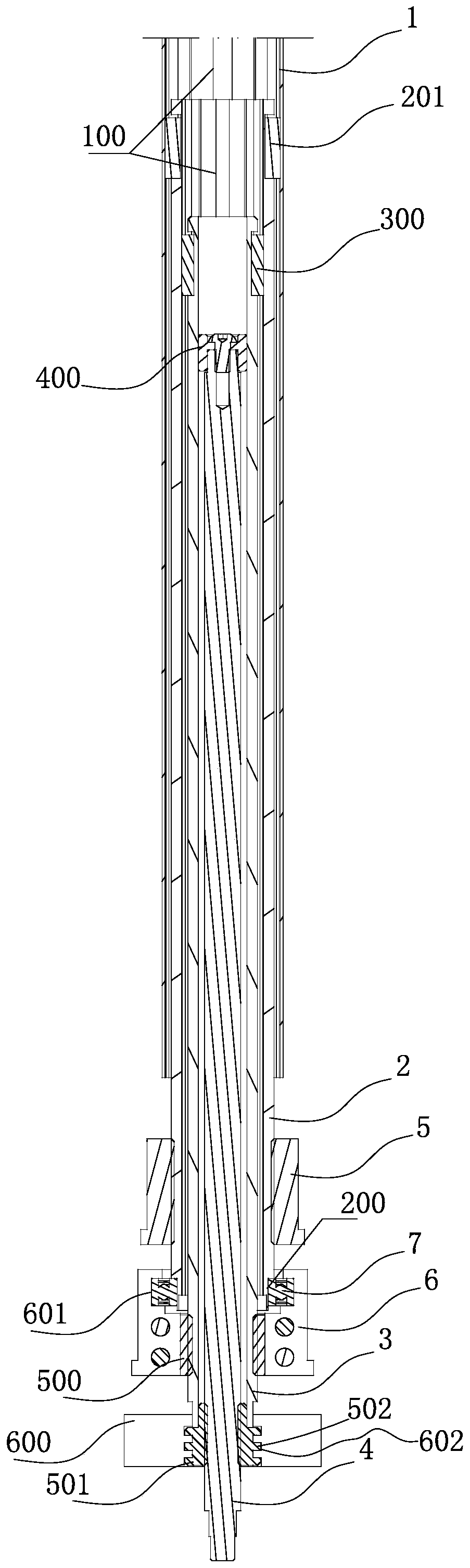

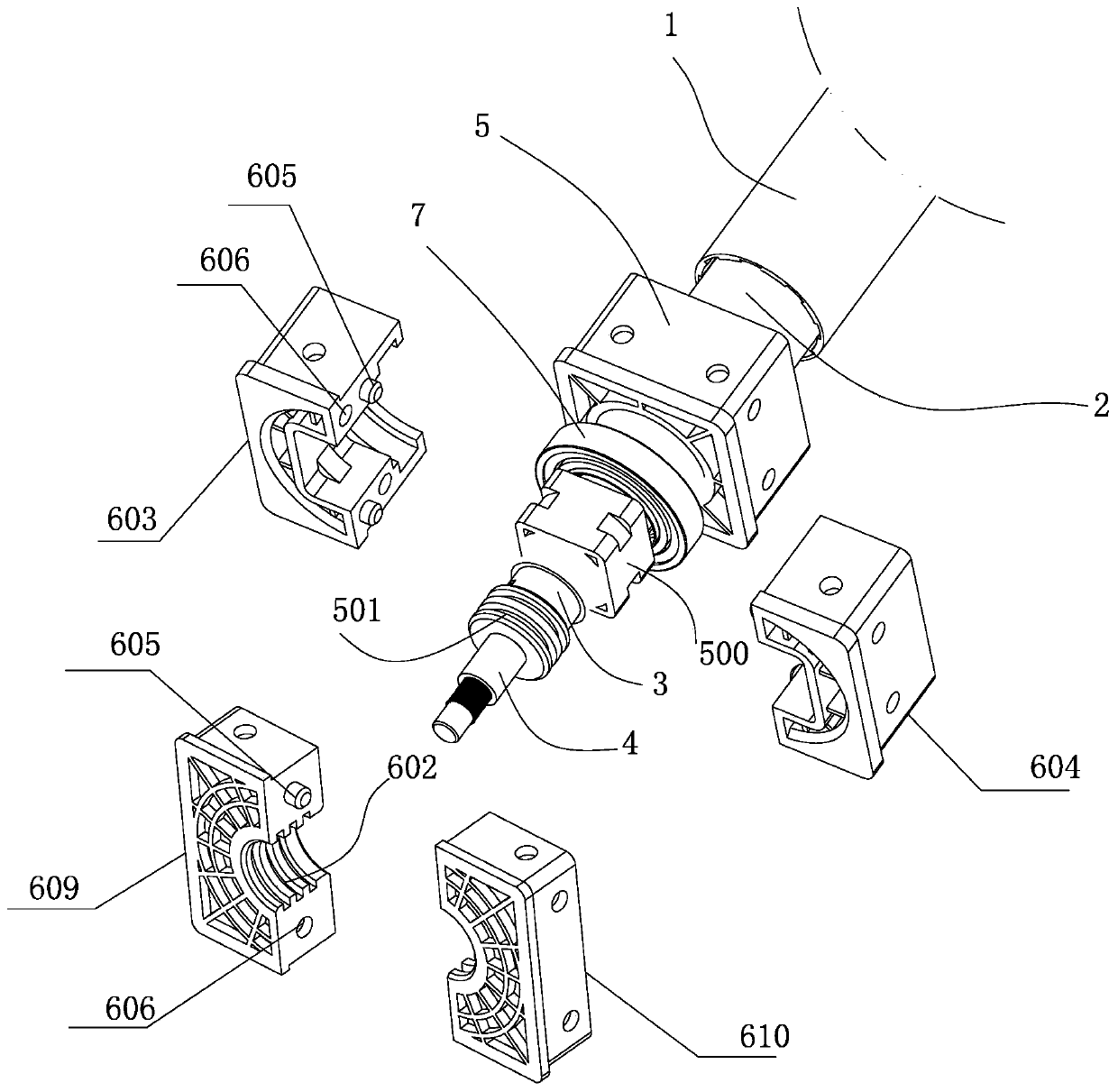

Linear transmission assembly and lifting table leg with application of linear transmission assembly

PendingCN110848352AIncrease the itinerarySatisfy travel maximization needsGearingFurniture partsScrew thread

The invention discloses a linear transmission assembly and a lifting table leg with application of the linear transmission assembly. The linear transmission assembly comprises a transmission tube, a first screw tube, a second screw tube and a lead screw, wherein the first screw tube can be synchronously rotated with the transmission tube, the first screw tube and the transmission tube can generatedisplacement through relative sliding in an axial direction, and a first transmission nut is in threaded connection to the first screw tube; the second screw tube can be synchronously rotated with the first screw tube, the second screw tube and the first screw tube can generate displacement by relative sliding, a second transmission nut is in threaded connection to the second screw tube, and a first connecting base is connected to the second transmission nut; the lead screw is fixedly disposed in the second screw tube, and the outer side wall of the lead screw is in clearance fitting with theinner wall of the second screw tube; a third transmission nut is in threaded connection to the lead screw, and the third transmission nut is connected to the second screw tube; and a second connecting base sleeves the third transmission nut, and the third transmission nut and the second connecting base are connected in a rotatable manner and limited axially. The linear transmission assembly and the lifting table leg with application of the linear transmission assembly can increase a stroke of a lifting upright.

Owner:ZHEJIANG LEGE INTELLIGENT DRIVE TECH CO LTD

Rolling-type adhesive tape pasting device

The invention relates to a rolling-type adhesive tape pasting device which comprises a mounting plate. A feeding tray is fixed to the upper left portion of the mounting plate, and a first guide rolleris fixed to the upper right portion of the mounting plate. A sensor is fixed to the middle position of the right end of the mounting plate, and a second guide roller is fixed to the lower right portion of the mounting plate. A rolling device is arranged at the left side of the second guide roller. A shearing device is fixed to the left side of the rolling device. The rolling device comprises a rolling fixed plate, a rolling wheel, a channel plate, a transition nozzle, a connecting rod, a power rod and a rolling air cylinder. The shearing device comprises a fixed plate, a translation air cylinder fixing rack, a translation air cylinder, a translation plate, a shearing air cylinder, a scissor tray and scissors. The rolling-type adhesive tape pasting device provided by the invention is simple in structure, stable in action, high in dimension control precision, compact in overall structure, capable of saving processing space and making rolling-type movements, smooth in action, easy to control and convenient to operate.

Owner:苏州恒铭达电子科技股份有限公司

power strip

ActiveCN105006679BReduce resistance to movementAvoid stickingCoupling device detailsPatch panelCPU socket

The invention provides a wiring board comprising a top cover, a middle frame, and a bottom casing. The top cover is equipped with dual-purpose jacks and single jack baffle plates equipped with elastic repositioning mechanisms. Each single jack baffle plate is provided with a guiding slope on which a metallic slice is fixed. The top cover is equipped with USB sockets. One inner sidewall of each USB socket on the top cover is provided with a USB guiding slope. Each USB socket on the top cover is correspondingly provided with a USB baffle plate equipped with an elastic repositioning mechanism. Each USB baffle plate comprises a transverse sealing plate and a vertical pushing plate. The bottom casing is provided with a plurality of screw bolts. The middle frame is provided with a screw placing vertical groove. The screw placing vertical groove is provided with a screw nut stopping step. The inner sidewall of the top cover is connected with the outer sidewall of the middle frame through a buckling structure. The wiring board has beneficial effects that one baffle plate seals two jacks so as to simplify structure; each baffle plate is provided with the metallic slice so as to effectively prevent a plug from being jammed; each USB baffle plate is provided with the vertical pushing plate so as to achieve simple structure and stable and reliable operation; the middle frame is in screw connection with the bottom casing and the top cover is in buckled connection with the middle frame such that fast assembly and good firmness are achieved.

Owner:WENZHOU VAN SHEEN ELECTRIC APPLIANCE

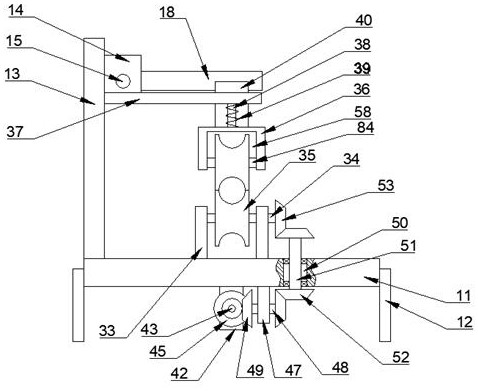

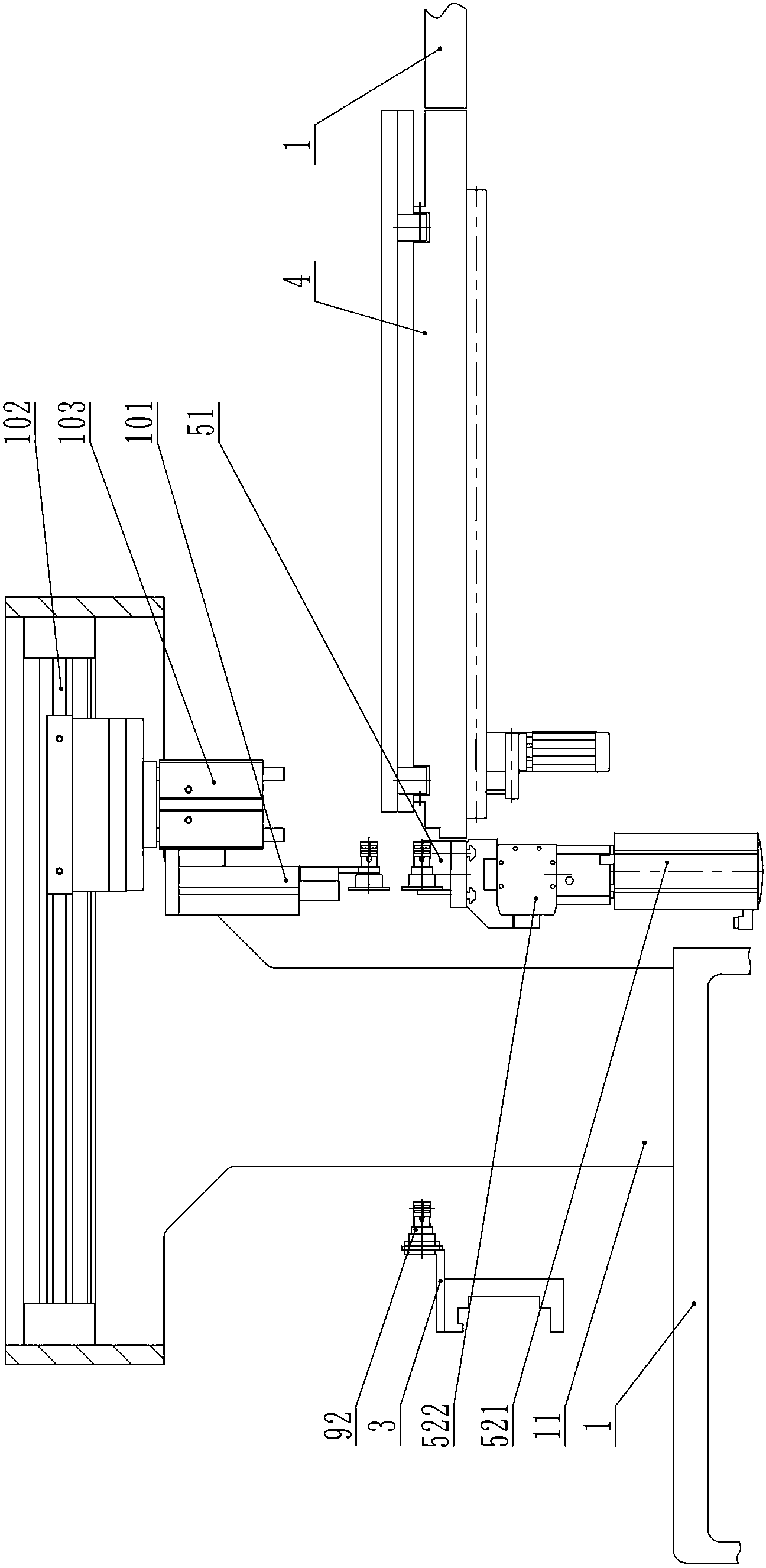

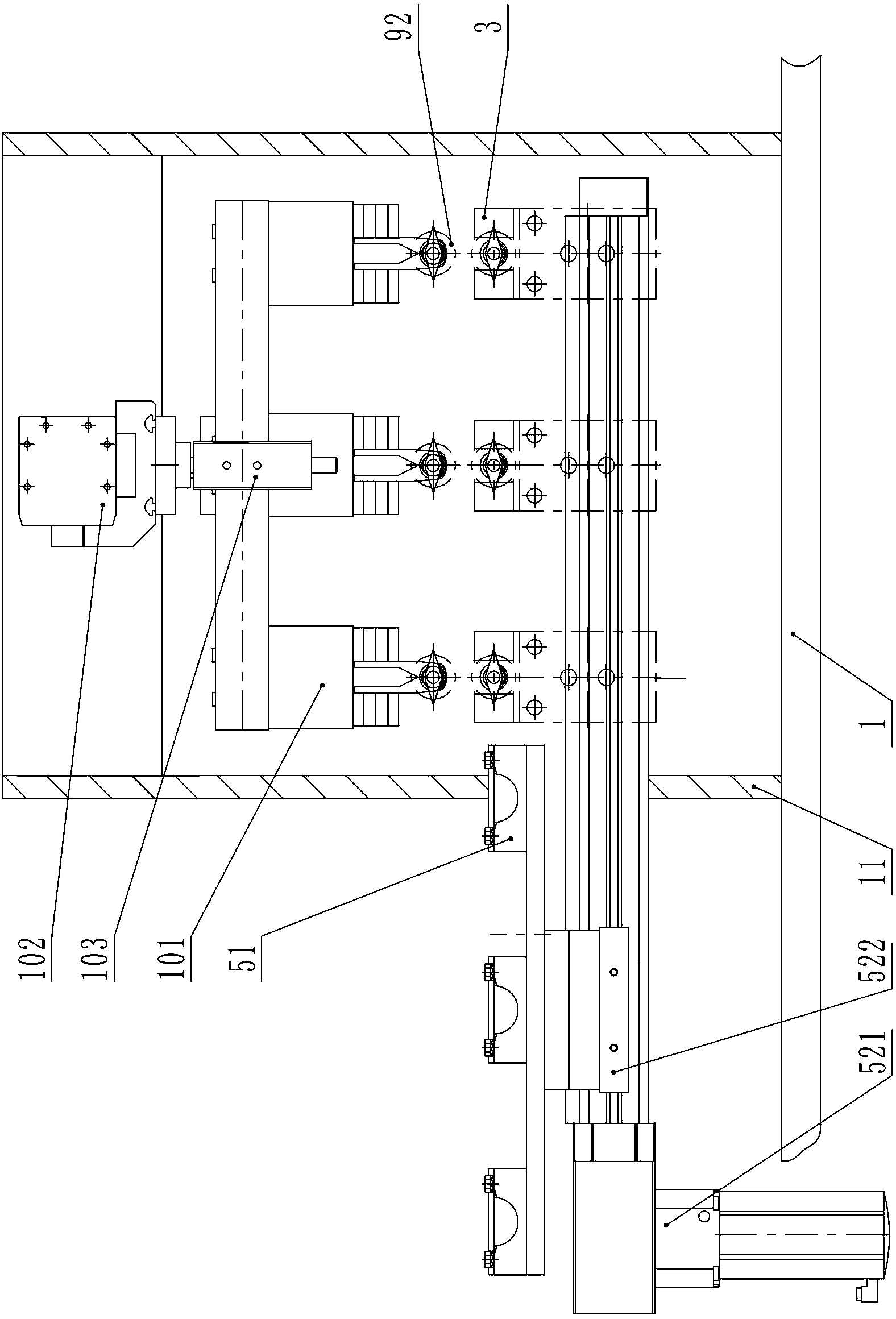

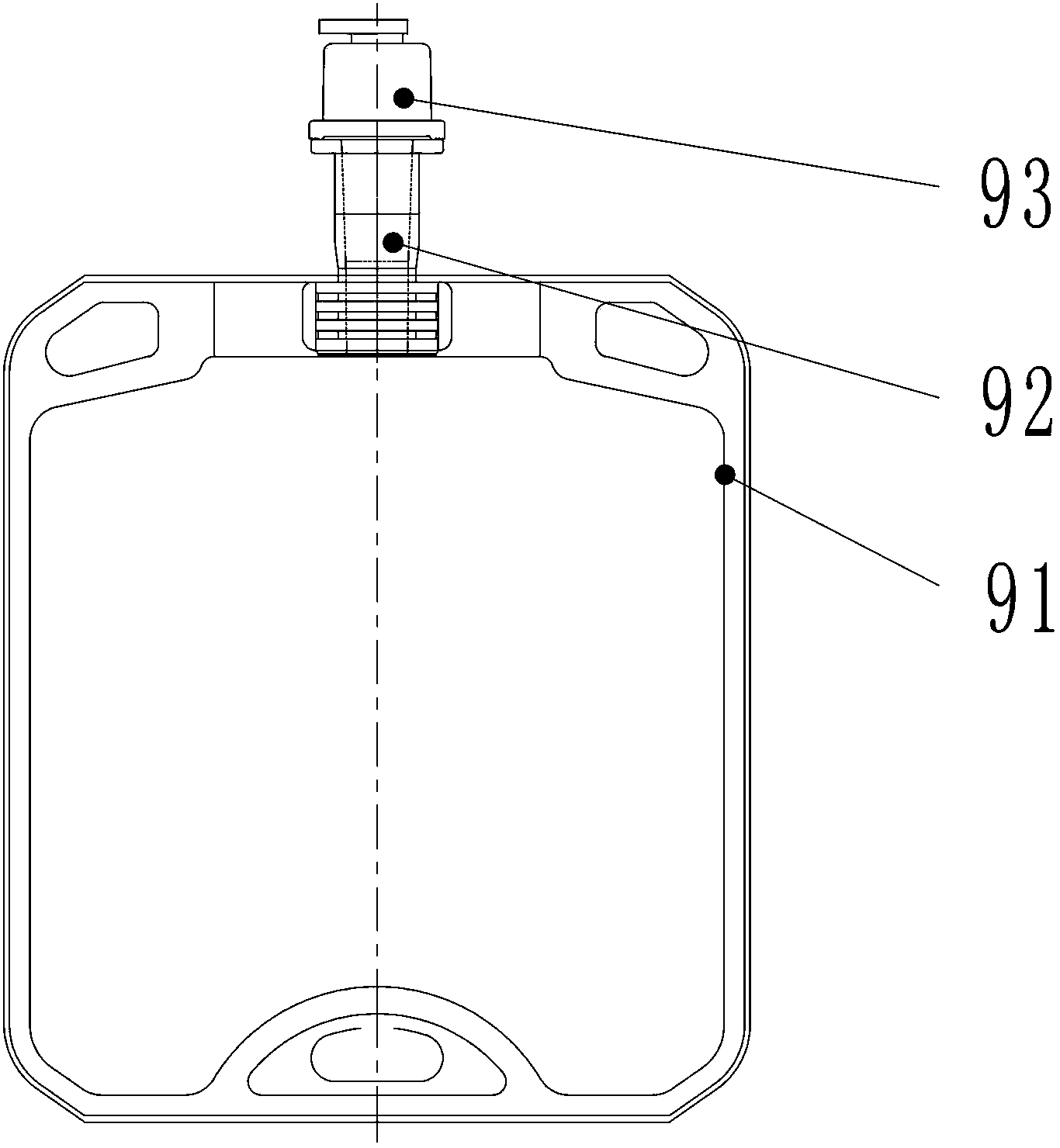

Connector installing device for large soft infusion bag production line

ActiveCN103434675AImprove accuracyCompact structureBox making operationsPaper-makingProduction lineEngineering

The invention discloses a connector installing device for a large soft infusion bag production line. The connector installing device for the large soft infusion bag production line comprises a connector transmitting sliding way mechanism (4), a connector clamp mechanism (3) and a connector pushing mechanism (6), wherein the connector pushing mechanism (6) is used for pushing connectors (92) into the connector clamp mechanism (3) in the transmitting direction of the connector transmitting sliding way mechanism (4), and the connector pushing mechanism (6) is placed on one side of the connector transmitting sliding way mechanism (4). The connector installing device for the large soft infusion bag production line has the advantages of being simple and compact in structure, low in cost, high in reliability, high in work efficiency and the like.

Owner:TRUKING TECH LTD

Intelligent plate conveying and collection mechanism applied to LED full-color plate plug-in

InactiveCN105501965ASimple structureImprove stabilityCharge manipulationConveyor partsLED lampMechanical engineering

The invention discloses an intelligent plate conveying and collection mechanism applied to an LED full-color plate plug-in. The mechanism comprises a plate conveying mechanism, a moving mechanism, a plate fixing mechanism, a plate clamping mechanism and a plate abutting mechanism. The plate conveying mechanism comprises a machine frame, a front conveying portion and a rear conveying portion which are used for controlling plate conveying. The plate fixing mechanism comprises a clamping plate used for plate fixing. The clamping plate is arranged on the surface of the rear conveying portion of the machine frame in a slidable mode. The clamping mechanism comprises a first vertical air cylinder, a push-pull device and a plate supporting device and used for driving the abutting plate mechanism to fixing a plate. The plate supporting device comprises a first clamping plate and a second clamping plate which are located on the two sides of the machine frame. The side portion of the first clamping plate and the side portion of the second clamping plate are provided with a plurality of containing cavities and spring supporting tongues arranged inside the containing cavies and used for plate collection. The intelligent plate conveying and collection mechanism has the advantages that the structure is simple, LED lamp panel pushing is more stable, the whole plate conveying mechanism and the whole plate collection mechanism are in close fit, the motion is coordinated and compact, the production efficiency is improved, and the market application value is good.

Owner:SHENZHEN SHENGTIANDA AUTOMATION TECH CO LTD

Injection mold for upper shell of automobile air filter

The invention discloses an injection mould for an upper housing of a car air filter. The injection mould comprises a fixed mould assembly (1), a movable mould assembly (2), a lateral loose core device (3) and an oblique loose core device (4), wherein the fixed mould assembly comprises a fixed mould seat plate (11), a fixed mould plate (12) and a cavity (13); the movable mould assembly comprises a movable mould seat plate (21), a movable mould supporting plate (22), a movable mould plate (23), a cavity (24) and a mould pushing device (25); the lateral loose core device comprises a telescopic push-pull mechanism (31), a mounting plate (32) and a lateral loose core (24); the oblique loose core device comprises a wedge-shaped supporting plate (41), a supporting baffle (42), a traction mechanism (43) and an oblique loose core (44). According to the injection mould, mutually staggered plastic parts along the loose cores can be conveniently manufactured and repaired, easily damaged parts can be conveniently replaced, the service life of the mould can be prolonged, the precision of the plastic parts can be guaranteed, and the maintenance expense of the mould can be reduced.

Owner:青岛宇信机电科技有限公司

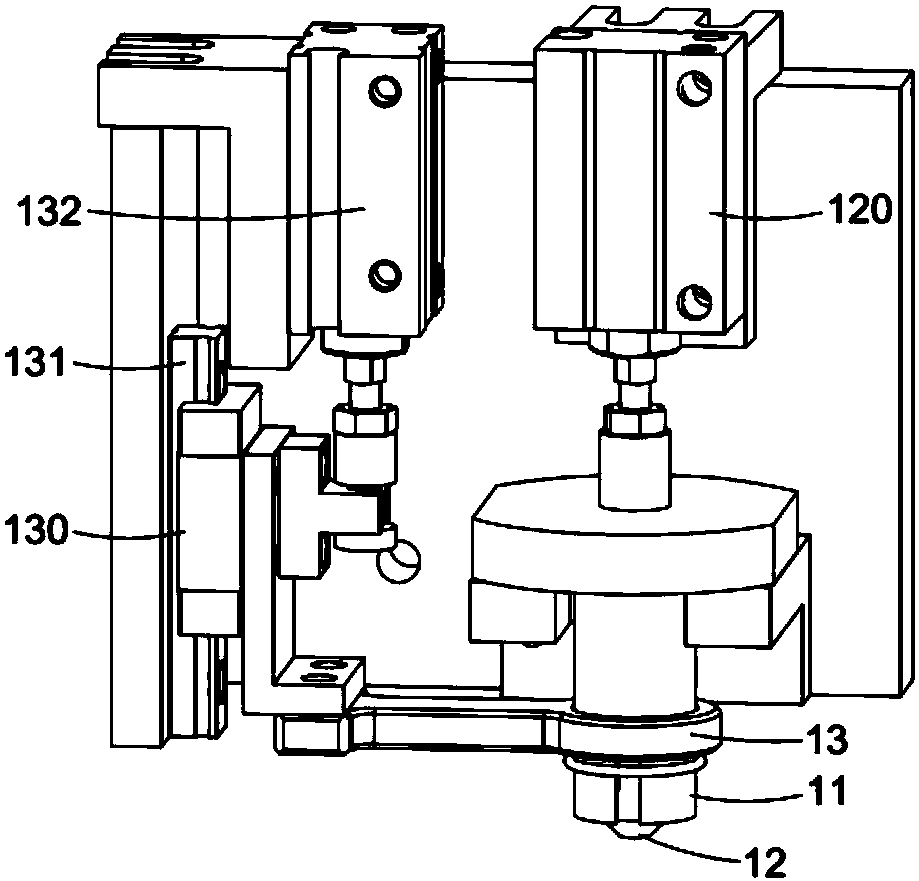

A sealing ring assembly device

ActiveCN106217014BReduced precision requirementsLow costMetal working apparatusDegrees of freedomEngineering

The invention discloses an assembly device for a seal ring. The assembly device comprises a locating assembly part and floating assembly jigs which are arranged up and down, wherein the floating assembly jigs are of three-layer structures; clamping locating mechanisms are arranged at the uppermost layers; the lower two layers adopt vertical crossed linear slide rails, so that the uppermost layers have finite degrees of freedom in the X and Y directions; before seal ring assembly, a locating cone head in the locating assembly part is inserted into a product for guide locating, floating in the X and Y directions is limited, and the to-be-assembled product is forced to be coaxial with the locating cone head and a charging head; and then, the seal ring on the charging head passively slides downwards to a groove of the to-be-assembled product, and assembly is completed. According to the assembly device, a two-time locating manner is utilized, the precision requirement on a rotary disc driving part, a horizontal carrying module and a vertical carrying module is greatly reduced, and the cost is greatly reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

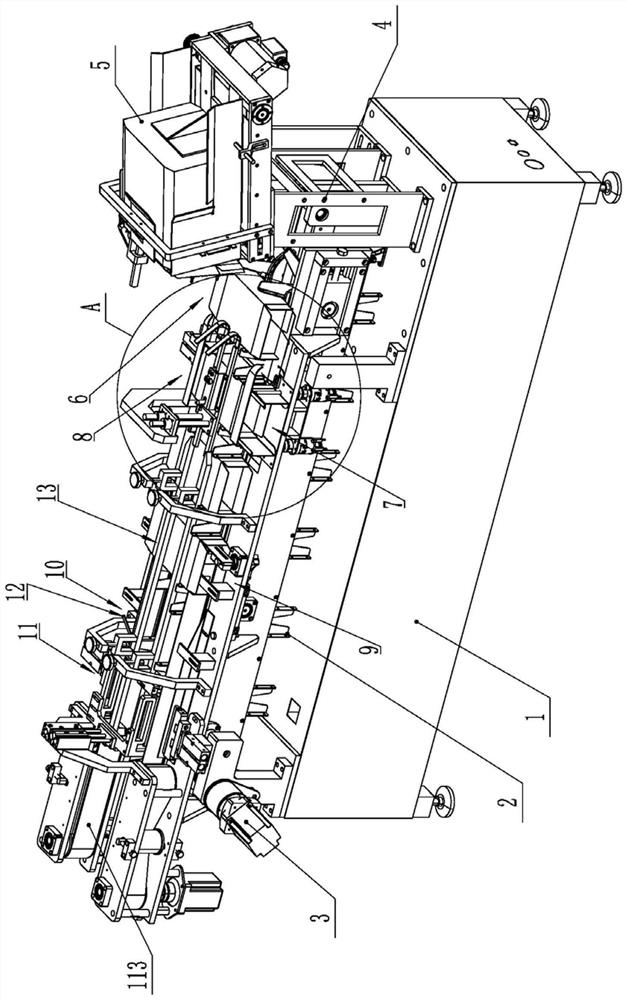

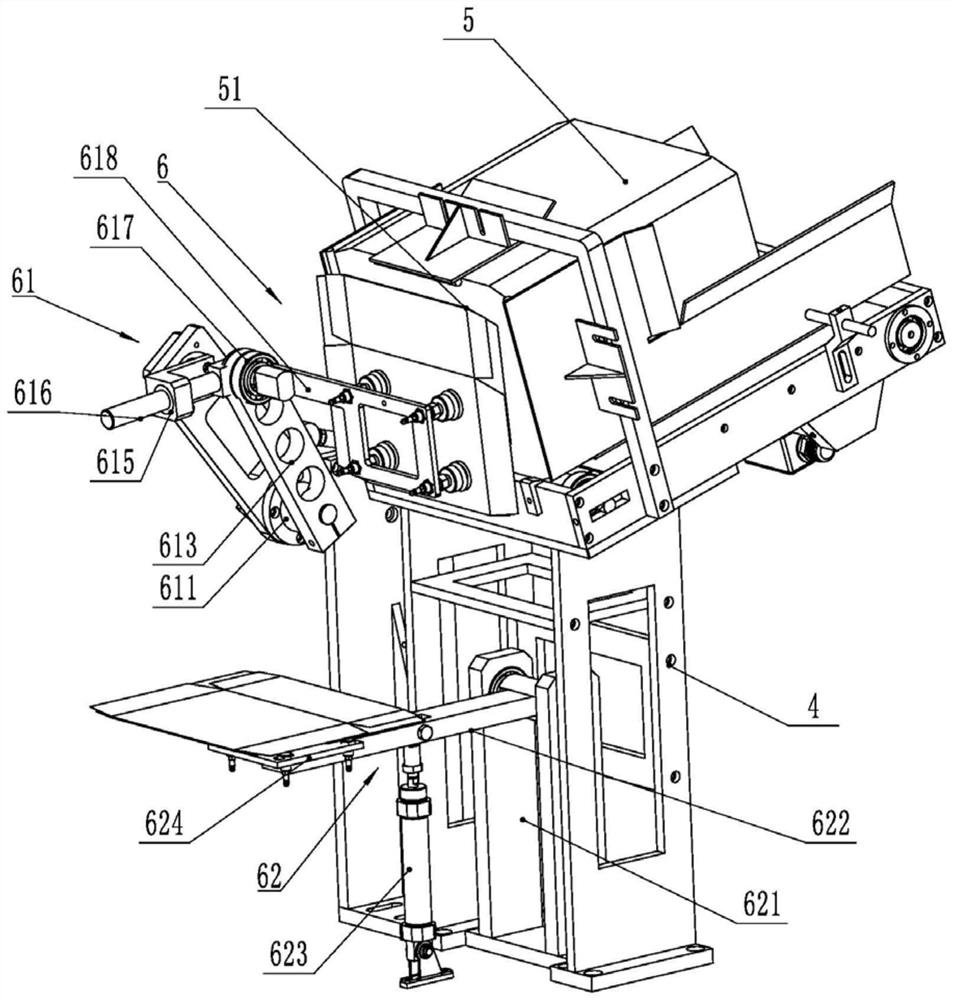

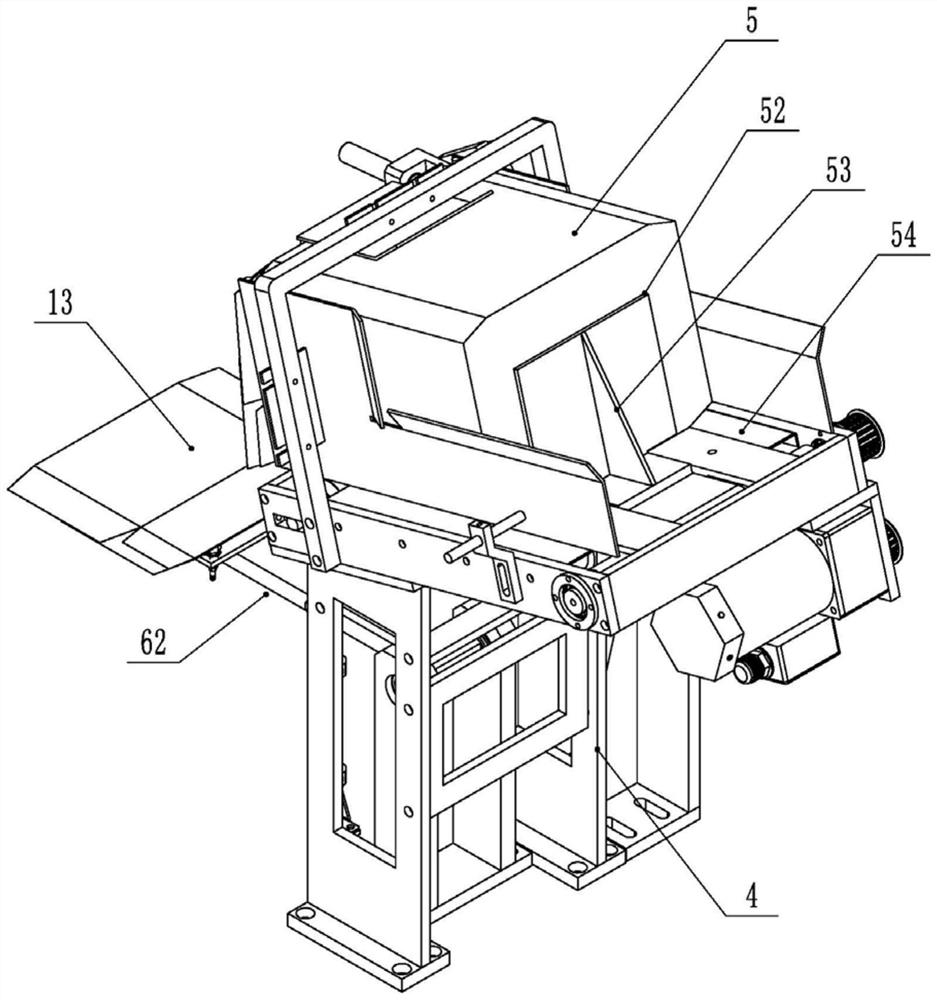

Automatic box sealing and packaging method for pastries

ActiveCN113306786ATight actionHigh degree of automationPackagingIndustrial engineeringPacking method

The invention discloses an automatic box sealing and packaging method for pastries. The method comprises the following steps that S1, a packaging box is placed in a storage bin; S2, an upper deflection box taking mechanism sucks the packaging box and deflects, and a lower deflection suction mechanism deflects upwards to suck the bottom of the packaging box so that the packaging box can be unfolded and fall into a placement area; S3, moving to the next station downstream is conducted; S4, an upper cover piece, a lower cover piece, an upstream side cover piece and a downstream side cover piece at the boxing end of the packaging box are opened through an uncovering mechanism; S5, moving to the next station downstream is conducted; S6, a side cover piece closing mechanism closes the upstream side cover piece and the downstream side cover piece at the two ends of the packaging box; S7, moving to the next station downstream is conducted, and the lower cover piece and the upper cover piece are closed; S8, heat sealing is conducted on the two ends of the packaging box; and S9, the packaging box enters a conveying area between two side pressure circulating conveying belts to be extruded and then is sent out. According to the automatic box sealing and packaging method, automatic box taking, box opening, cover opening, boxing, cover closing and heat sealing can be achieved, and efficiency is higher.

Owner:哈工大机器人南昌智能制造研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com