Wafer transfer box cleaning equipment and system

A technology for wafer transfer boxes and cleaning equipment, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc. It can solve the problems of solid particle pollution, long maintenance time, and time difficulties, and achieve short maintenance time and less space occupation , the effect of reducing the possible pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0120] According to the embodiment shown in the drawings, the detailed description is as follows:

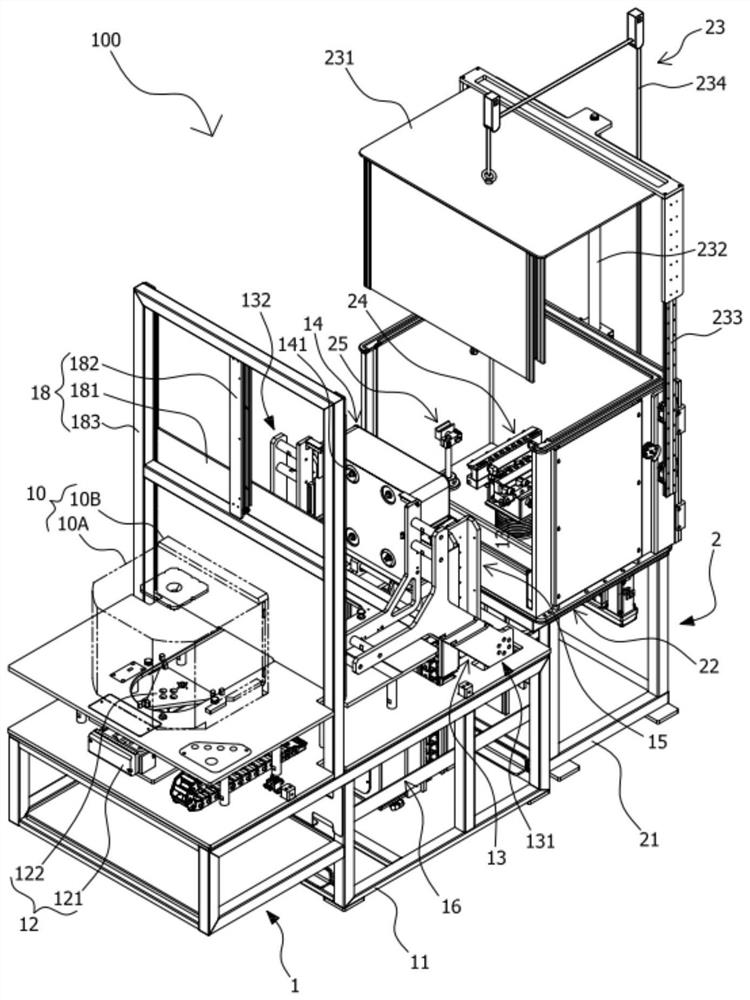

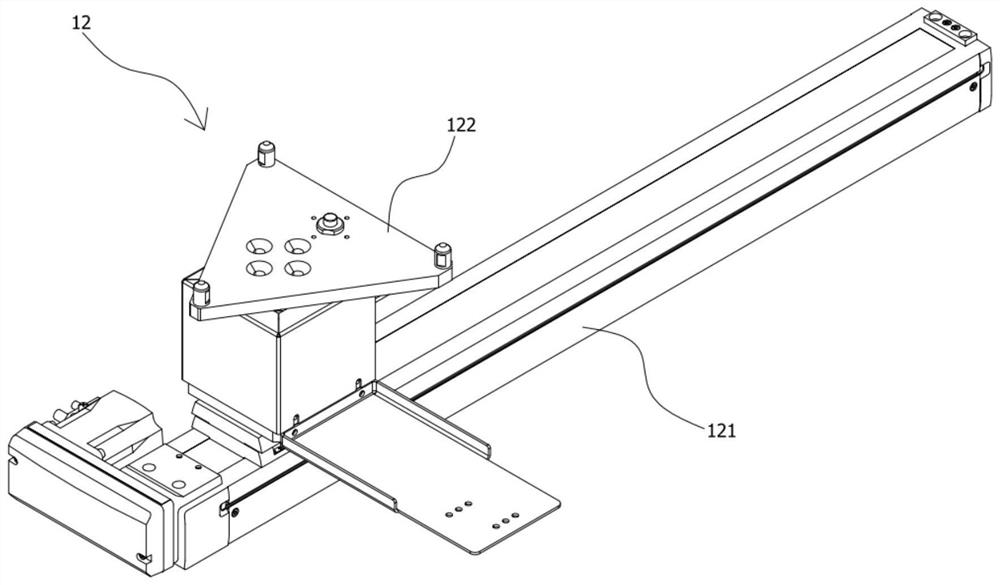

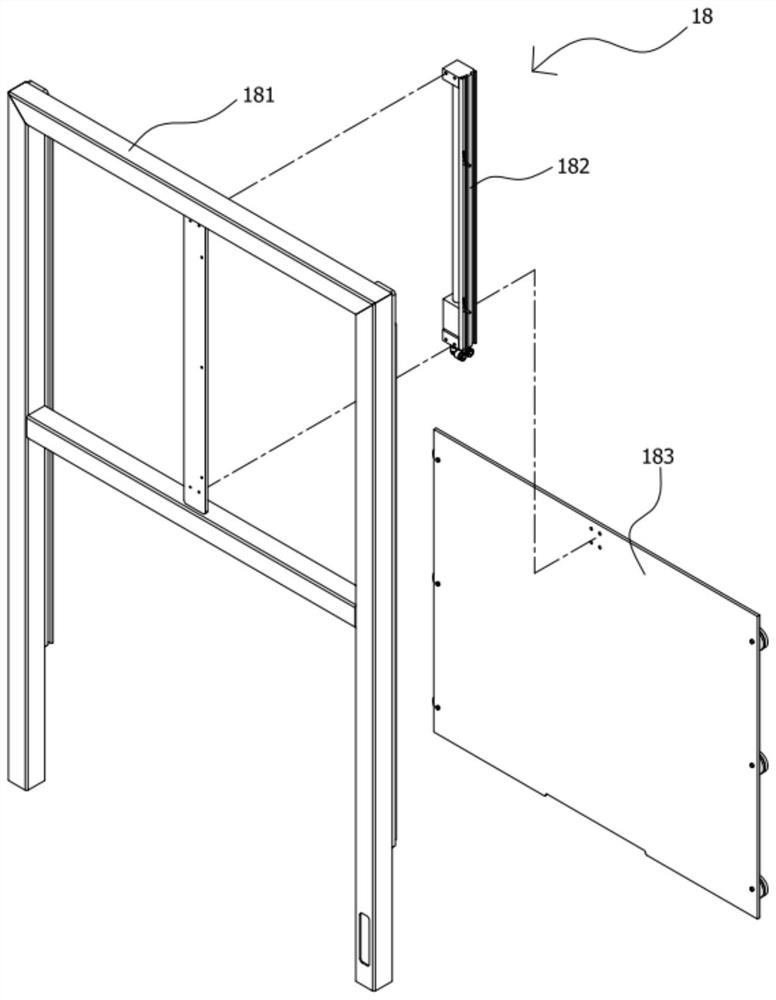

[0121] Such as Figure 1 to Figure 12 As shown, what is disclosed in the figure is a FOUP cleaning device. The cleaning device 100 can be applied to cleaning the FOUP 10. It is characterized in that: the cleaning device 100 includes at least At least one front machine platform 1 and one rear machine platform 2 located at the rear side end of said front machine platform 1; said front machine platform 1 includes a first frame body 11, a The first horizontal displacement mechanism 12 at the front side of the top end of the body 11, the flipping mechanism 13 arranged at the rear side of the top of the first frame body 11 corresponding to the first horizontal displacement mechanism 12, and the flipping mechanism 13 corresponding to the flipping mechanism at the top rear side of the first frame body 11 13 and the suction device 14 arranged at the top rear side of the first frame body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com