Continuous production equipment of embossed gypsum ceiling

A production equipment and ceiling technology, applied to ceramic molding machines, manufacturing tools, etc., can solve the problems of large workshop area, uncompacted and smoothed slurry, cumbersome work procedures, etc., and achieve high quality of finished products and high production efficiency , the effect of a single program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

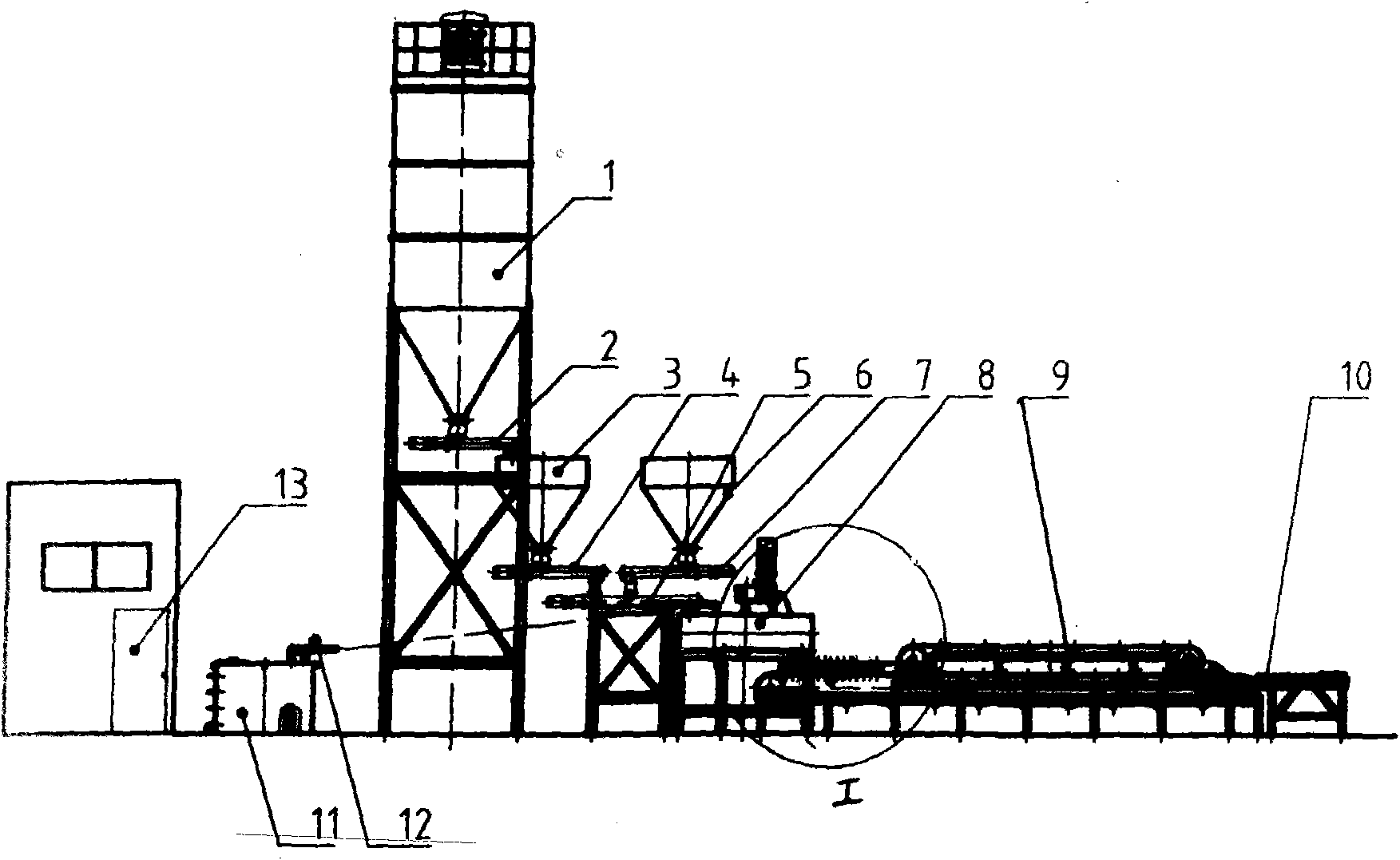

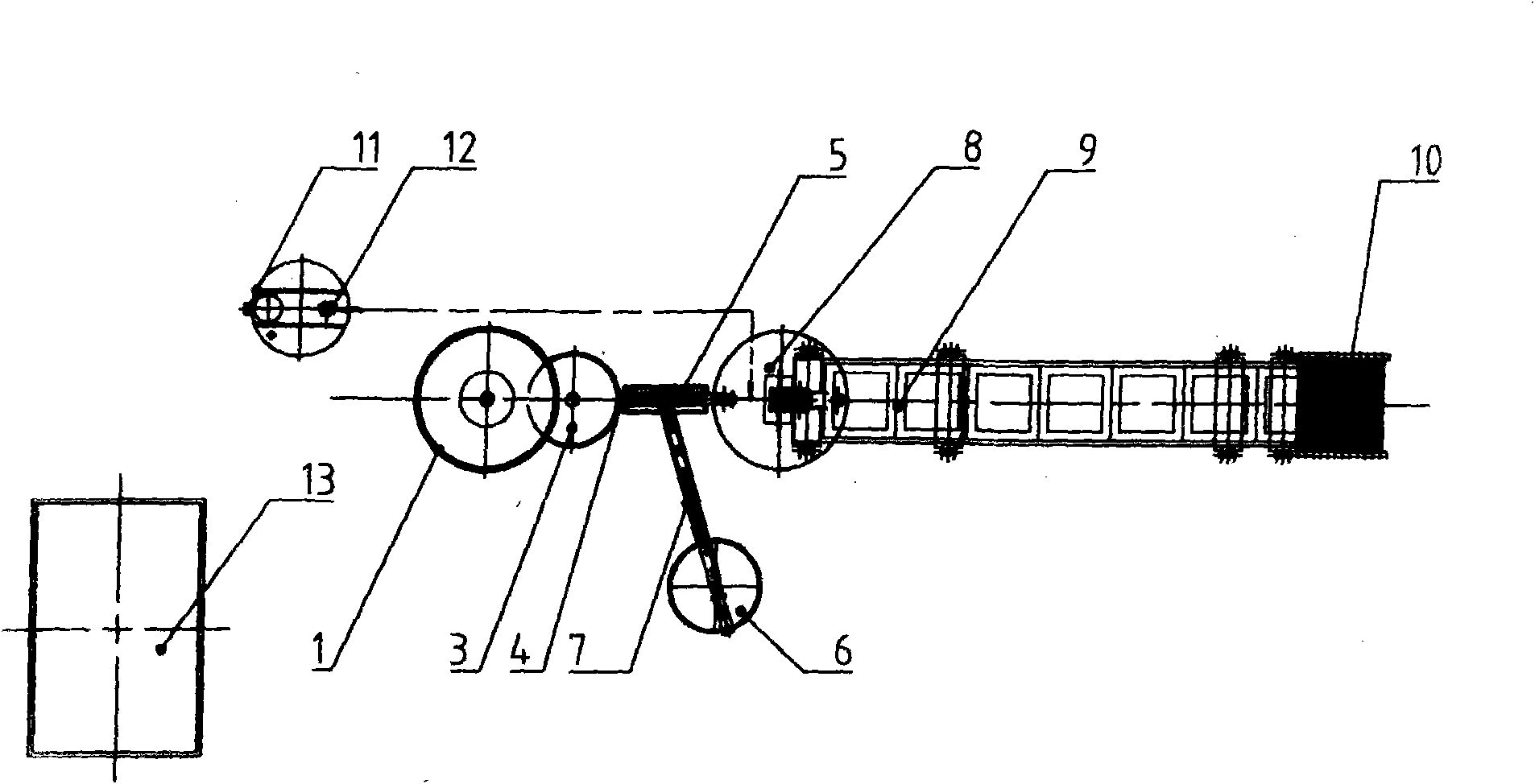

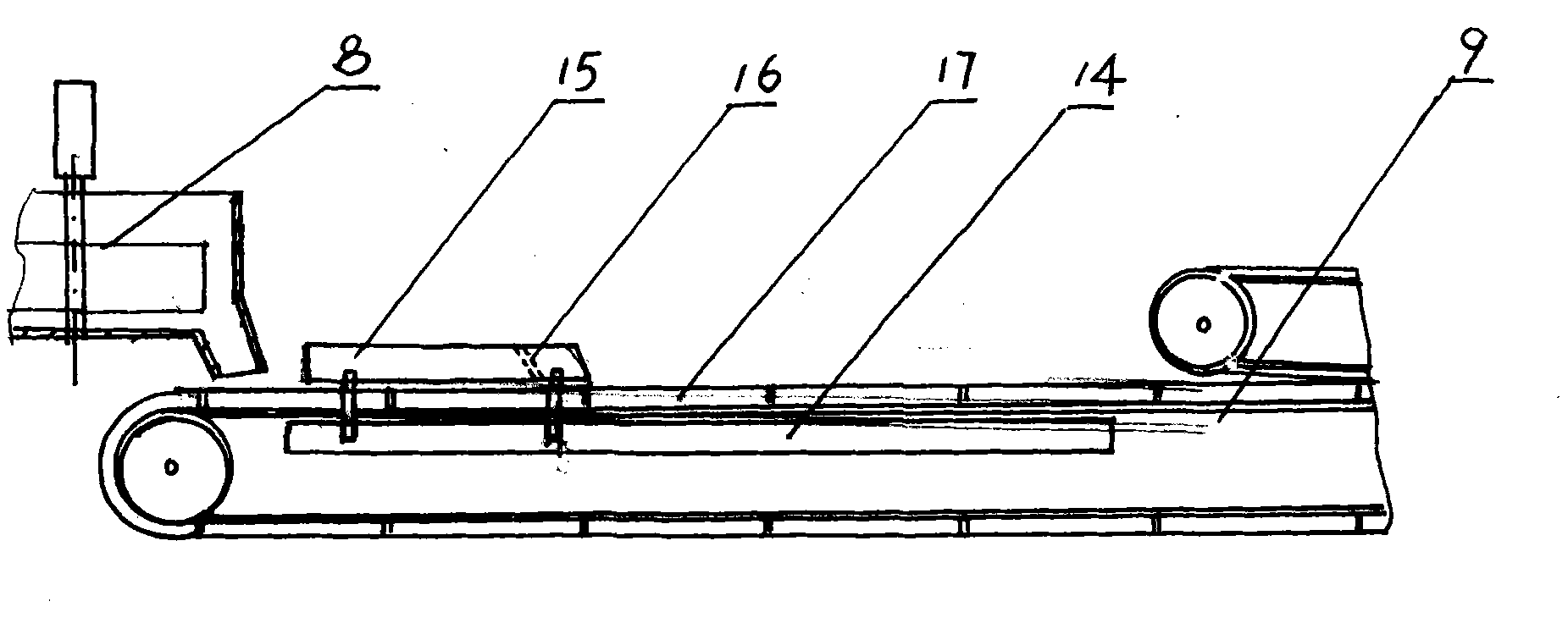

[0020] Such as figure 1 As shown, the continuous production equipment for embossed gypsum ceiling of the present utility model includes a raw material conveying mechanism, a mixer 8, a water tank 11, a shaking table 14, a finished product clamping and demoulding mechanism 9, a finished product roller conveyor 10 and a power distribution control box 13; wherein:

[0021] The raw material conveying mechanism comprises a gypsum powder temporary storage bin 3, a fiber bin 6, a dry powder metering conveyor 4, a fiber metering conveyor 7 and a mixing screw conveyor 5, wherein the output of the gypsum powder temporary storage bin 3 and the fiber bin 6 The feed port is connected to the feed port of the mixture screw conveyor 5 through the dry powder metering conveyor 4 and the fiber metering conveyor 7 respectively; during operation, the dry powder from the gypsum powder bin 1 is transported to the gypsum powder temporary storage bin through the screw conveyor 2 3. The powder in the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com