Variable pitch propeller

A variable-pitch propeller and propeller root technology, which is applied to propellers, aircraft parts, transportation and packaging, etc., can solve the problems of complex structure and action, matching problems of connection parts, high cost of blades, etc., and achieve simple and compact structure and guaranteed connection strength , The effect of simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

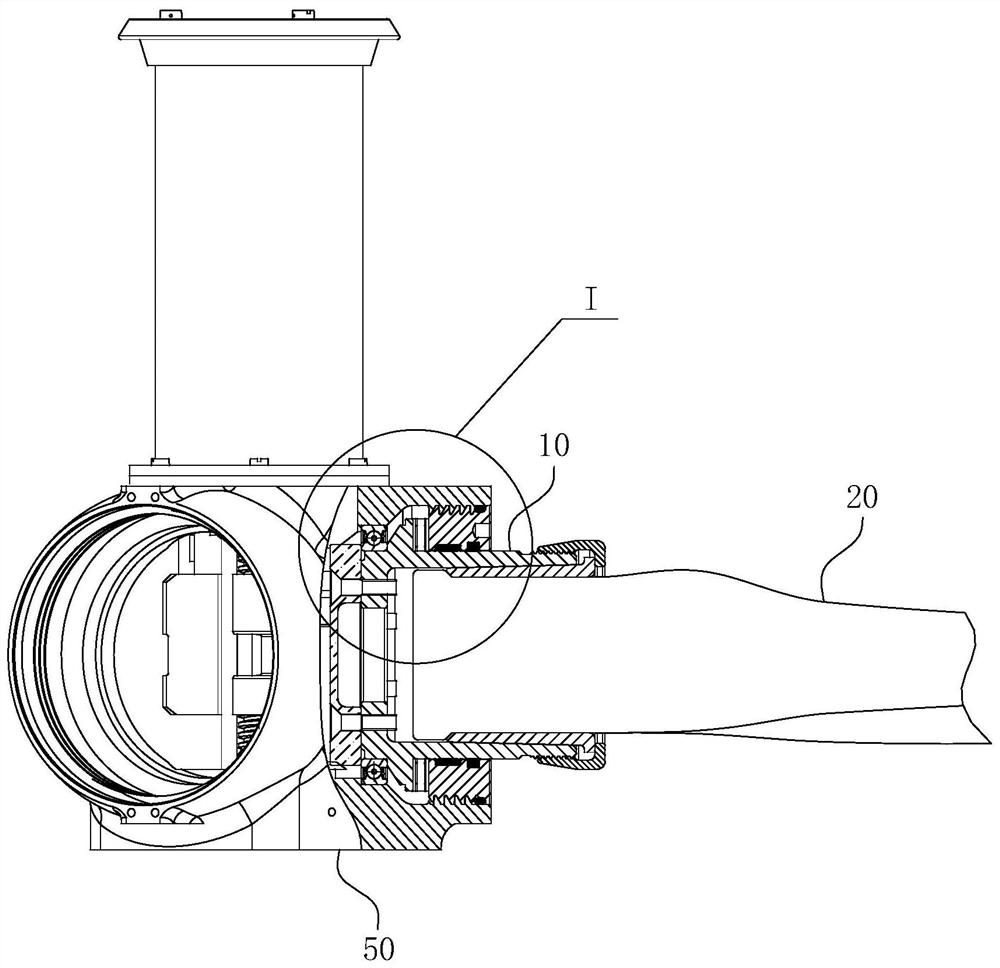

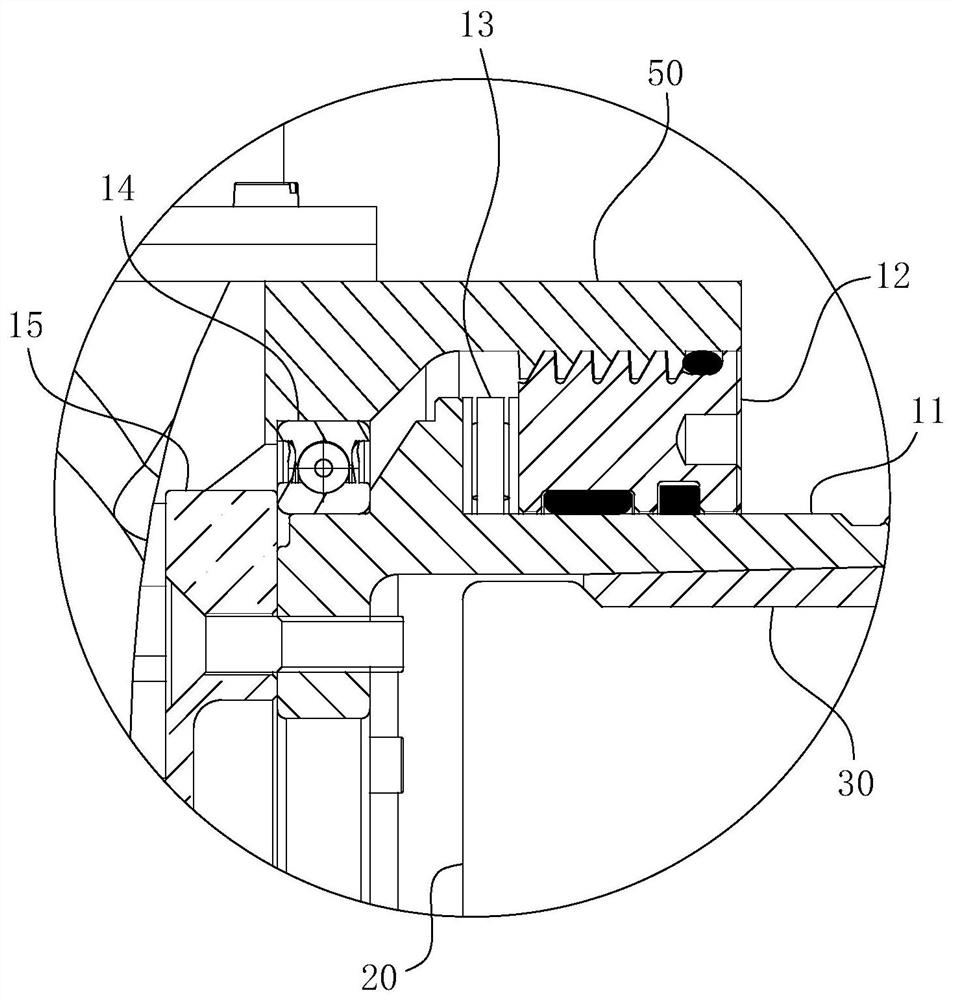

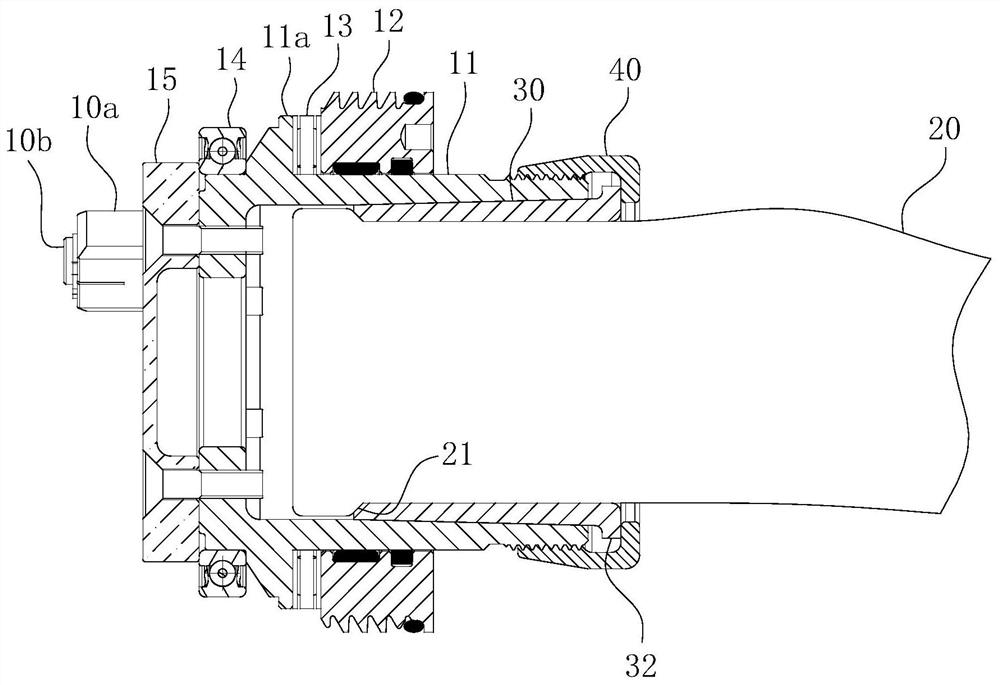

[0059] For ease of understanding, here in conjunction with accompanying drawing, the concrete structure of the present invention and working mode are further described as follows:

[0060] The specific structure of the present invention is as Figure 1-17 As shown, it is mainly based on the variable-pitch rotary assembly that realizes the controllable rotation of the blade relative to the hub 50, supplemented by a variable-pitch drive assembly that drives the variable-pitch rotary assembly to generate action, and an induction that automatically switches the action mode of the variable-pitch actuator assembly. Components, thereby jointly forming three major modules of the present invention. For easier understanding, the variable pitch rotary assembly can be regarded as mainly aimed at the change of the blade, the variable pitch drive assembly is mainly aimed at the change of the inner structure of the propeller hub 50 , and the induction component is mainly aimed at the change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com