power strip

A plug-in board and socket technology, which is applied in the direction of coupling devices, electrical components, connections, etc., can solve the problems of potential safety hazards, damage, and safety, and achieve the effects of effective use of space, stable and reliable movements, and fast and accurate assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further described:

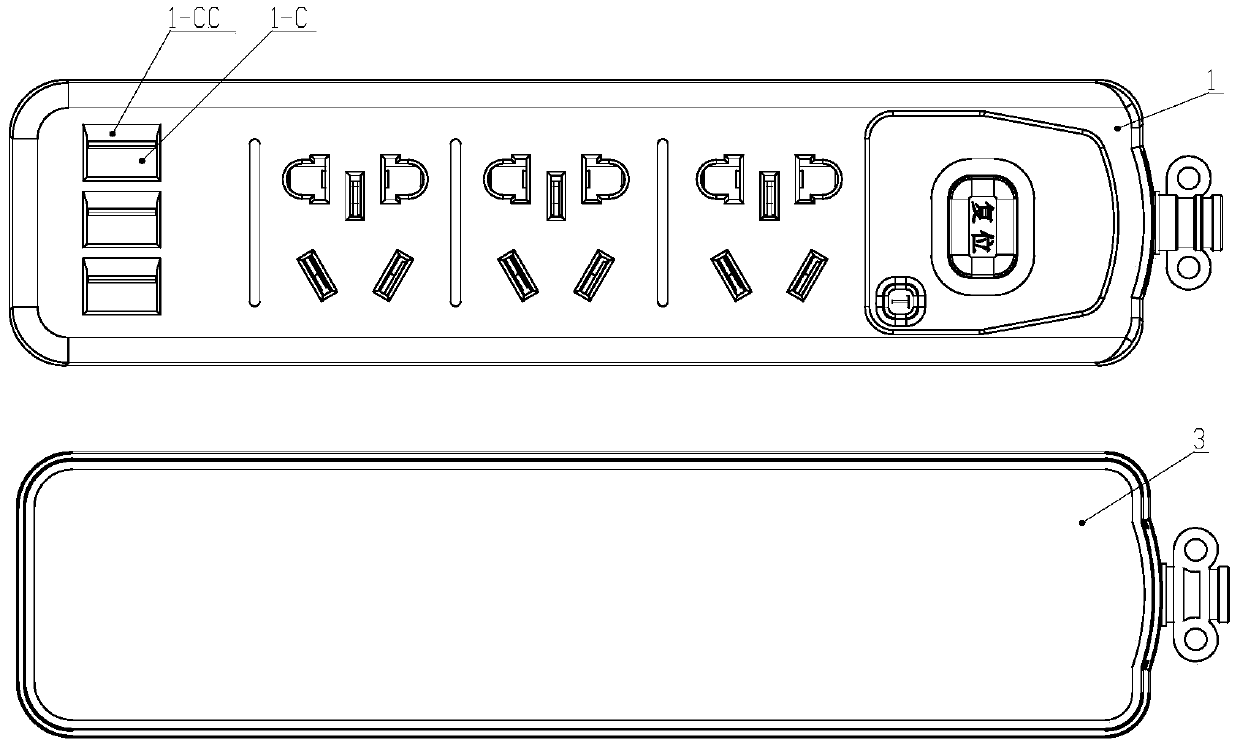

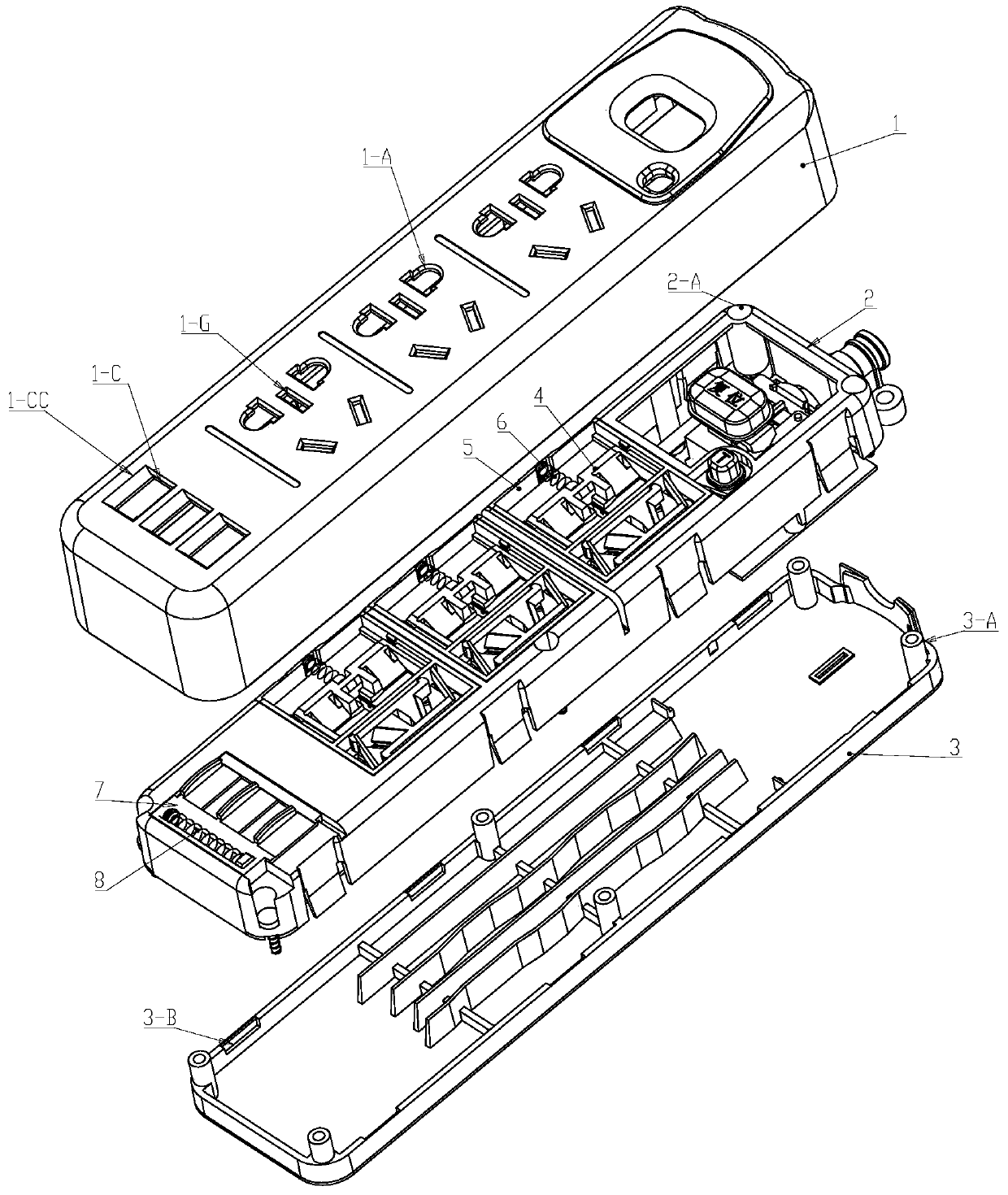

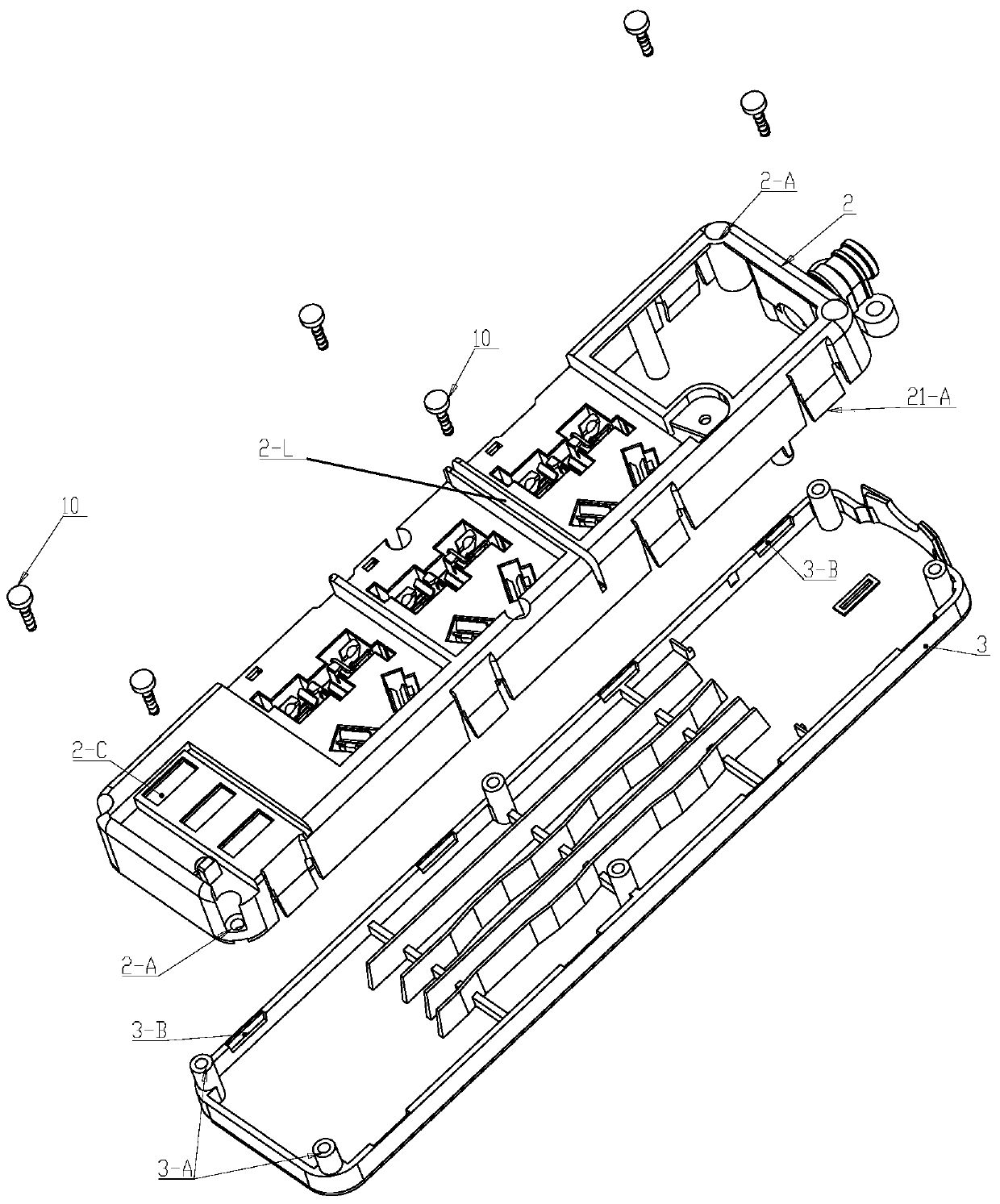

[0024] refer to Figure 1 to Figure 5 As shown, the plug-in board of the present invention includes an upper cover 1 with jacks, a middle frame 2 provided with conductive sockets, and a bottom case 3. The middle frame 2 is provided with at least one pair of dual-purpose sockets, and the upper cover corresponds to There is a dual-purpose jack 1-A, and a single-piece jack baffle 4 with an elastic reset mechanism is provided. The single-piece jack baffle 4 has the ability to cover a pair of dual-purpose jacks under the natural state of the elastic reset mechanism and When the plug is inserted, it moves to the side of the dual-purpose jack to expose the guide slope 4-B of the dual-purpose socket, and the metal sheet 9 is fixedly arranged on the guide slope 4-B; the middle frame 2 is provided with a USB charging module (located on Below the USB jack 2-C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com