Automatic box sealing and packaging method for pastries

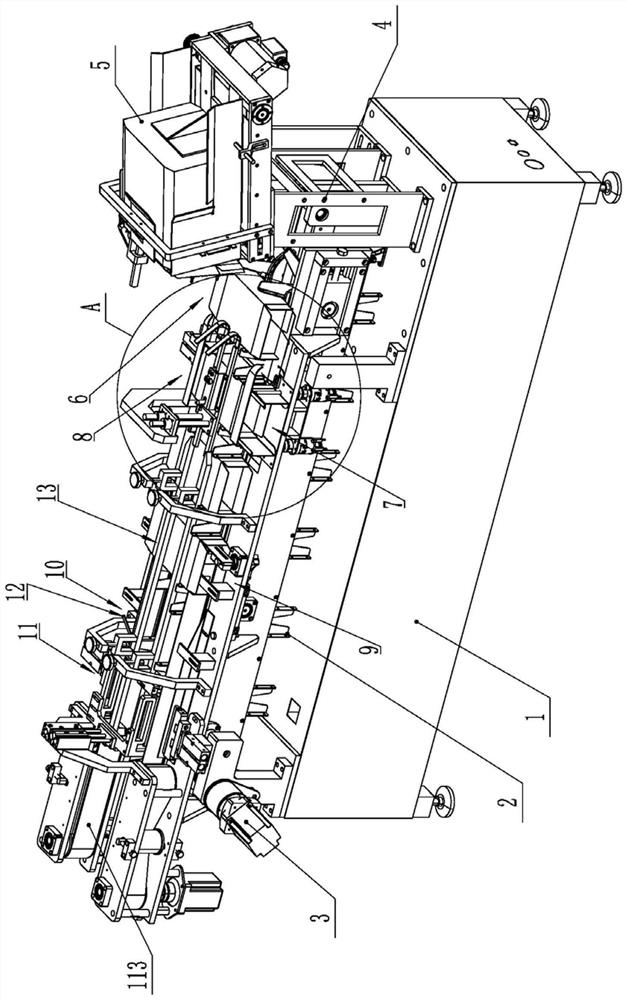

A box packaging and automatic technology, applied in packaging and other directions, can solve the problems of inability to realize automatic continuous operation, low packaging efficiency, and scattered movements, and achieve the effect of high degree of automation, smooth movement process and compact movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below through specific examples.

[0034] A method for automatic box sealing and packaging of cakes, comprising the following steps: S1, placing stacked packaging boxes in a storage bin; one side of the storage bin is a discharge port, and the other side is a feeding port;

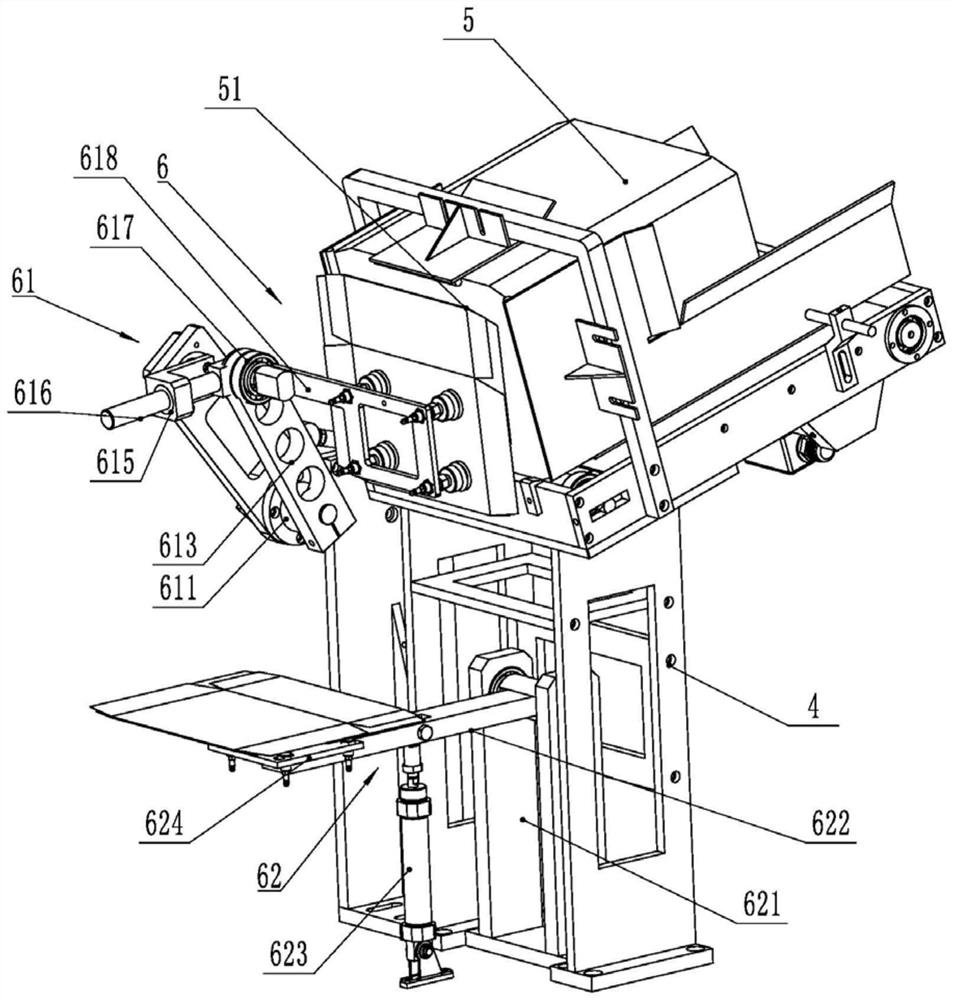

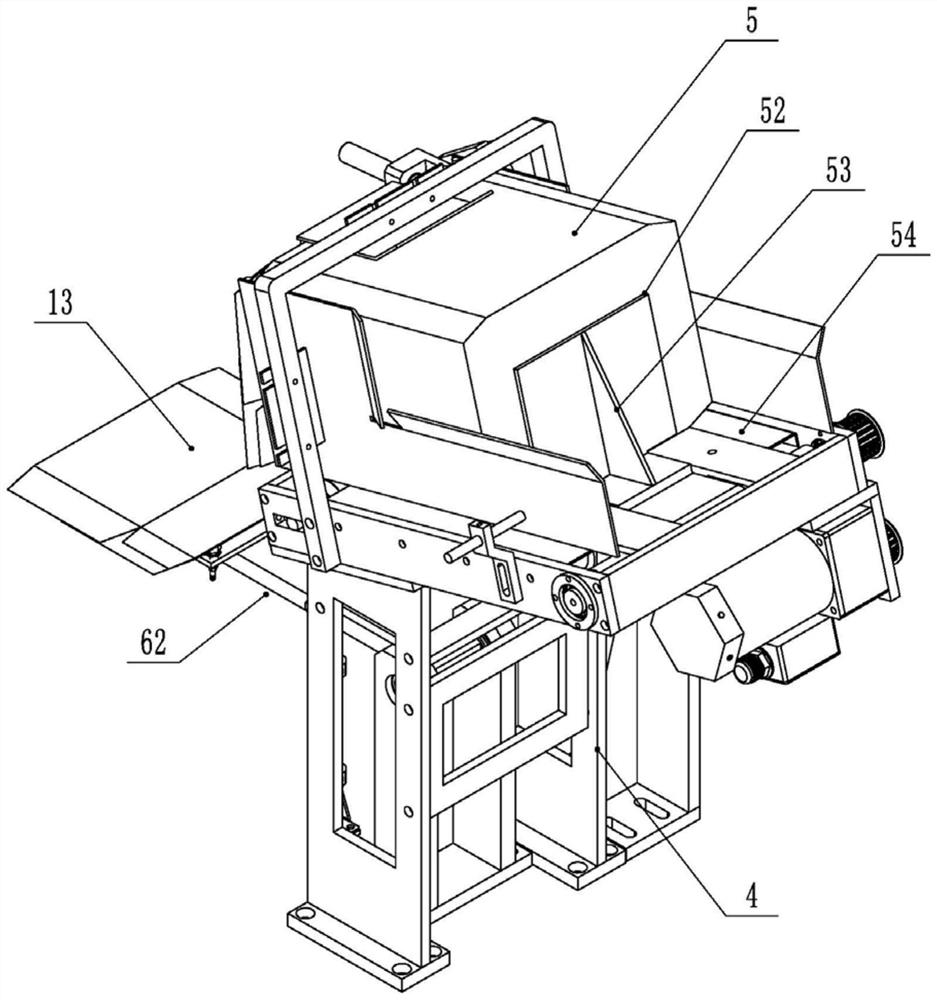

[0035] S2. The upper deflection box taking mechanism 61 deflects to the box taking station to absorb a package box in the storage bin and then deflects to the box putting station of the toothed chain conveying device 2. During the deflection movement, the downward deflection The pendulum suction mechanism 62 deflects upwards to absorb the bottom of the packaging box and then deflects downwards so that the upper surface and the lower surface of the packaging box form relative motion in the up-down direction and left-right direction and unfold the box-releasing tool that falls into the toothed chain conveyor 2. The placement area of the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com