A sealing ring assembly device

A technology of assembling device and sealing ring, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of low precision of each moving part of clamping equipment, low repeatability of charging head, and non-concentricity of products to be loaded, etc. problems, to achieve the effect of reducing assembly time, occupying less space, and having a simple and exquisite structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

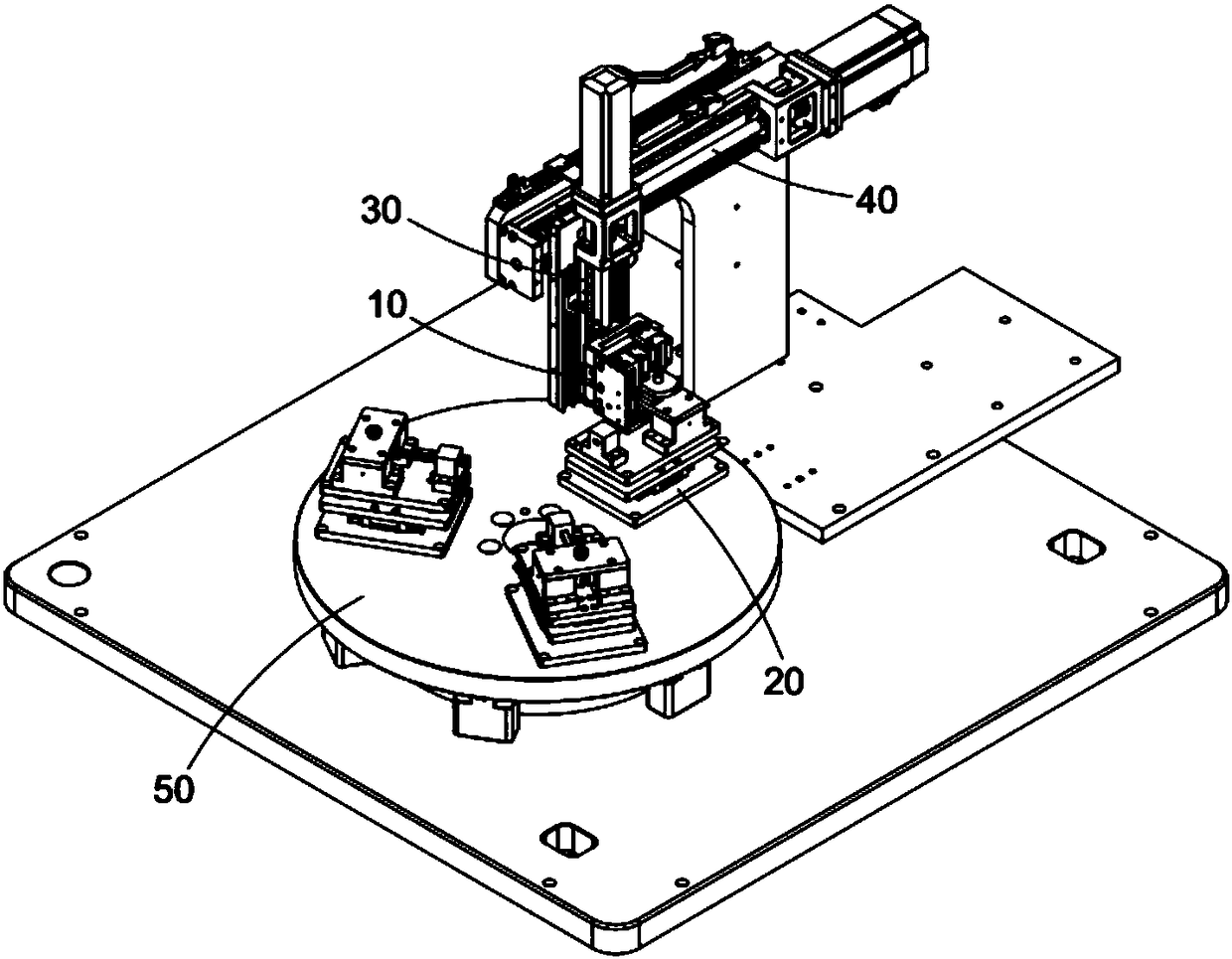

[0031] Such as figure 1 , a sealing ring assembly device, comprising a positioning assembly part 10 and a floating assembly jig 20 arranged up and down.

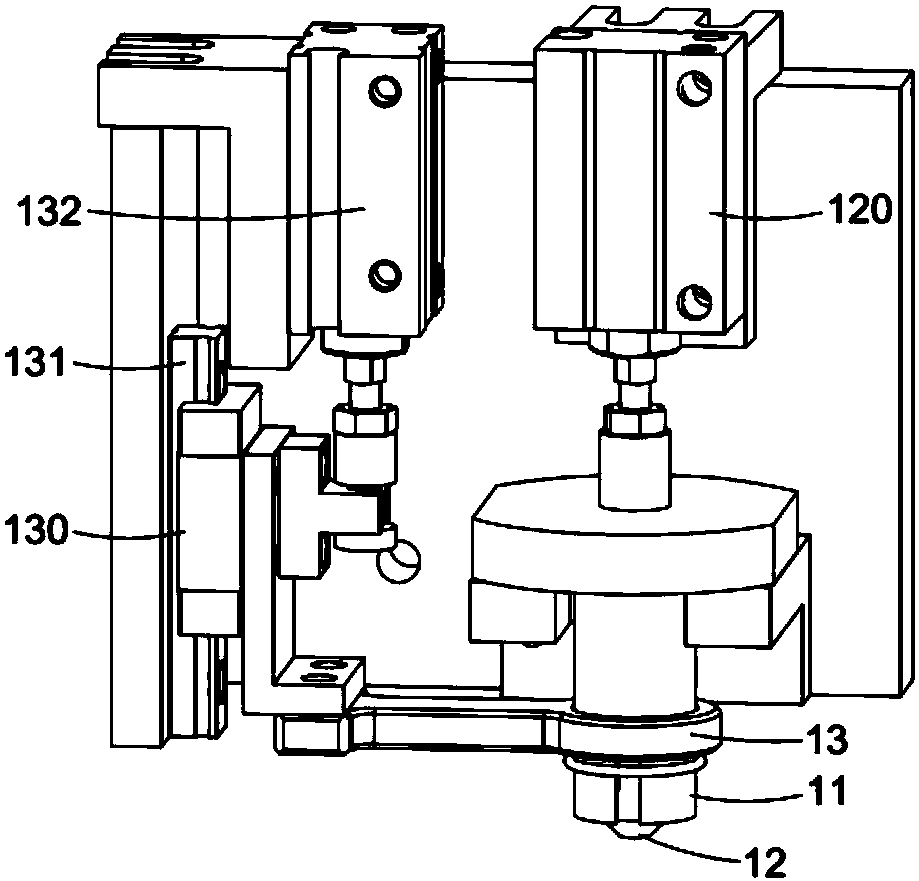

[0032] Such as figure 2 , the positioning assembly part 10 includes a lifting charging head 11, the charging head is hollow, and a lifting positioning cone 12 is inserted in the charging head, the positioning cone is connected with the positioning cylinder 120, and the positioning cylinder is installed in the positioning Assemble the components on the substrate.

[0033] With regard to the positioning assembly part 10, the charging head 11 is movably provided with an ascending and descending dial ring 13, and the ascending and descending dial ring is located above the sealing ring sleeved on the charging head.

[0034] Regarding the positioning assembly part 10, the material shifting ring 13 is installed on the material shifting slider 130, the material shifting slider is slidably fitted on the linear slide rail 131, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com