Connector installing device for large soft infusion bag production line

An interface device and production line technology, which is applied in the field of food and pharmaceutical packaging machinery, can solve the problems that the upper interface equipment is difficult to adapt to the development of high-speed and high-reliability, the efficiency and accuracy of the upper interface are low, and the cost of manufacturing and maintenance is high. Reduce the difficulty of debugging, improve the reliability of the work, and the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

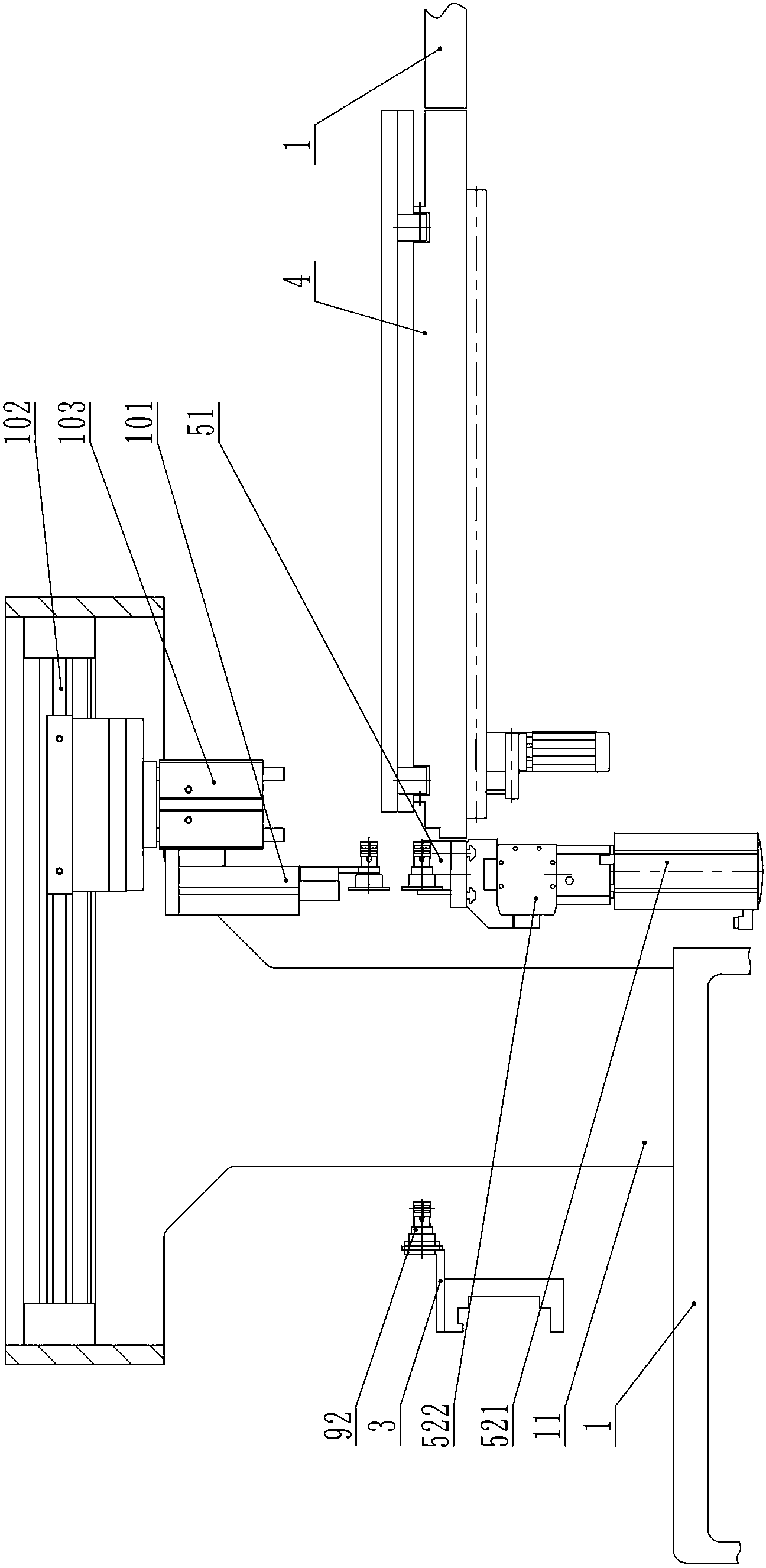

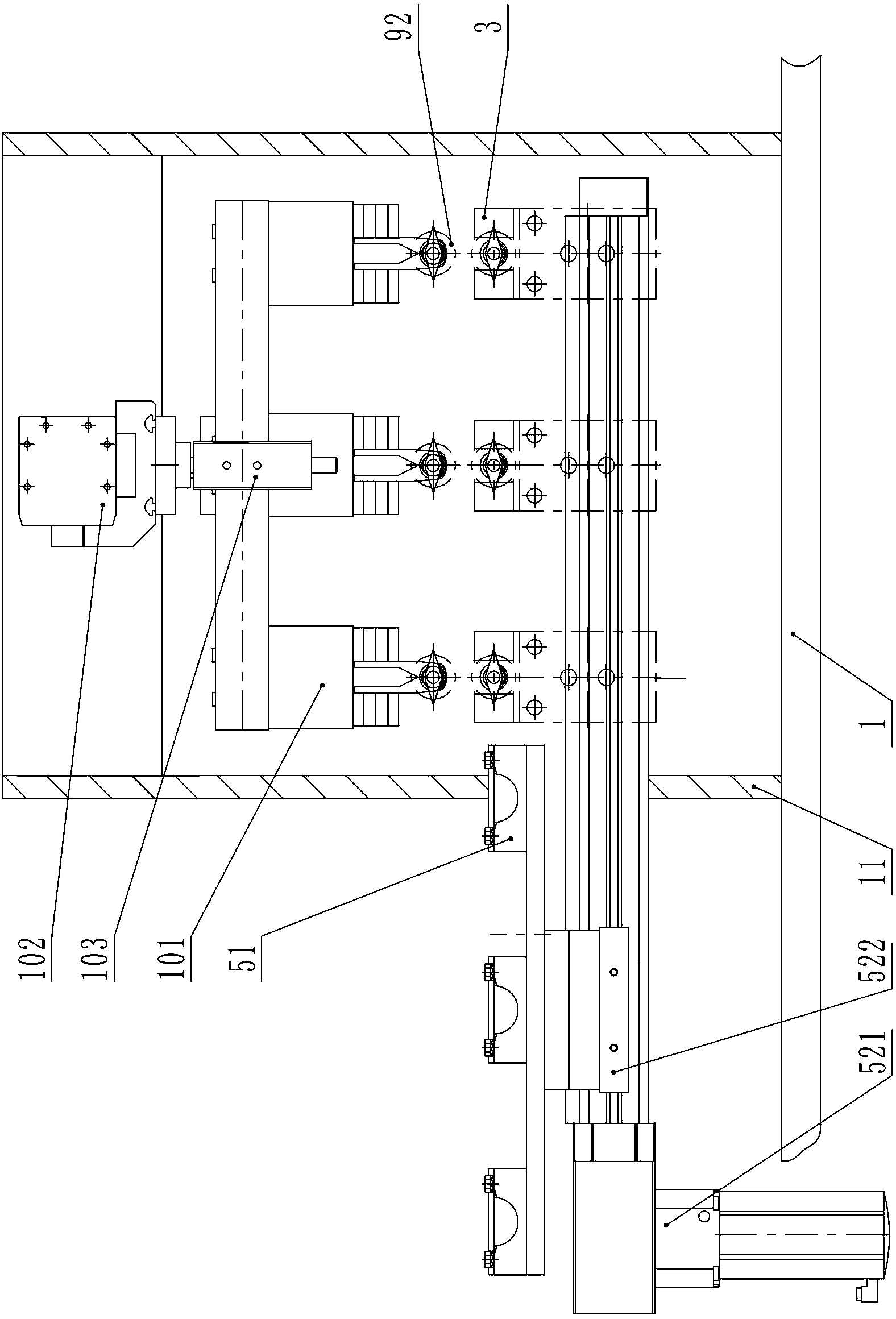

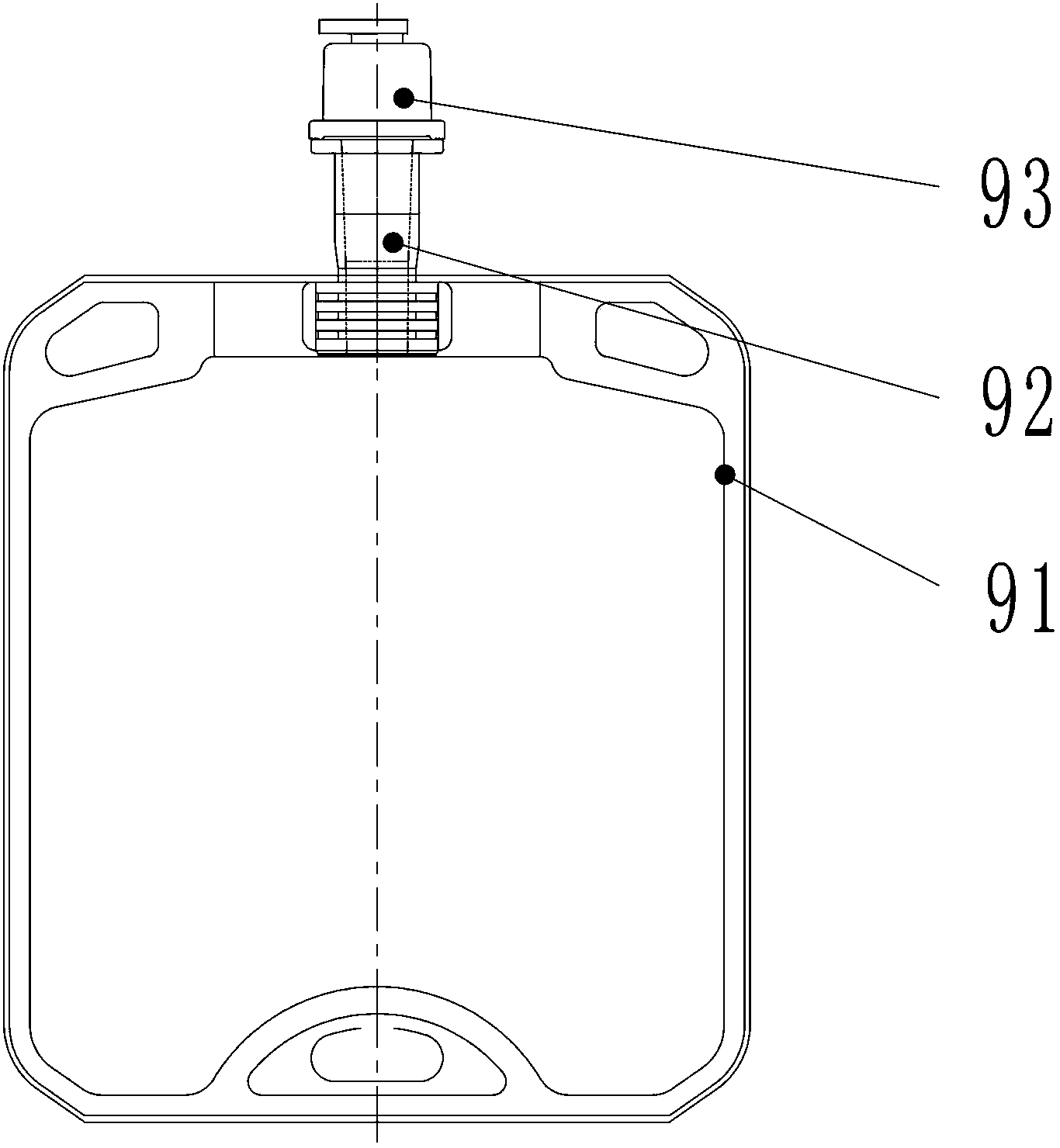

[0028] Such as figure 1 As shown, the upper interface device for the large infusion soft bag production line of the present invention includes a frame 1, a vibrating upper hopper 2, an interface clamp mechanism 3 installed on the frame 1, and a mounting frame installed on the frame 1 The input interface slideway mechanism 4 and the push interface mechanism 6 on the 11. The number of outlets of the vibration upper hopper 2 is consistent with the number of slideways of the input interface slideway mechanism 4. The present embodiment takes a single as an example. During work, the interface 92 enters the output interface slideway mechanism 4 from the outlet of the vibration upper hopper 2, and Under the action of air force, it is quickly conveyed in the slideway mechanism 4 of the input port. The interface pushing mechanism 6 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com