A special coil box for an ignition transformer

A wire coil box and transformer technology, applied in the field of transformers, can solve problems such as damage and failure, and achieve the effect of protecting lines, complete functions, and simple structure

Inactive Publication Date: 2018-12-28

SUZHOU HUANYAN ELECTRIC

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Existing finished ignition transformers are usually square devices with input and output wiring on the same side. In order to expand the scope of application, the wiring is usually set longer and needs to be coiled and fixed. Therefore, during the production process and transportation process, the wiring often appears Damage and failure problems caused by collision wear and other conditions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

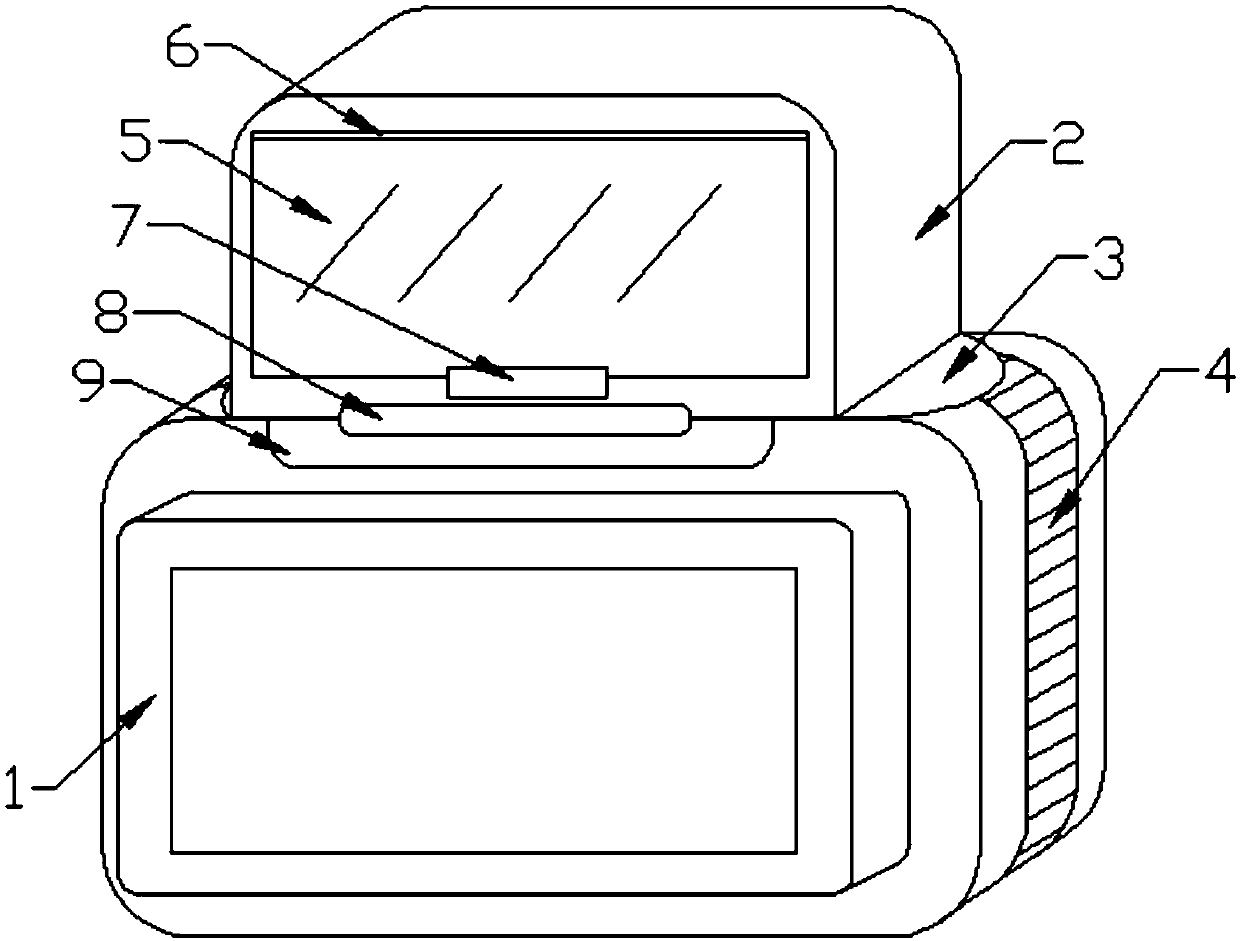

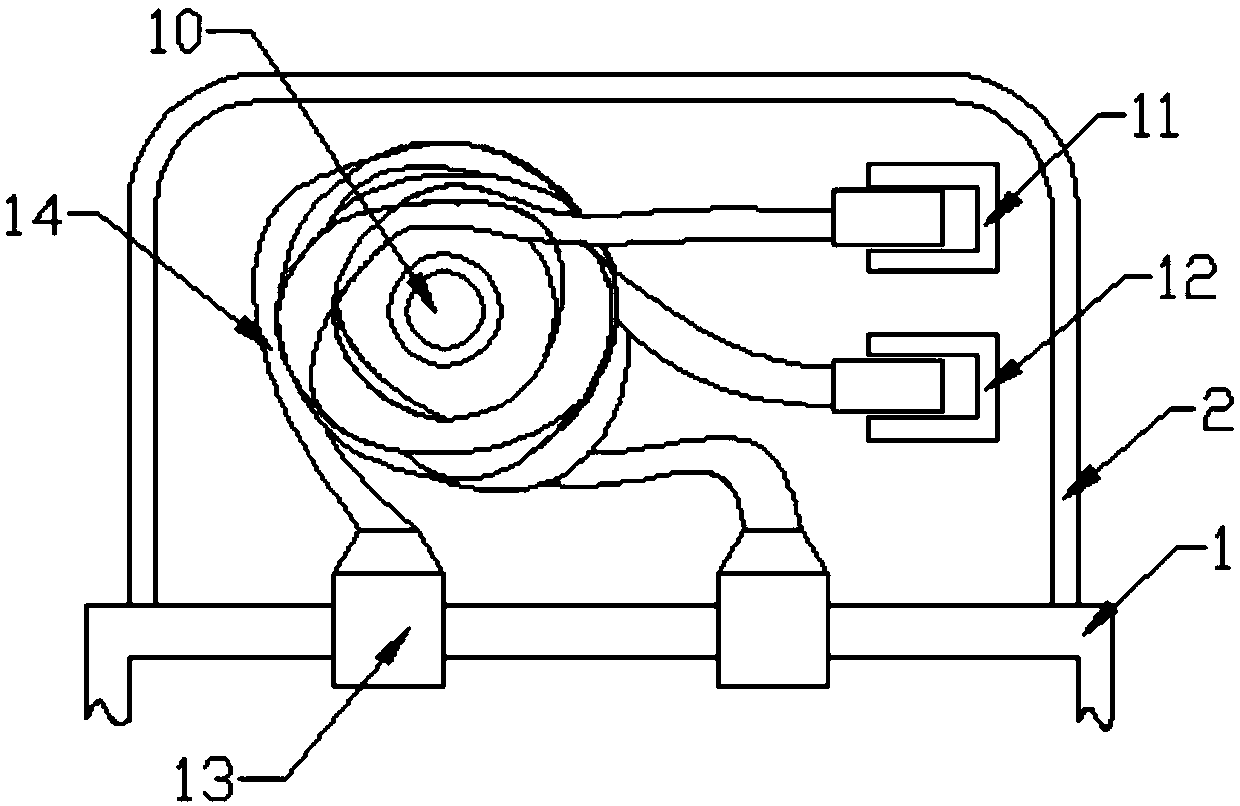

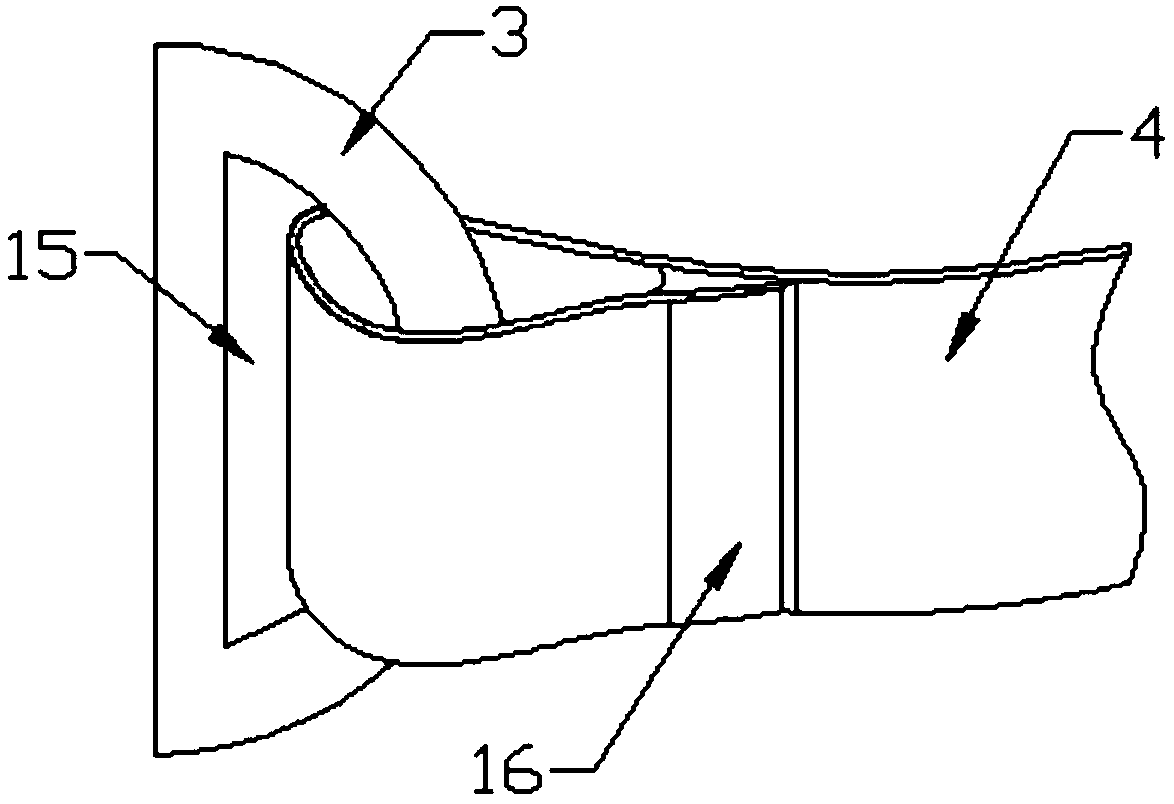

The invention discloses a special coil box for an ignition transformer, which includes a coil box, an ignition transformer is arranged at the bottom of the coil box, a positioning plate is arranged onboth side of the coil box, a fastening belt is installed on the outside of the positioning plate, the fastening belt is made of elastic rubber tape, a positioning edge is installed on the bottom of the coil box, a detection cover is installed on the surface of the coil box, a winding column is installed inside the coil box, and an input end clasp and an output end clasp are installed inside the coil box. The coil box can be fully fixed on the ignition transformer by the cooperation of the positioning edge protector and the fastening belt, the transparent detection cover enables people to visually observe the condition of the signal cable, and can be opened and closed conveniently with the snap fastener, so that the signal cable is convenient to arrange and the simple quality inspection operation is carried out, the coil box is simple in structure but complete in function, can effectively protect the circuit, and the cost is relatively low, the process is simple and convenient to produce, and has the popularization value.

Description

technical field The invention relates to the technical field of transformers, in particular to a coil box dedicated to ignition transformers. Background technique The main functions of the transformer are voltage transformation, impedance transformation, isolation and voltage regulation, etc. Transformers are widely used in the automatic control of burners, and there are many types and types. The ignition transformer is mainly used in the ignition system of the burner to realize the function of automatic ignition of the burner. Existing finished ignition transformers are usually square devices with input and output wiring on the same side. In order to expand the scope of application, the wiring is usually set longer and needs to be coiled and fixed. Therefore, during the production process and transportation process, the wiring often appears Damage and failure problems caused by collision wear and other conditions. Therefore, how to design a special coil box for the ignit...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H02G3/08H01F27/28

CPCH02G3/08H01F27/28

Inventor 颜欢

Owner SUZHOU HUANYAN ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com