Cigarette Defect Simulator

A technology for simulators and defects, applied in the field of simulators, can solve problems such as mixing, and achieve the effects of improving production efficiency, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

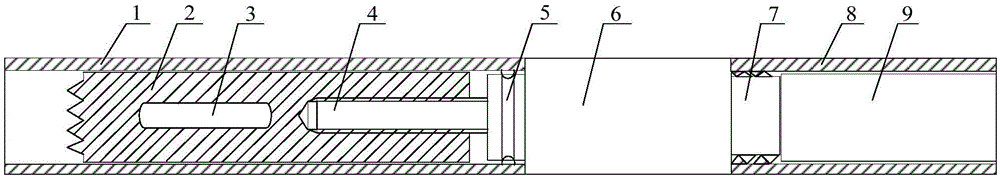

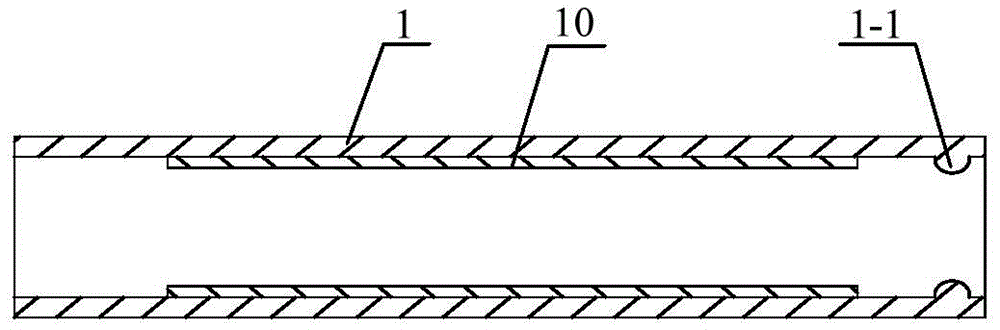

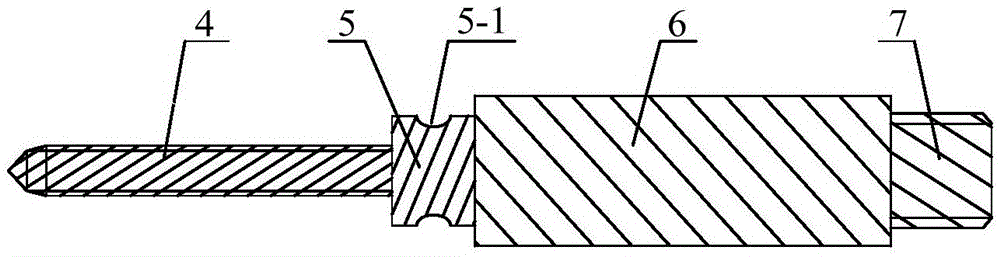

[0032] Such as Figure 1~3 As shown, the cigarette defect simulator of the present invention includes a casing, and a simulation inner core is also arranged inside the casing. The simulation inner core includes a hollow simulation inner core 2, and the hollow simulation inner core 2 is used for simulating the hollow defect of a cigarette. The front end of the short simulation inner core 2 is a reflection end, and the surface of the reflection end of the short simulation inner core 2 is set as a concave-convex surface, such as figure 1 As shown in , the concave-convex surface of the reflective end can be used to simulate the irregular shape of the tobacco end surface of the blank cigarette.

[0033] An electronic transponder 3 is also provided on the short simulation inner core 2 , the electronic transponder 3 in this embodiment is built in the short simulation inner core 2 , and the electronic transponder 3 is located at the front end of the short simulation inner core 2 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com