Positioning device for power electronic component production

A positioning device, power electronics technology, applied in the direction of auxiliary devices, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of long positioning time, cumbersome positioning mechanism and affecting welding efficiency of welding machines, etc., to prevent heat The effect of stacking, improving the welding range, and saving positioning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

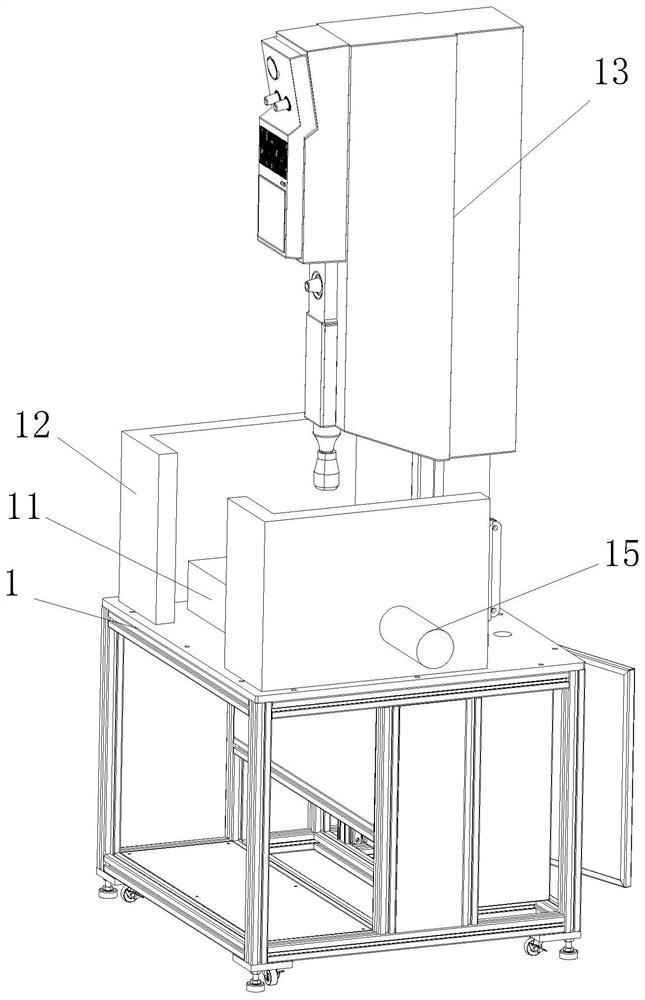

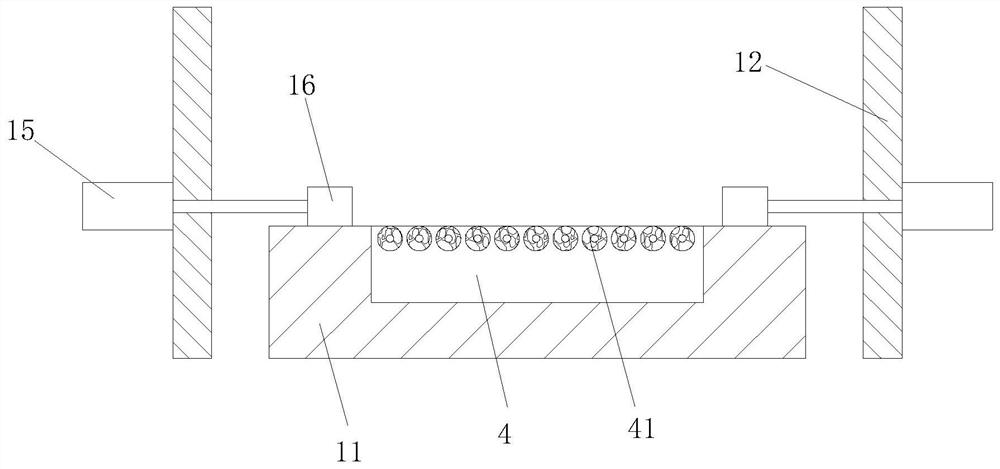

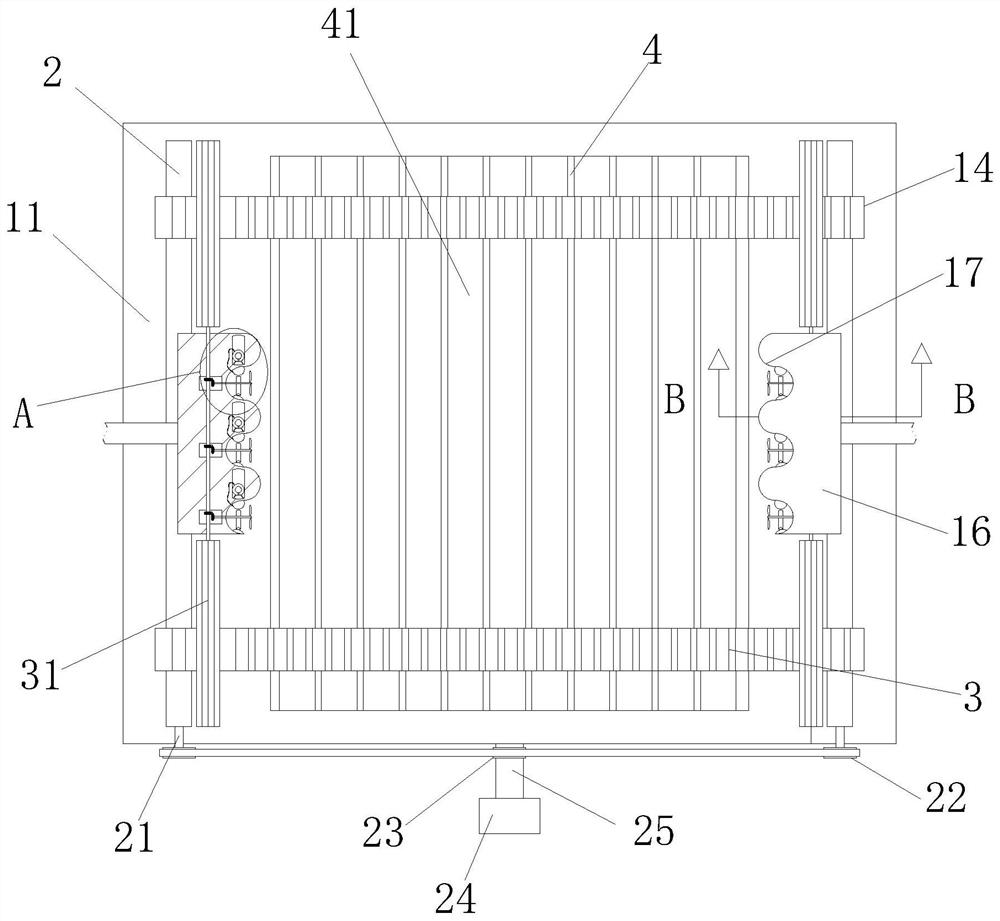

[0032] Such as Figure 1 to Figure 6 As shown, a positioning device for the production of power electronic components according to the present invention includes a workbench 1; a welding unit 13 is installed on the workbench 1; a placement seat 11 is fixedly connected to the workbench 1; The placement seat 11 is located directly below the welding unit 13; the workbench 1 is fixed with a protective cover 12, and the protective cover 12 is arranged around the placement seat 11; the side walls on both sides of the protective cover 12 are fixed with Hydraulic cylinder 15, and the hydraulic rod end of hydraulic cylinder 15 runs through protective cover 12 and is fixedly connected with positioning plate 16; Said positioning plate 16 slides on placement seat 11; Symmetrically distributed clamping plates 14, and the positioning plate 16 is located between a pair of clamping plates 14; in the prior art, when square power electronic components are automatically welded by an intelligent ...

Embodiment 2

[0041] see Figure 7-Figure 8 As shown in Comparative Example 1, as another embodiment of the present invention, a first groove 6 is opened on the opposite surface of the pair of locking plates 14, and the inside of the first groove 6 is rotatably connected by a rotating shaft. There is a second roller 61; the outer side wall of the second roller 61 and the opposite surfaces of a pair of clamping plates 14 are flat to each other; when working, because the positioning plate 16 pushes the square components for positioning and fixing, the front and rear sides of the components The wall needs to slide on the clamping plate 14. In order to further reduce the generation of friction, a set of second rollers 61 are arranged on the opposite surface of the clamping plate 14, and the opposite surfaces of the second rollers 61 and the clamping plate 14 are relatively flat , will not affect the removal and insertion of components.

[0042]A group of cleaning brushes 62 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com