Continuous concentration and sewage discharge device and method for shrimp farming system

A sewage discharge device and sewage pipe technology, applied in separation methods, chemical instruments and methods, fish farming and other directions, can solve the problems of high input cost and energy consumption, complex overall structure of sewage collectors, etc. The effect of preventing live shrimp from escaping and reducing sewage and water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

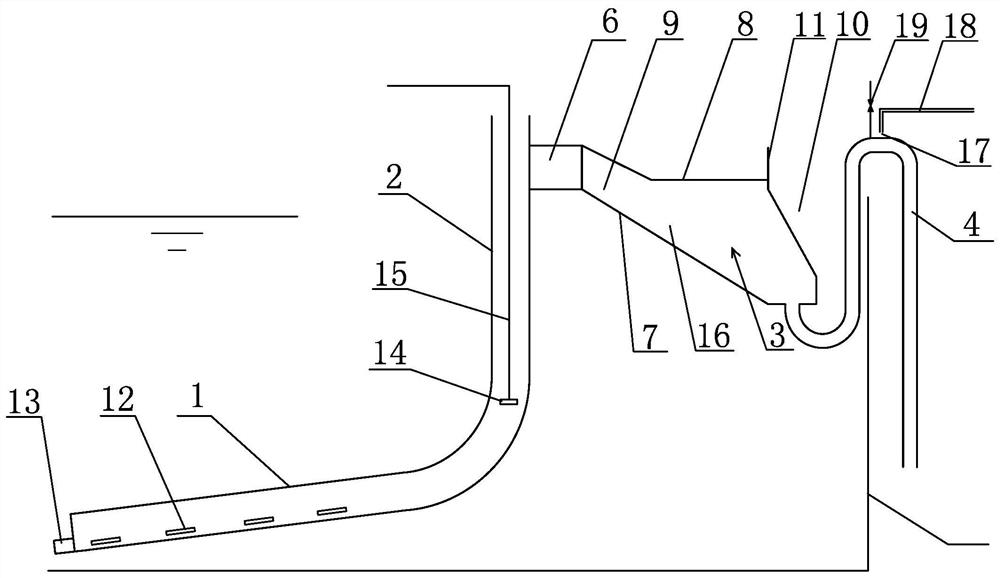

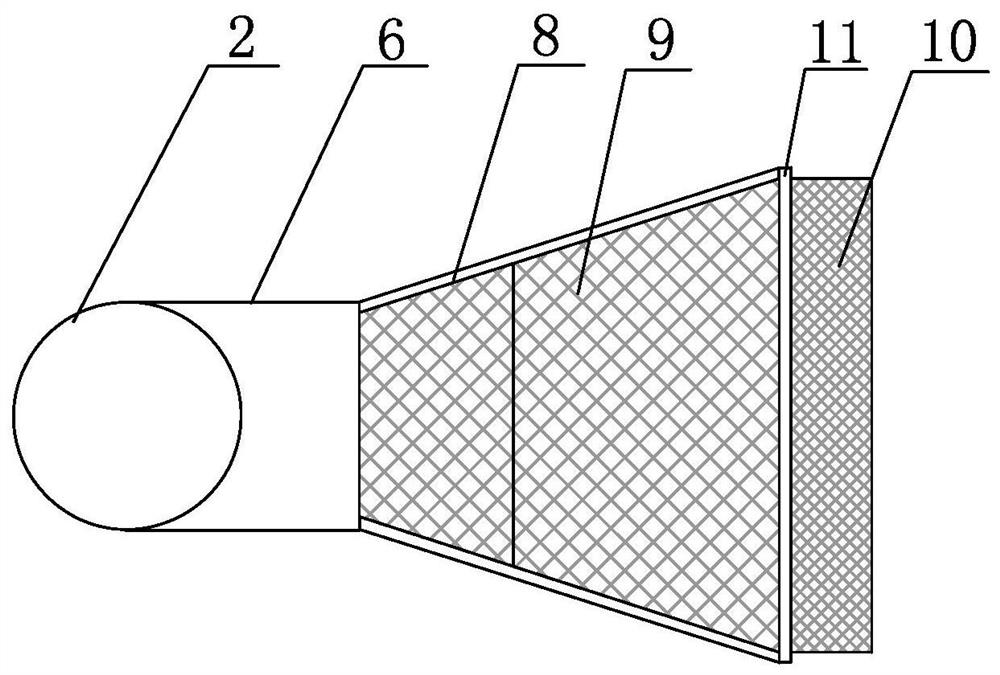

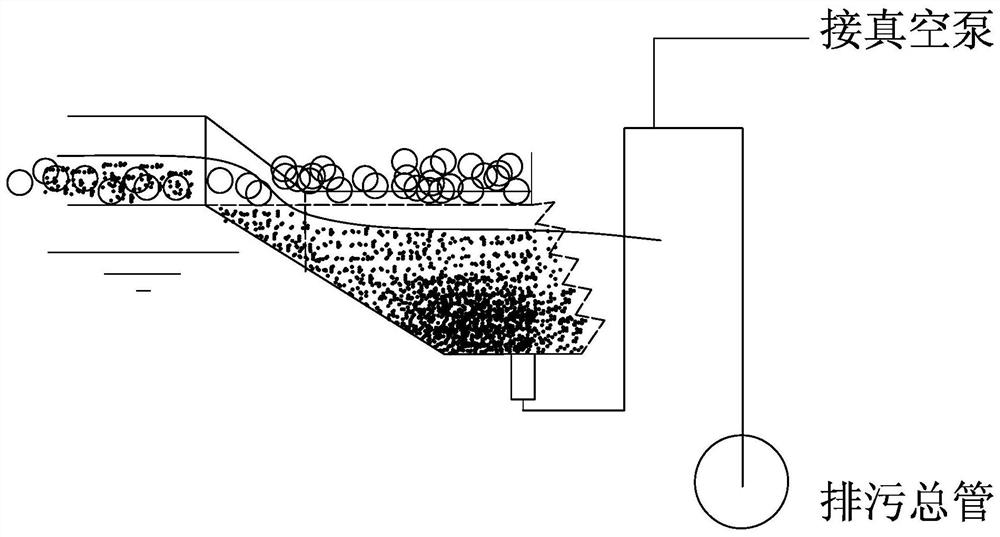

[0027] A continuous concentrated sewage discharge device for a shrimp farming system, such as figure 1 , figure 2 and image 3 As shown, including the sewage collection pipe 1, the air lift pipe 2, the sewage storage bin 3 and the sewage discharge pipe 4, the sewage collection pipe 1 is placed close to the bottom of the culture pond 5, and the open end of the sewage collection pipe 1 is located at the center of the bottom of the culture pond 5 and Its other end communicates with the airlift pipe 2, and the upper side wall of the airlift pipe 2 is located at the water surface and communicates with the sewage storage bin 3 through the sewage suction pipe 6. The side baffles 8 on both sides of the bottom plate 7, the detachable coarse filter screen 9 for intercepting large-size particles and the detachable fine filter screen 10 for intercepting small-size particles are surrounded, and the coarse filter screen 9 is horizontally arranged on Between the two side baffles 8 and the...

specific Embodiment 2

[0031] Utilize the method described in the above-mentioned embodiment one to carry out the method for continuously concentrating the sewage of the shrimp farming system, comprising the following steps:

[0032] (1) When feeding bait, close the air lift and stop the water and sewage collection;

[0033] (2) After 1.0-1.5 hours of baiting, the prawns have finished eating, and the air lift is turned on to start the water and sewage collection; after the air lift works for 1 hour, turn off, open the vacuum tube 18, form a siphon and start automatic sewage discharge, and clean the water. The fine filter screen 10 is backwashed, and after 2-3 minutes of sewage discharge, the vacuum pipe 18 is closed, the solenoid valve 19 is opened, the siphon is destroyed, and the sewage discharge is stopped; at the same time, the air lift is opened again to enter the next working cycle;

[0034] (3) The coarse filter 9 is inspected once a day, and the shrimp shells, dead shrimp, and diseased shrim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com