Mushroom head assembly of water mist sand blasting device

A technology of sand blasting device and mushroom head, which is applied in the direction of explosion generation device, abrasive feeding device, used abrasive processing device, etc., which can solve the problem that the abrasive mixing cylinder cannot be completely sealed and the water mist abrasive blasting machine is not perfect , the guide device cannot be guaranteed, etc., to achieve the effect of high concentricity, not easy to deform, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

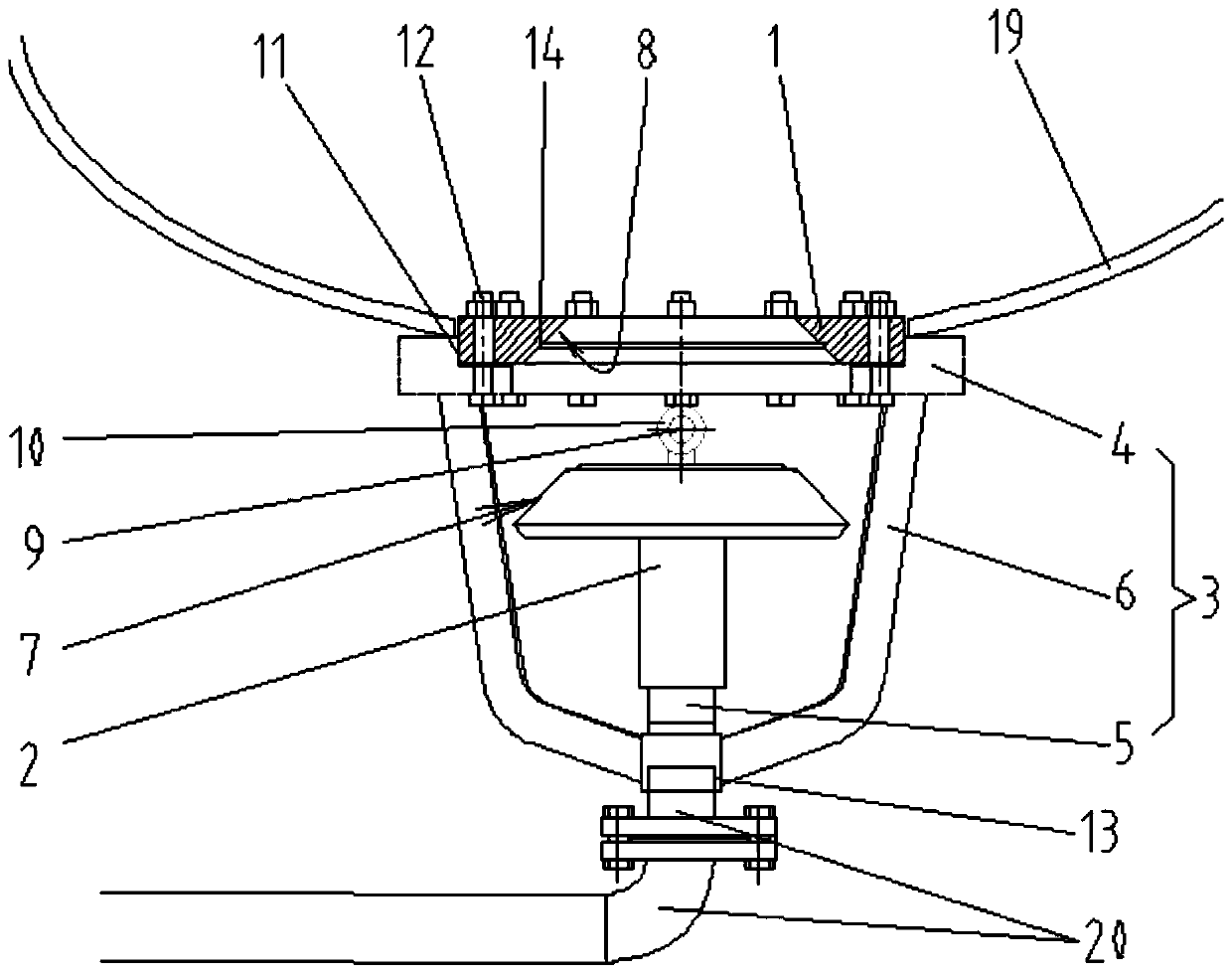

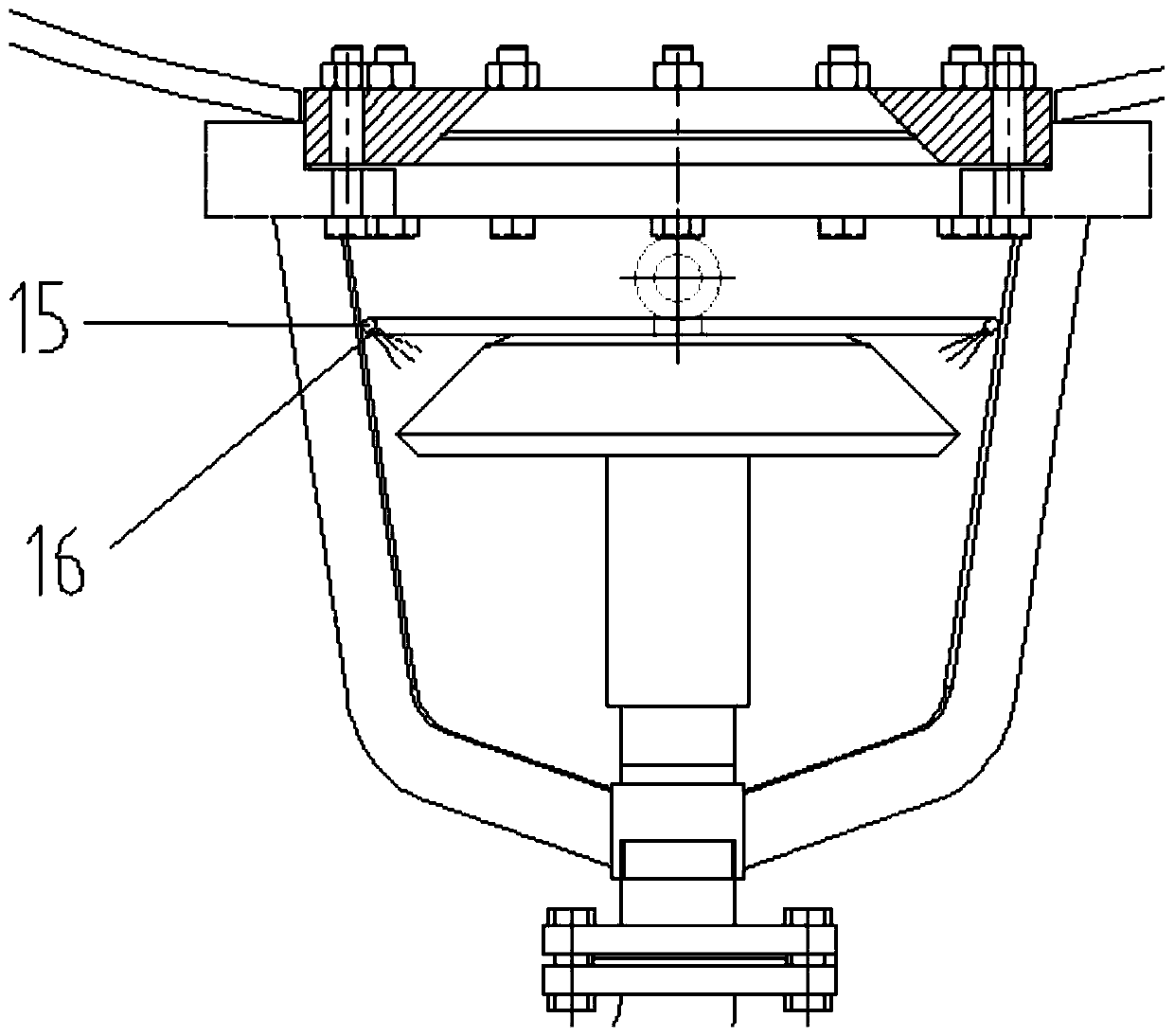

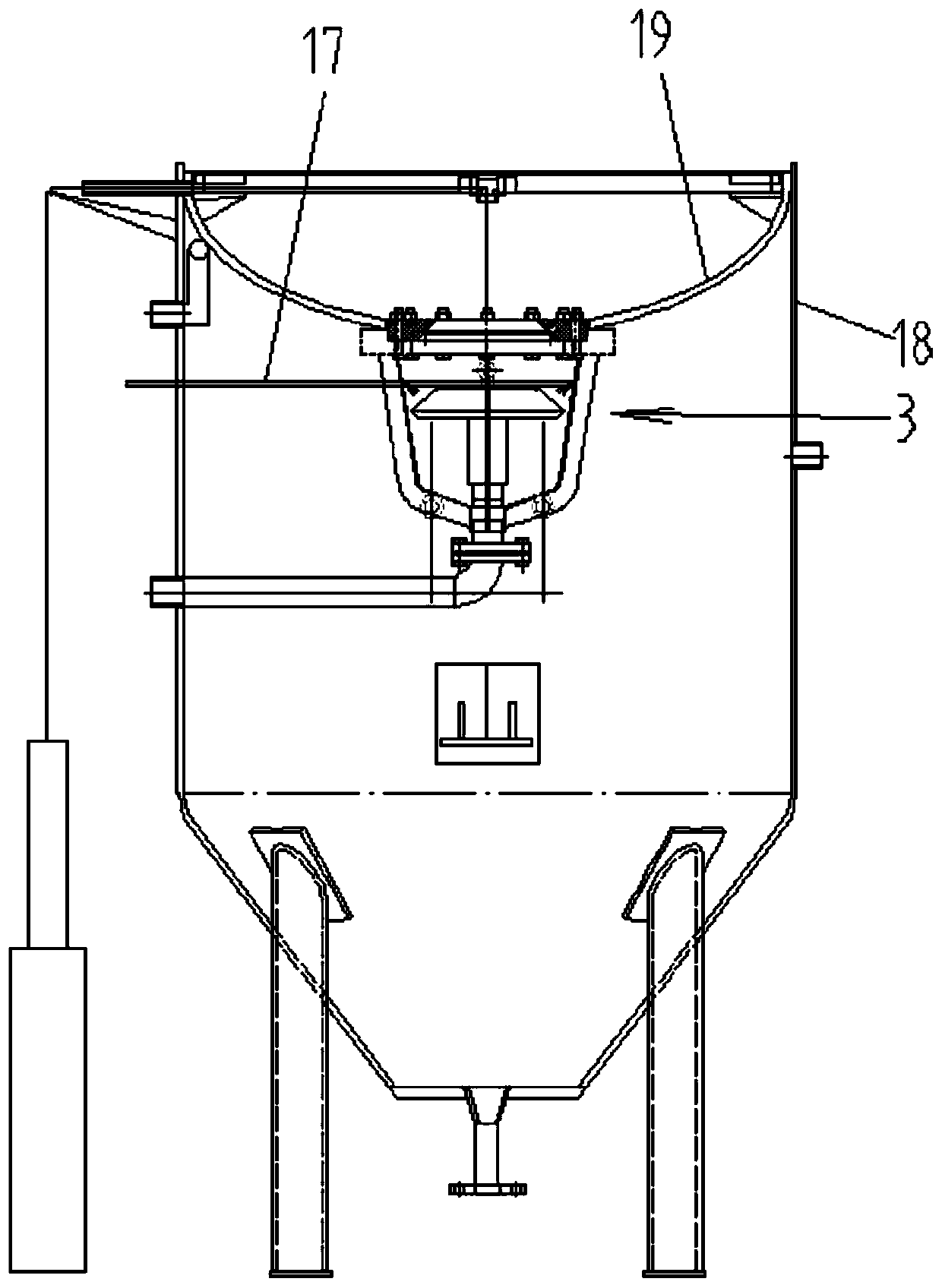

[0037] like Figures 1 to 3 Shown is an embodiment of the mushroom head assembly of a water mist sandblasting device of the present invention, including a flange 1 with a sand inlet hole in the middle, located below the sand inlet hole of the flange 1 for opening and closing all The mushroom-shaped head 2 of the sand inlet hole, the lower end of the flange 1 is connected with a support 3, and the support 3 includes a positioning ring 4 connected to the flange 1, and is vertically arranged below the positioning ring 4. The guide rod 5 is connected between the positioning ring 4 and the guide rod 5 with a number of ribs 6 spaced along the circumferential dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com