Industrial quenching oil cooler

A cooler and quenching oil technology, which is applied to quenching devices, manufacturing tools, heat treatment equipment, etc., can solve the problems that cannot be disassembled and cleaned, easy to be blocked, etc., to achieve convenient disassembly and cleaning, reduce maintenance costs, and improve heat dissipation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] combined with Figure 1-5 The technical scheme and structure of the technology of the present invention are described to facilitate the understanding of those skilled in the art.

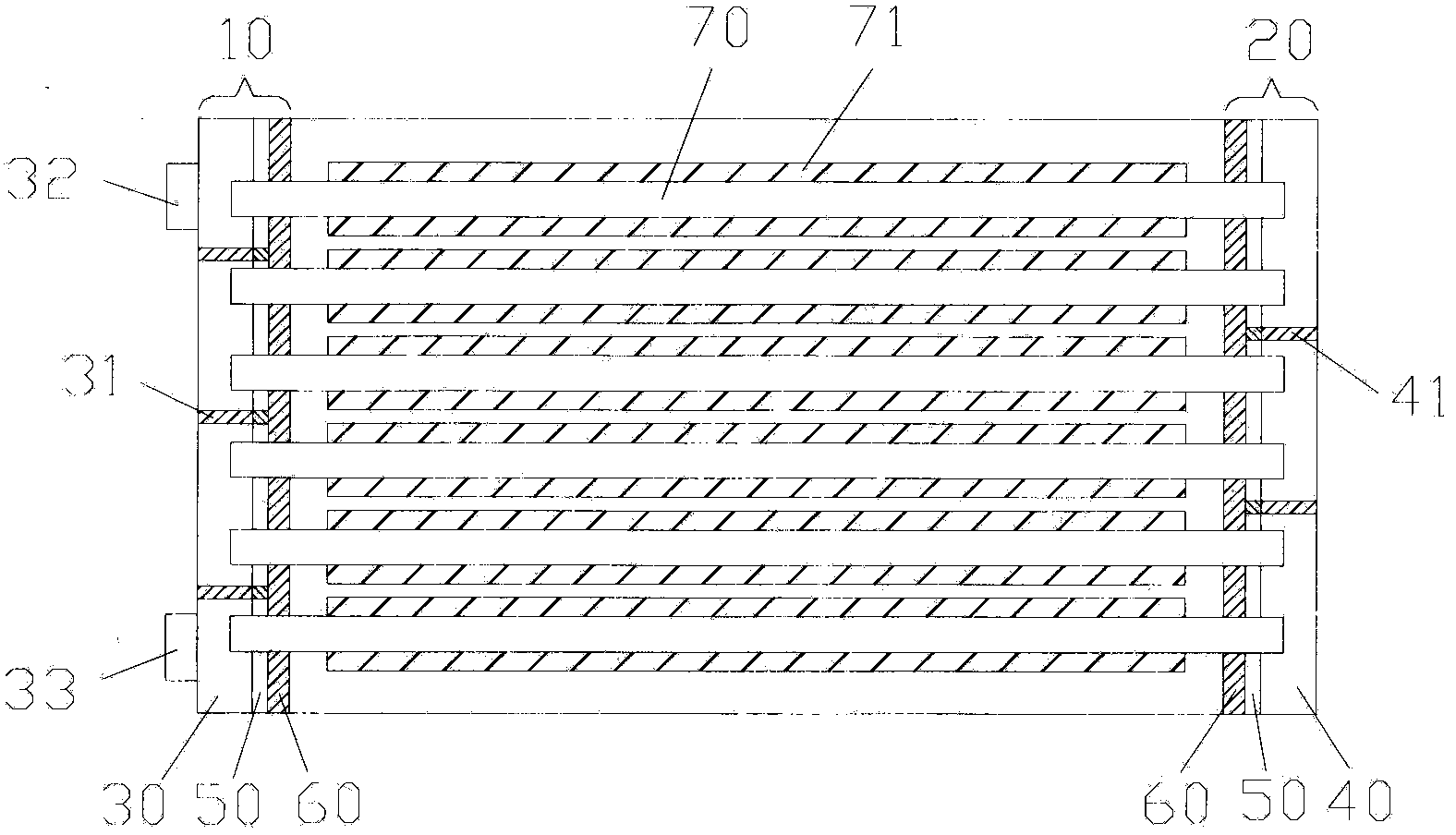

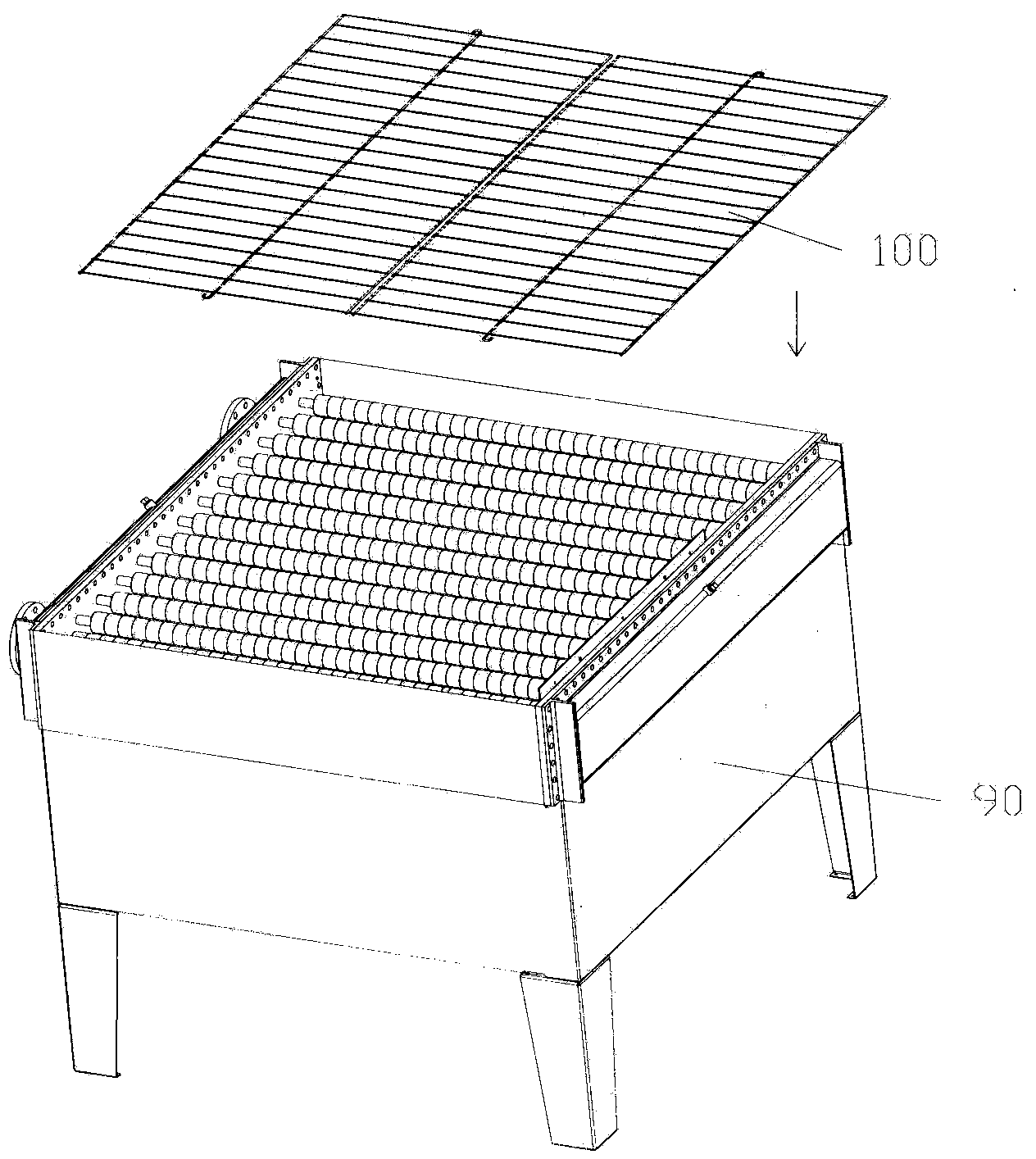

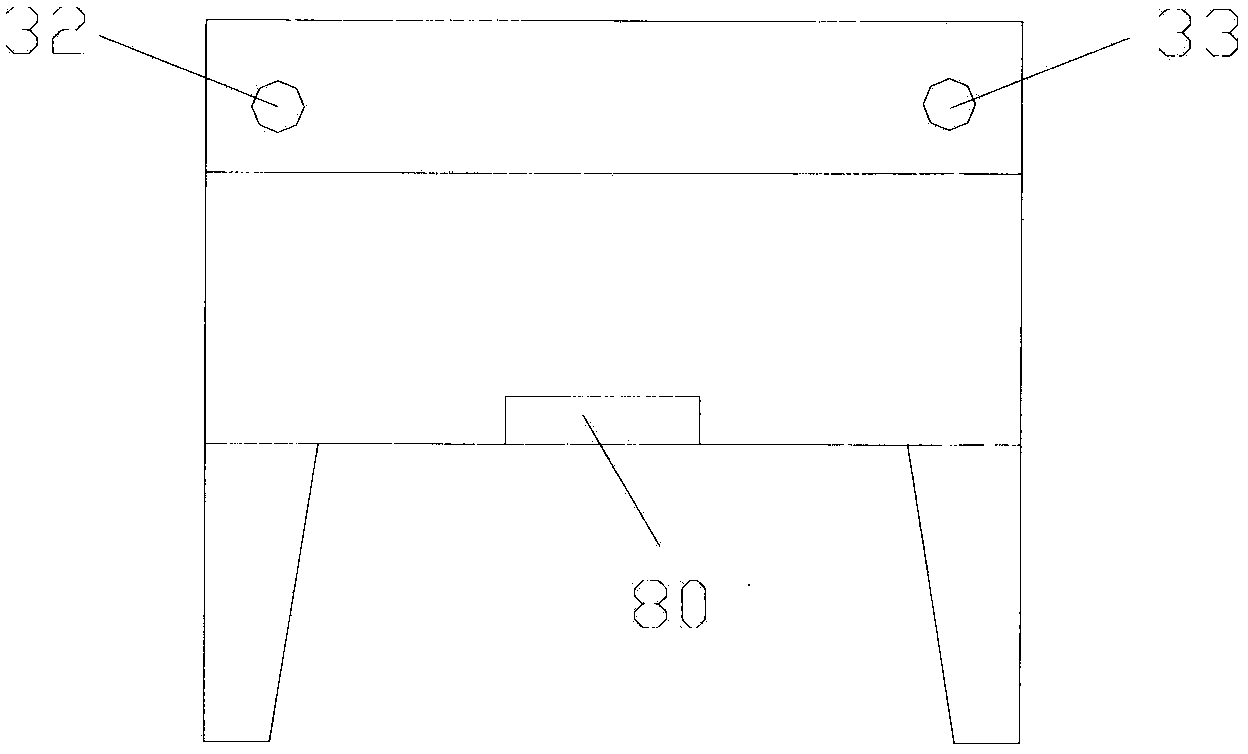

[0025] An industrial quenching oil cooler, comprising several layers of radiating pipes 70 evenly arranged, each layer is provided with a plurality of, the lower end of the radiating pipes 70 is provided with a fan 80, and the two ends of the radiating pipes 70 are connected to the second oil chamber 20 and the device respectively. A first oil chamber 10 with an oil inlet 32 and an oil outlet 33;

[0026] The first and second oil chambers 10 and 20 are provided with a plurality of splitter plates, which divide the oil outlets of the previous group of heat dissipation pipes 70 and the oil inlet ends of the rear group of heat dissipation pipes 70 into independent chambers to realize Quenching oil circulates along each group of cooling pipes 70 .

[0027] Preferably, the first oil chamber 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com