Patents

Literature

85results about "Weighing apparatus using radiation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

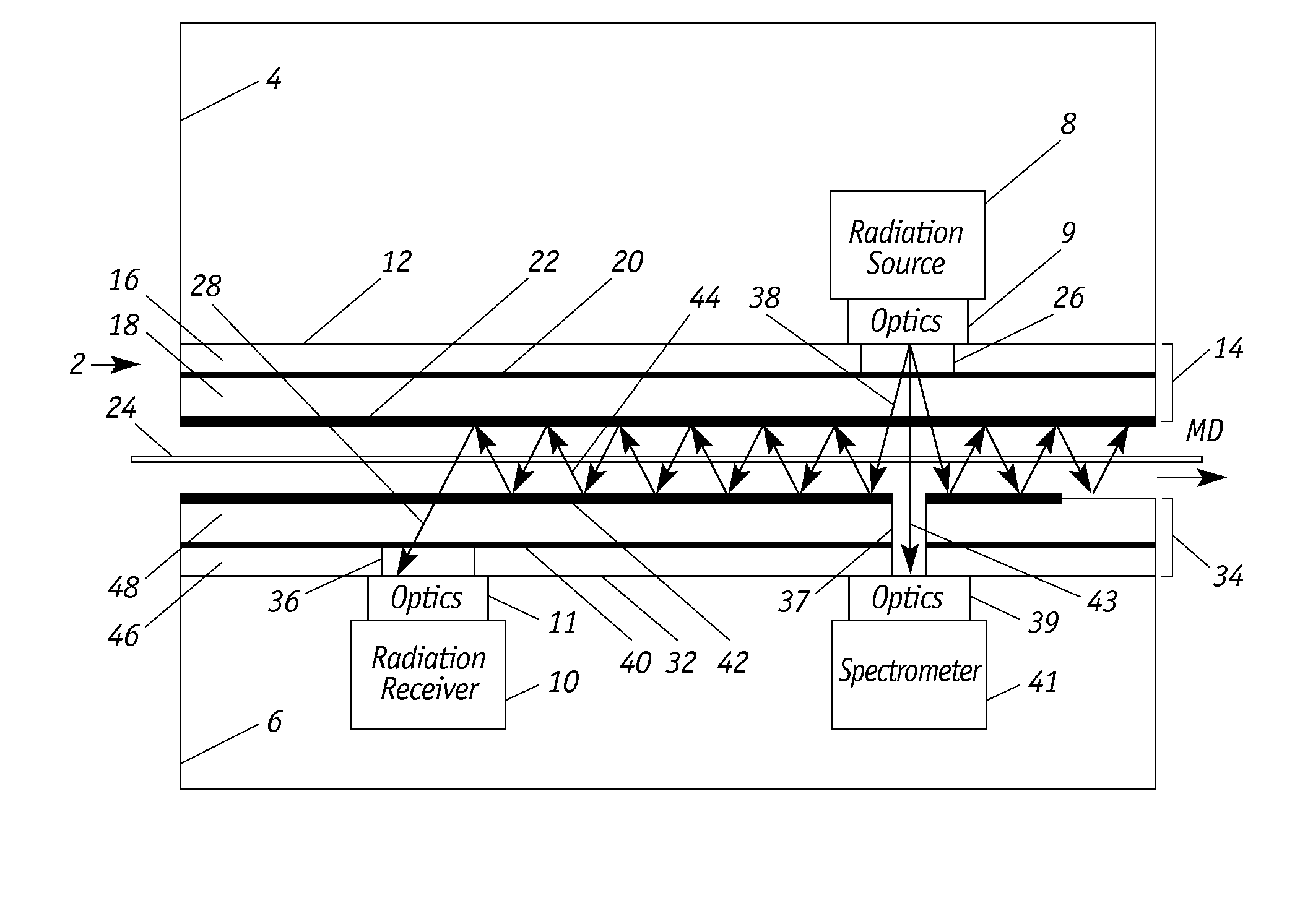

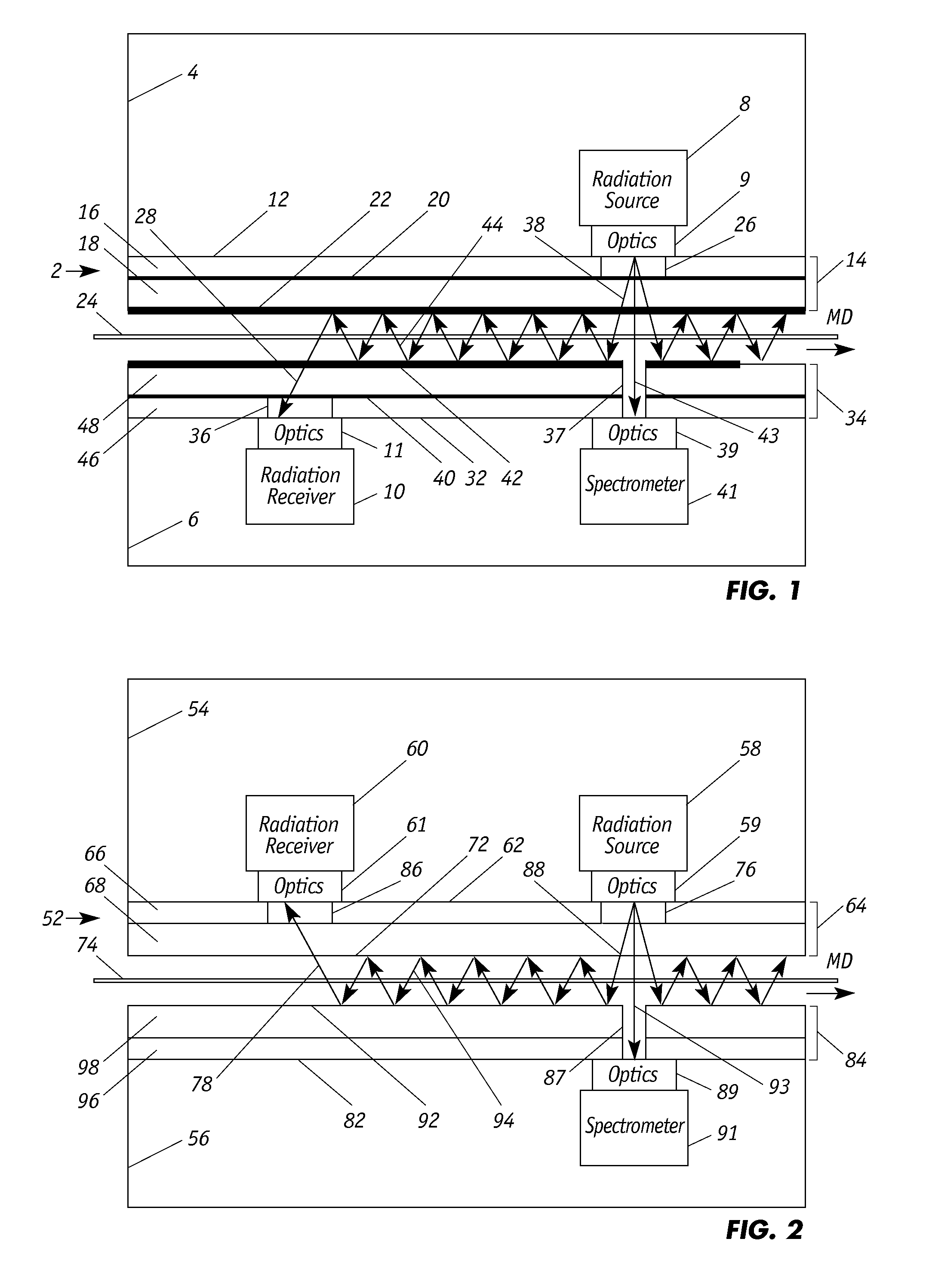

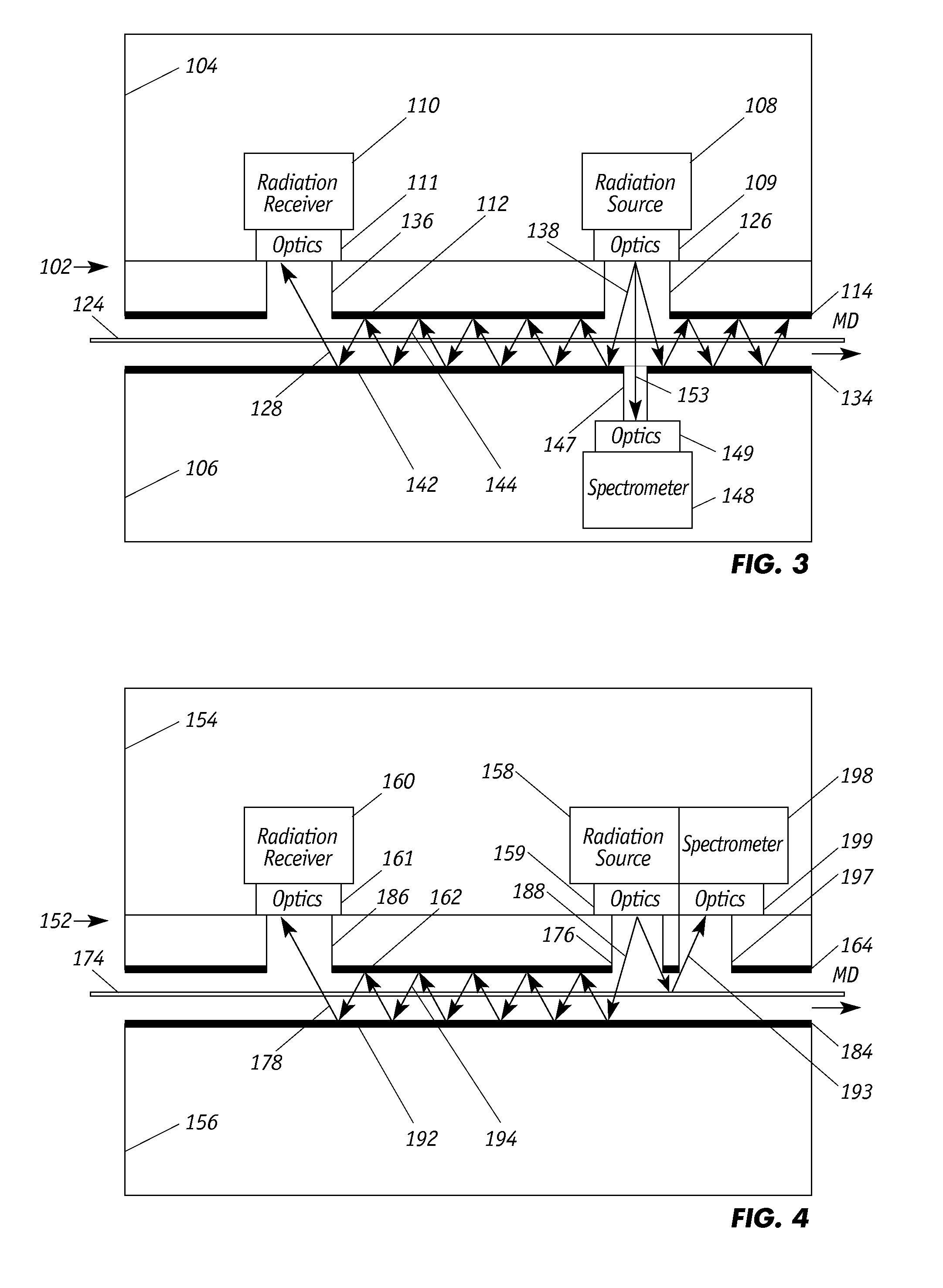

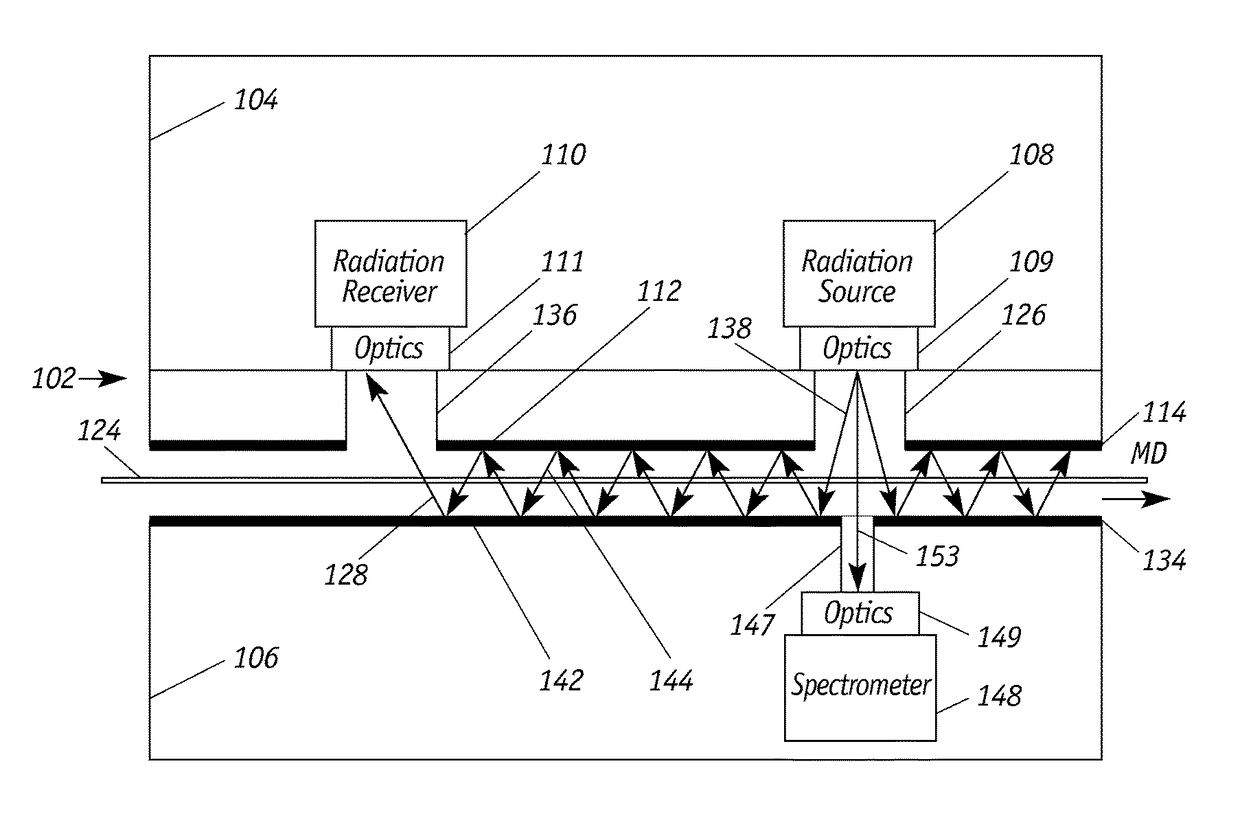

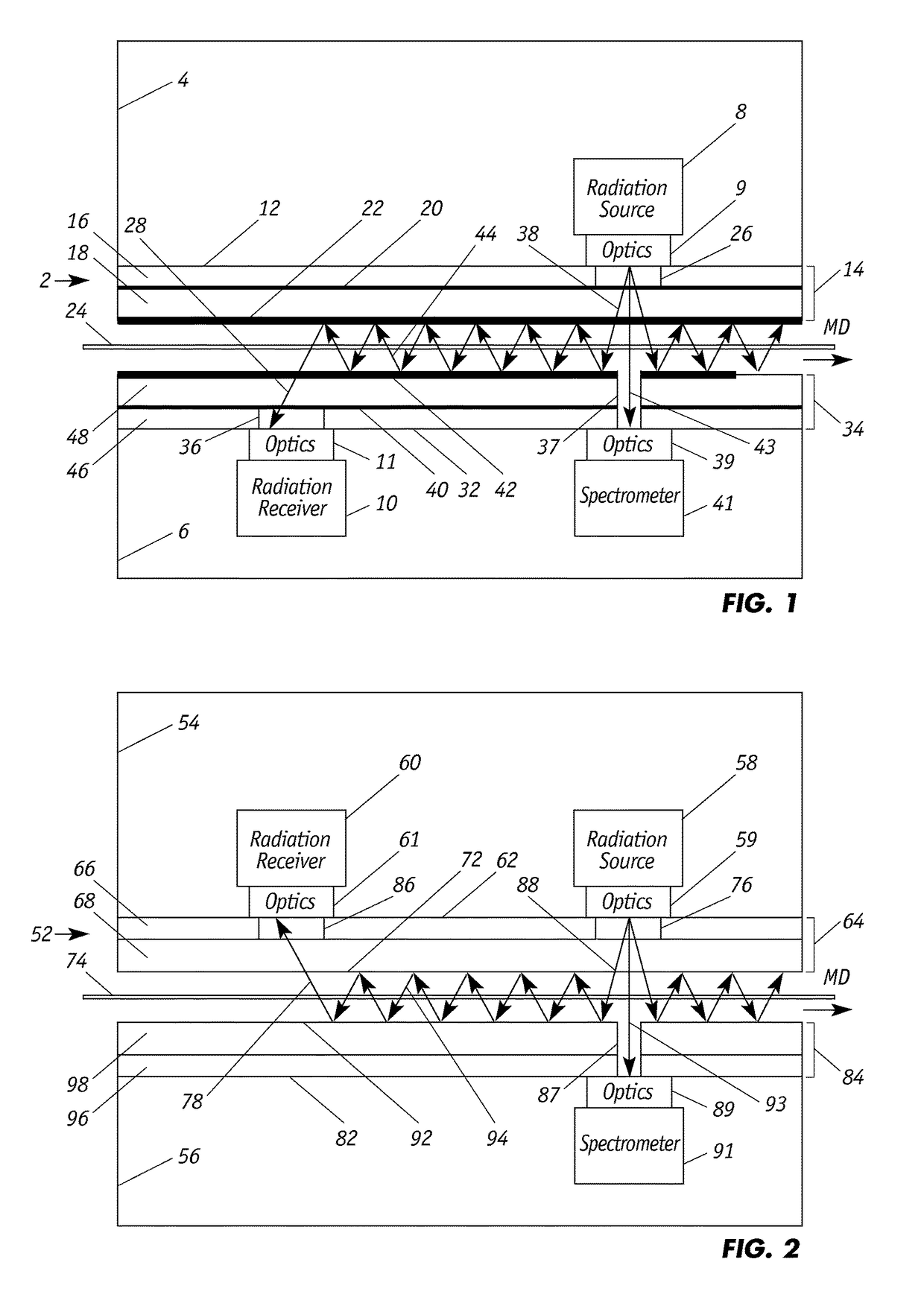

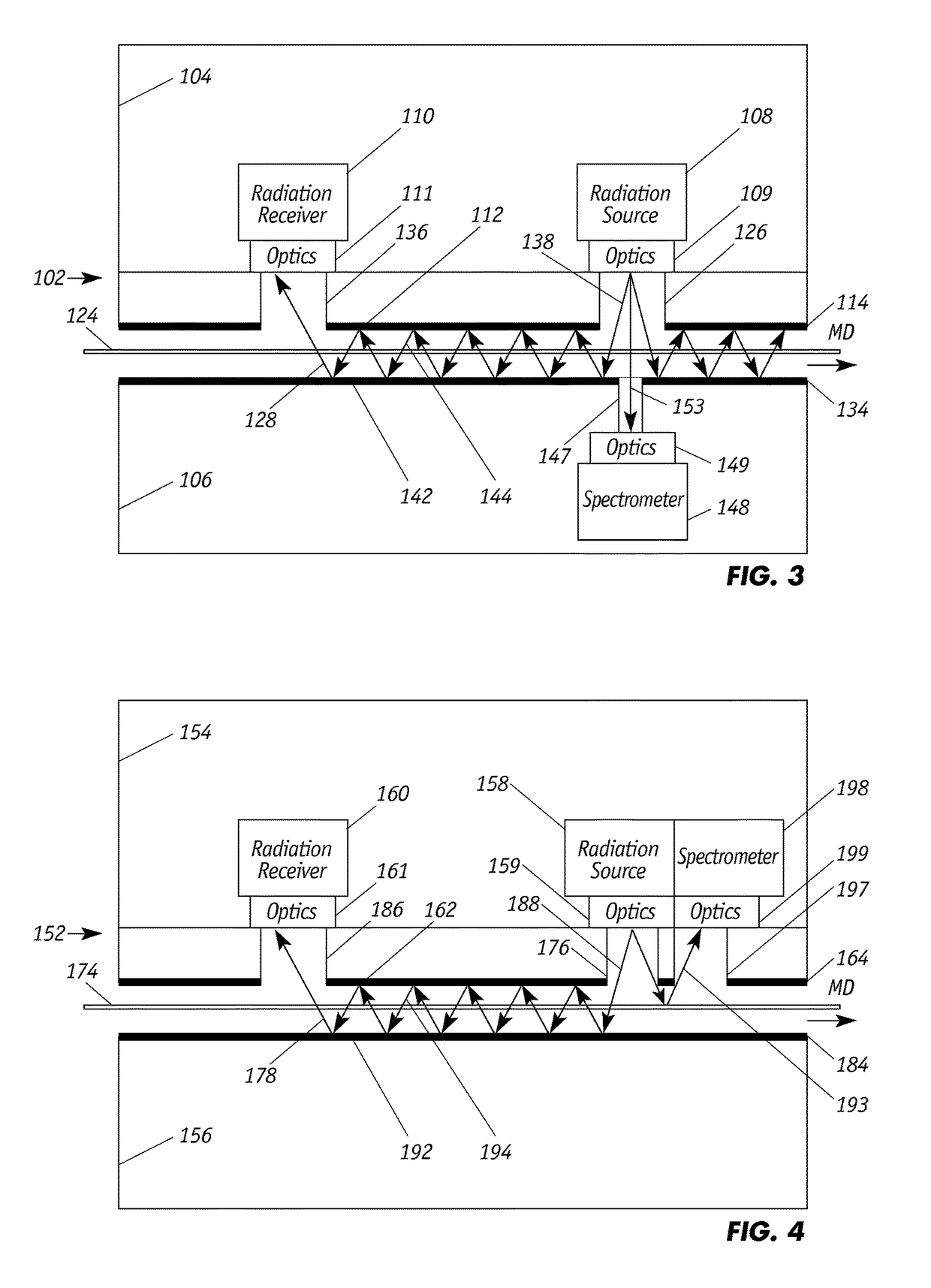

Spectroscopic Sensor for Thickness or Weight Measurement of Thin Plastic Films

ActiveUS20160282277A1High sensitivityInterferometric spectrometryInvestigating moving sheetsBroadbandFar infrared

Continuous on-line thin film measurements employ a sensor having a spectrometer for interferometric measurements and a stack of single channel detectors for adsorption measurements. The stack is separated from the spectrometer, which analyzes radiation that emerges (transmitted pass or reflected from) the film, whereas the stack analyzes radiation that has passed through the film multiple times. The spectrometer is (i) positioned directly opposite the source of radiation so that it detects transmitted radiation or (ii) disposed on the same side of the film as is the source of radiation so that the spectrometer detects radiation that is specularly reflected from the film. The sensor includes a broadband radiation source emitting visible to far infrared light which propagates through a measurement cell defined by reflective surfaces exhibiting Lambertian-type scattering. The sensor is capable of measuring thin plastic films with thicknesses down to 1 micron or less.

Owner:HONEYWELL INC

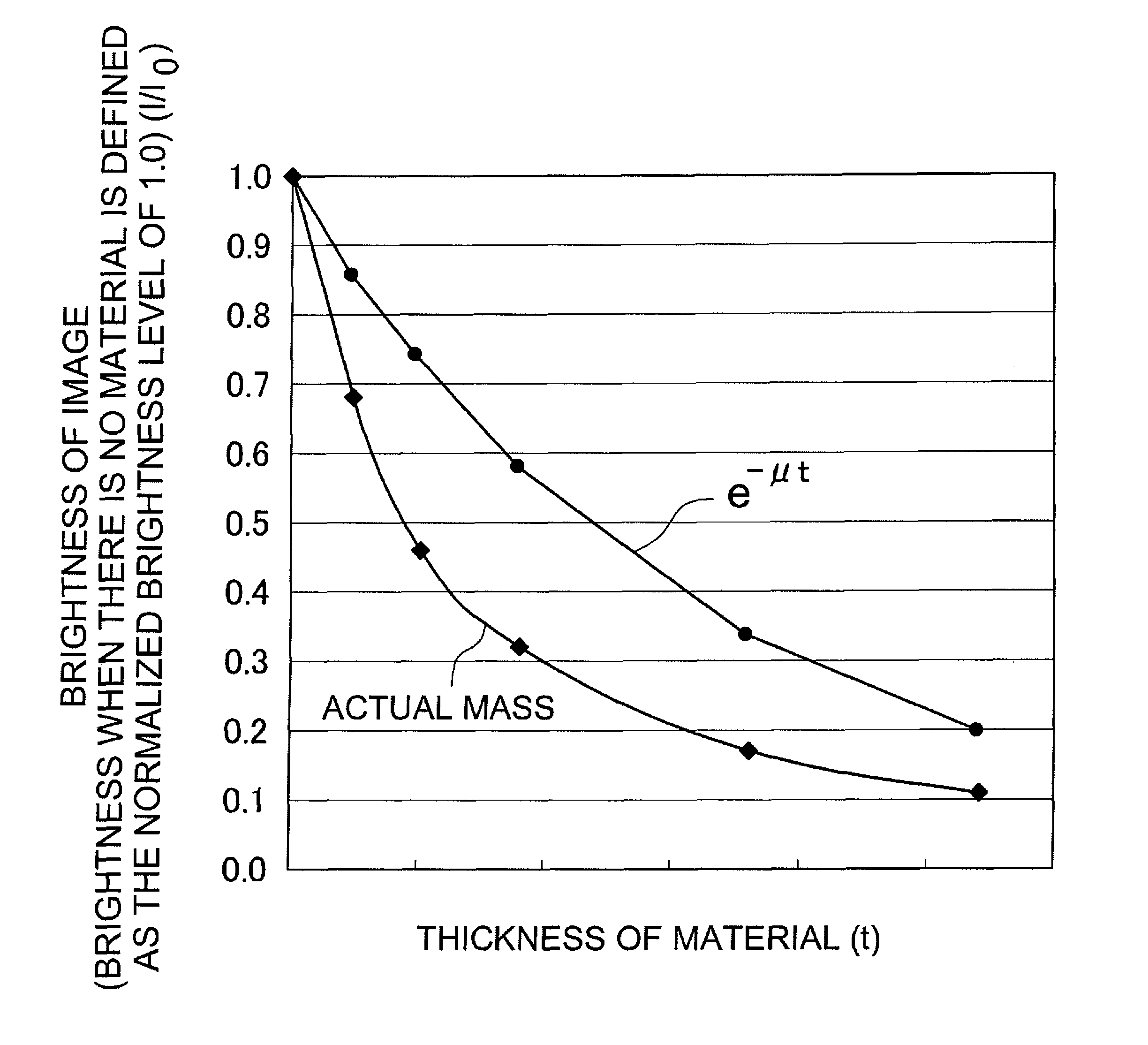

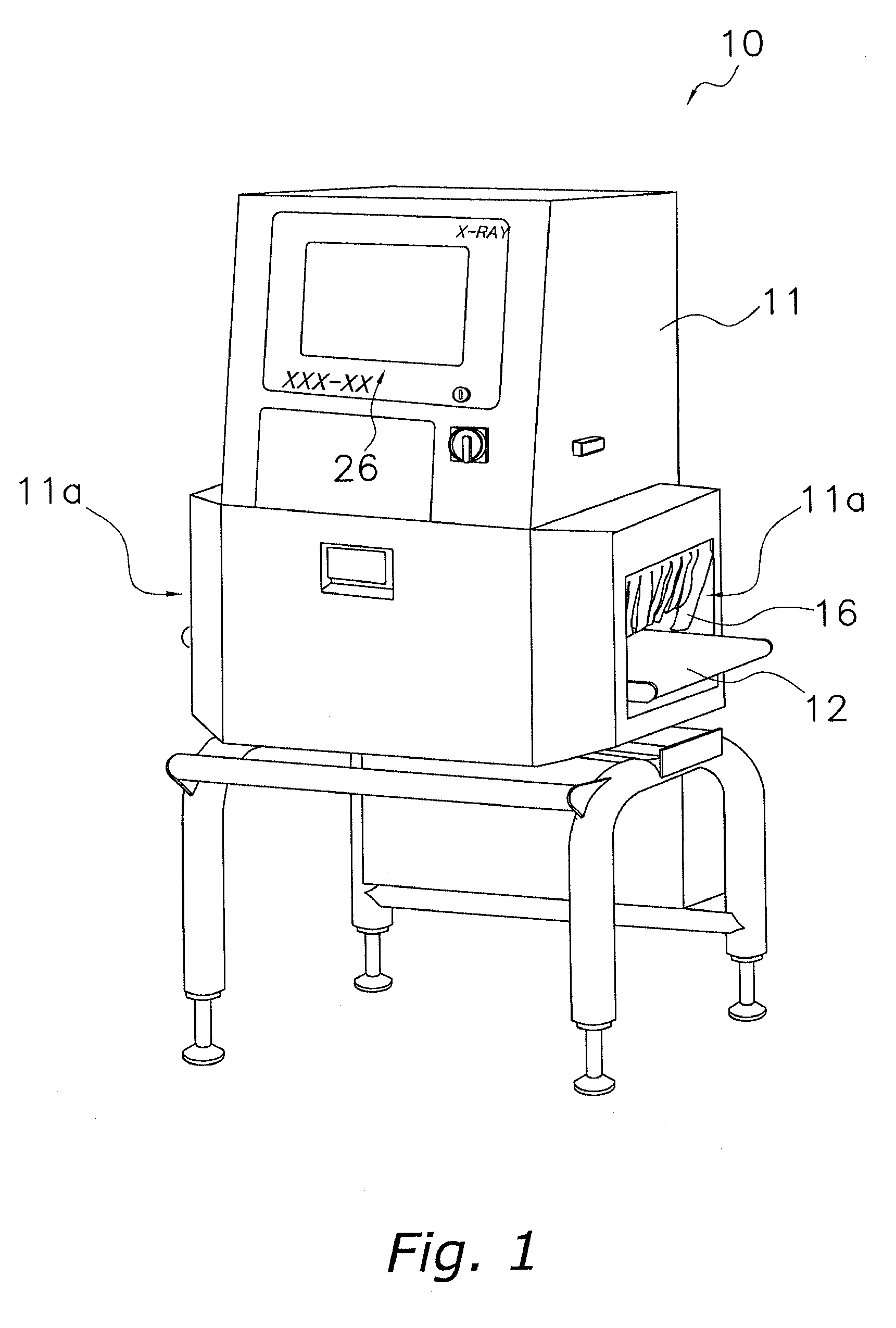

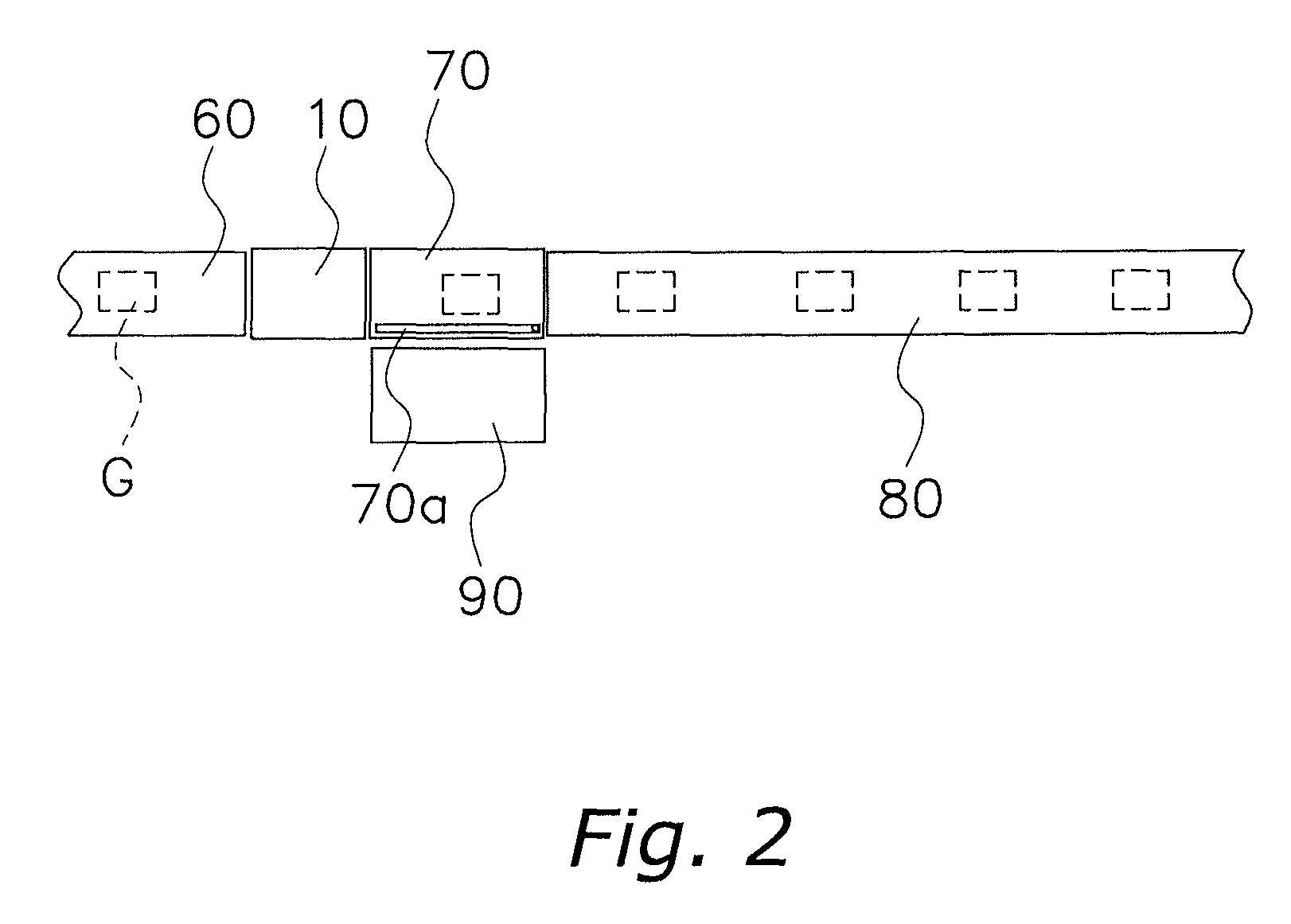

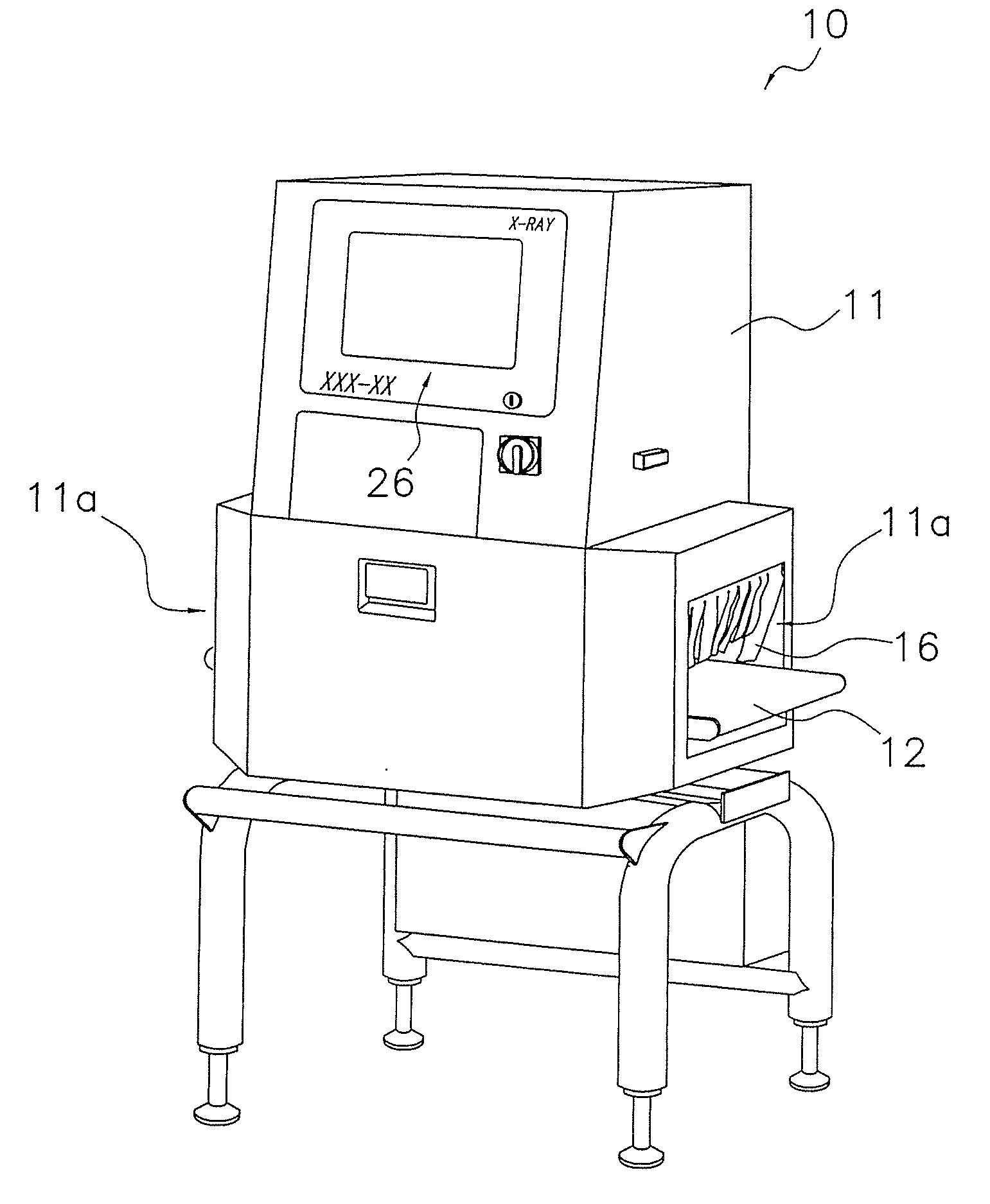

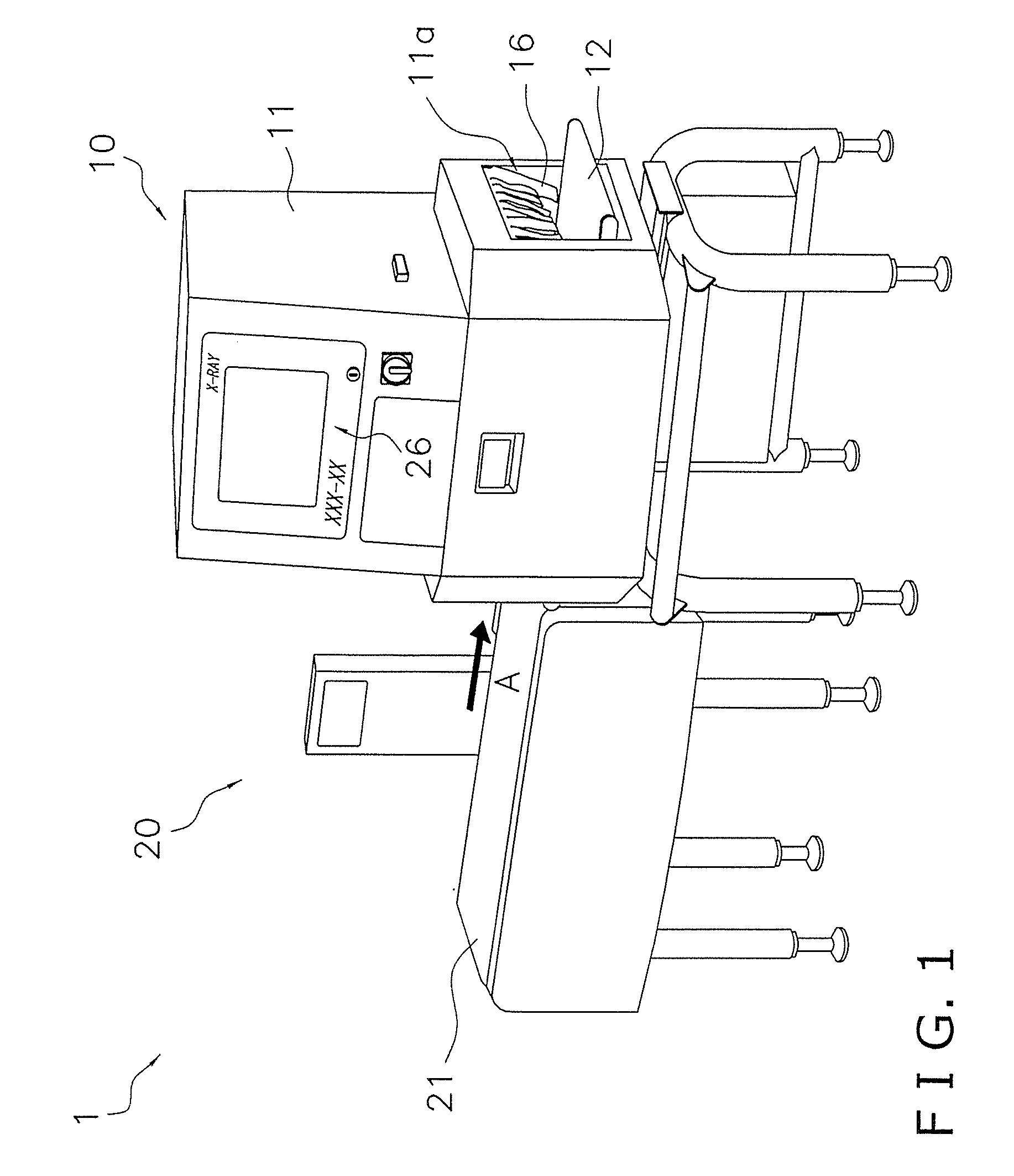

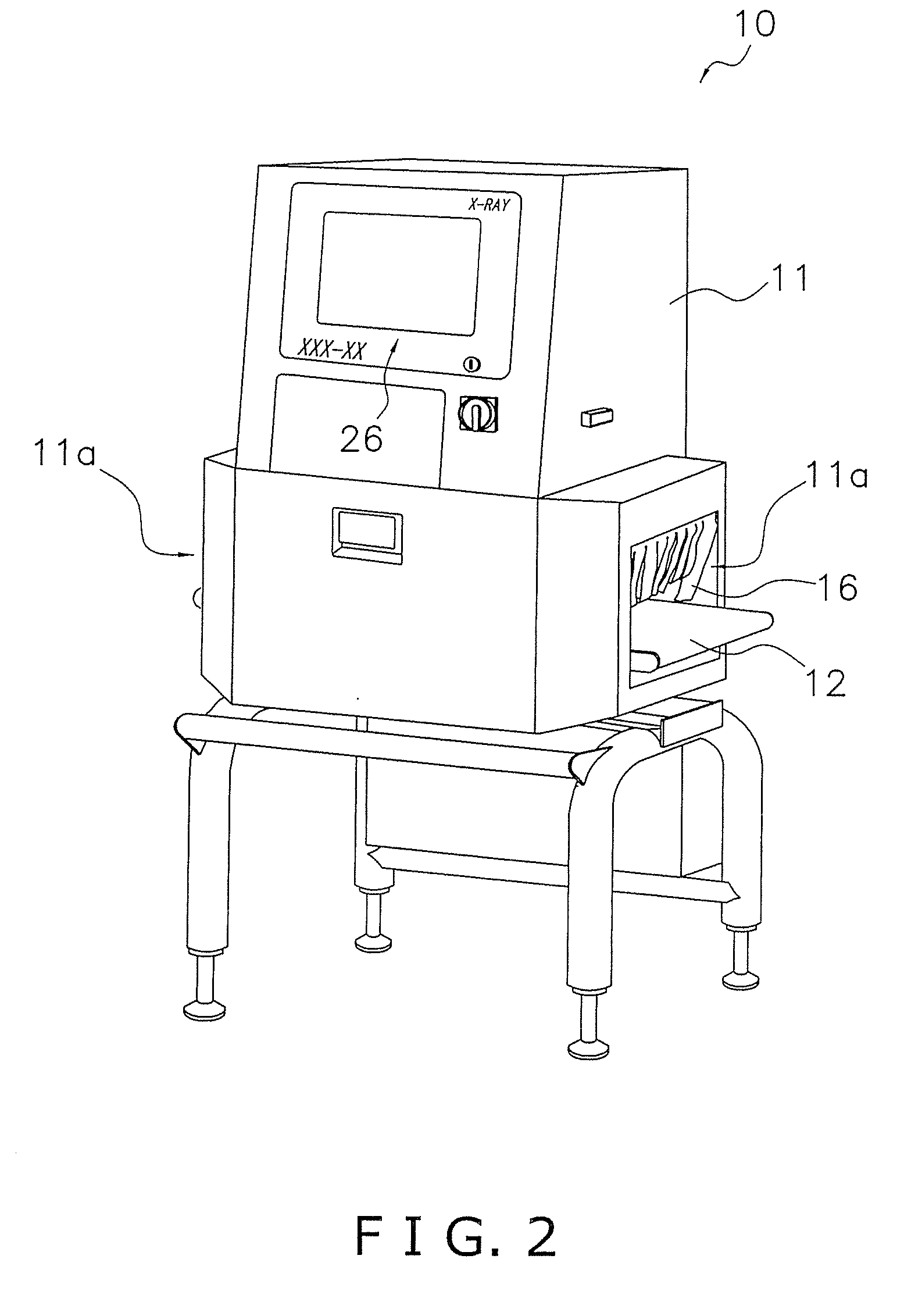

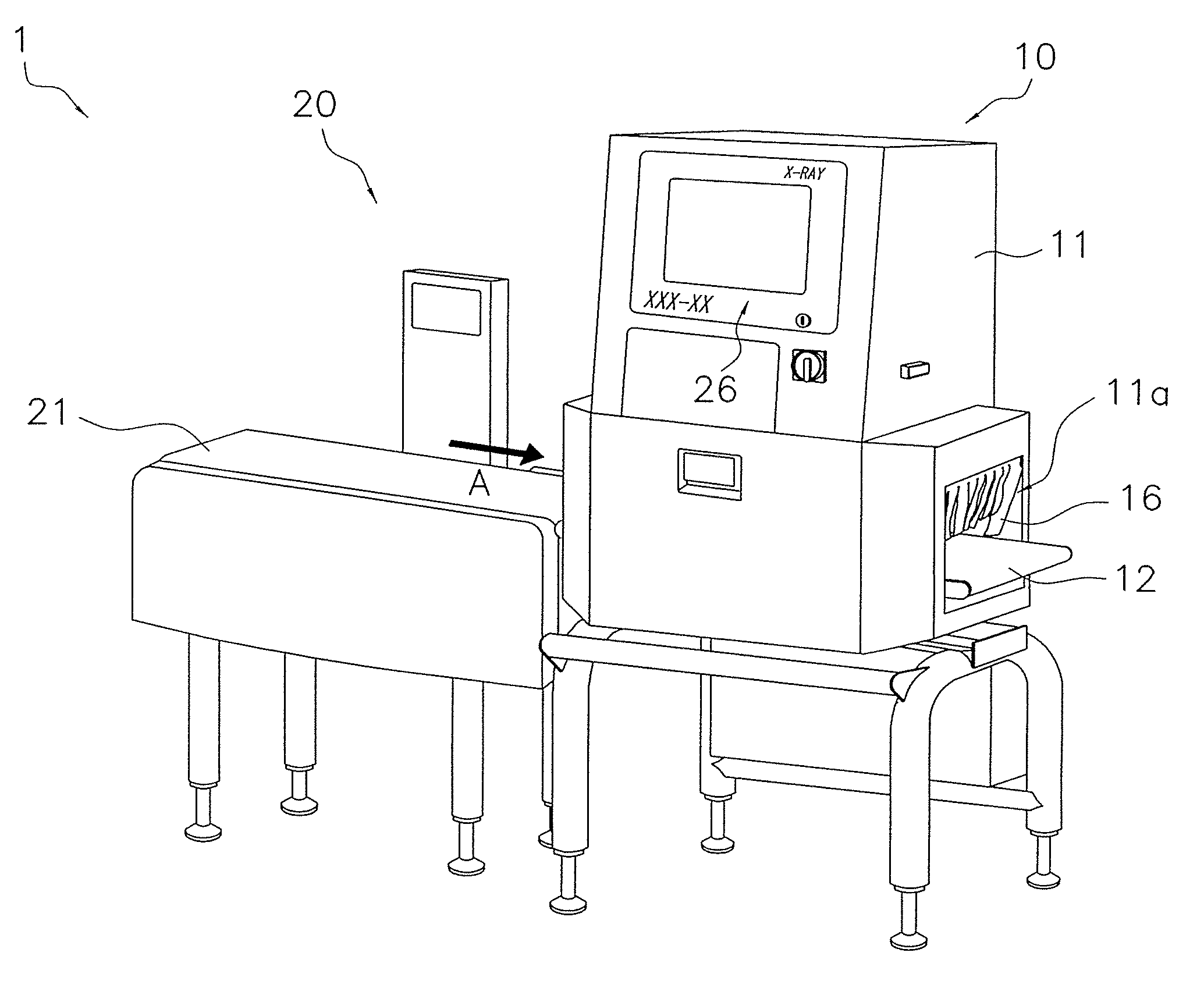

X-ray inspection apparatus

ActiveUS8068656B2Improve accuracyExclude influenceAnalogue computers for vehiclesWeighing apparatus using radiationX-raySample image

An x-ray inspection apparatus includes a sample image obtaining unit, an ideal curve generating unit, a curve adjustment unit, and a mass estimation unit as a function block generated by a control computer. The sample image obtaining unit obtains 10 x-ray transmission images of sample inspected products each of whose mass is known in advance. The ideal curve generating unit generates a table based on a formula that indicates a relationship between the brightness of an area included in the x-ray transmission images and the estimated mass of the area. The curve adjustment unit refers to the input actual mass of each x-ray transmission image and adjusts the table such that the estimated mass approximates the actual mass. The mass estimation unit determines the estimated mass per unit area based on the post-adjusted table and adds up these masses to determine the total estimated mass of the product.

Owner:ISHIDA CO LTD

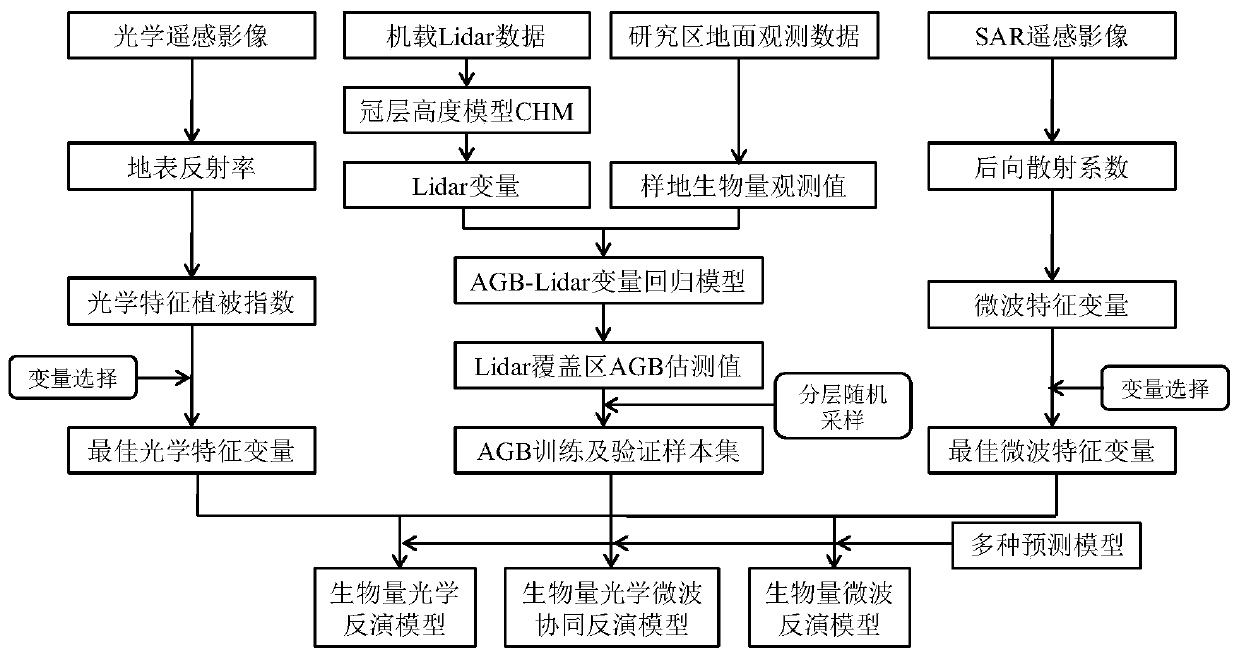

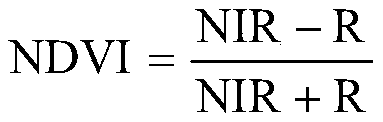

Optical microwave cooperative inversion method and system for urban above-ground biomass

ActiveCN109884664AAvoid Manual Sampling MethodsAchieve full coverageImage enhancementImage analysisData setAbove ground

The invention discloses an optical microwave cooperative inversion method and system for an urban above-ground biomass. The method comprises the steps of obtaining an AGB observation value of a samplebiomass by use of a sample area single-plant parameter data set acquired by a ground surface observation test; performing pretreatment to obtain a canopy height value CHM, surface reflectance data and a backscattering coefficient; extracting various LiDAR variables based on the CHM data, and extracting multiple optical characteristic vegetation indices based on the optical surface reflectance data, and simultaneously extracting multiple microwave characteristic variables based on the microwave backscattering coefficient data; extracting a biomass estimation value of an LiDAR data coverage area; selecting a sample for subsequent modeling and verification by use of a stratified random sampling method with the biomass value of the LiDAR data coverage area as a training and verification sample set; screening out an optimal optical and microwave characteristic variable by use of a variable screening method; and constructing an AGB-inverted optical model, a microwave model and an optical and microwave cooperative model, and selecting an optimal model to realize biomass inversion.

Owner:WUHAN UNIV

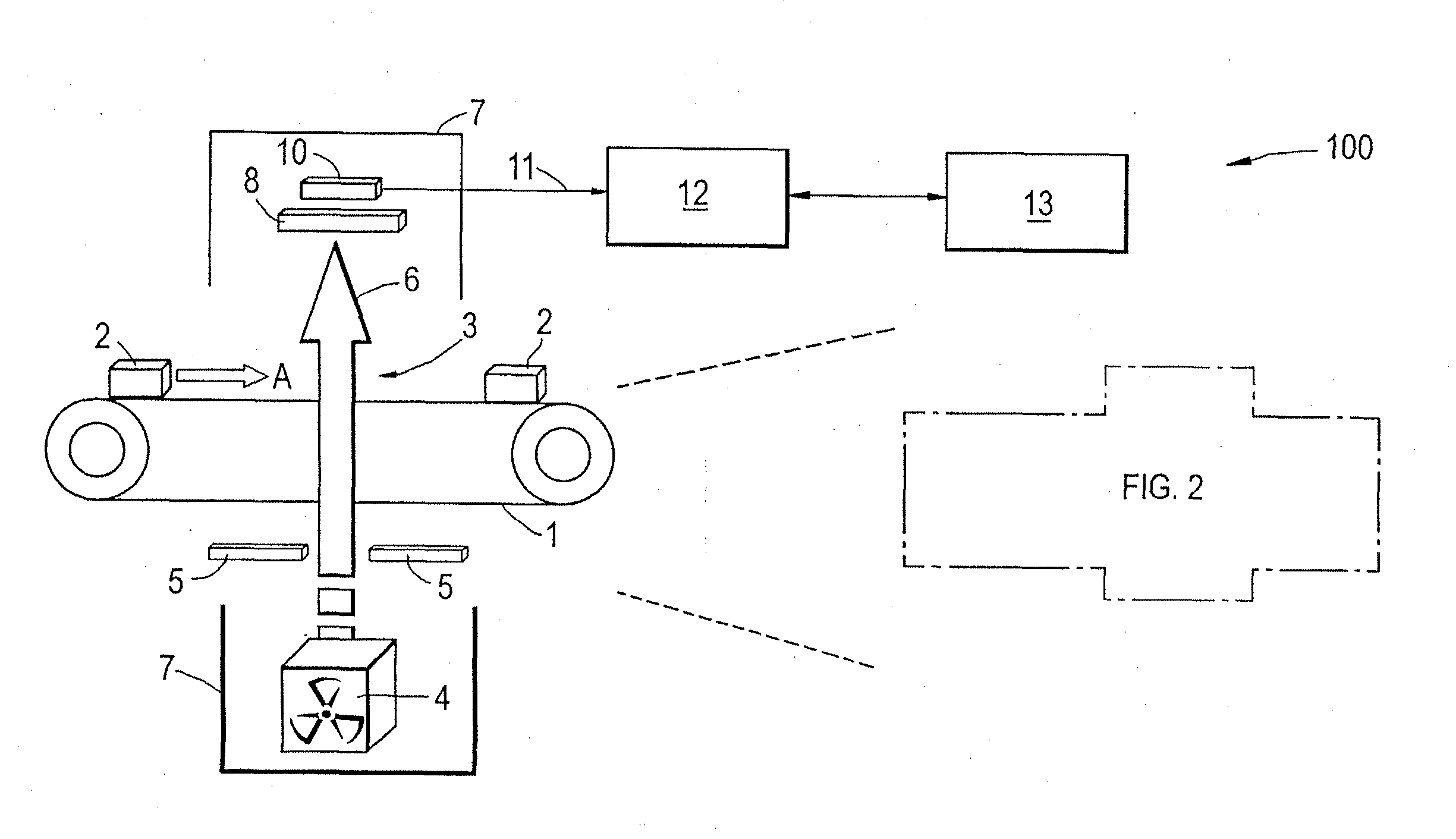

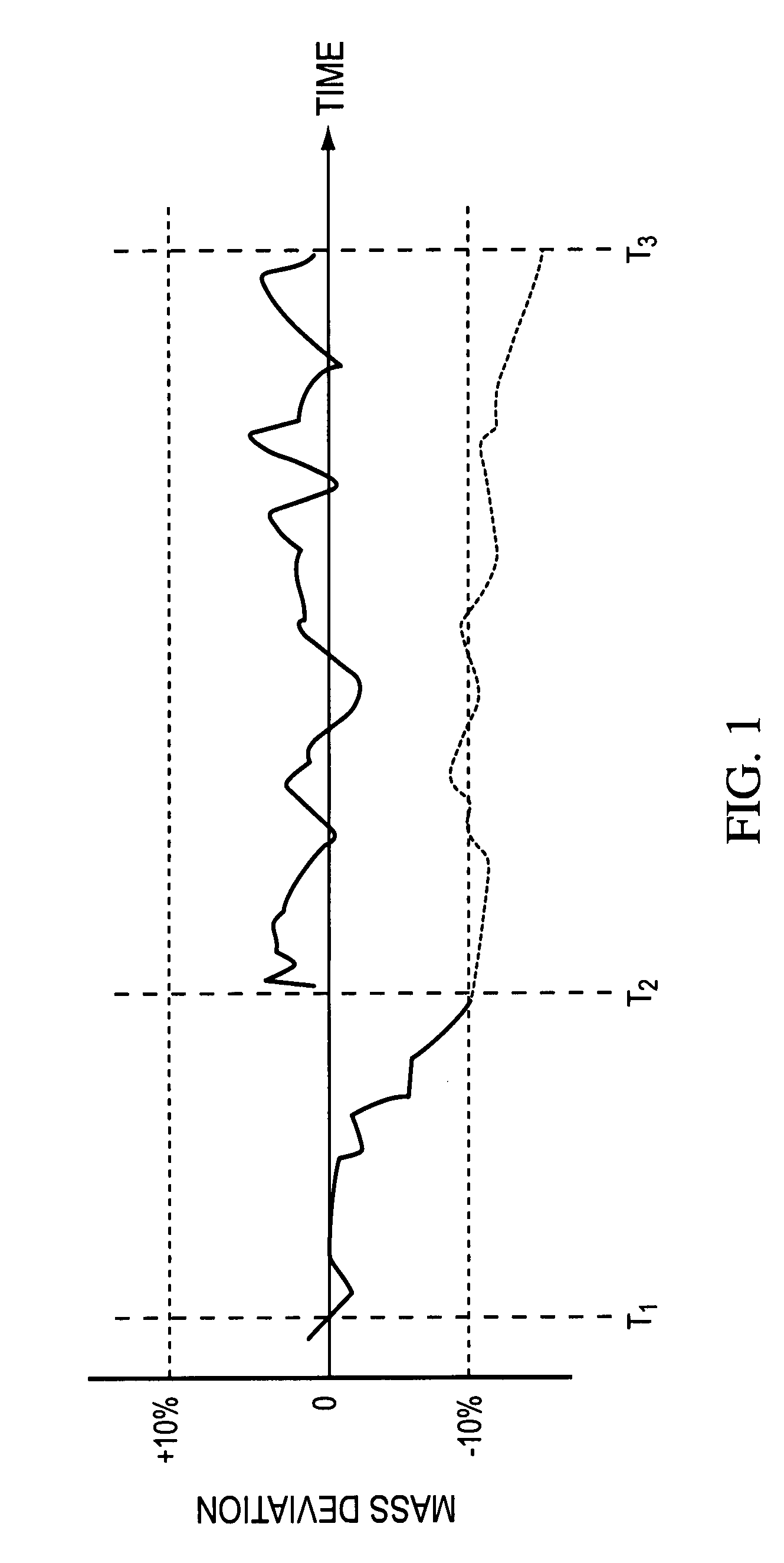

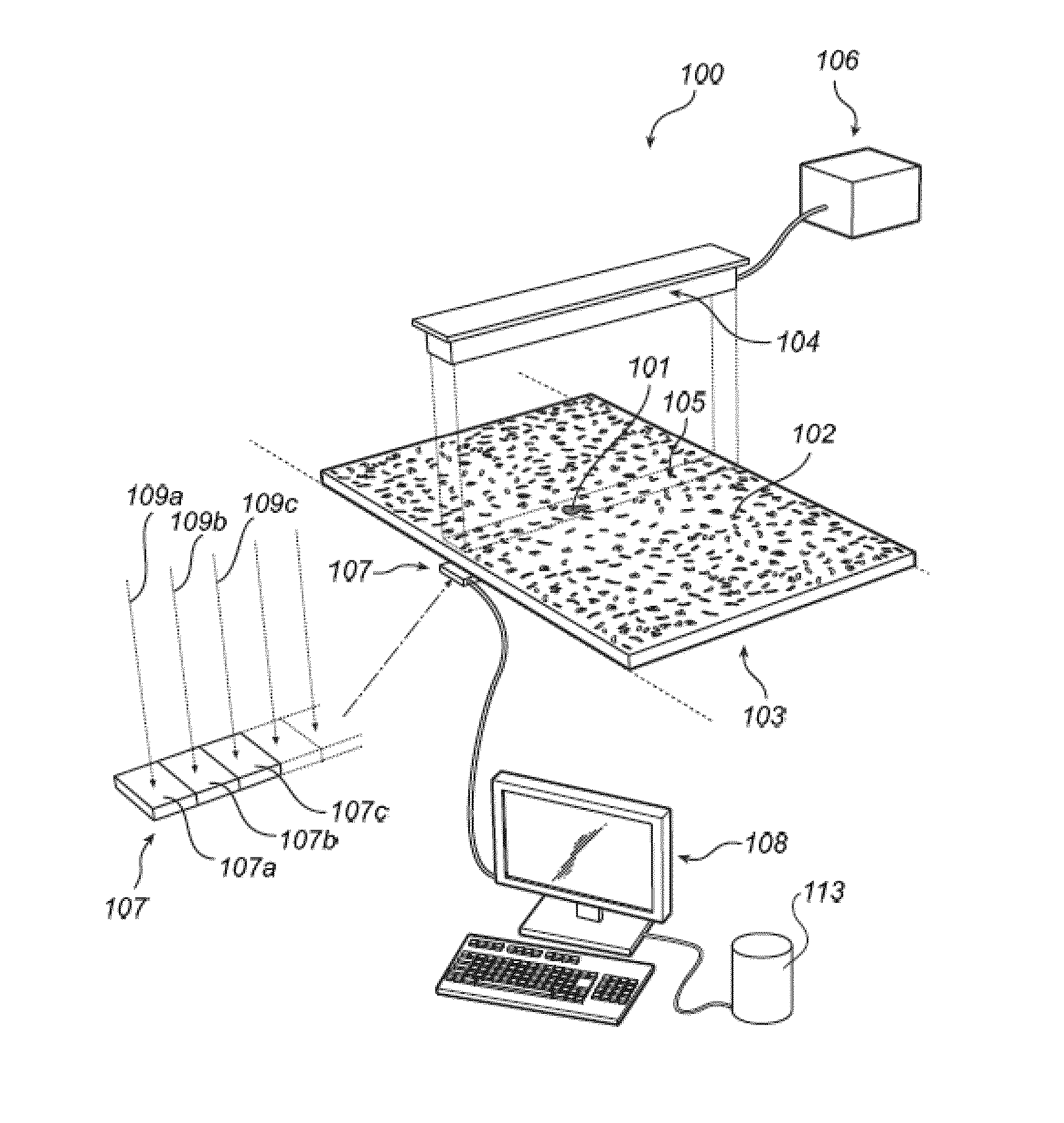

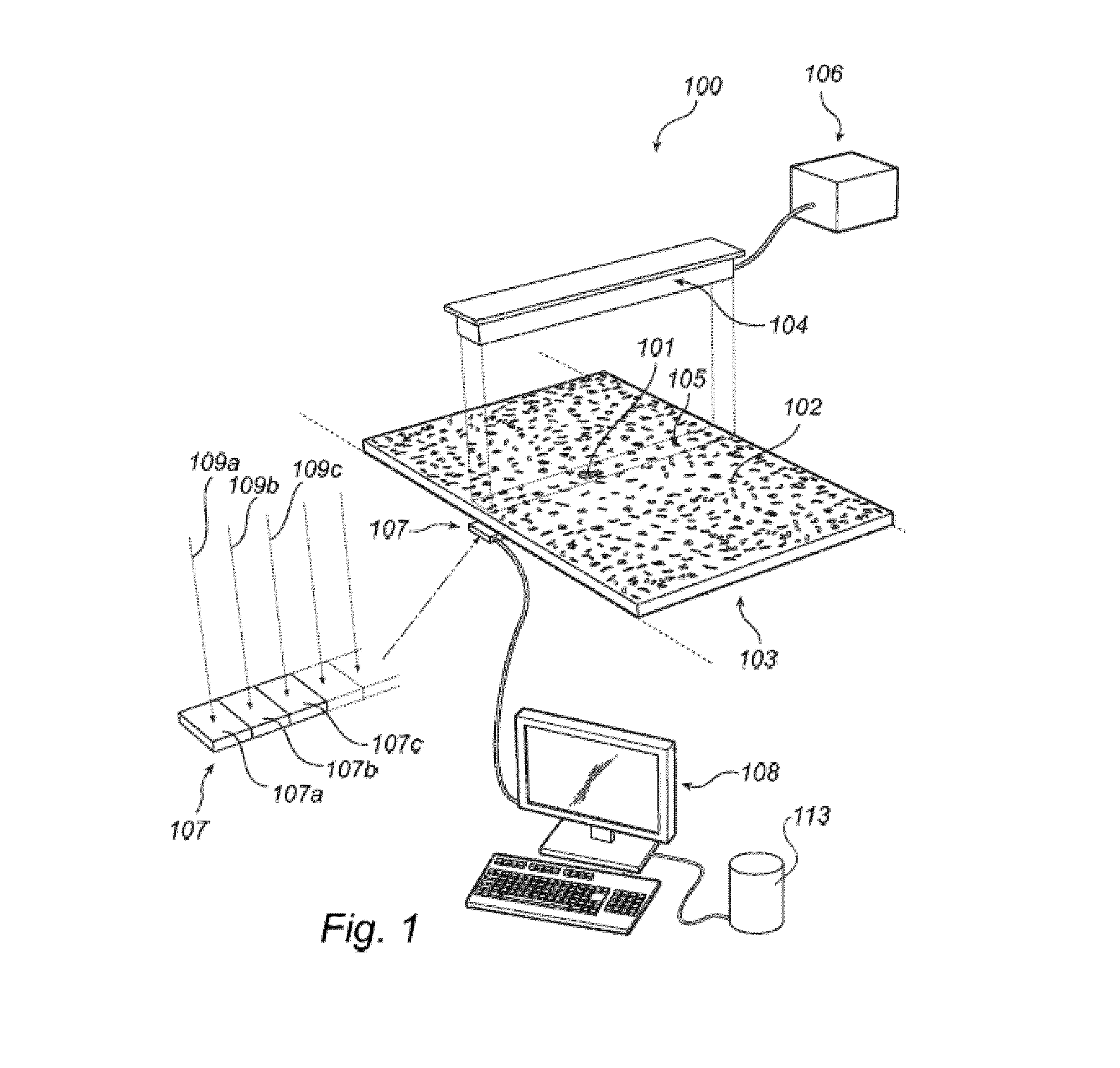

Inspection apparatus and method using penetrating radiation

InactiveUS20100256952A1Faster throughputWeighing apparatus using radiationDigital computer detailsX-rayTotal energy

A method of determining a parameter of an object using penetrating radiation such as X-rays. The parameter of the object could be weight or mass or volume. The method comprises the step of passing the penetrating radiation through the object; determining a first value derived from the total energy of penetrating radiation absorbed by the object; determining a second value related to the mean energy per unit area of penetrating radiation absorbed by the object and determining the parameter from the first and second values. An algorithm representing a proportionality relationship is derived from the first and second value. The parameter is determined by establishing an exponential relationship to an amount derived from the algorithm.

Owner:ILLINOIS TOOL WORKS INC

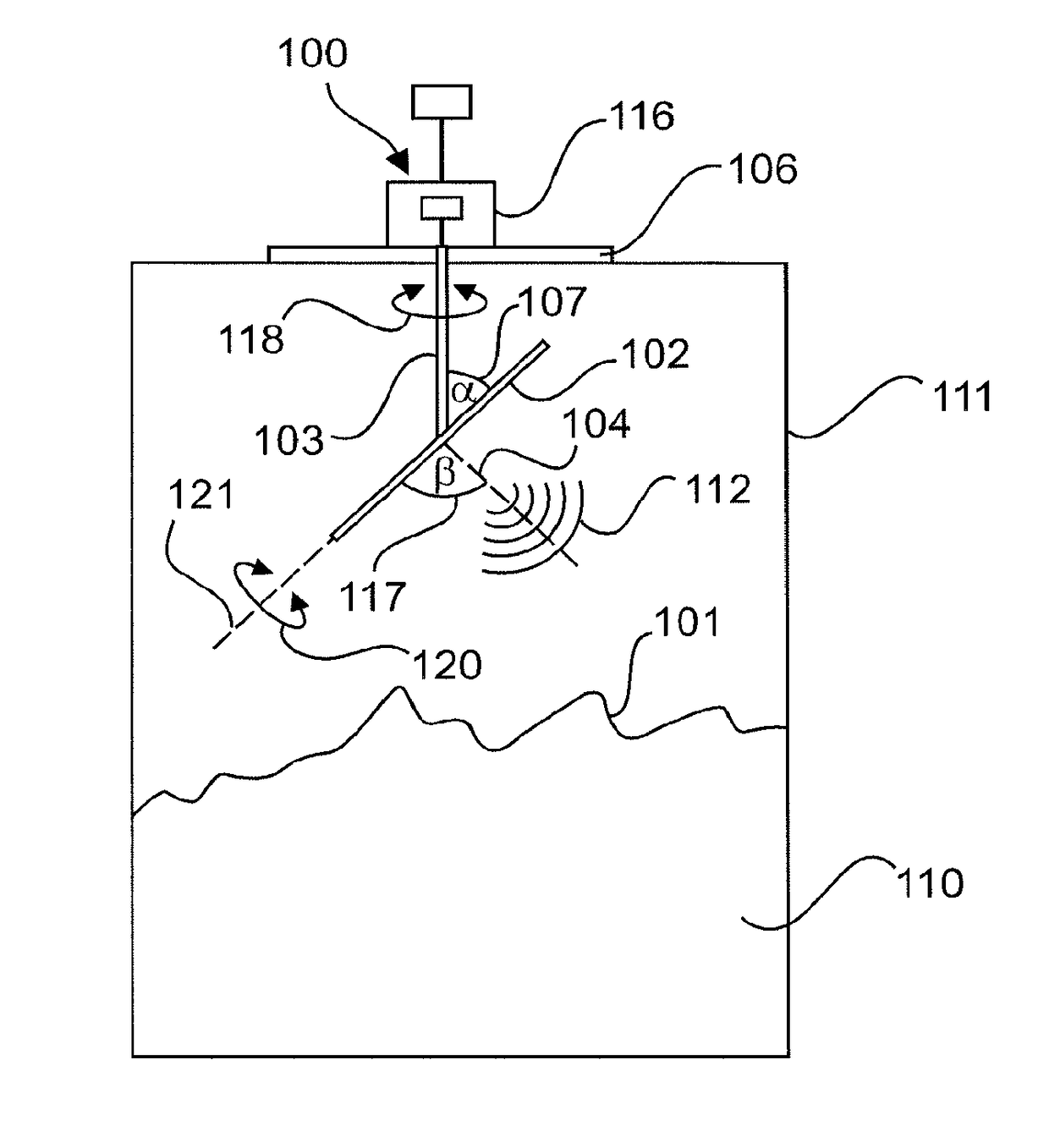

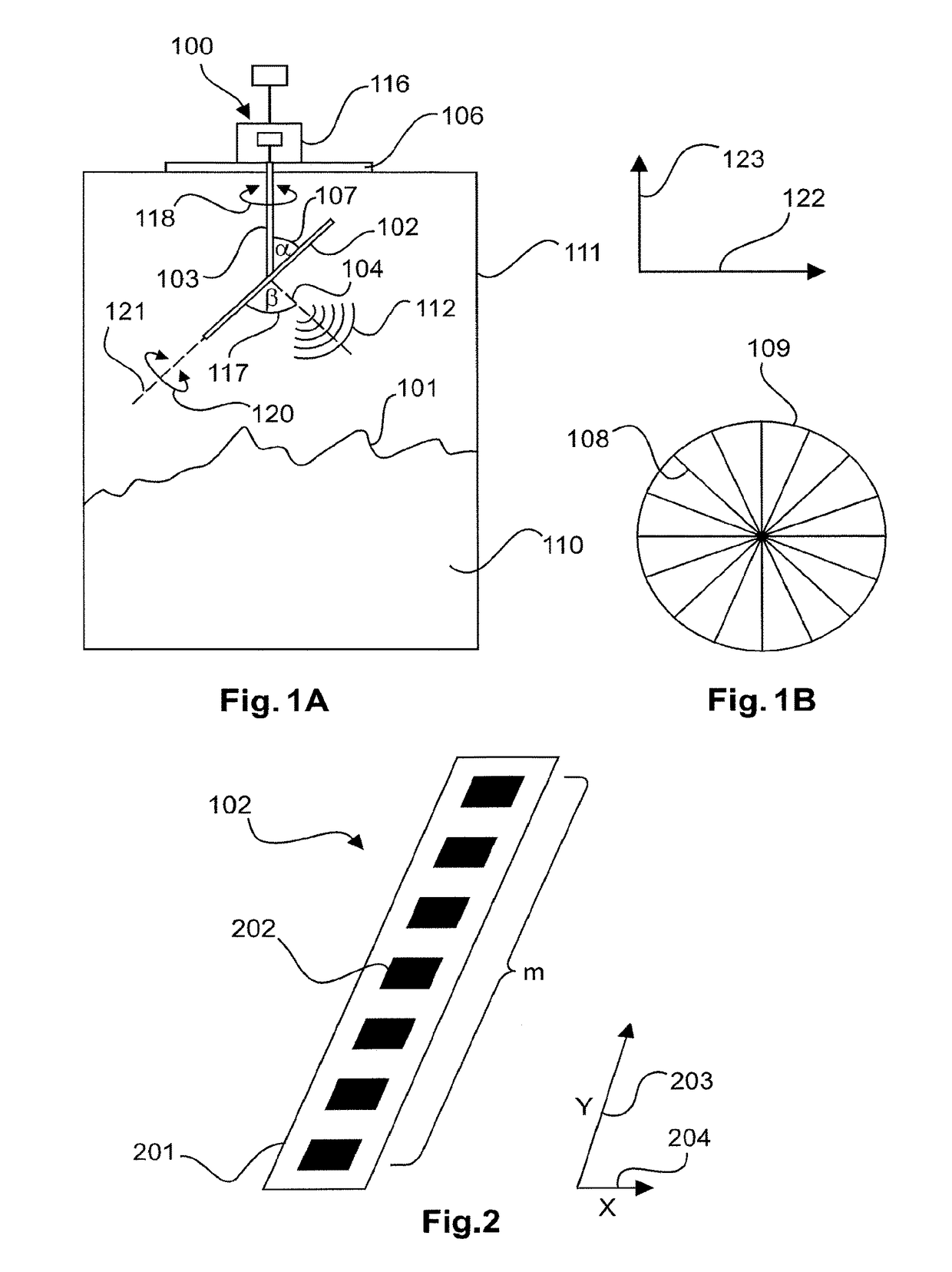

Topology determination of a filling material surface with uniform line scanning

ActiveUS20170309989A1Quick checkScanning uniformityVolume measurement apparatus/methodsFlow propertiesMeasurement deviceFilling materials

A fill level measurement device for determining a topology of a filling material surface is provided, including an antenna apparatus including an array of radiator elements and a rotatable mount configured to rotate the antenna apparatus about an axis that is in parallel with the array, such that a plurality of emission angles of the antenna apparatus are electronically and mechanically settable relative to the filling material surface without local overscanning occurring.

Owner:VEGA GRIESHABER GMBH & CO

Measuring device for rapid non-destructive measurement of the contents of capsules

ActiveUS7071706B2Resistance/reactance/impedenceMaterial analysis using microwave meansNon destructiveMeasurement device

Owner:BOEHRINGER INGELHEIM INT GMBH

Device and method for determining weight, in particular the weight of a container filled with product

ActiveUS20160140413A1The process is simple and accurateImprove accuracyImage enhancementImage analysisX-rayEngineering

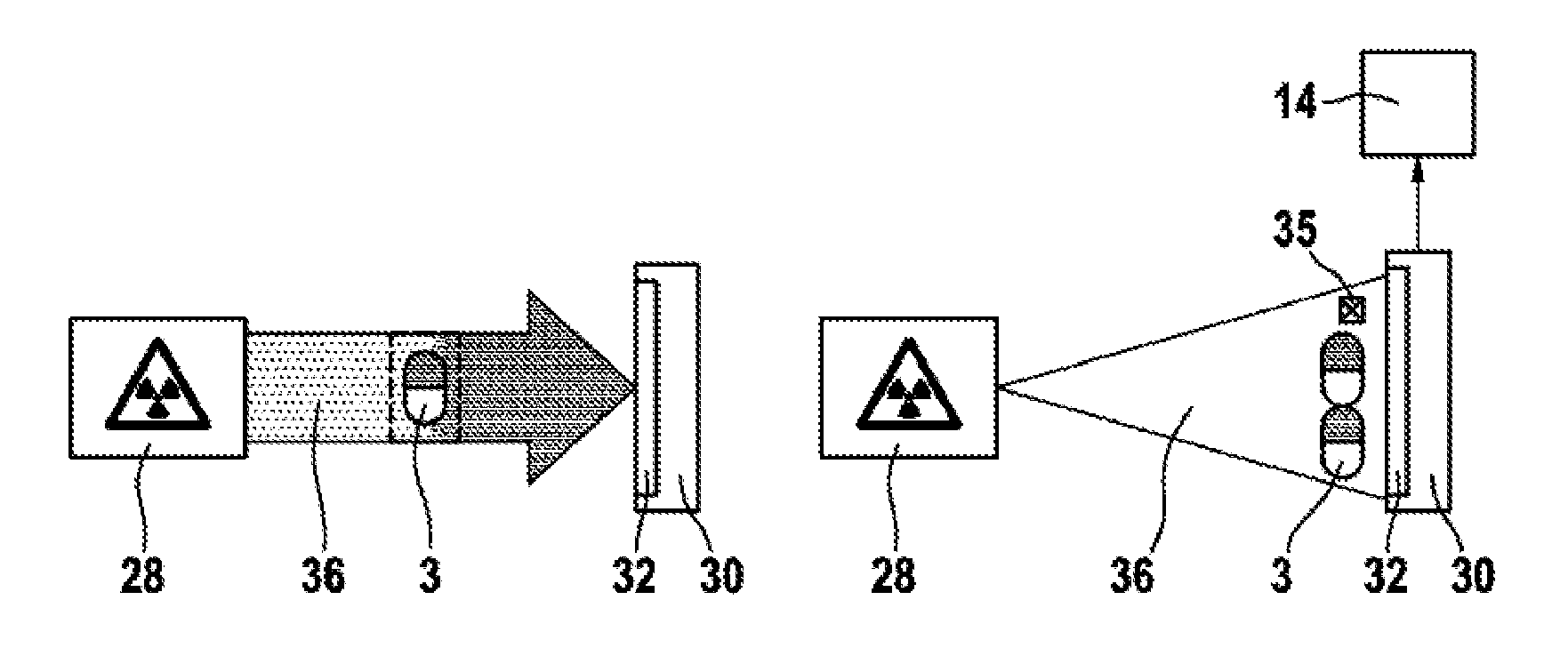

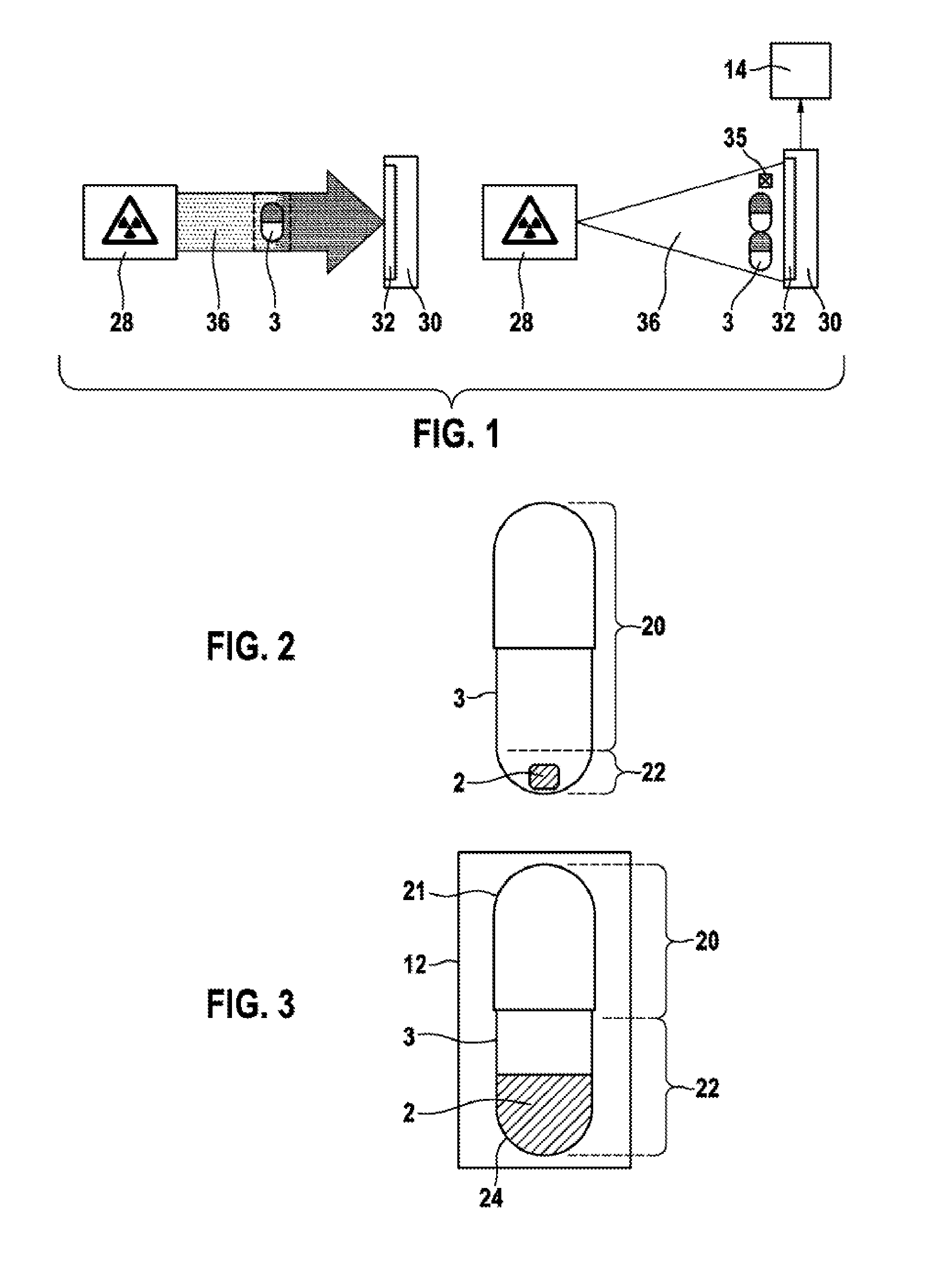

The invention relates to a device and a method for determining the weight of product (2), in particular a pharmaceutical product, which is located in a container (3). The device comprises at least one x-ray source (28), which produces a radiation path (18), for passing radiation through the container (3), and a sensor (14), which detects the radiation of the container (3) through which radiation is passed in the form of an image (12), wherein an evaluating apparatus (14), is provided, which divides the image (12) of the container (3) through which radiation is passed into at least one evaluation region (21) in which there is no product (2).

Owner:SYNTEGON TECHNOLOGY GMBH

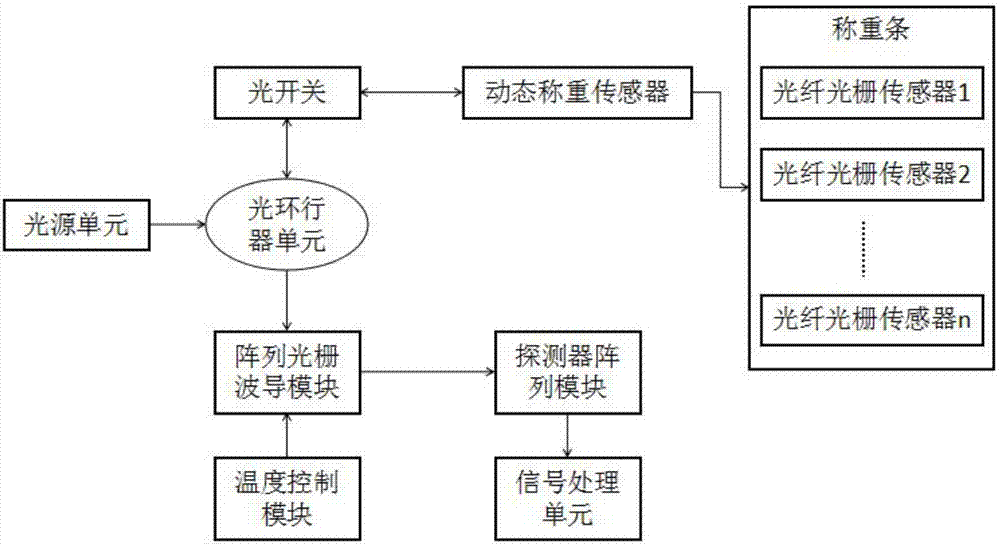

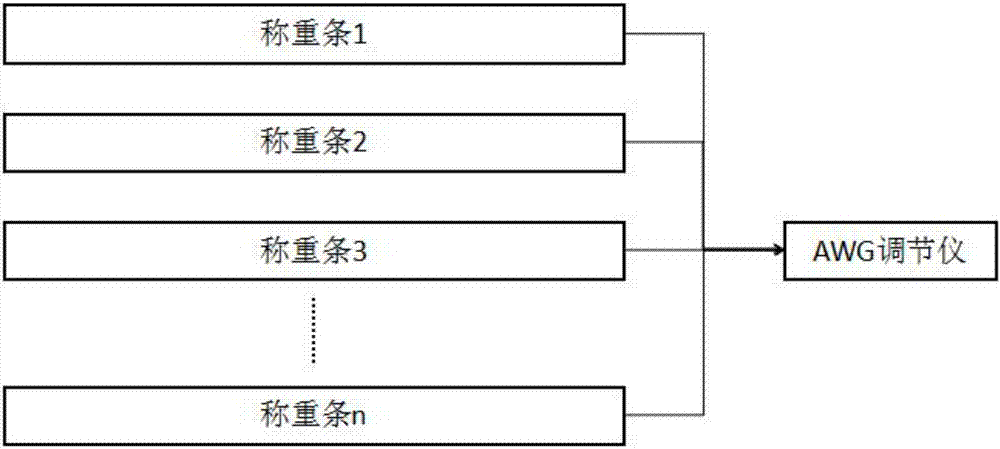

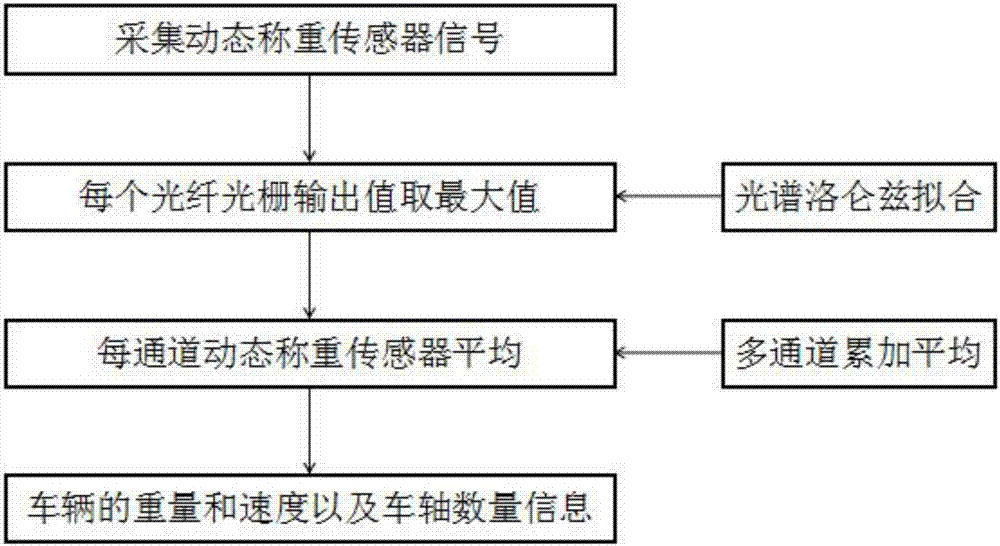

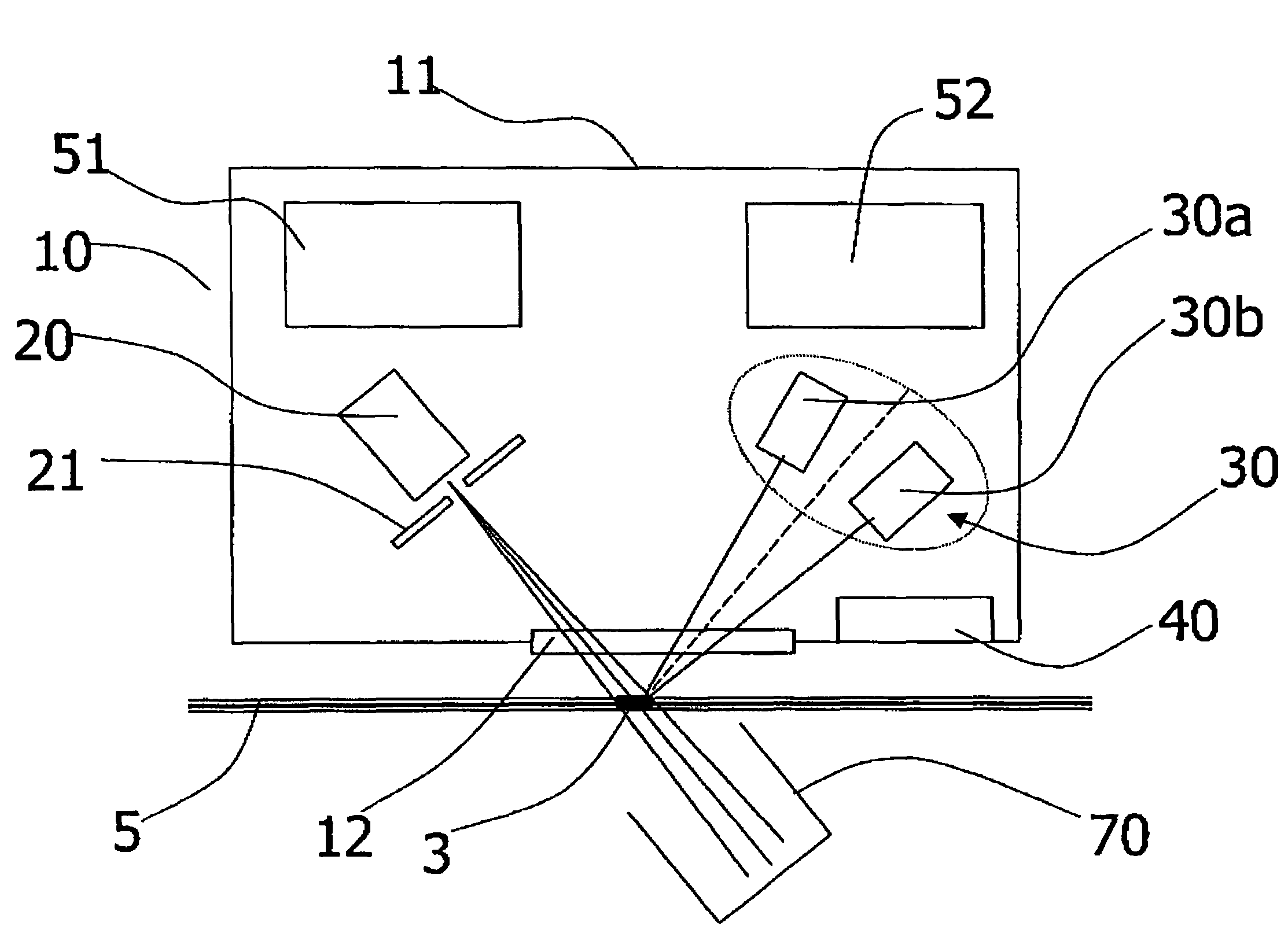

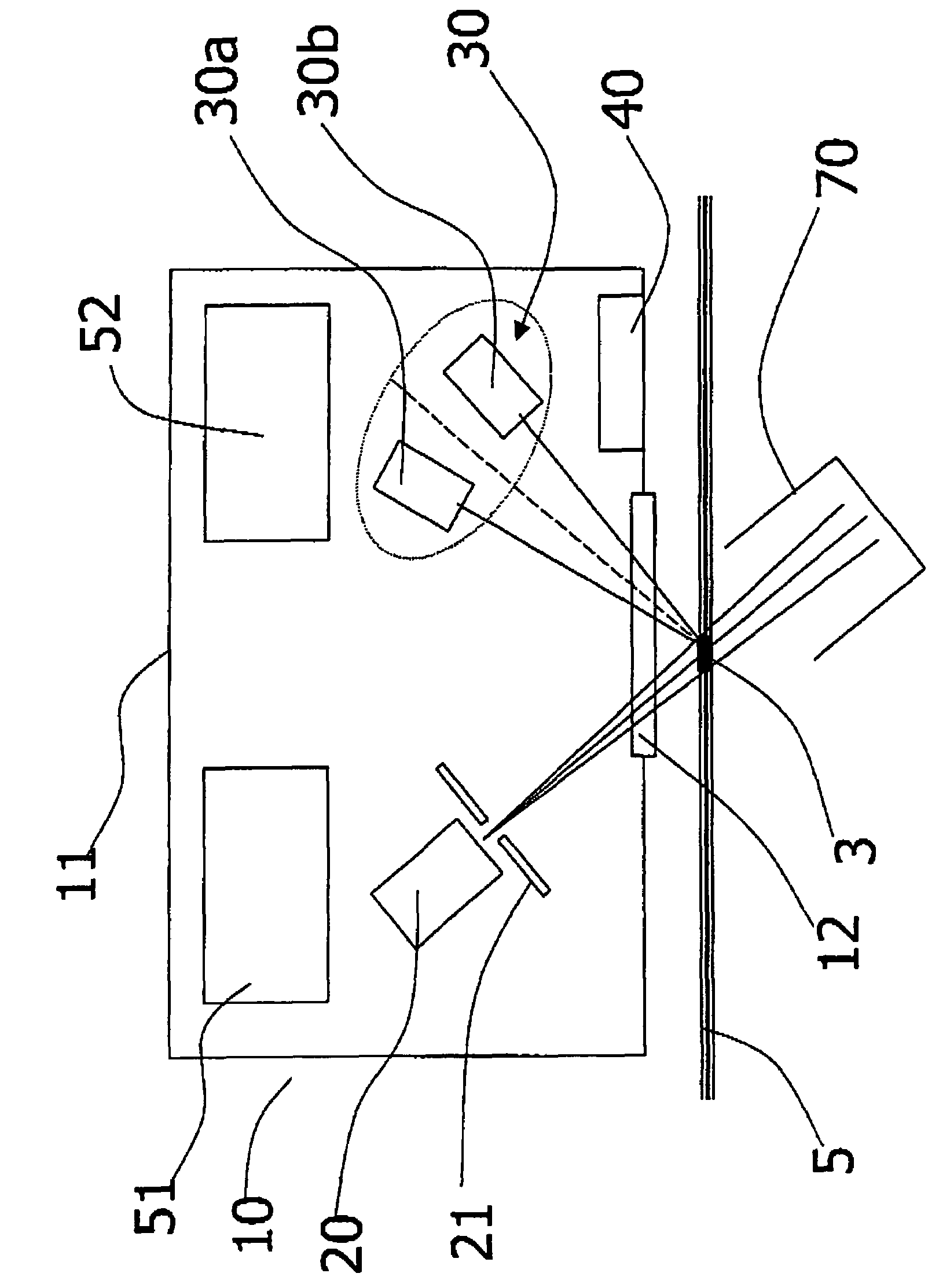

Vehicle dynamic weighing system and monitoring method thereof

InactiveCN107131938AHighly integratedReduce volumeWeighing apparatus using radiationSpecial purpose weighing apparatusVehicle dynamicsLight source

The invention discloses a vehicle dynamic weighing system and a monitoring method thereof. It includes a light source unit for providing broadband; a dynamic load cell for collecting dynamic signals; the light source unit enters the dynamic load cell through an optical coupler formed by an optical circulator unit and an optical switch; it is used for signal processing of the dynamic load cell A unit; a detector array module and an array grating waveguide module are arranged between the signal processing unit and the optical circulator unit; a temperature control module for controlling the temperature of the grating in the array grating waveguide module. The present invention obtains the weight and speed information of vehicles passing through and the information on the number of axles through the array grating waveguide module, conductive communication optical cable, dynamic weighing sensor, grating signal demodulation module, and signal processing and analysis module; Detection, with high integration, small size, and sensitive detection, can be used for real-time overrun detection of overloaded vehicles in the field of highway and railway transportation.

Owner:李俊

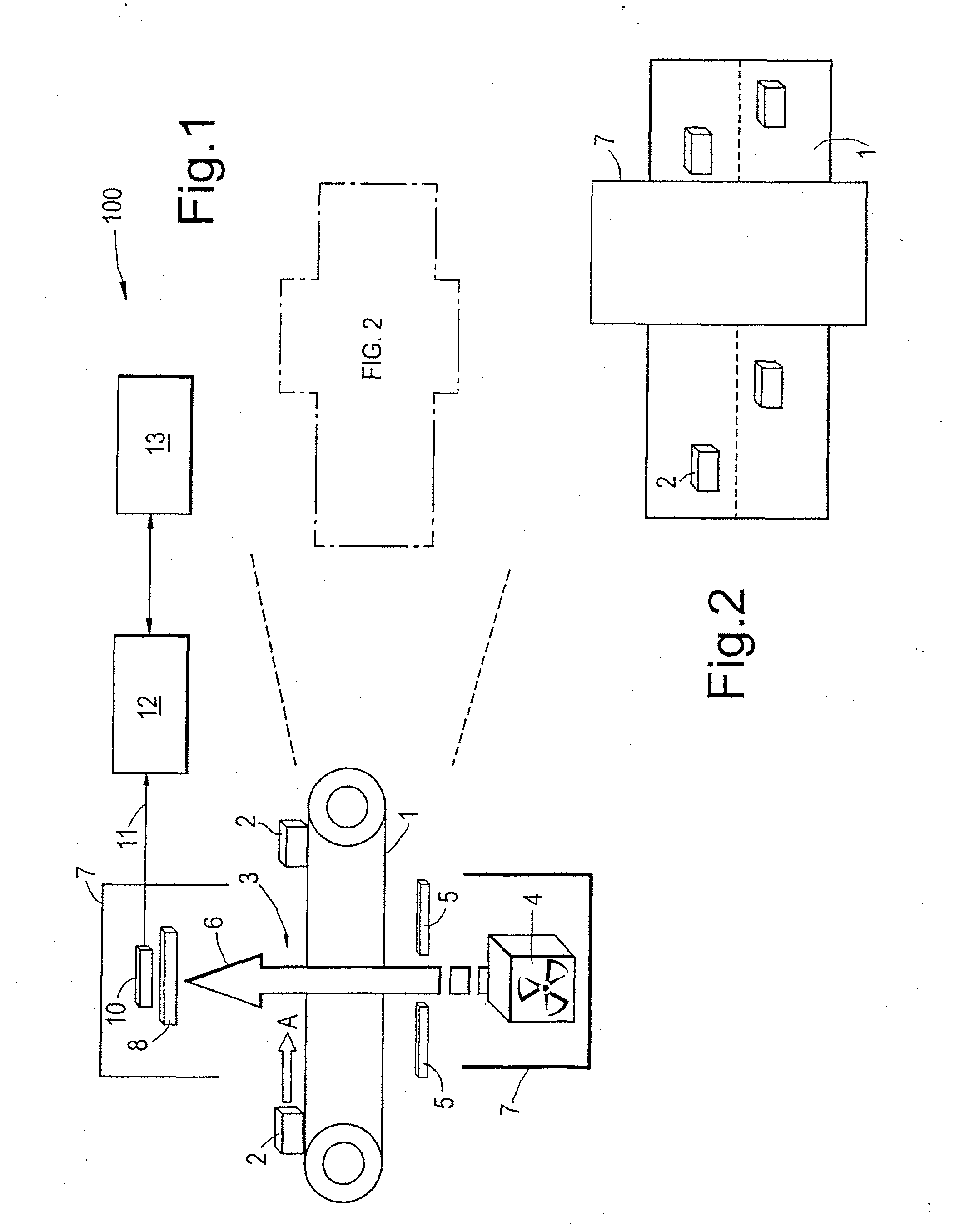

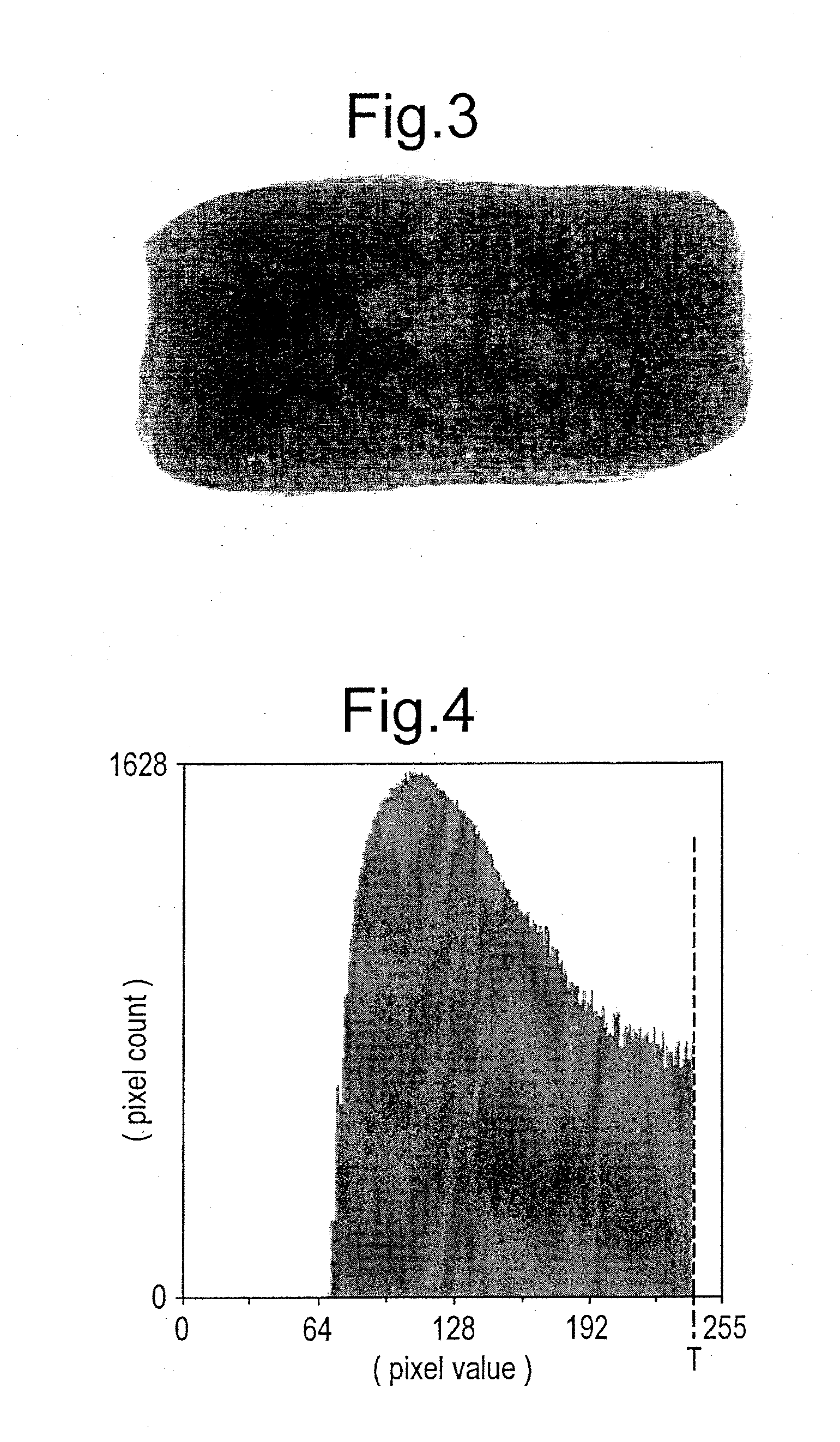

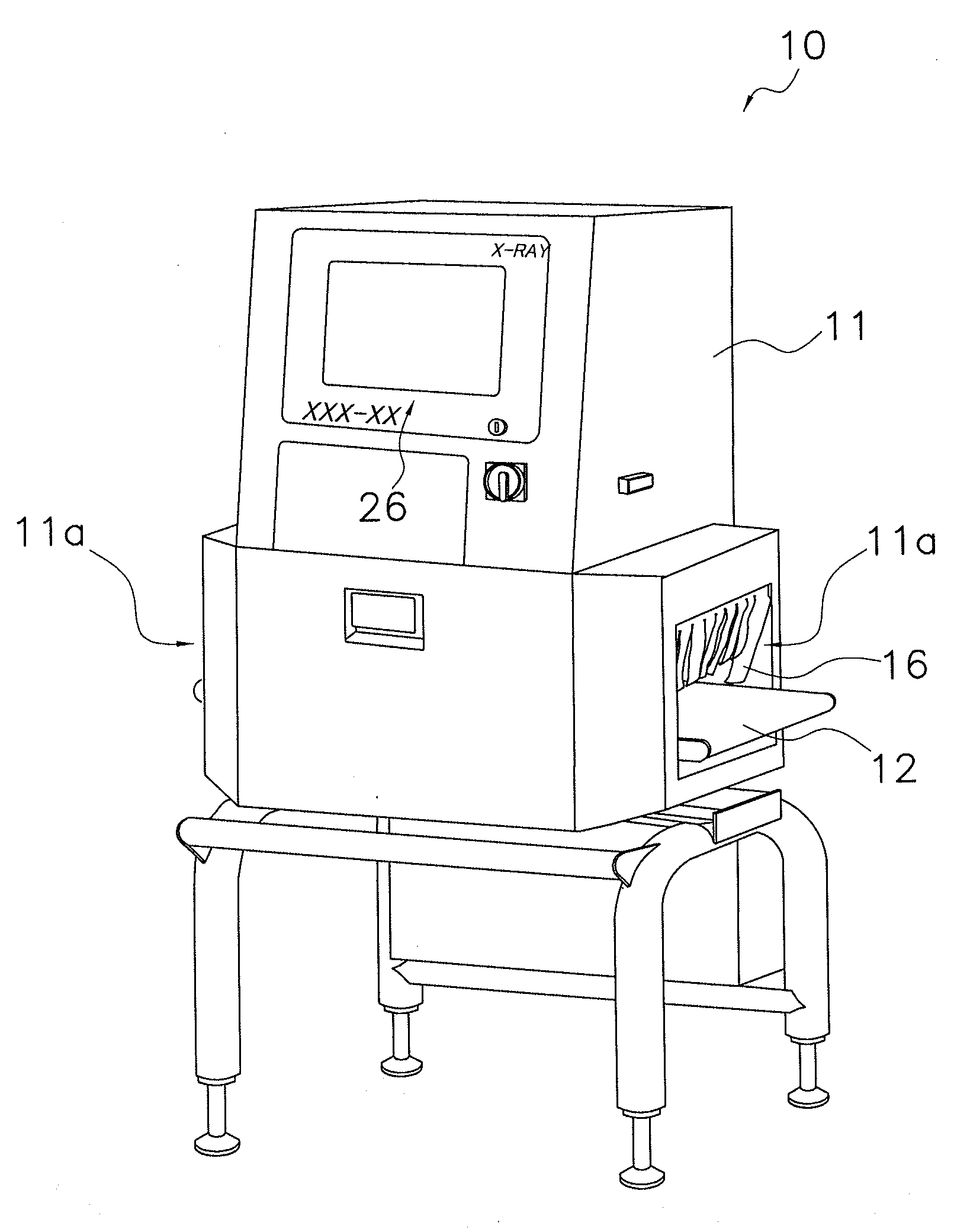

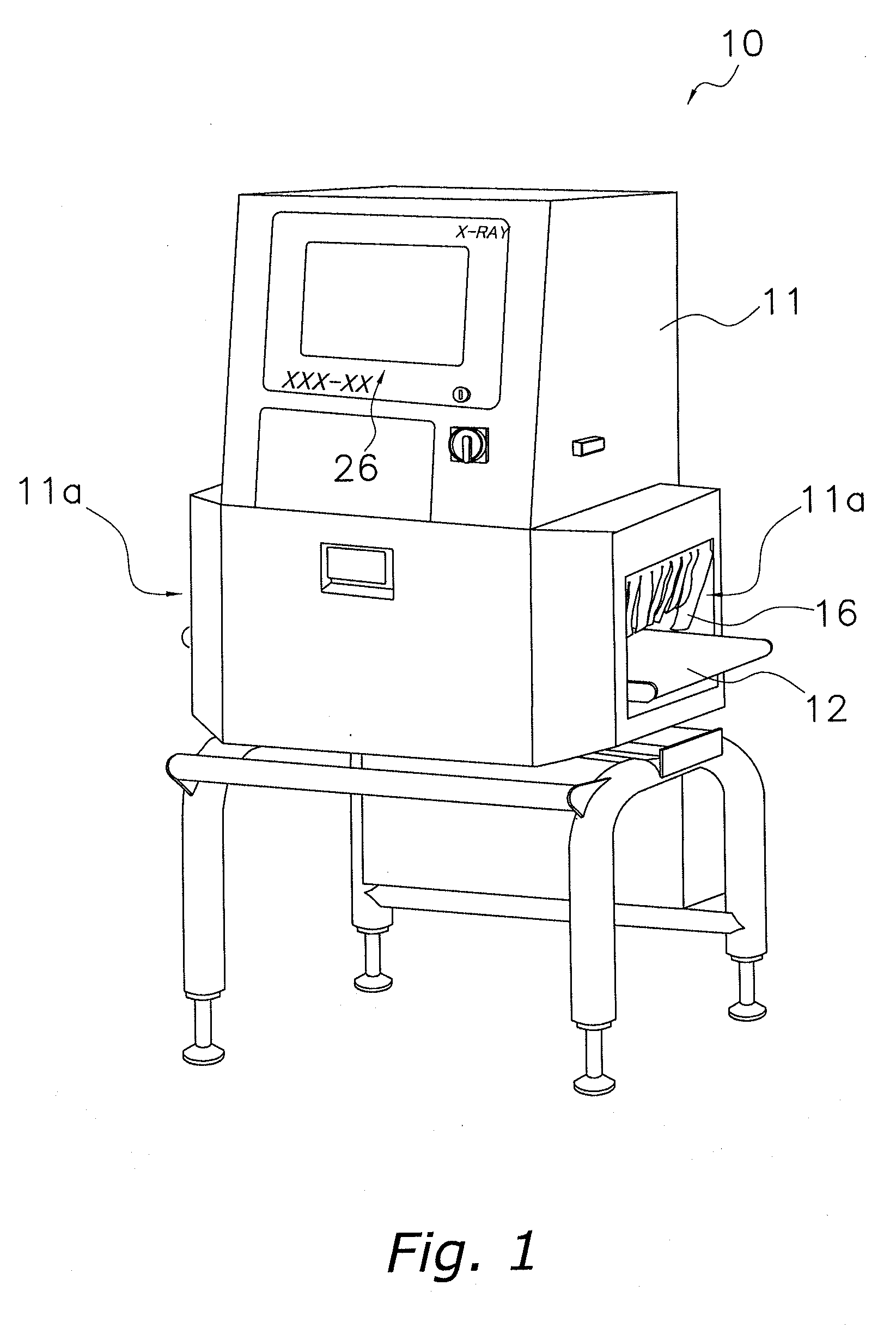

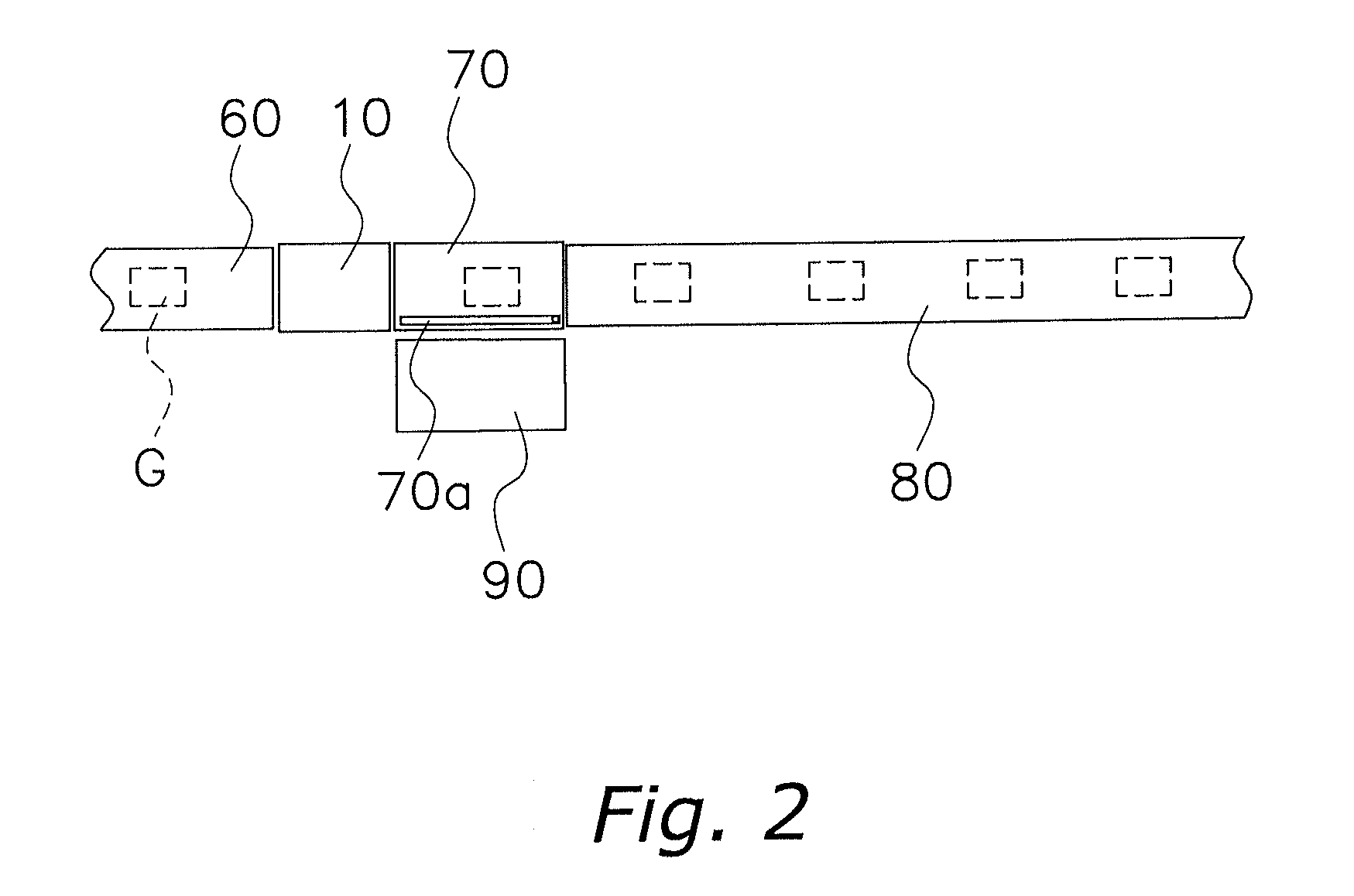

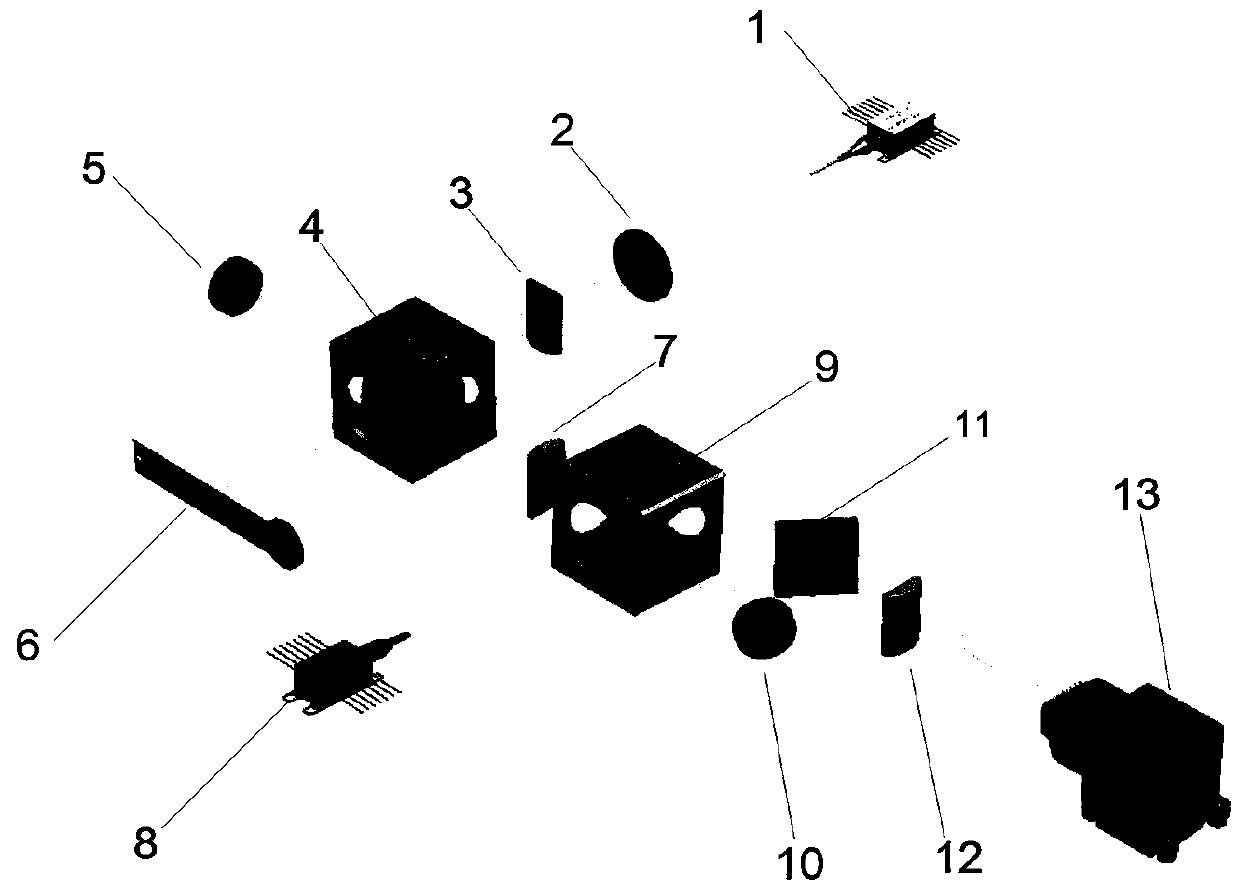

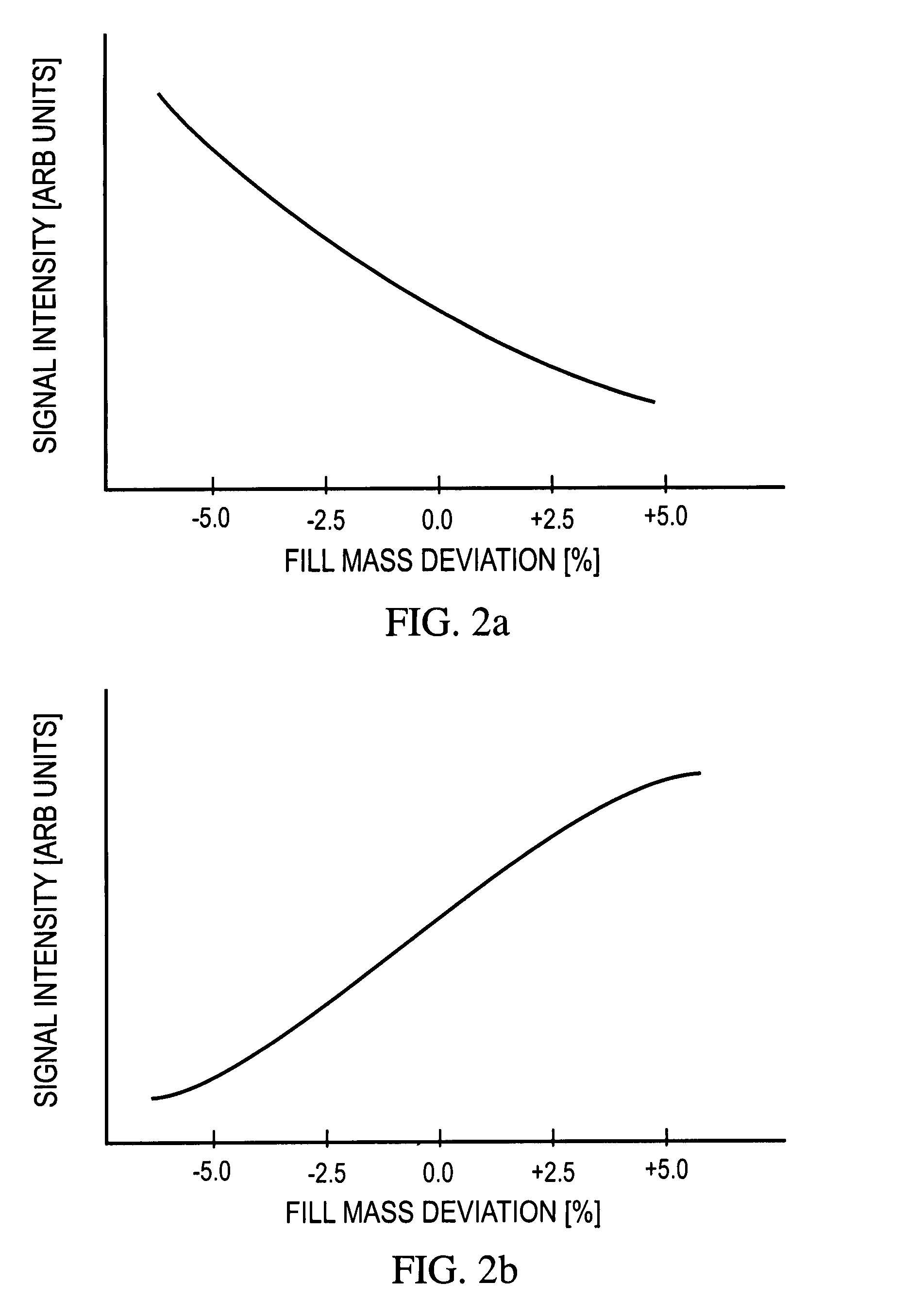

X-ray inspection apparatus

ActiveUS20090147987A1Highly accurately calculateReduce variationAnalogue computers for vehiclesImage analysisX-raySample image

An x-ray inspection apparatus includes a sample image obtaining unit, an ideal curve generating unit, a curve adjustment unit, and a mass estimation unit as a function block generated by a control computer. The sample image obtaining unit obtains 10 x-ray transmission images of sample inspected products each of whose mass is known in advance. The ideal curve generating unit generates a table based on a formula that indicates a relationship between the brightness of an area included in the x-ray transmission images and the estimated mass of the area. The curve adjustment unit refers to the input actual mass of each x-ray transmission image and adjusts the table such that the estimated mass approximates the actual mass. The mass estimation unit determines the estimated mass per unit area based on the post-adjusted table and adds up these masses to determine the total estimated mass of the product.

Owner:ISHIDA CO LTD

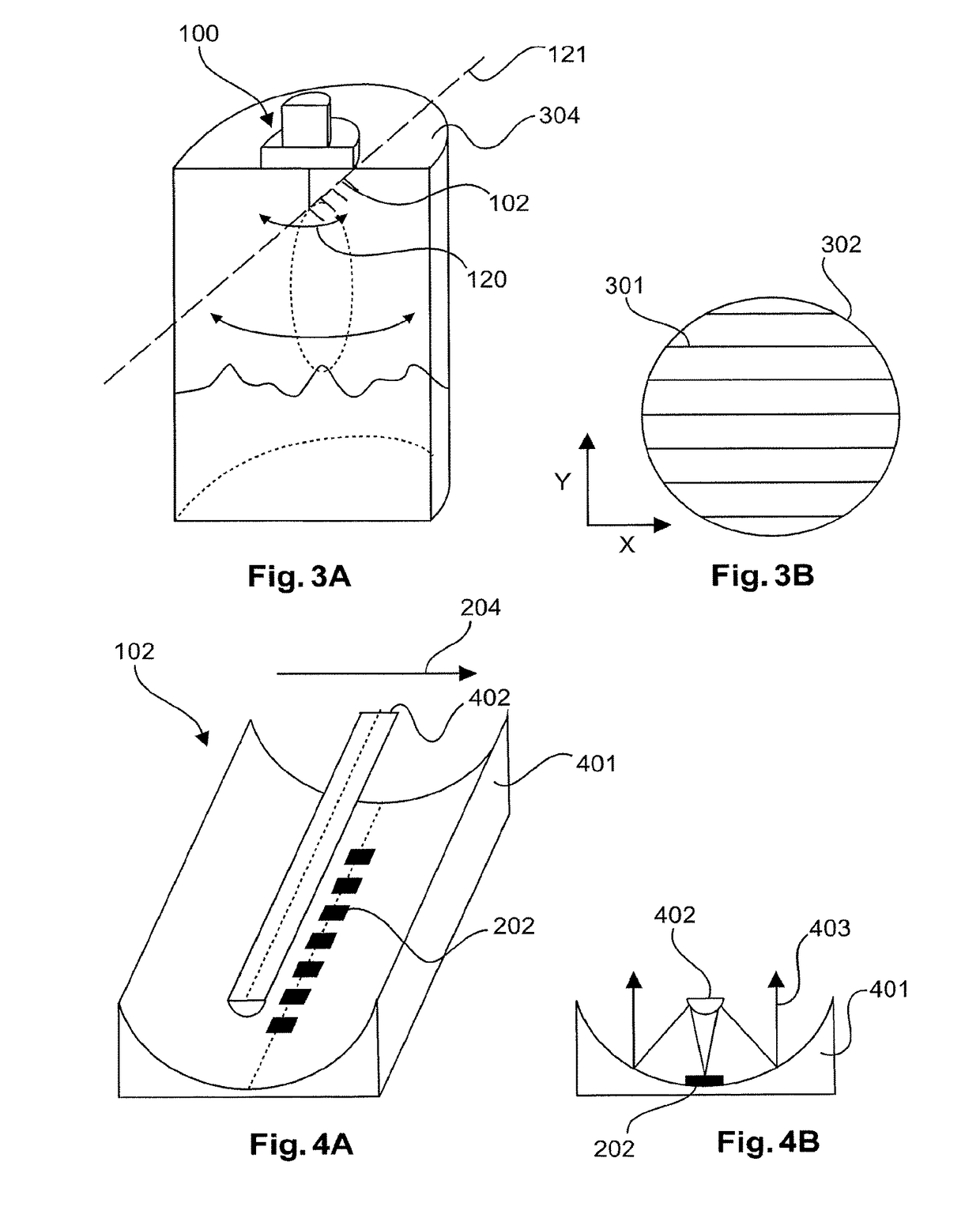

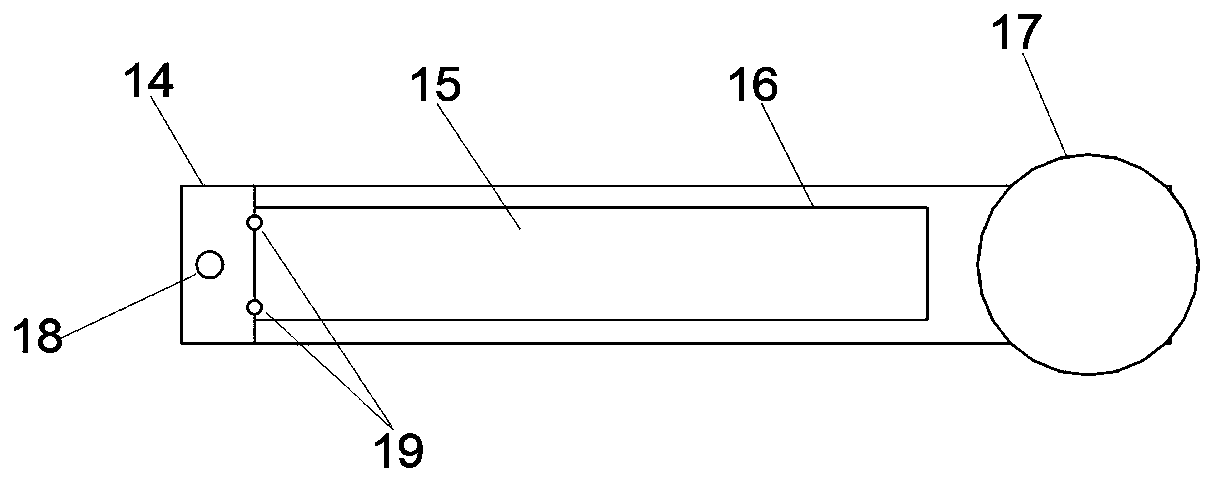

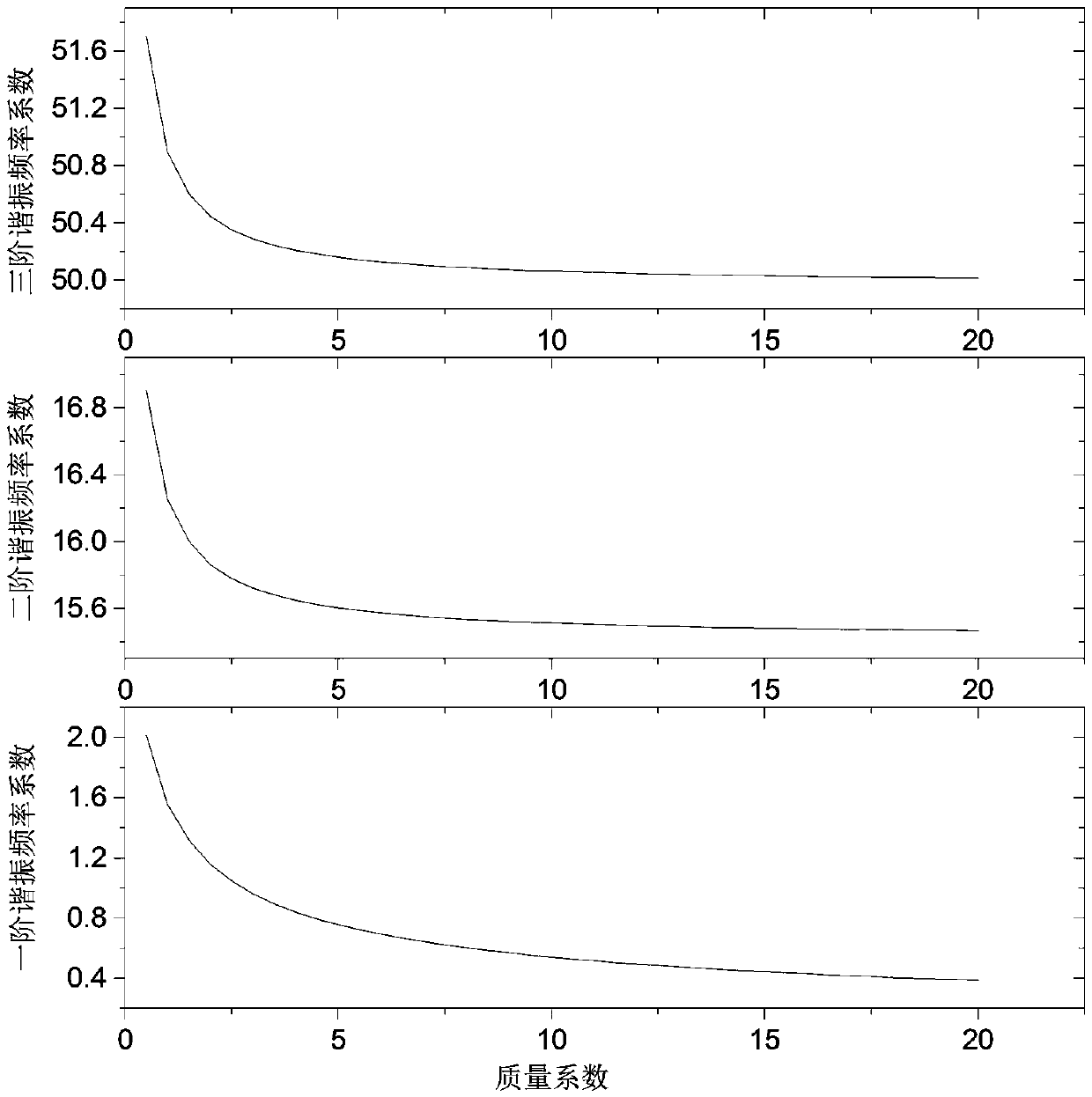

Weighing device and method based on modal frequency of cantilever beam

PendingCN108917895AEasy to detectRealize high-precision measurementWeighing apparatus using radiationComputational physicsMichelson interferometer

The invention relates to a weighing device and weighing method based on modal frequency of a cantilever beam. The device comprises a tungsten halogen lamp light source module, a Michelson interferometer module, a two-dimensional spectrograph module, a cantilever beam module and a computer. The invention provides a structure modal analysis method that is high in efficiency and accuracy, non-contact, lossless and high in resolution ratio and does not introduce additional weight on the basis of learning and research on vibration detection and modal analysis of a light thin-wall structure piece; by using the method, real-time modal analysis can be performed on the beam structure without knowing the information of a shock excitation input signal, and weighing can be implemented without knowingthe shock excitation input signal.

Owner:FUZHOU UNIV

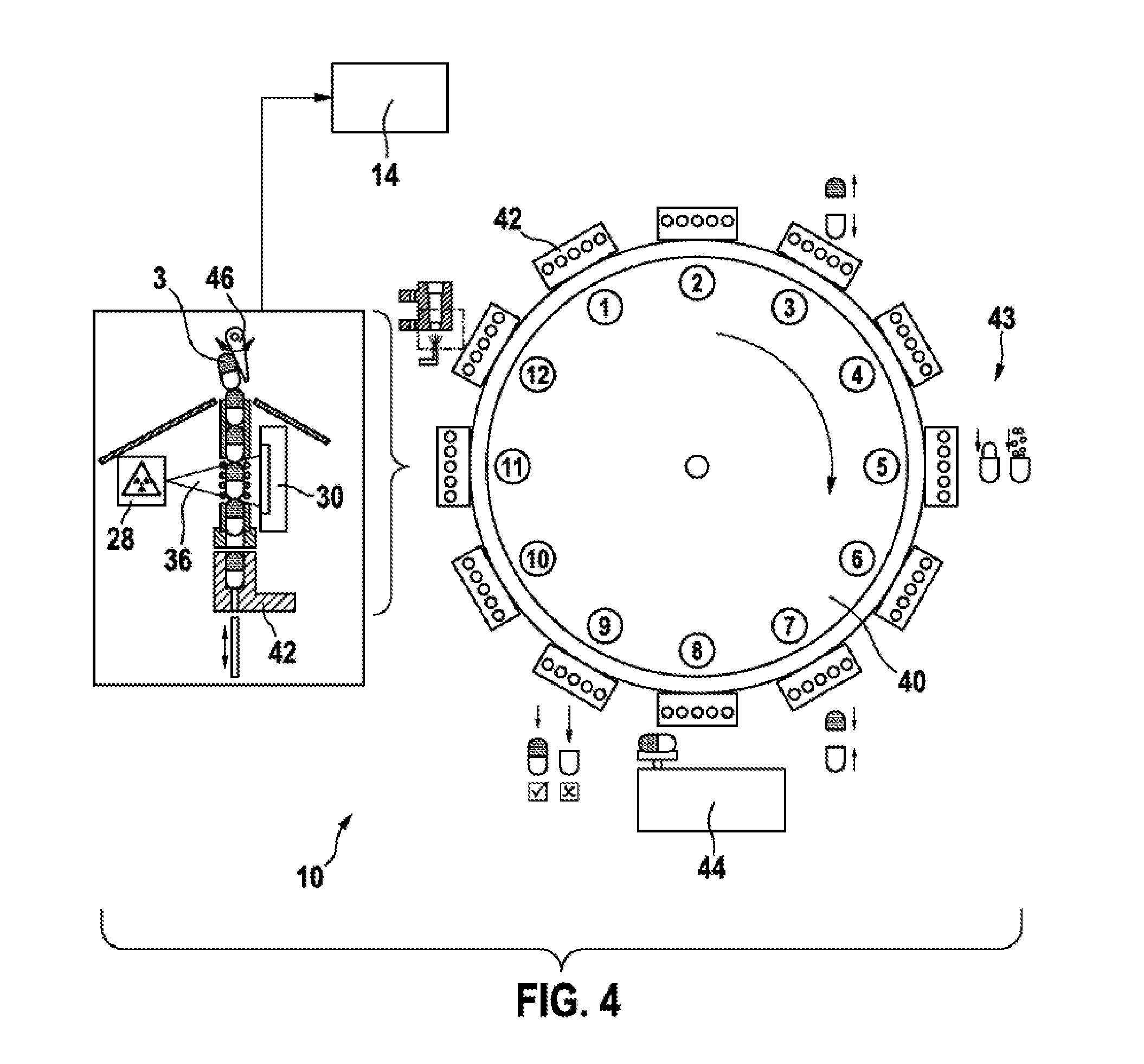

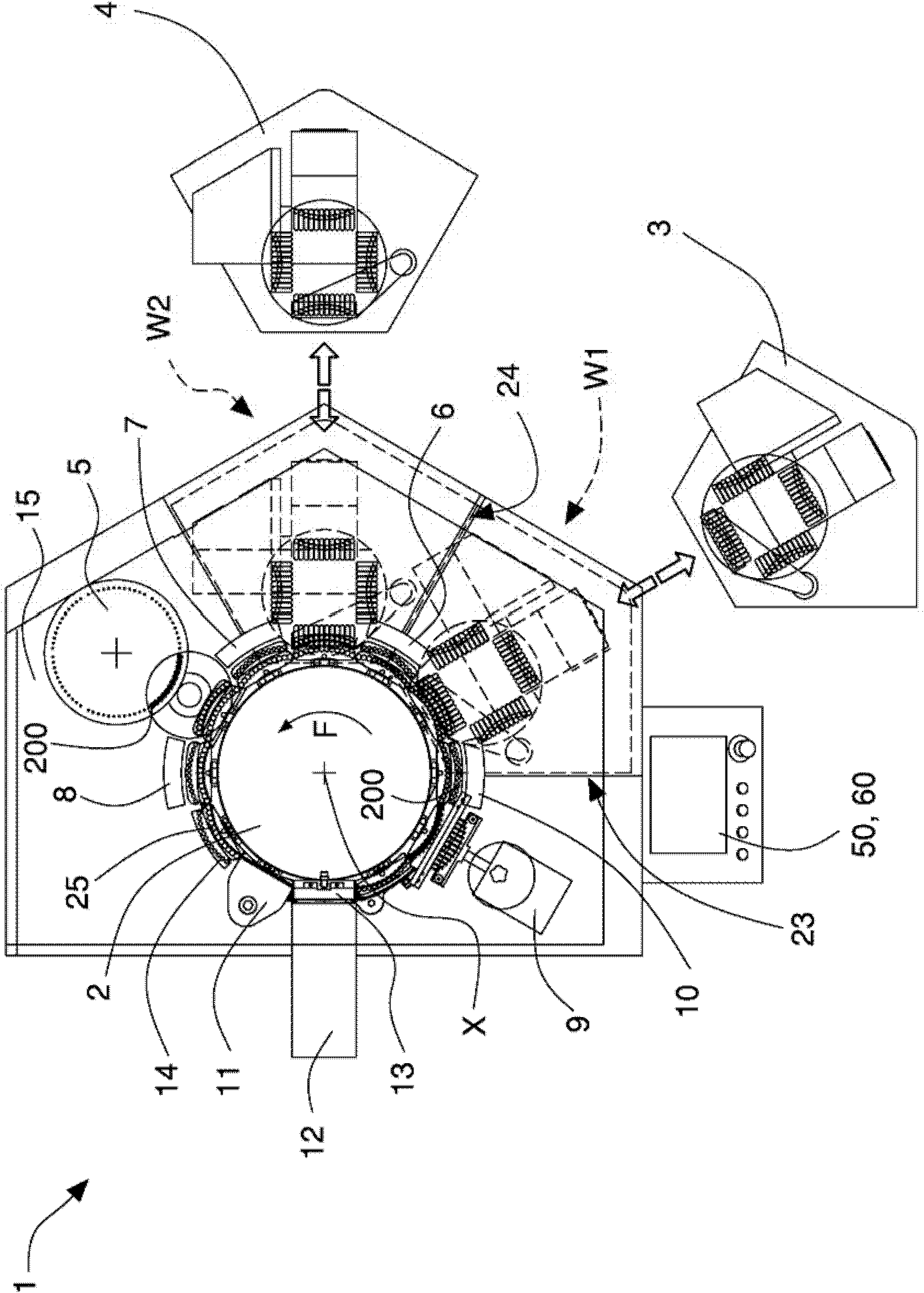

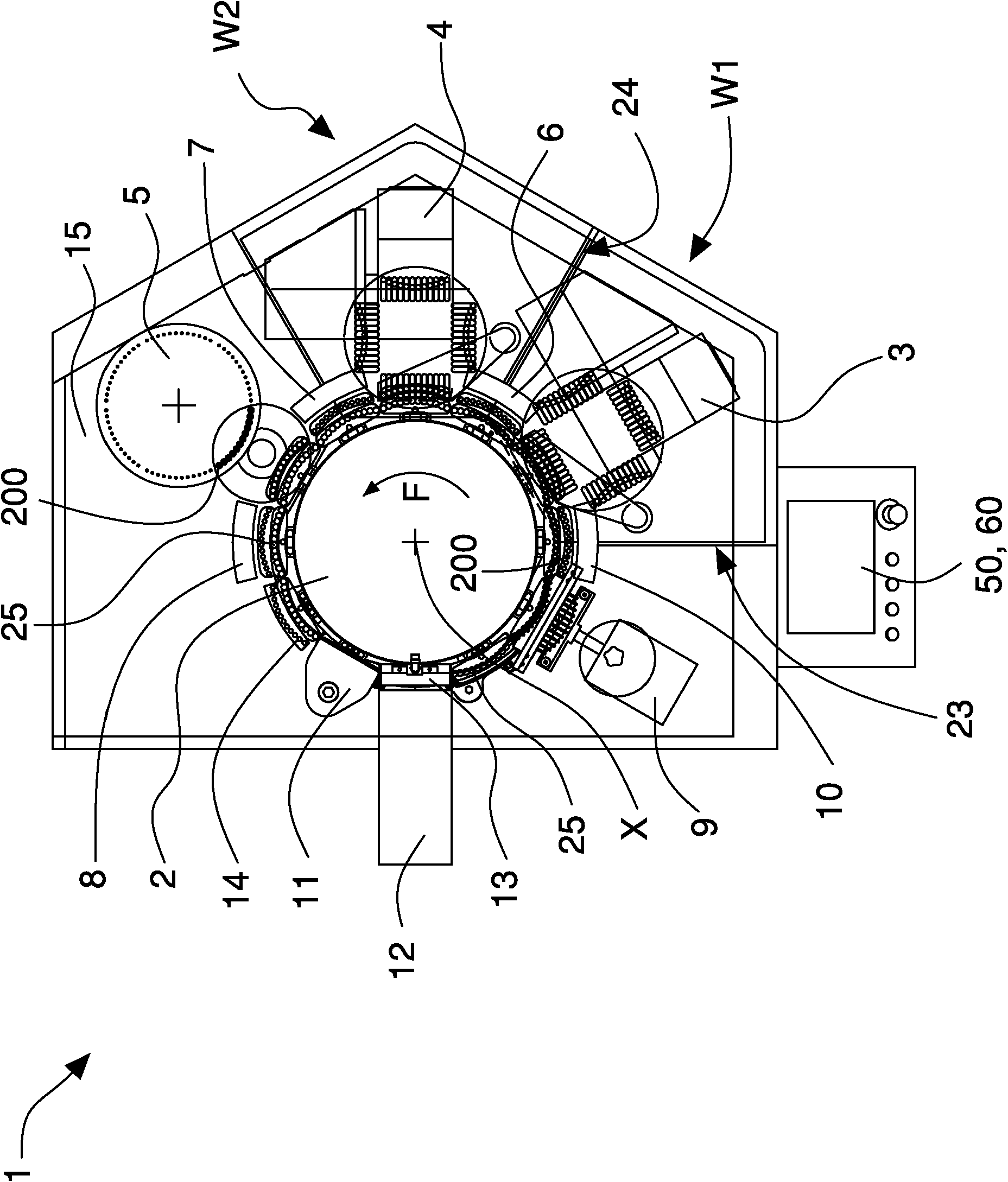

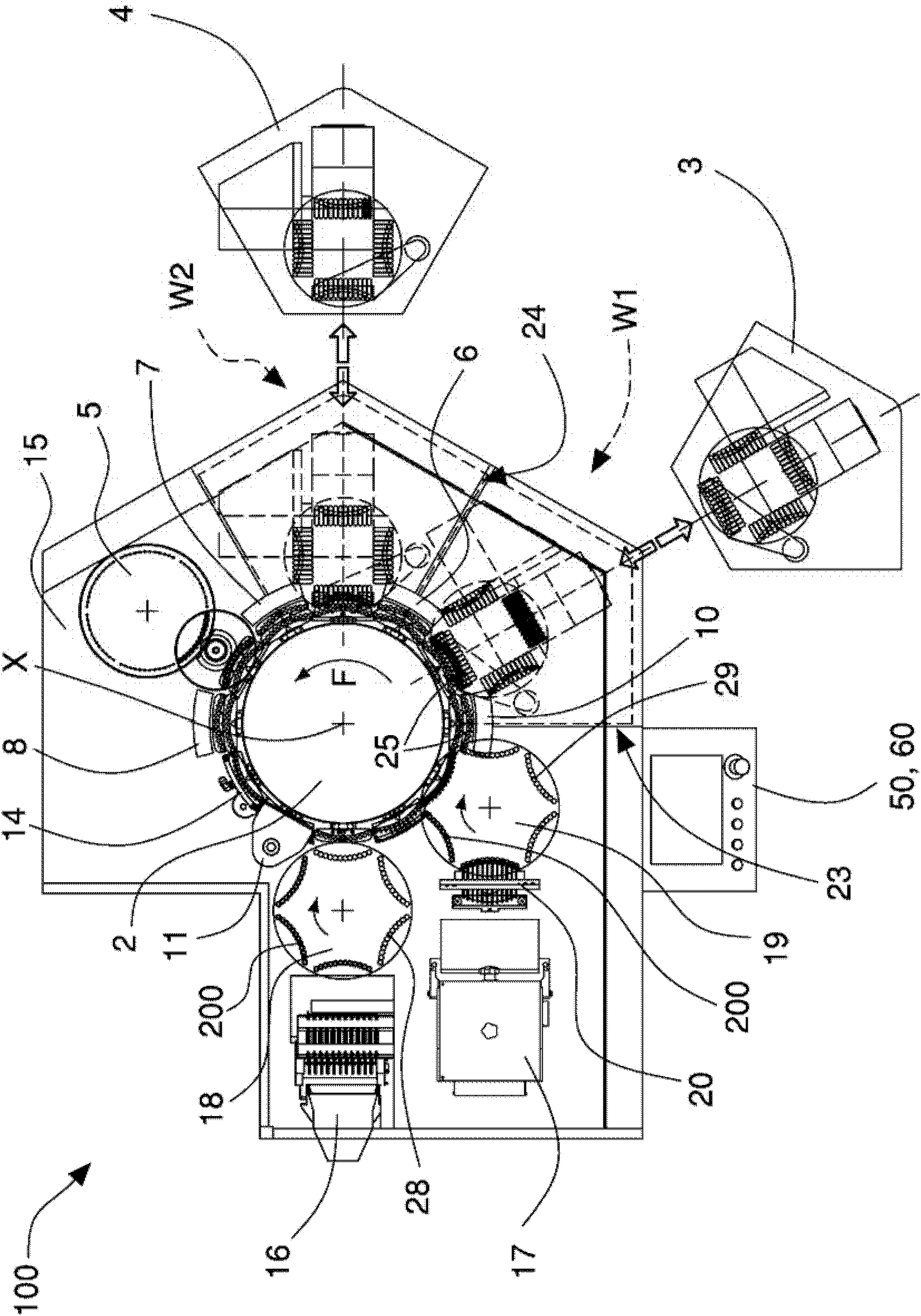

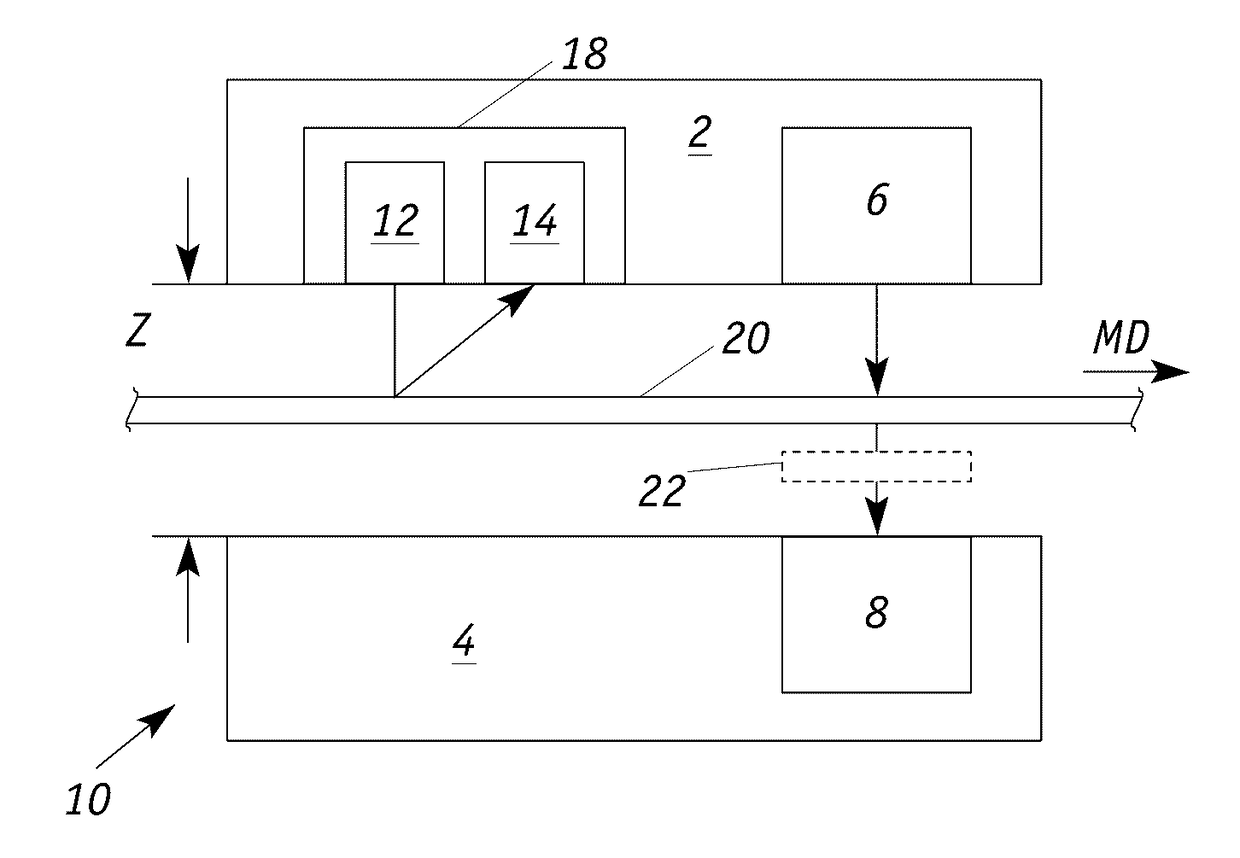

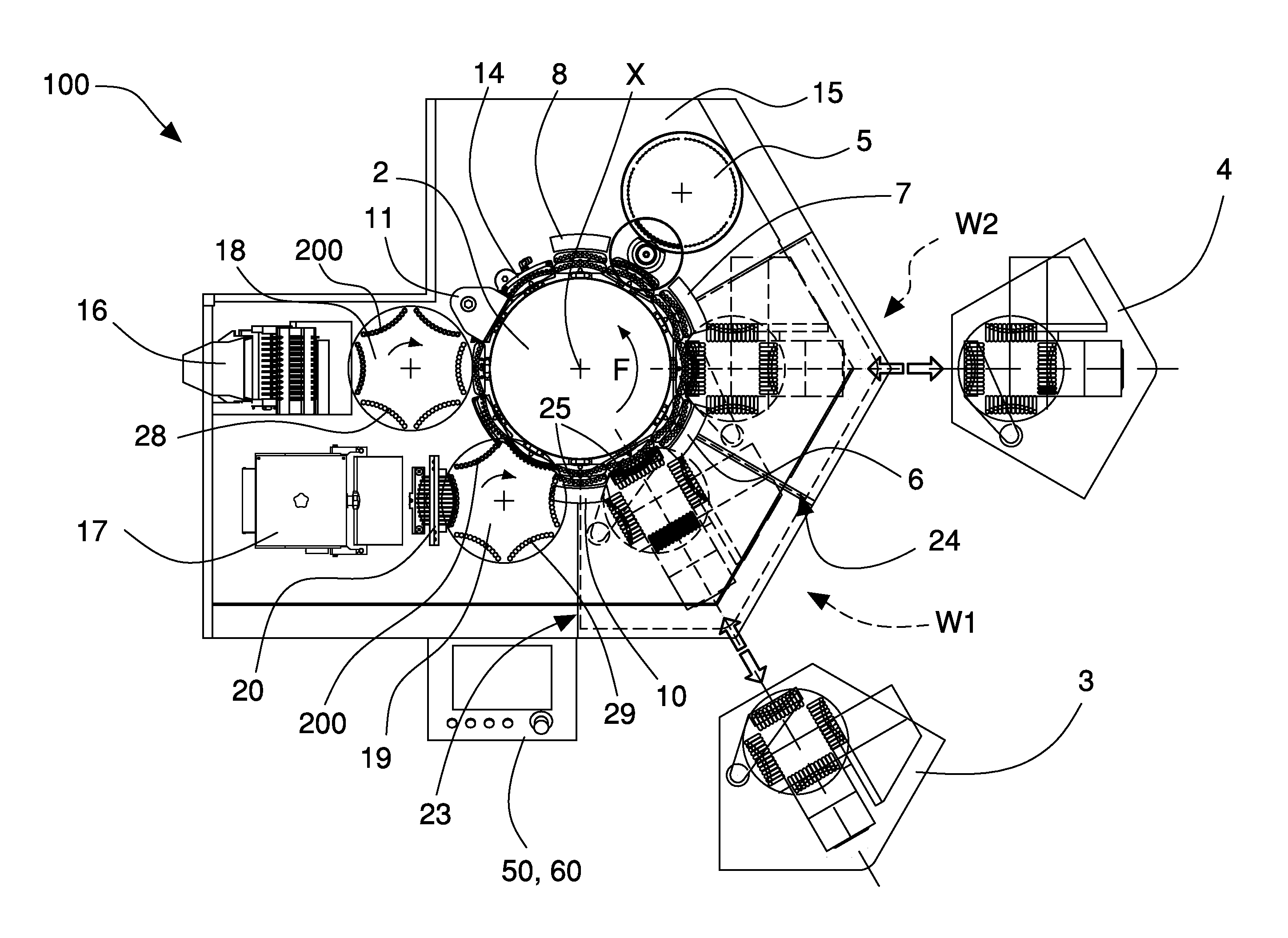

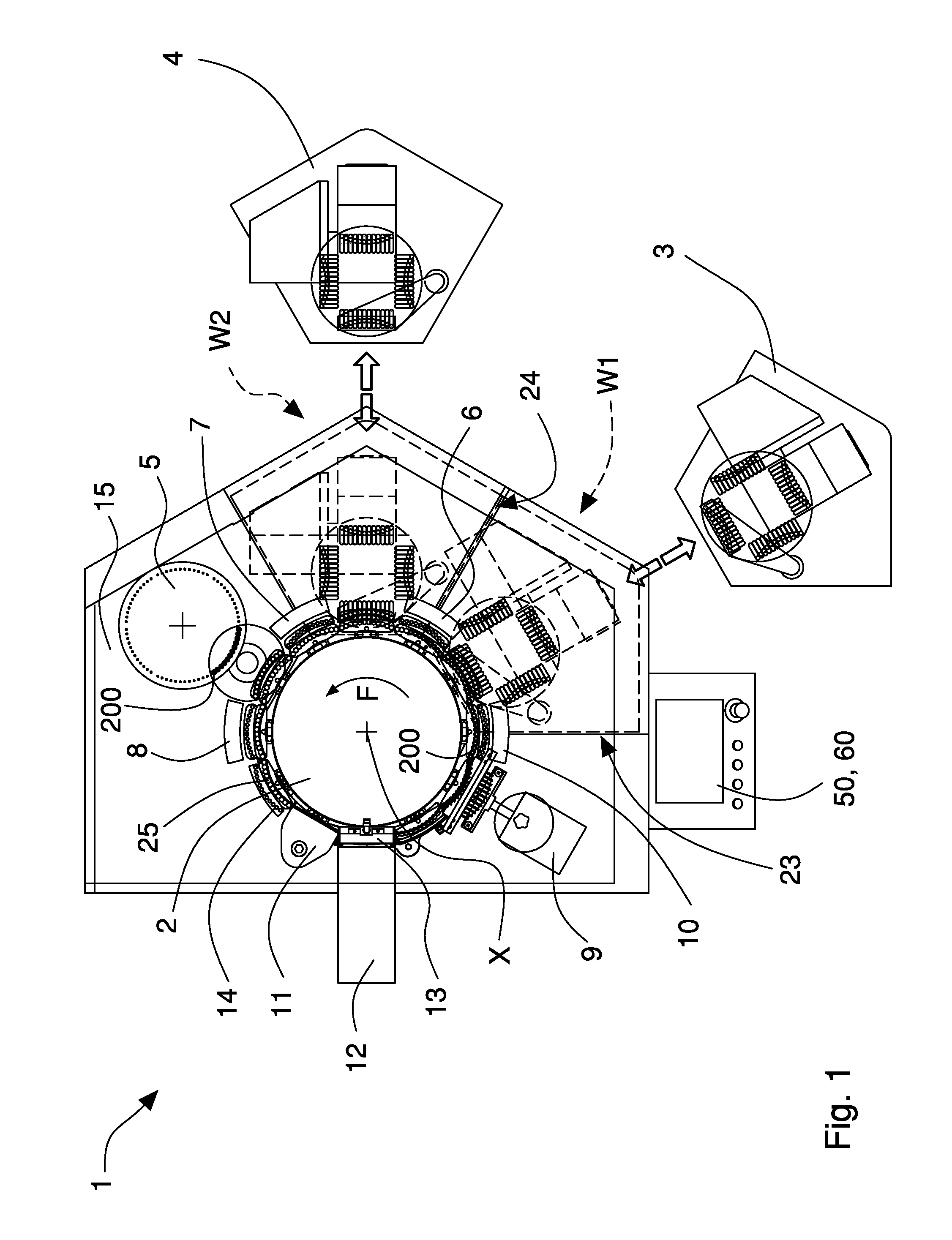

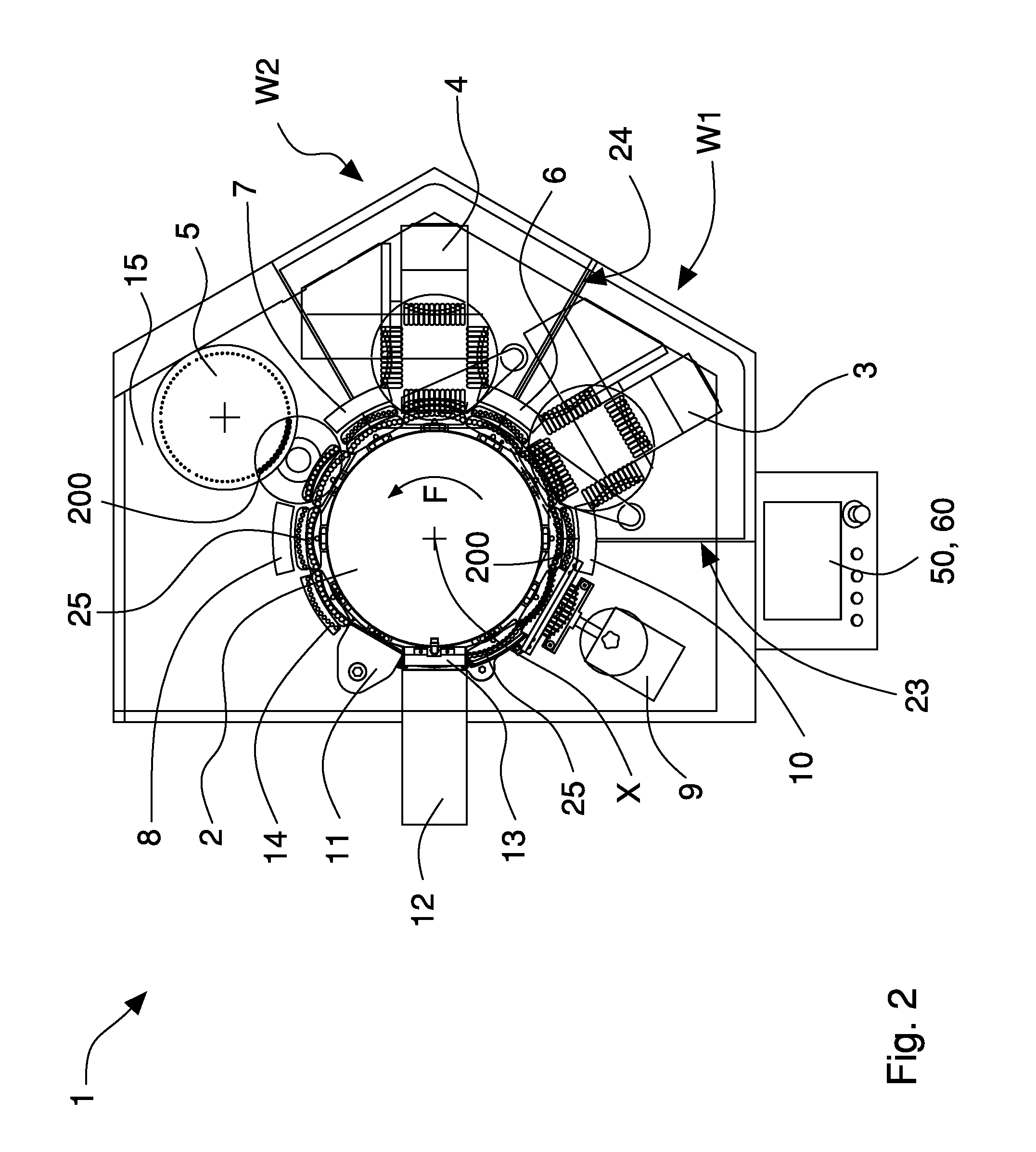

Machine and method for filling and checking capsules

ActiveCN102256586AWeighing apparatus using electrostatic balancingWeighing apparatus using radiationEngineeringBiomedical engineering

A machine for dosing a plurality of products in capsules (200), or similar containers, comprises a plurality of dosing units (3, 4, 5) for filling the capsules (200) with respective products and turret means (2) that rotates intermittently and is arranged for housing and moving the capsules (200) in sequence through the dosing units (3, 4, 5); the machine further comprises a plurality of checking units (6, 7, 8) each of which is located downstream of a respective dosing unit (3, 4, 5) for measuring a quantity of product dosed in the capsules (200) by said respective dosing units (3, 4, 5).

Owner:IMA IND MASCH AUTOMATICHE SPA

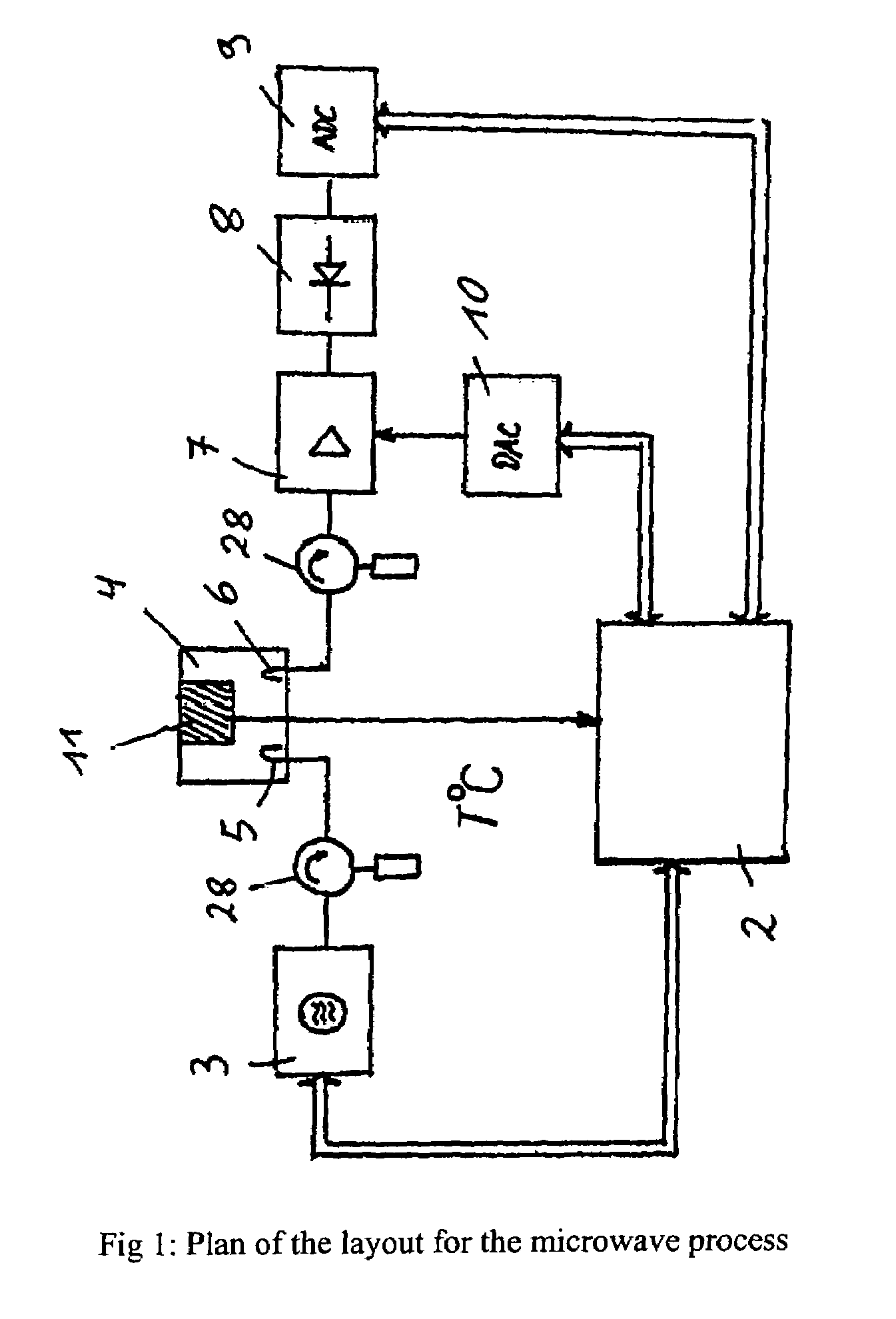

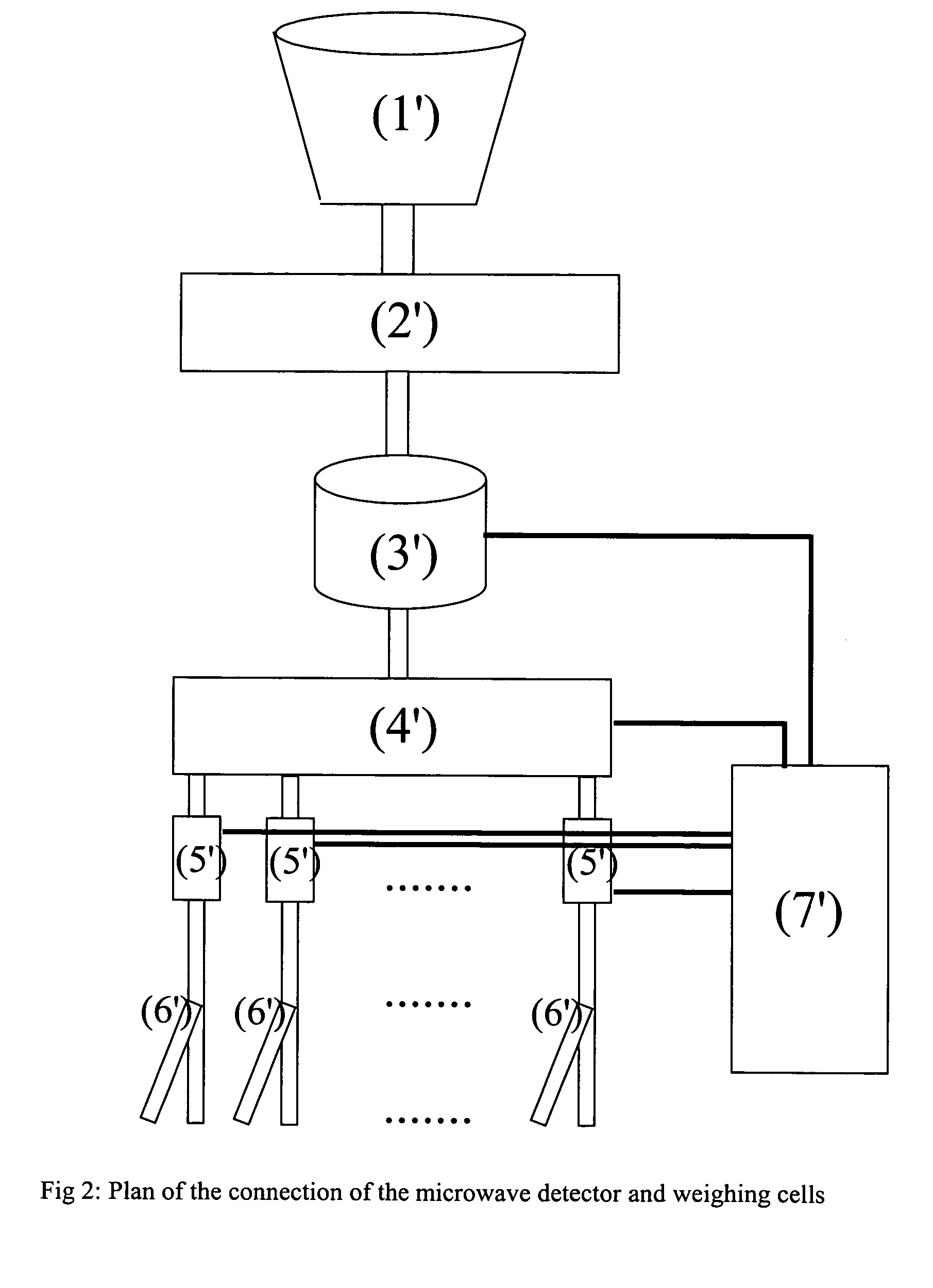

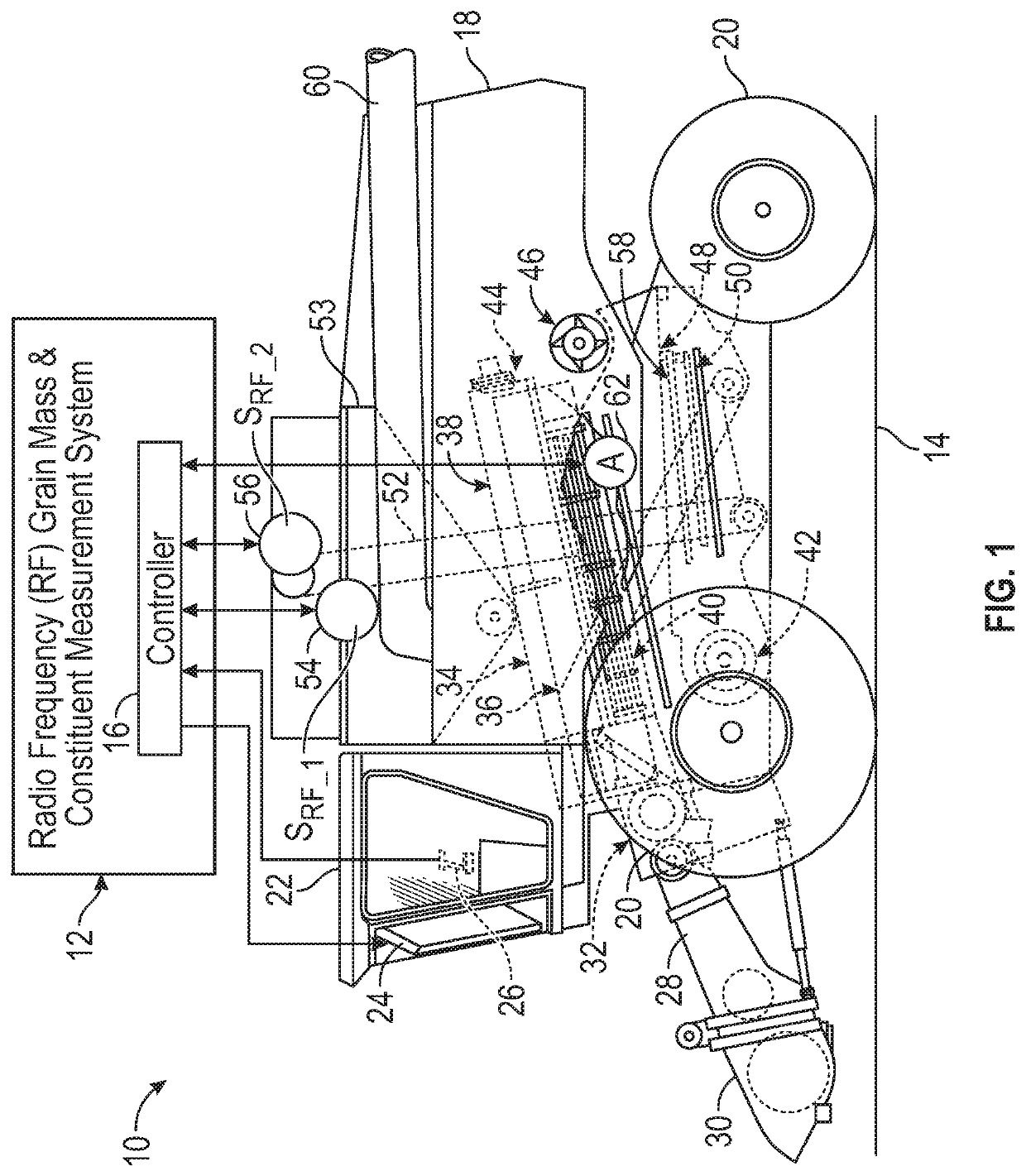

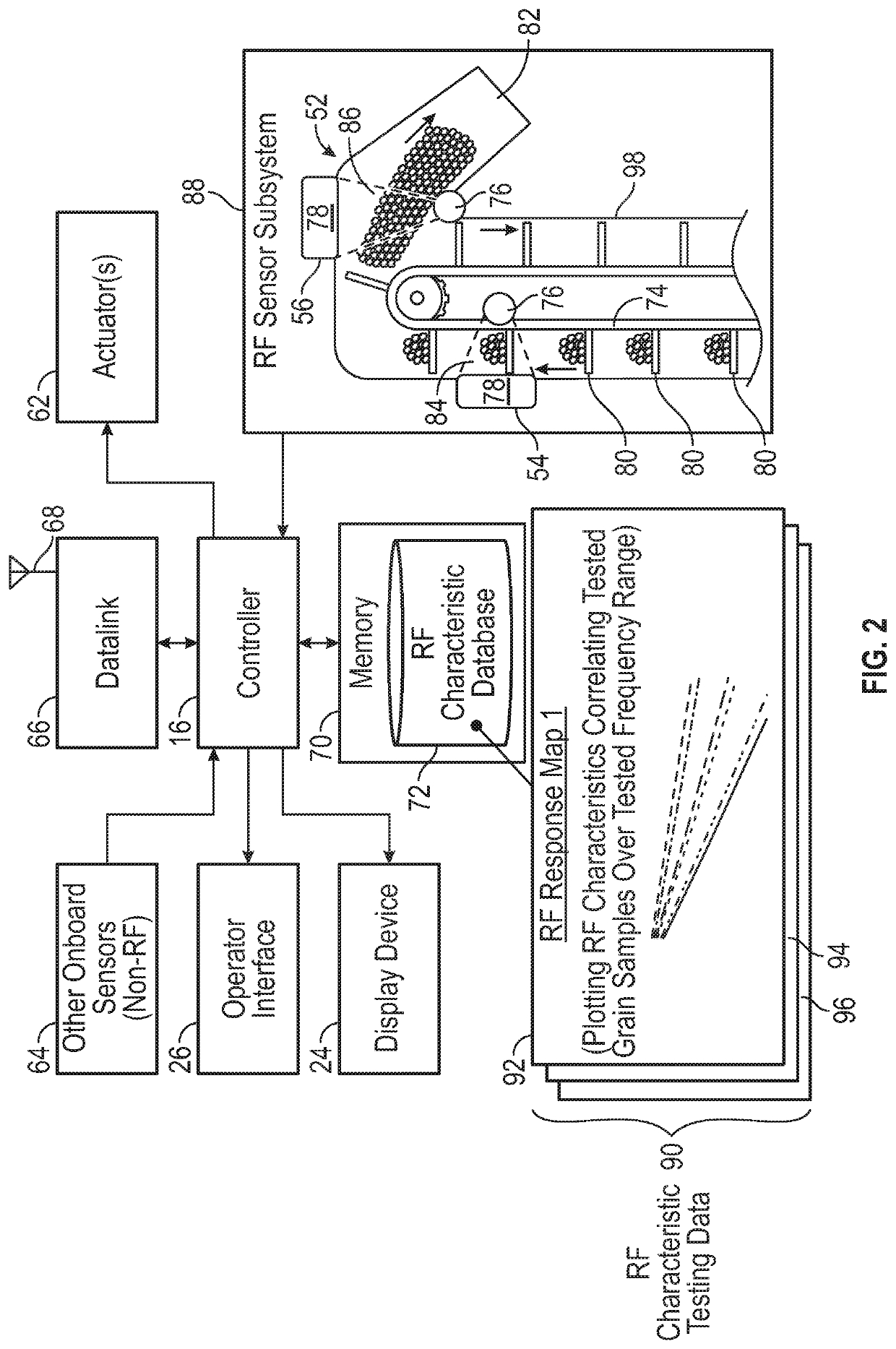

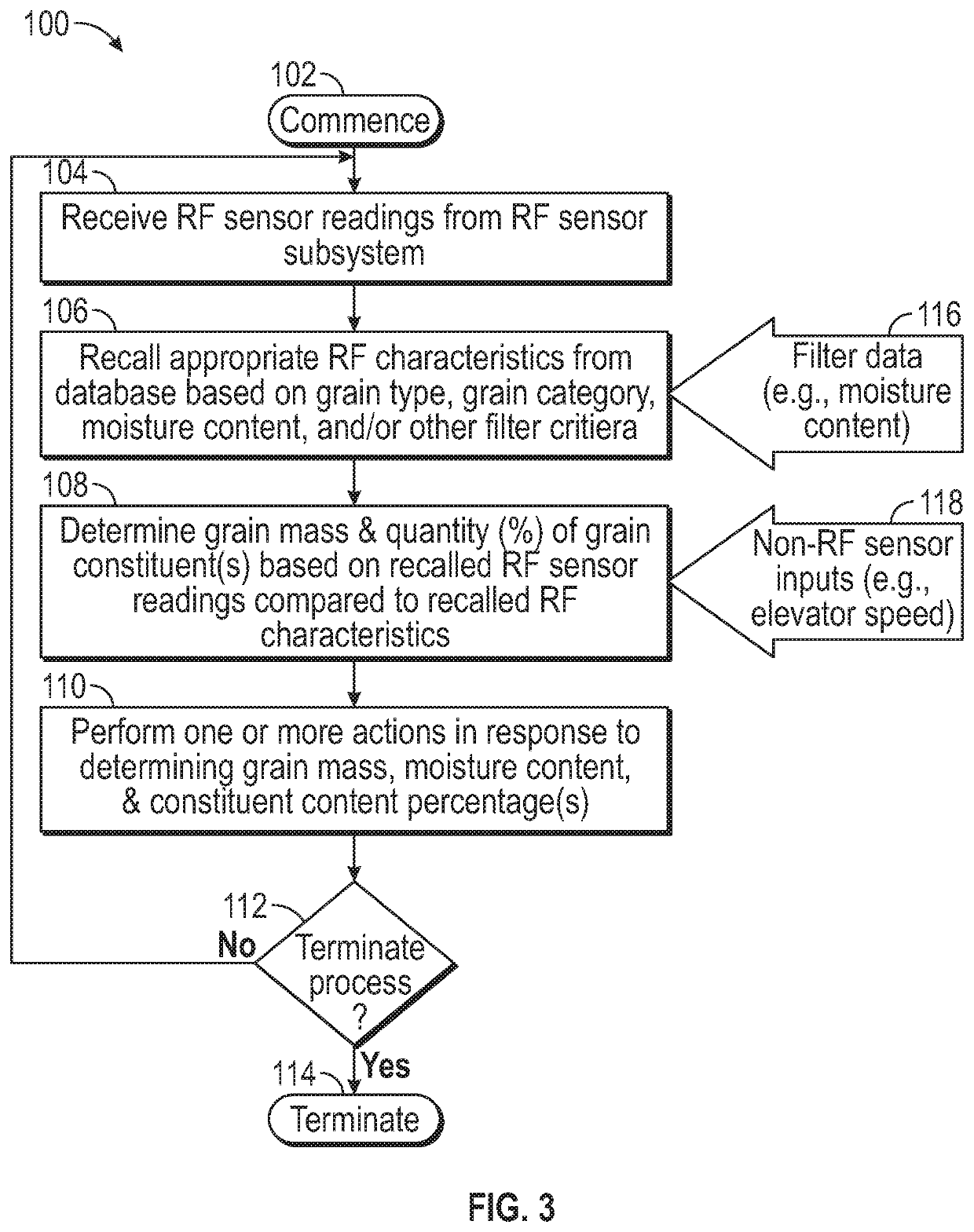

Radio frequency grain mass and constituent measurement systems for combine harvesters

A radio frequency (RF) grain mass and constituent measurement system utilized onboard a combine harvester includes an RF sensor subsystem for capturing RF sensor readings of a harvested grain within an area of the combine harvester. A memory stores an RF characteristic database, which contains RF characteristic testing data collected for tested grain samples over one or more tested frequency ranges. A controller, operably coupled to the RF sensor subsystem and to the memory, is configured to: (i) receive the RF sensor readings from the RF sensor subsystem; (ii) determine grain mass and a first constituent content of the currently-harvested grain based, at least in part, on an analytical comparison between the RF sensor readings and the RF characteristic testing data; and (iii) perform at least one action in response to determining the grain mass and the first constituent content of the harvested grain.

Owner:DEERE & CO

Systems and methods for non-destructive mass sensing

ActiveUS7304750B2Easy to measureWeighing apparatus using elastically-deformable membersWeighing apparatus using radiationAmount of substanceClassical mechanics

Owner:NOVARTIS AG

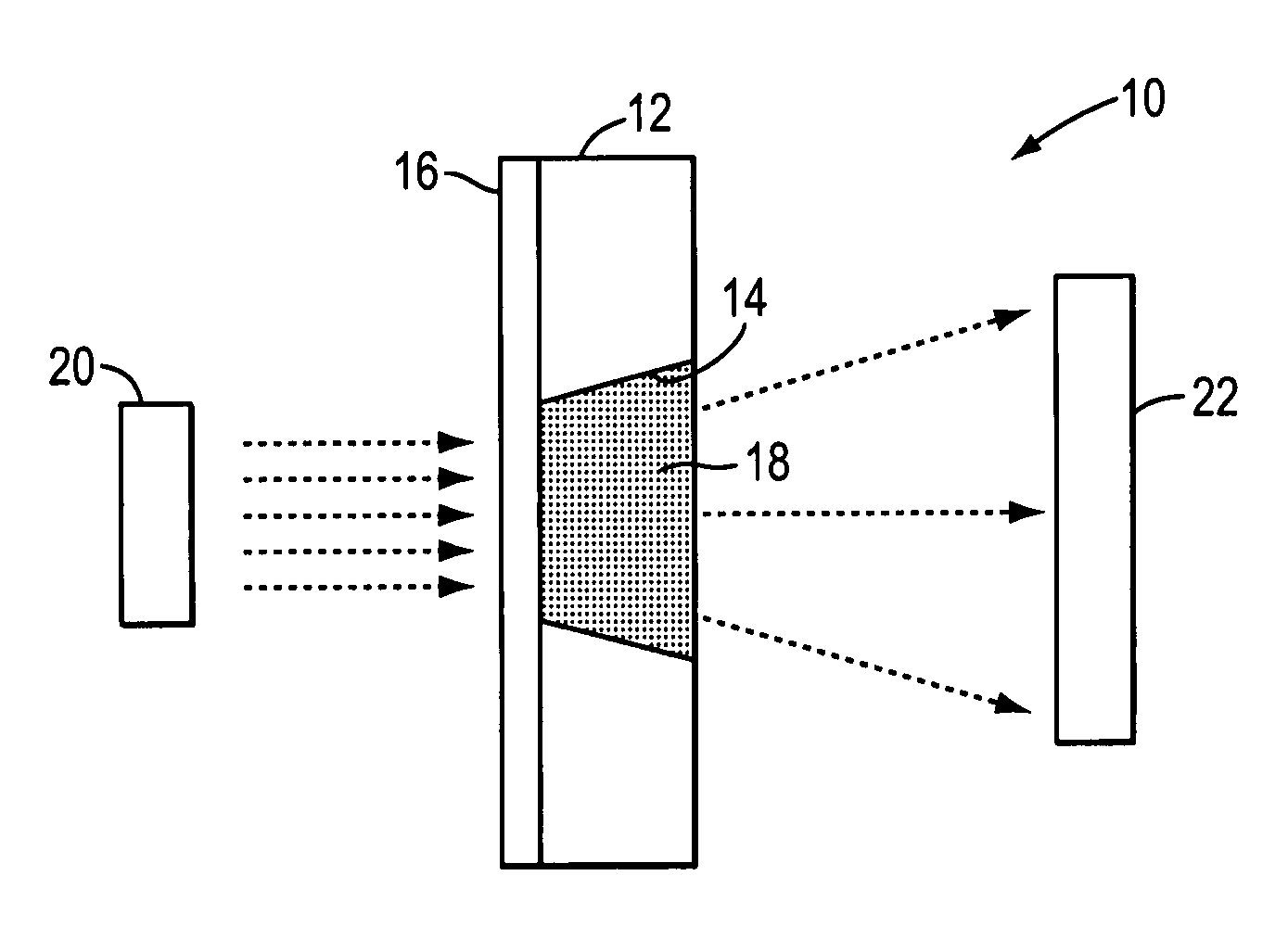

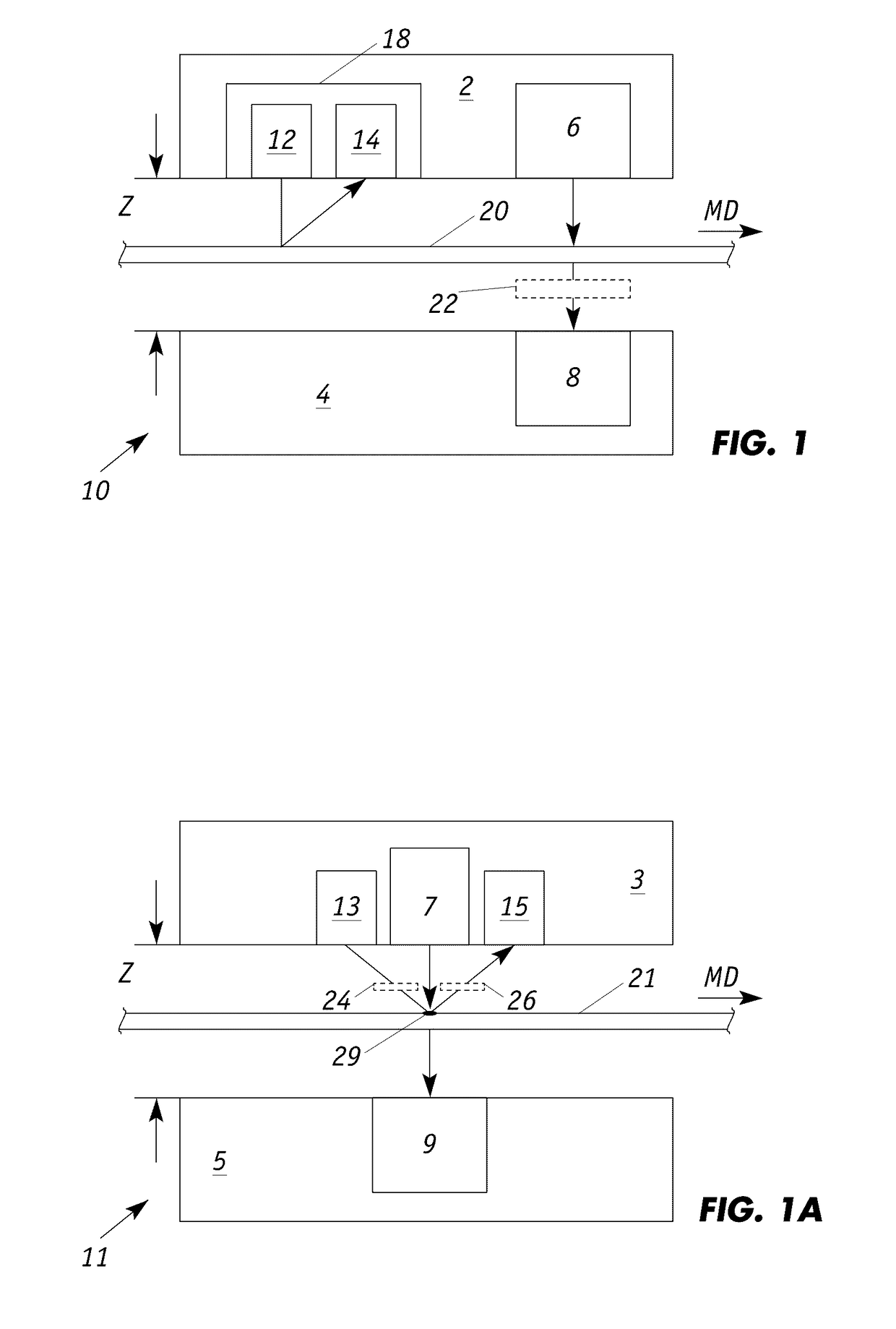

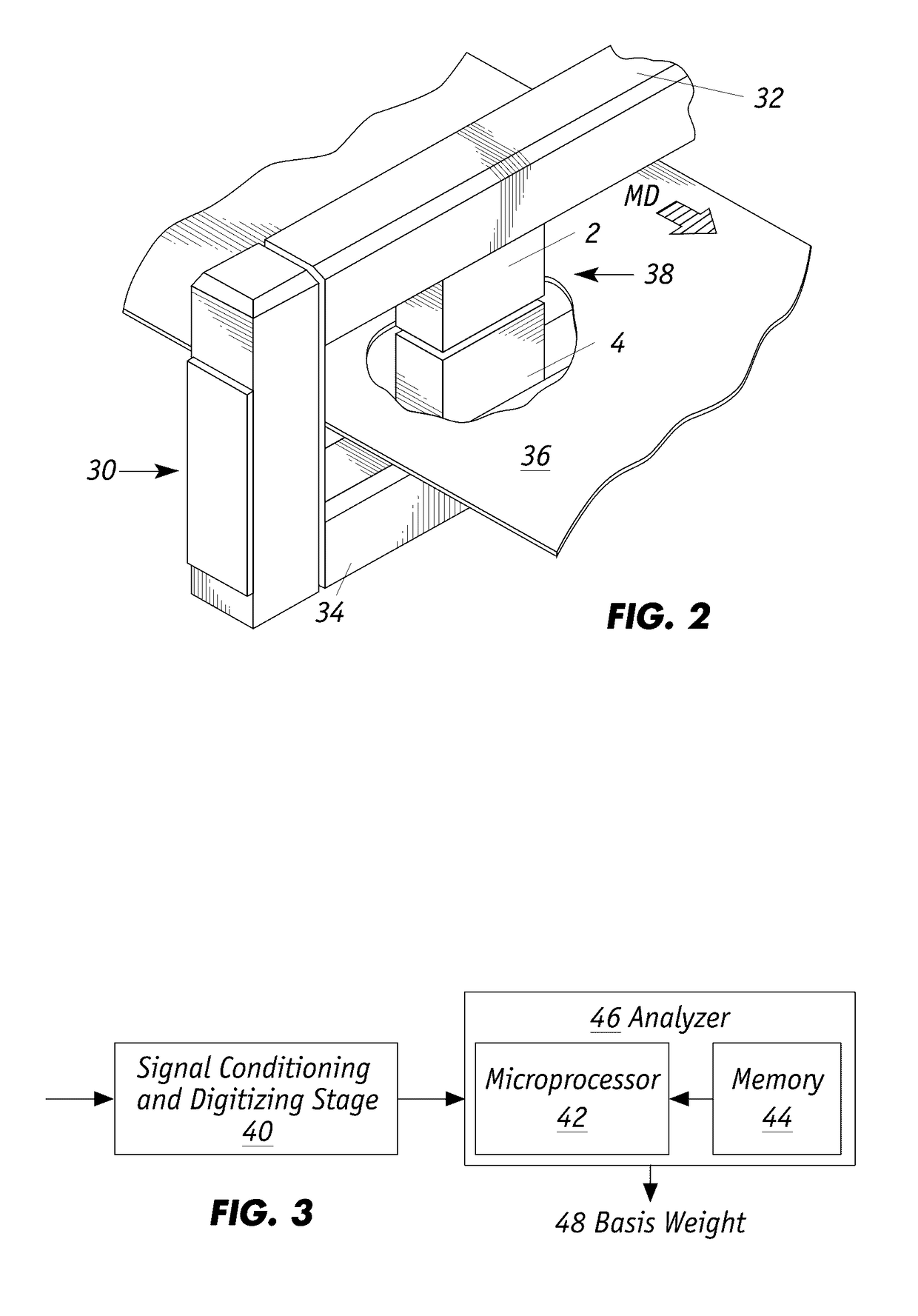

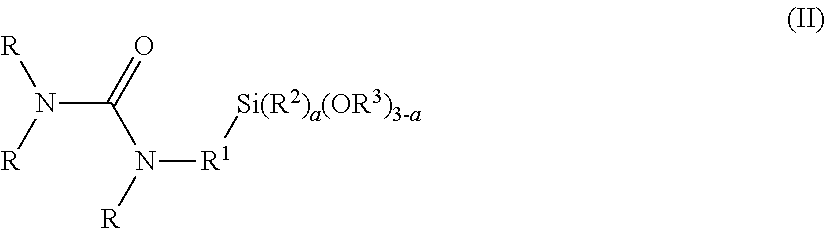

Automatic z-correction for basis weight sensors

ActiveUS9612213B2Weighing apparatus using radiationWeighing apparatus for materials with special property/formObservational errorTriangulation

Nuclear-based basis weight sensors are passline-sensitive. Error in measurement is induced when the sheet moves up and down in the gap between the radiation source and detector. A passline-insensitive basis weight sensor includes a triangulation sensor to measure the position of the sheet within the gap. The sensor and gap is characterized in the laboratory for its passline behavior over a range of basis weights. The curves are either parameterized or a lookup table is created for each weight and passline position and the data added to the sensor's processor. The basis weight measured can be automatically corrected to account for deviations from the passline or nominal path through the sensor.

Owner:HONEYWELL ASCA INC

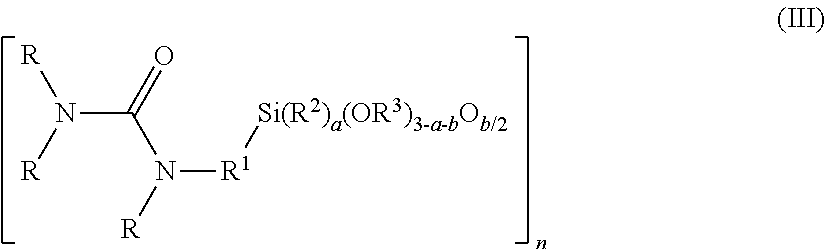

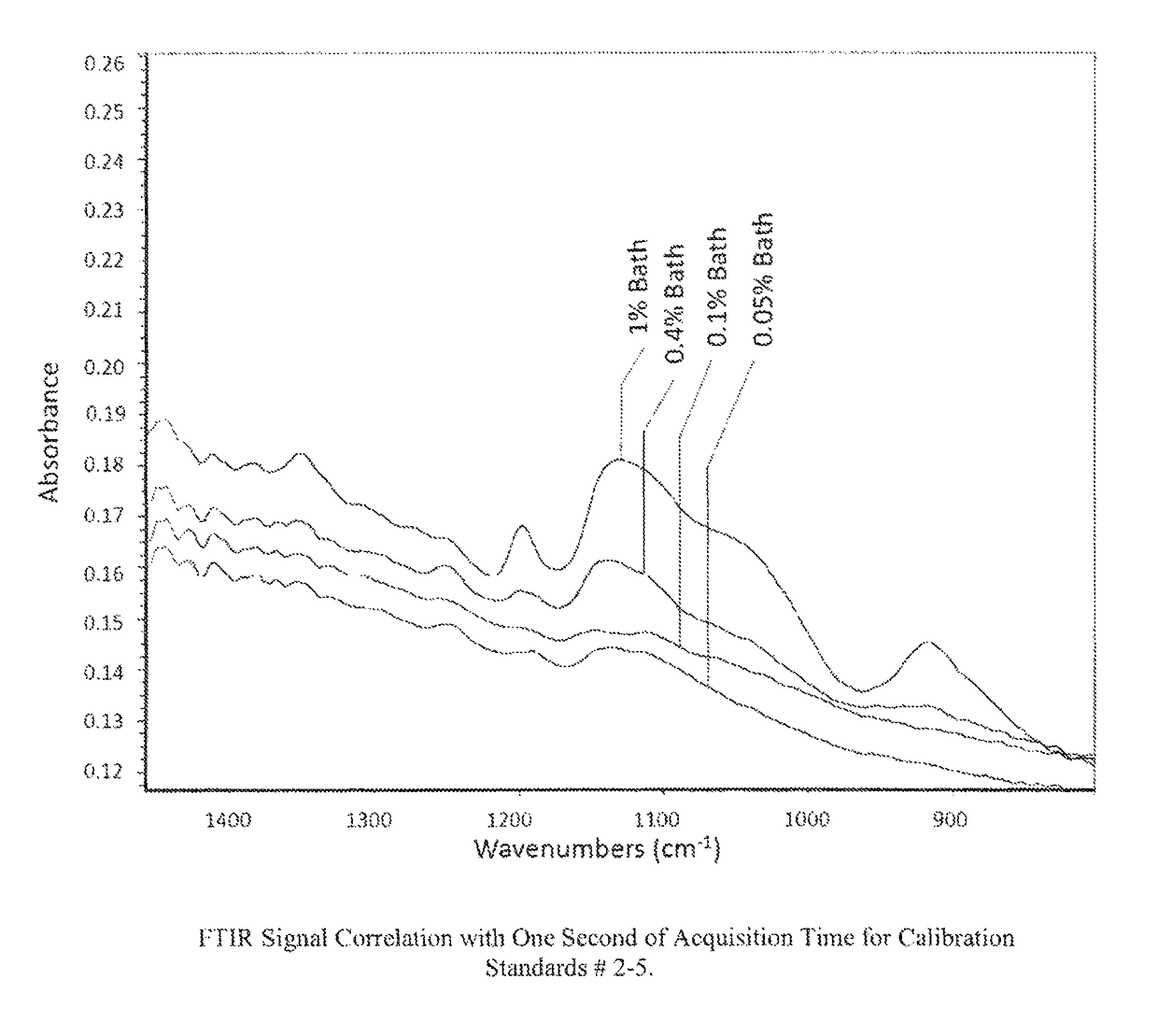

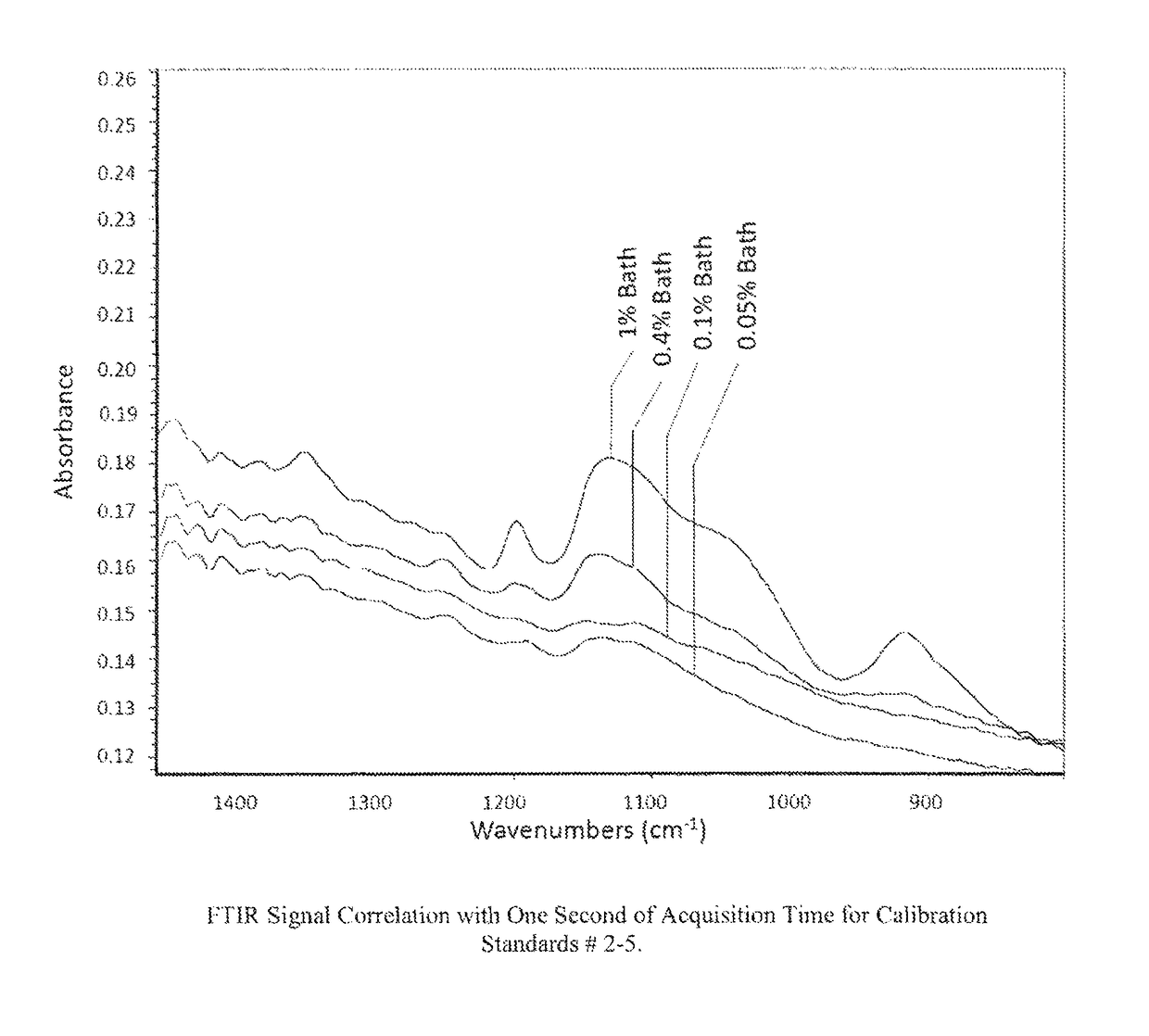

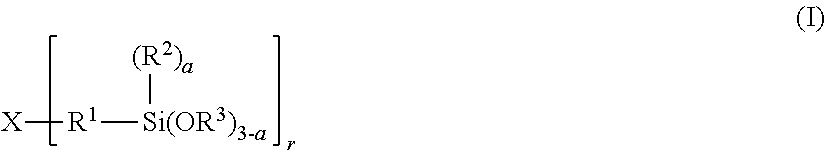

Method for determining the weight and thickness of a passivation or conversion coating on a substrate

ActiveUS20150377608A1Accurate measurementMinimum interruptionRadiation pyrometryWeighing apparatus using radiationQuality controlIndustrial setting

The present invention relates to a method for measuring the weight of a passivation coating composition on a moving substrate with minimal interruption. The method of present invention is especially useful for effective quality control in an industrial setting.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

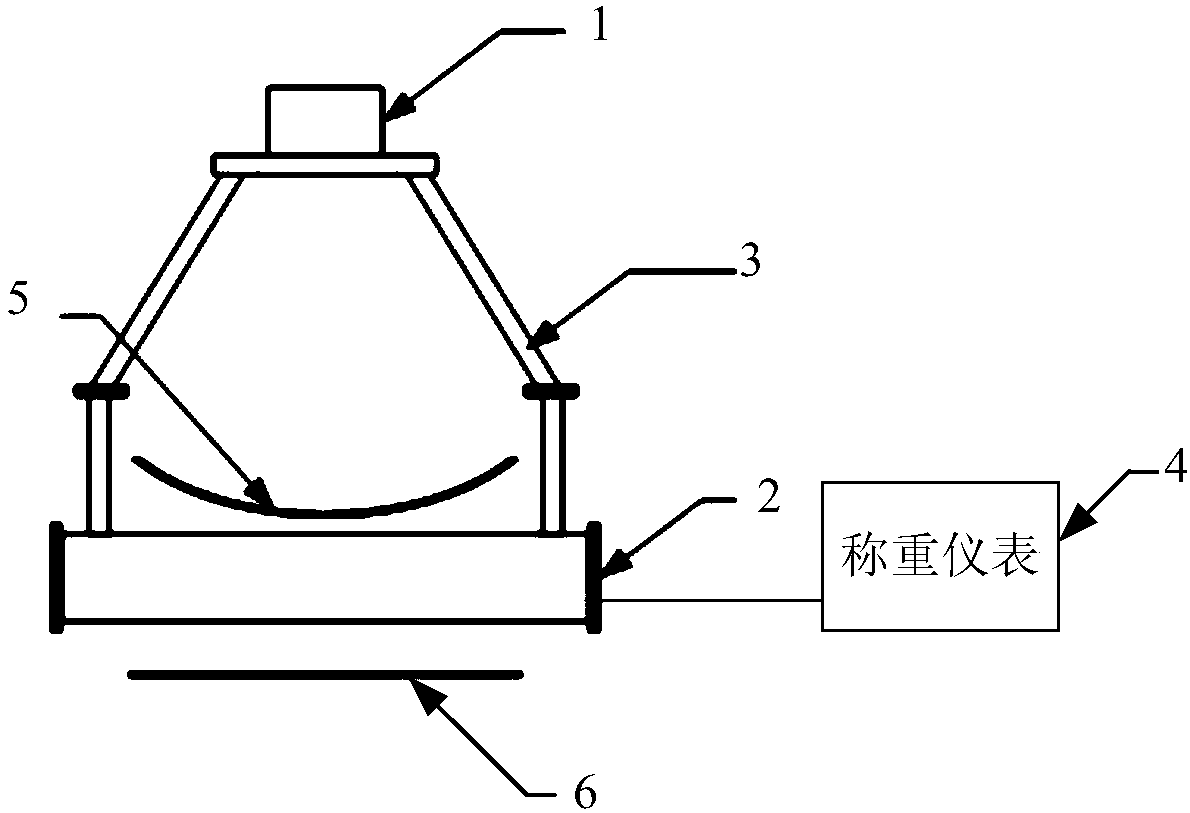

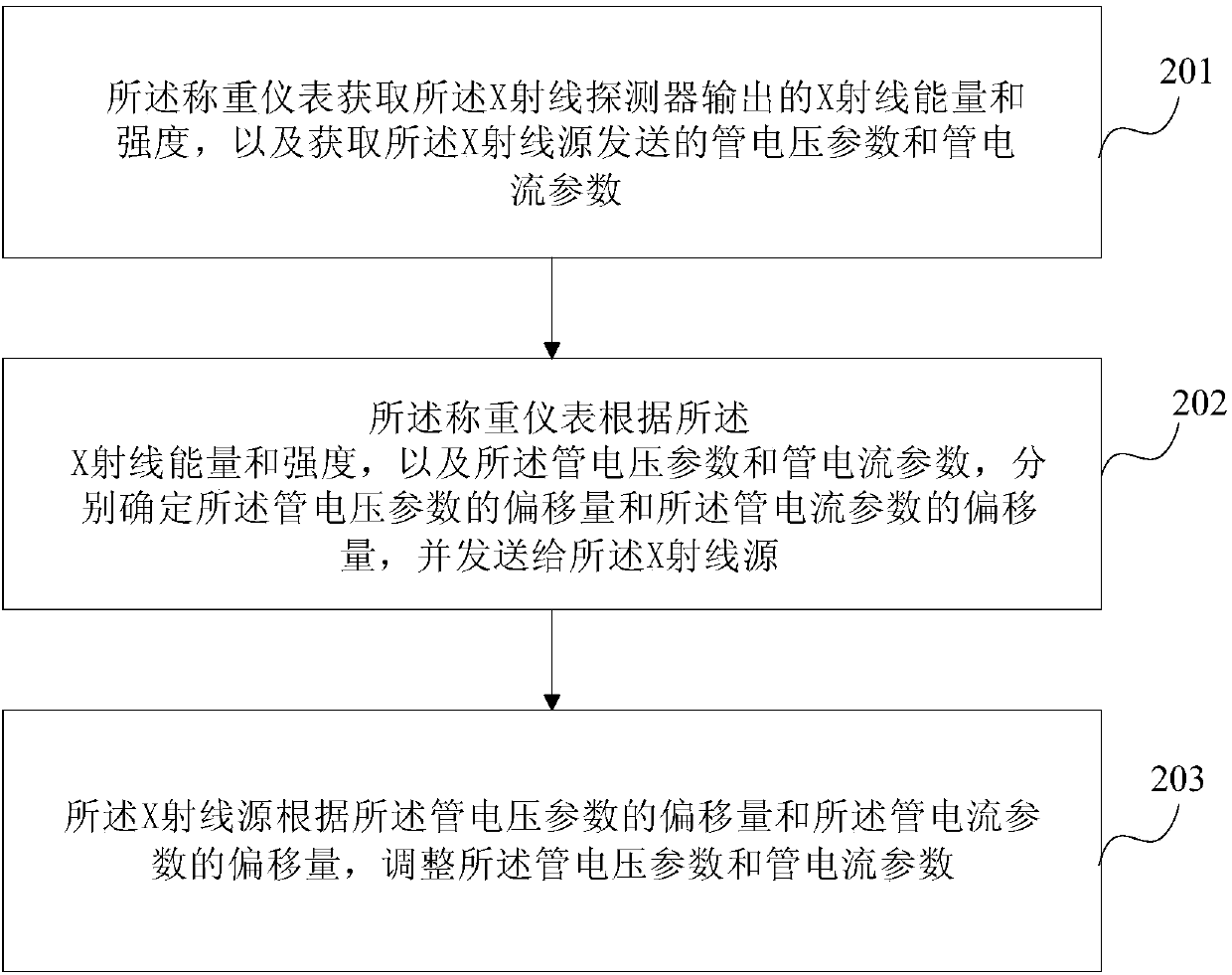

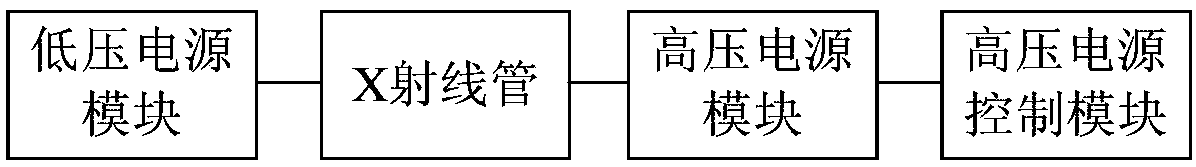

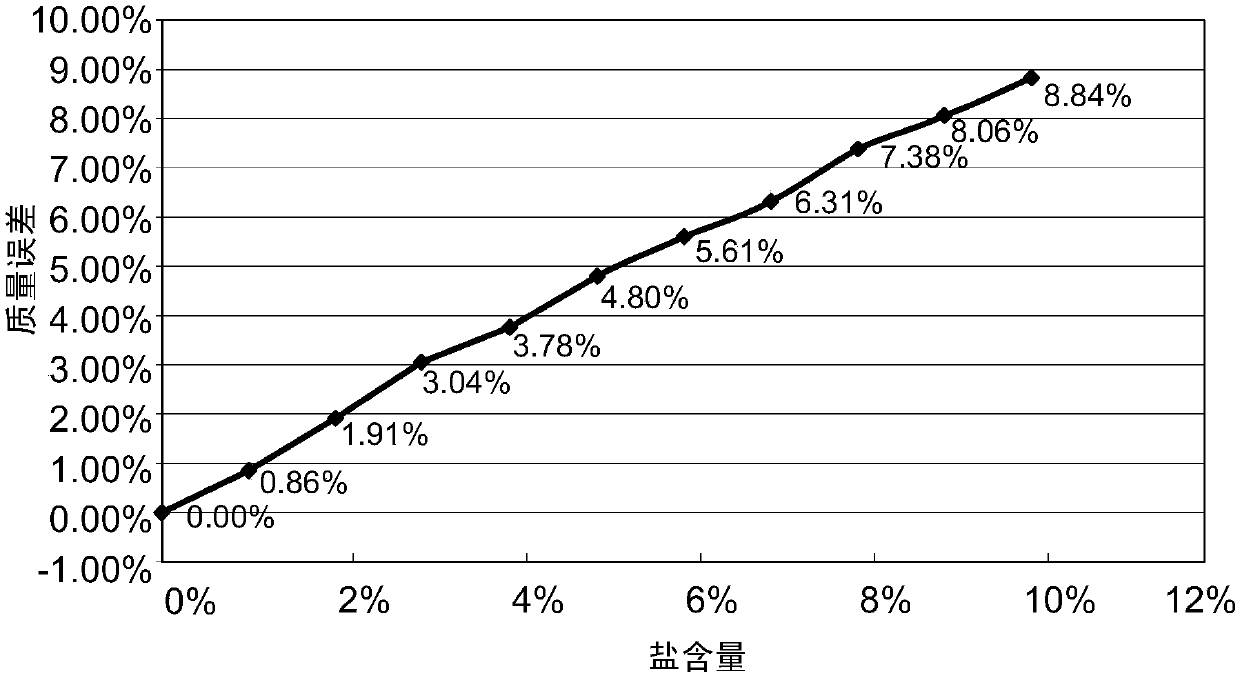

Calibration method for X-ray nuclear scale and X-ray nuclear scale

PendingCN108051069AImprove stabilityNo need to think about handling issuesWeighing apparatus using radiationWeighing apparatus testing/calibrationPower flowX-ray

The invention provides a calibration method for an X-ray nuclear scale and the X-ray nuclear scale. The calibration method is applied to the X-ray nuclear scale. The X-ray nuclear scale includes an X-ray source, an X-ray detector, brackets and a weighing instrument. The method includes the steps that the weighing instrument acquires X-ray energy and intensity output by the X-ray detector and a tube voltage parameter and a tube current parameter sent by the X-ray source; the weighing instrument determines the offset of the tube voltage parameter and the offset of the tube current parameter according to the tube voltage parameter and the tube current parameter respectively; the X-ray source adjusts the tube voltage parameter and the tube current parameter based on the offset of the tube voltage parameter and the offset of the tube current parameter. According to the calibration method of the embodiment, the X-ray detector is doubled as a feedback sensor for monitoring the X-ray energy and intensity, the tube voltage and tube current of the X-ray source are controlled through feedback to keep the X-ray parameters of the X-ray source constant, and the measurement stability of the X-raynuclear scale is improved.

Owner:BEIJING POLYTECHNIC COLLEGE +1

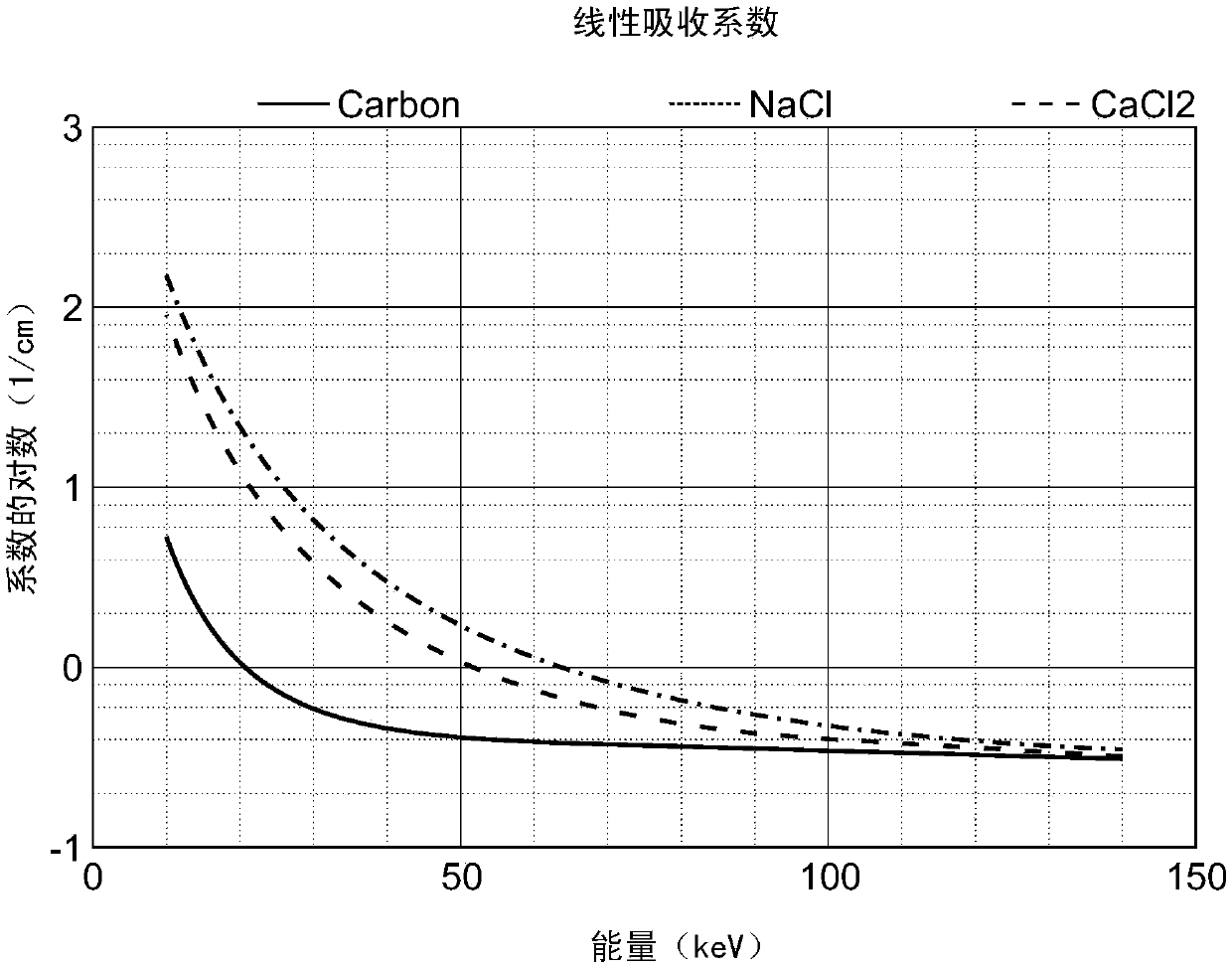

Method of determining mass of objects from plurality of x-ray images taken at different energy level

ActiveCN107430079AWeighing apparatus using radiationMaterial analysis by transmitting radiationX-rayComputer compatibility

A method of determining the mass of an object by scanning the object in a radiographic inspection system, specifically in an X-ray scanner with the capability to take scan images at a plural number J of energy levels, has three modes or parts, namely: an initial learning mode, a normal operating mode, and a learning improvement mode. An initial learning mode in which reference objects are scanned and their actual masses weighed and stored as reference values. A normal operating mode wherein sample objects with unknown mass m are scanned and analyzed for compatibility with the reference values, and if found incompatible, the method switches to the learning improvement mode. A learning improvement mode in which the actual mass of the sample object found incompatible is determined by weighing and updates the stored reference values.

Owner:METTLER TOLEDO INC

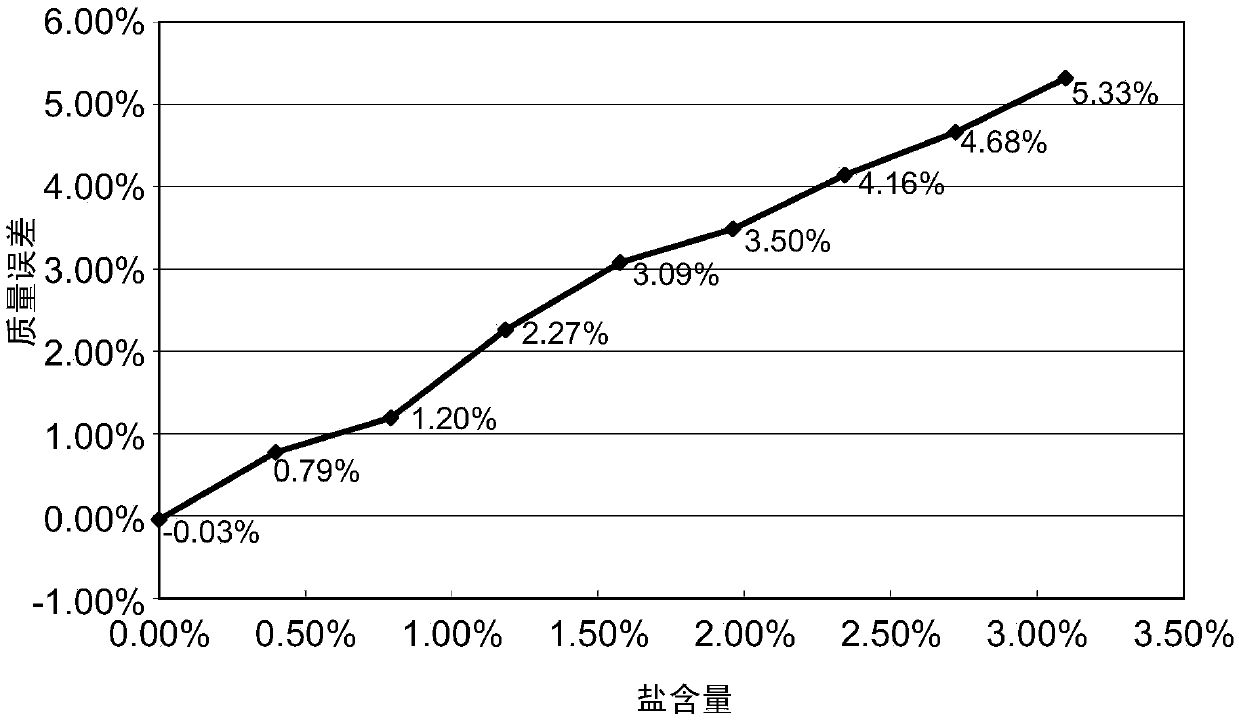

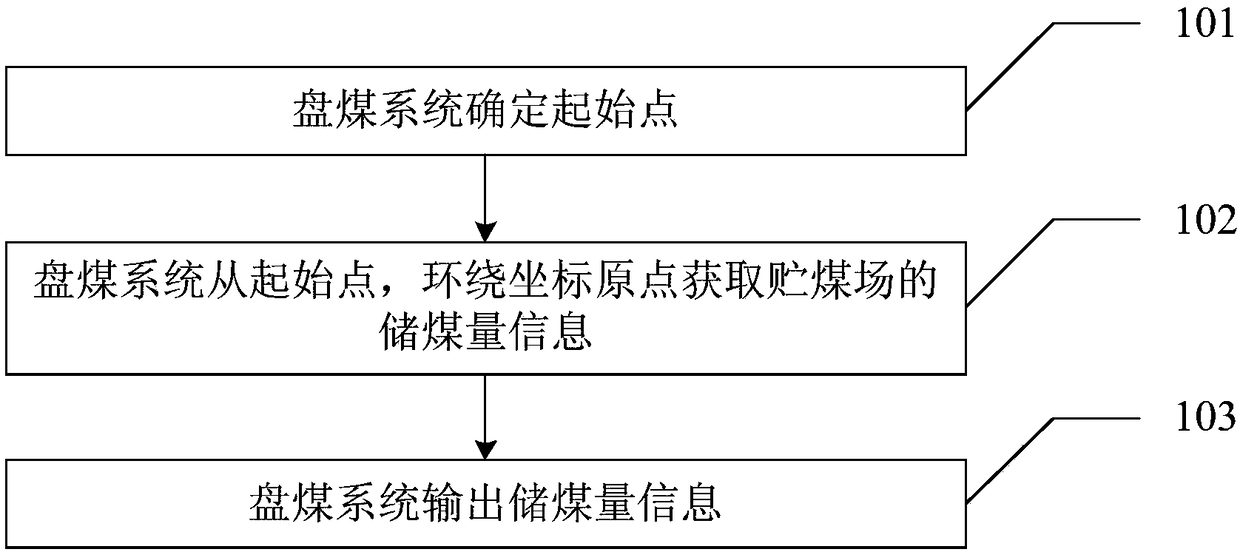

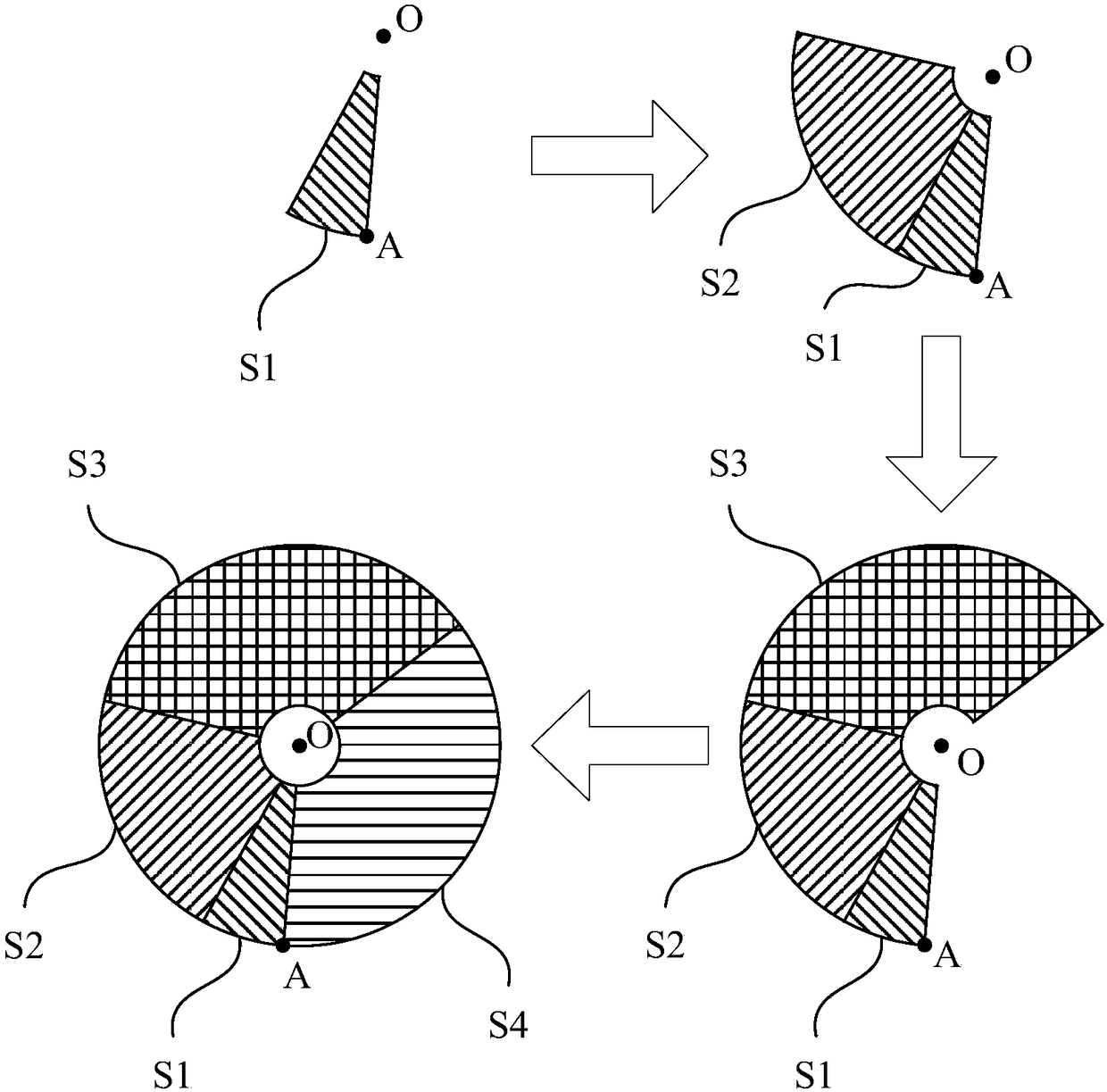

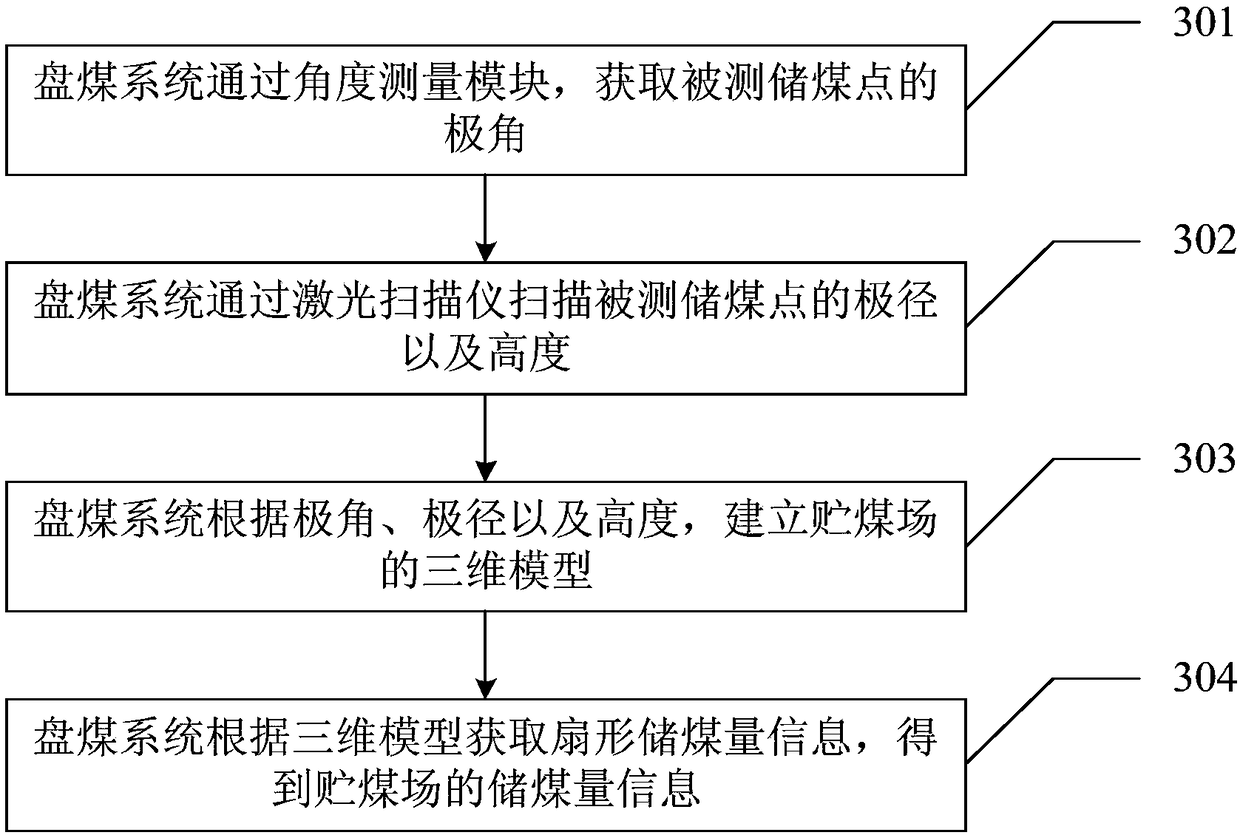

Coal stock counting method and coal stock counting system

PendingCN108317974AReduce stepsPromote intelligent operationImage analysisWeighing apparatus using radiationYard (length)Coal storage

The invention provides a coal stock counting method and a coal stock counting system which are used for conveniently and quickly counting a coal stock. The coal stock counting method provided by the invention comprises the following steps: the coal stock counting system determines a start point; the coal stock counting system acquires coal stock information of a coal storage yard around an originof coordinates from the start point; the coal stock counting system outputs the coal stock information. According to the technical scheme, the coal stock counting method has the following advantages:the coal stock counting system determines the start point, acquires the coal stock information of the coal storage yard around the origin of coordinates from the start point and outputs the coal stockinformation, so that high-automation coal stock counting work can be conveniently and quickly carried out, user operation is greatly avoided, and relatively high accuracy can be achieved; therefore,the coal stock information obtained by the coal stock counting work is more reliable, so as to promote intelligent operation of a thermal power plant.

Owner:GUANGZHOU CR THERMOELECTRICITY CO LTD

Method for determining a gsm substance and/or a chemical composition of a conveyed material sample, and a device for this purpose

InactiveUS7242747B2Accurate measurementMaterial analysis using wave/particle radiationWeighing apparatus using radiationChemical compositionX-ray

A method for determining a weight per unit area and / or a chemical composition of a conveyed material sample. From the analysis of a portion of an incident ionizing radiation, in particular an X-radiation, scattered from a material sample, a detector signal corresponding to the gsm substance and / or the chemical composition of the material sample is generated and used for determining the weight per unit area and / or the chemical composition of the material sample. A device for determining a weight per unit area and / or a chemical composition of a material sample has a compact measurement head arranged unilaterally with respect to the material sample. This measurement head includes an X-radiation source and a detector arrangement integrated into the measurement head of at least one X-ray detector connected to a voltage supply and an evaluation unit.

Owner:MAHLO

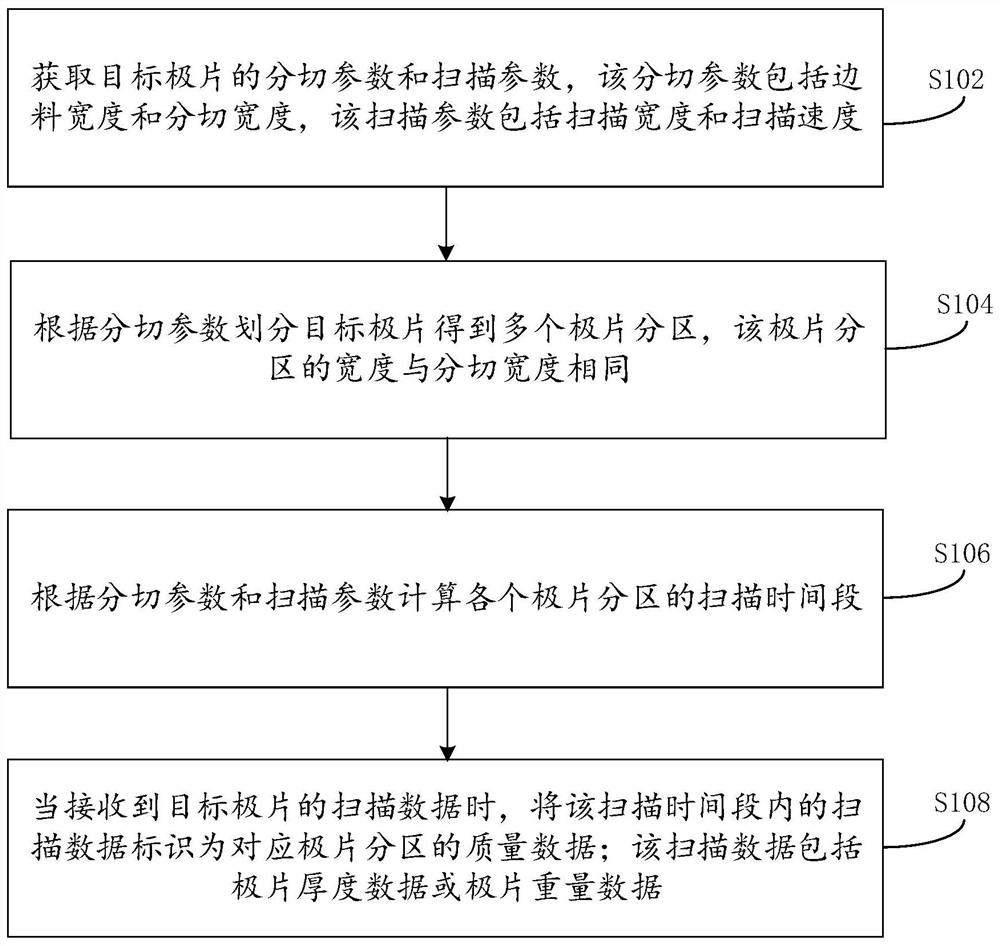

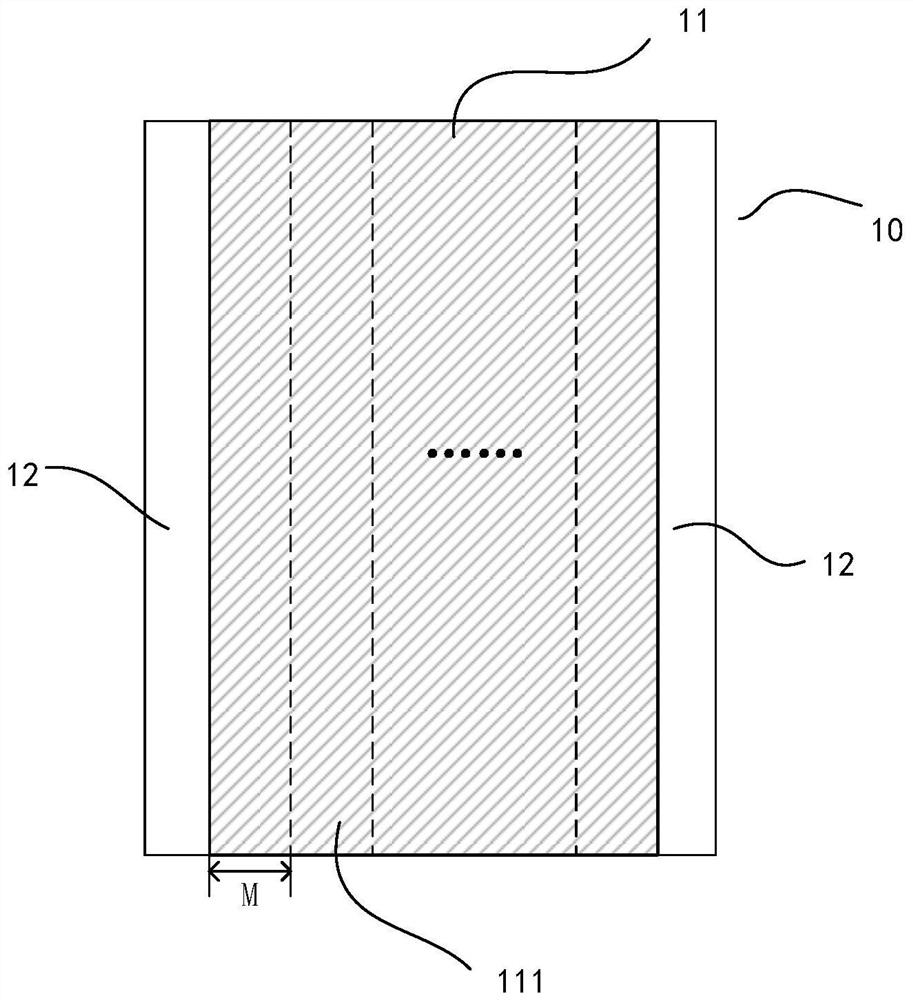

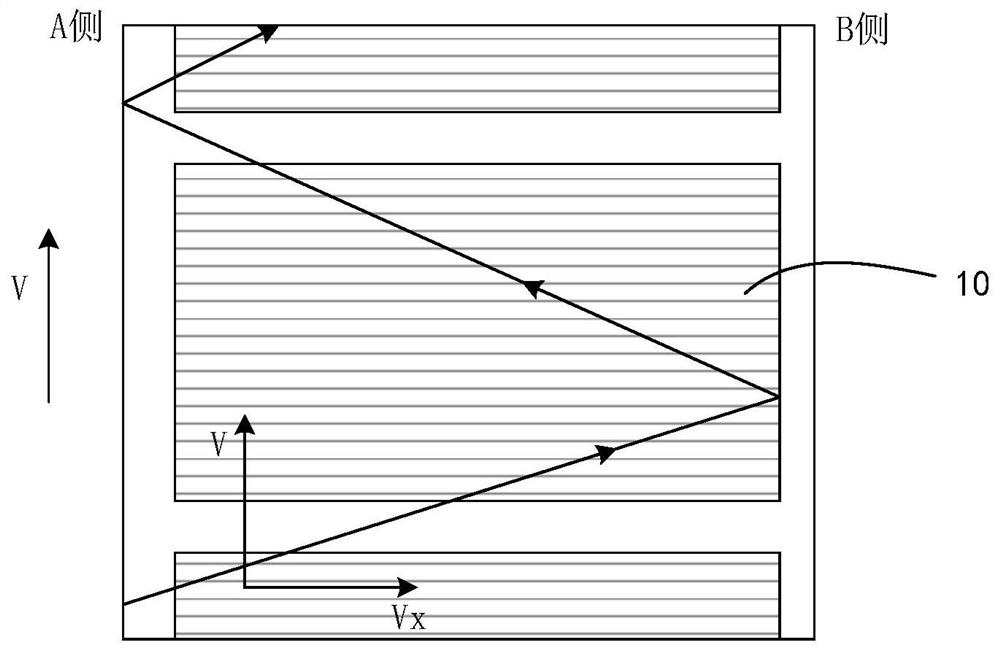

Pole piece quality information acquisition method, system and equipment

ActiveCN110108239BEnables coating quality assessmentReduce workloadWeighing apparatus using radiationUsing wave/particle radiation meansData packQuality data

The invention provides a method, system and equipment for acquiring pole piece quality information, and relates to the technical field of batteries. The method includes the following steps that slitting parameters and scanning parameters of a targeted pole piece are obtained, and the slitting parameters comprise an off-cut width and a slitting width and the scanning parameters include a scanning width and a scanning speed; the targeted pole piece is cut according to the slitting parameters to obtain a plurality of pole piece partions, and the width of the pole piece partions are the same as the slitting width; scanning duration of each pole piece partion is computed according to the slitting parameters and the scanning parameters; when the scanned data of the targeted pole piece are received, the scanned data in a scanning duration are identified as quality data correspond to the pole piece partions; and the scanned data includes pole piece thickness data or pole piece weight data. Theembodiment of the invention provides a method for acquiring pole piece quality information, quality information of each elementary volume after the pole piece is cut is acquired, the coating qualityassessment for one elementary volume is realized, and the accuracy of tracing the information of products is improved.

Owner:东莞维科电池有限公司

Method and apparatus for estimating the dry mass flow rate of a biological material

ActiveUS20130036831A1Accurately determinedEstimates are accurate and reliableMaterial analysis using wave/particle radiationVolume measurement and fluid deliveryTime rangeElectromagnetic radiation

A method and an apparatus for measuring dry mass flow rate for a biological material.—The method steps include conveying the biological material through a measuring station, scanning the biological material with electromagnetic radiation of at least two different energy levels, determining the amount of radiation transmitted through the biological material at said two energy levels, and summing, for each of sad two energy levels, the radiation transmission values over a time frame to summed radiation transmission values. Further, a wet dry mass flow rate is estimated based on the summed radiation transmission values for said two energy level. The moisture content of the biological material is estimated based on the amounts of radiation transmitted through the biological material. The estimated wet dry mass flow rate is scaled in accordance with the estimated moisture content of the biological material, thereby providing an estimate of the dry mass flow rate.

Owner:MANTEX IP AB

Method for determining the weight and thickness of a passivation or conversion coating on a substrate

ActiveUS9606048B2Accurate measurementMinimum interruptionWeighing apparatus using radiationMaterial analysis by optical meansIndustrial settingConversion coating

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

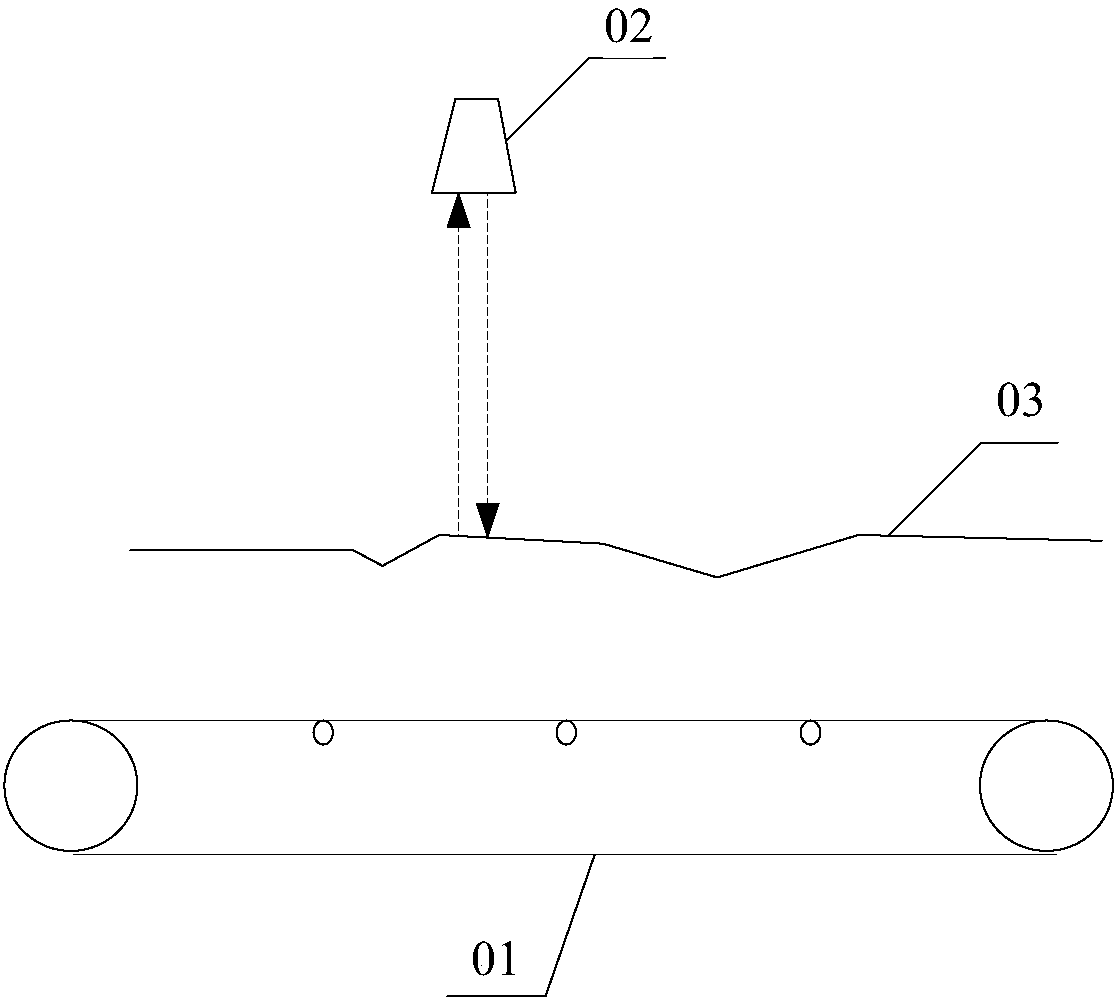

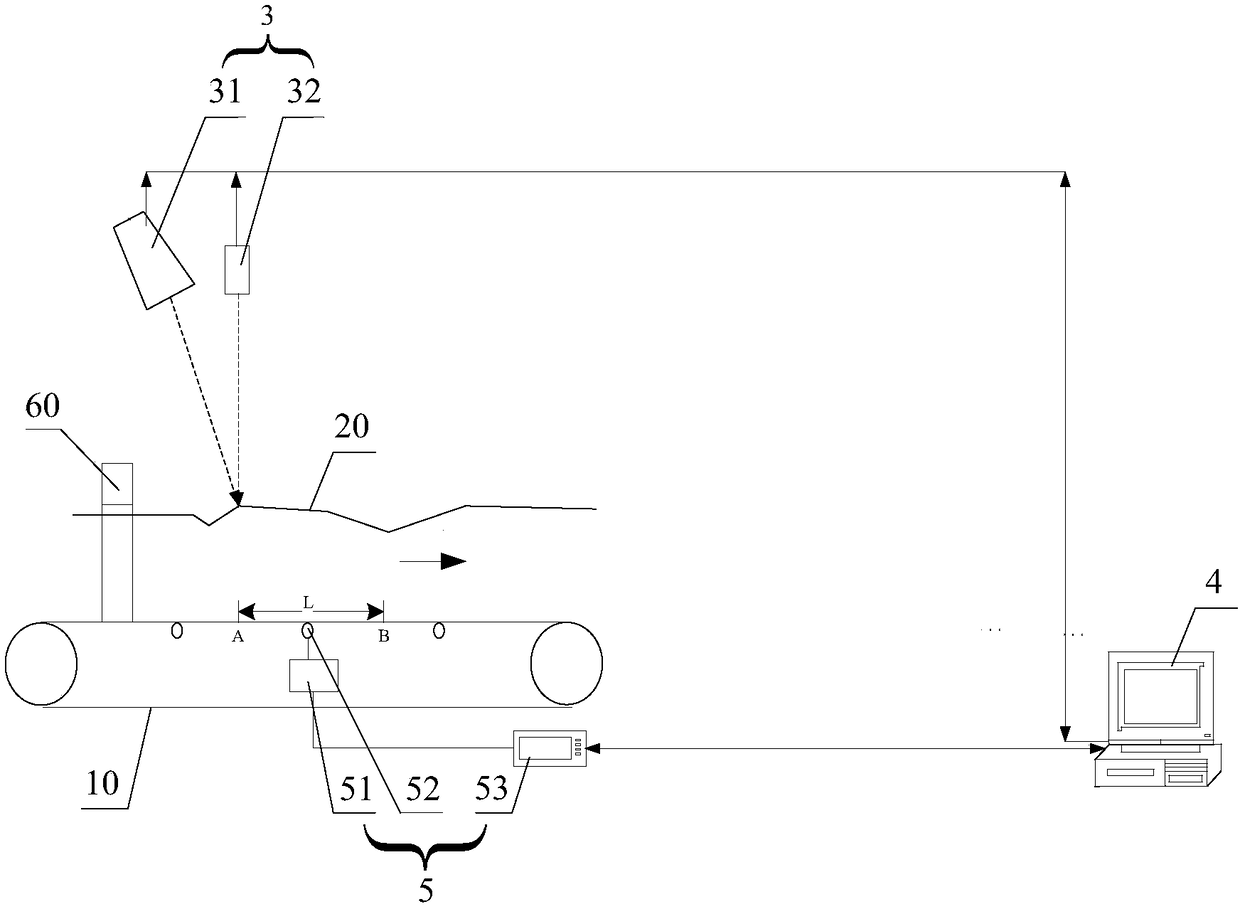

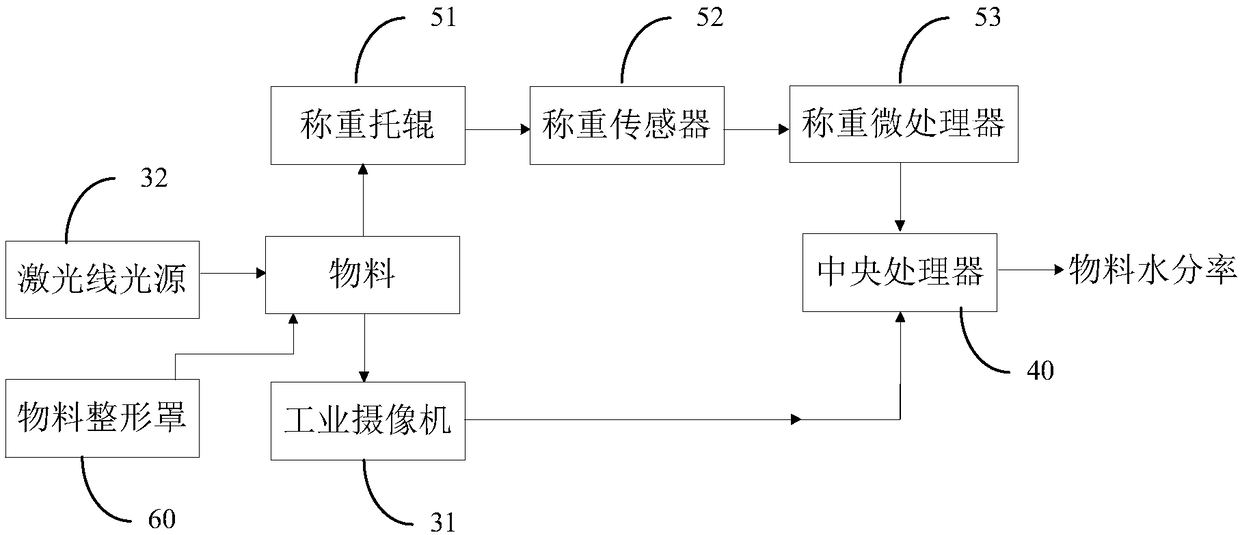

Belt conveyor material moisture content on-line detection method and device

ActiveCN108254281ANot easy to interfereAccurate detectionWeighing apparatus using radiationWeighing apparatus for continuous material flowEngineeringContact type

The invention relates to a belt conveyor material moisture content on-line detection method and device. The method includes: firstly, utilizing an image acquisition device for image acquisition of a material at the starting position of a belt conveyor weighing section according to a preset frequency; secondly, judging whether the sum of material advancing distance corresponding to the acquired material image meets the belt conveyor weighing section length requirement, if so, controlling a material weighing apparatus in terms of acquiring the actual weight of the material on the belt conveyor weighing section, and according to the pixel point information corresponding to the material surface in the acquired material image and a calibrated material dry base density, calculating the dry baseweight of the material on the weighing section; and according to the actual weight and the dry base weight, calculating the material moisture content. The method and device provided by the invention achieve calculation of the material dry base weight by acquiring the material image, and the actual mass of the material is directly measured by a contact-type weighing apparatus. Therefore, the detection result cannot be limited to moisture content detection at the material surface area and is not easily interfered by the external environment.

Owner:HUNAN CHANGTIAN AUTOMATION ENG CO LTD

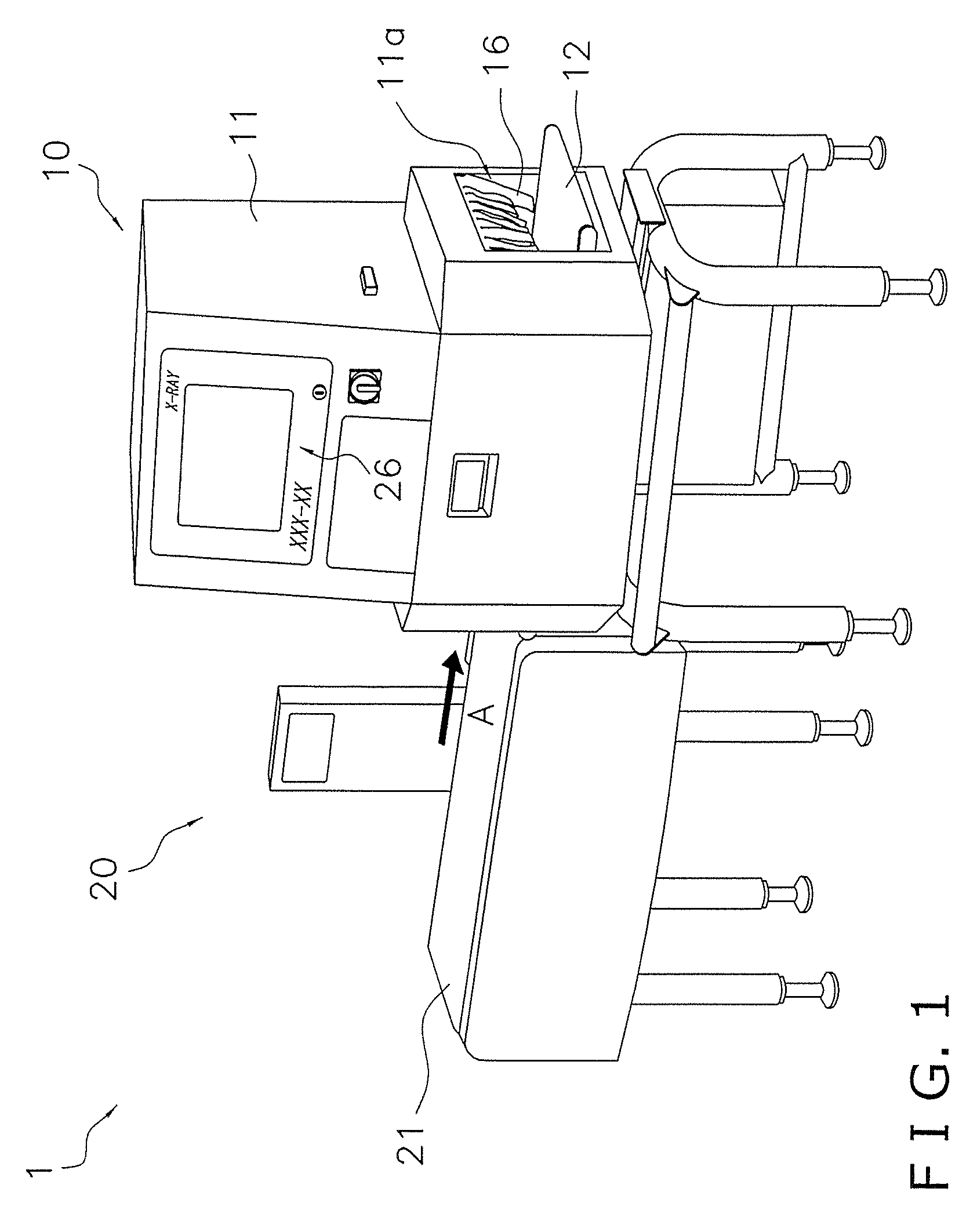

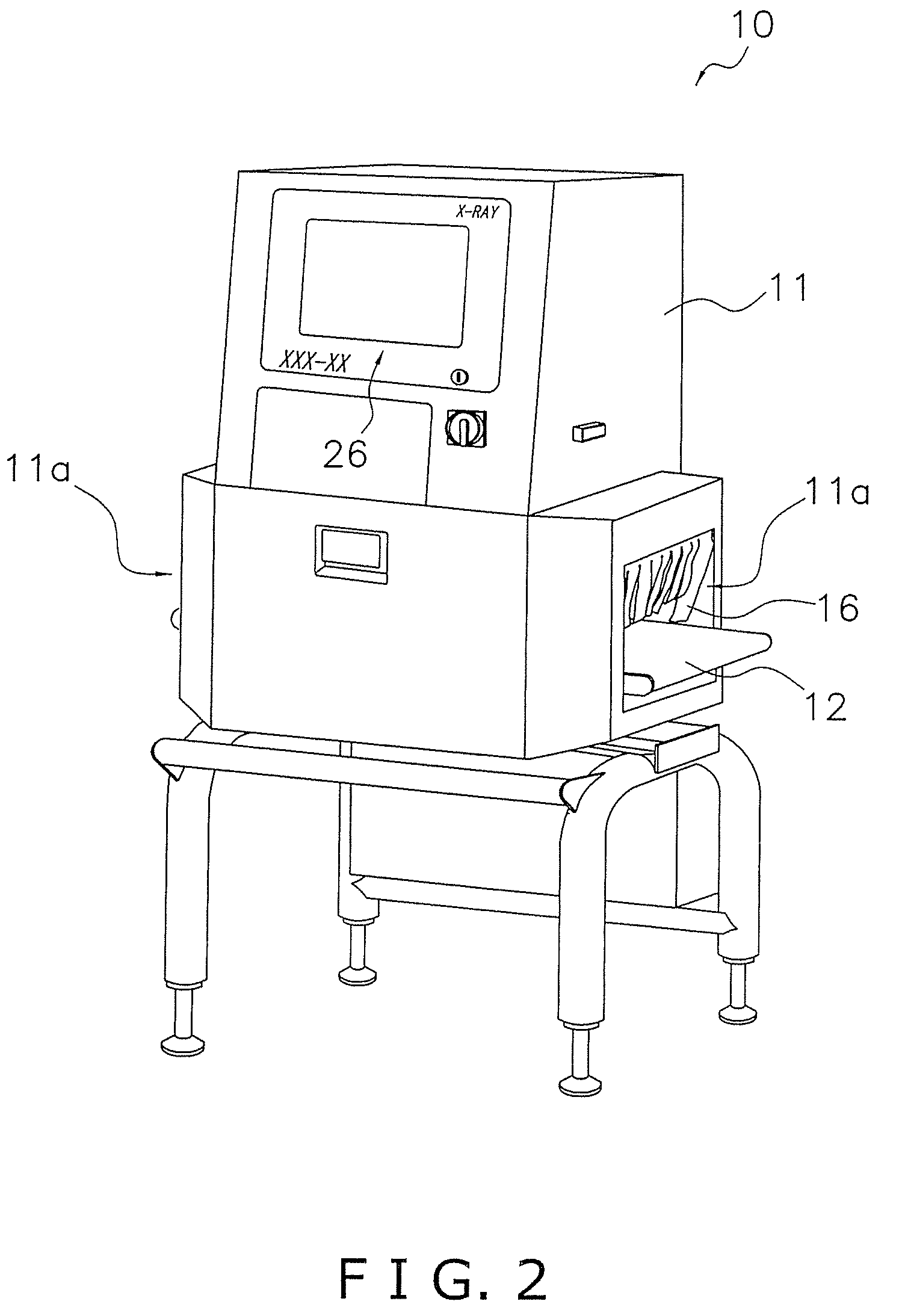

Weight inspection apparatus and weight inspection system provided therewith

InactiveUS20100046703A1High precisionImprove accuracyVolume/mass flow measurementWeighing apparatus using radiationEstimated WeightObject based

A weight inspection apparatus includes a weight obtaining unit, an irradiation unit, a detection unit and an estimated weight calculation unit. The weight obtaining unit is configured to obtain an actual weight of an inspection target object. The irradiation unit is configured to irradiate the inspection target object with energy waves. The detection unit is configured to detect the energy waves irradiated at the inspection target object. The estimated weight calculation unit is configured to calculate an estimated weight of the inspection target object based on a result of detection by the detection unit. The deviation amount calculation unit is configured to calculate a difference between the actual weight obtained by the weight obtaining unit and the estimated weight obtained by the estimated weight calculation unit.

Owner:ISHIDA CO LTD

Spectroscopic sensor for thickness or weight measurement of thin plastic films

ActiveUS9927366B2High sensitivityRadiation pyrometryInterferometric spectrometryOptical spectrometerThin membrane

Continuous on-line thin film measurements employ a sensor having a spectrometer for interferometric measurements and a stack of single channel detectors for adsorption measurements. The stack is separated from the spectrometer, which analyzes radiation that emerges (transmitted pass or reflected from) the film, whereas the stack analyzes radiation that has passed through the film multiple times. The spectrometer is (i) positioned directly opposite the source of radiation so that it detects transmitted radiation or (ii) disposed on the same side of the film as is the source of radiation so that the spectrometer detects radiation that is specularly reflected from the film. The sensor includes a broadband radiation source emitting visible to far infrared light which propagates through a measurement cell defined by reflective surfaces exhibiting Lambertian-type scattering. The sensor is capable of measuring thin plastic films with thicknesses down to 1 micron or less.

Owner:HONEYWELL INC

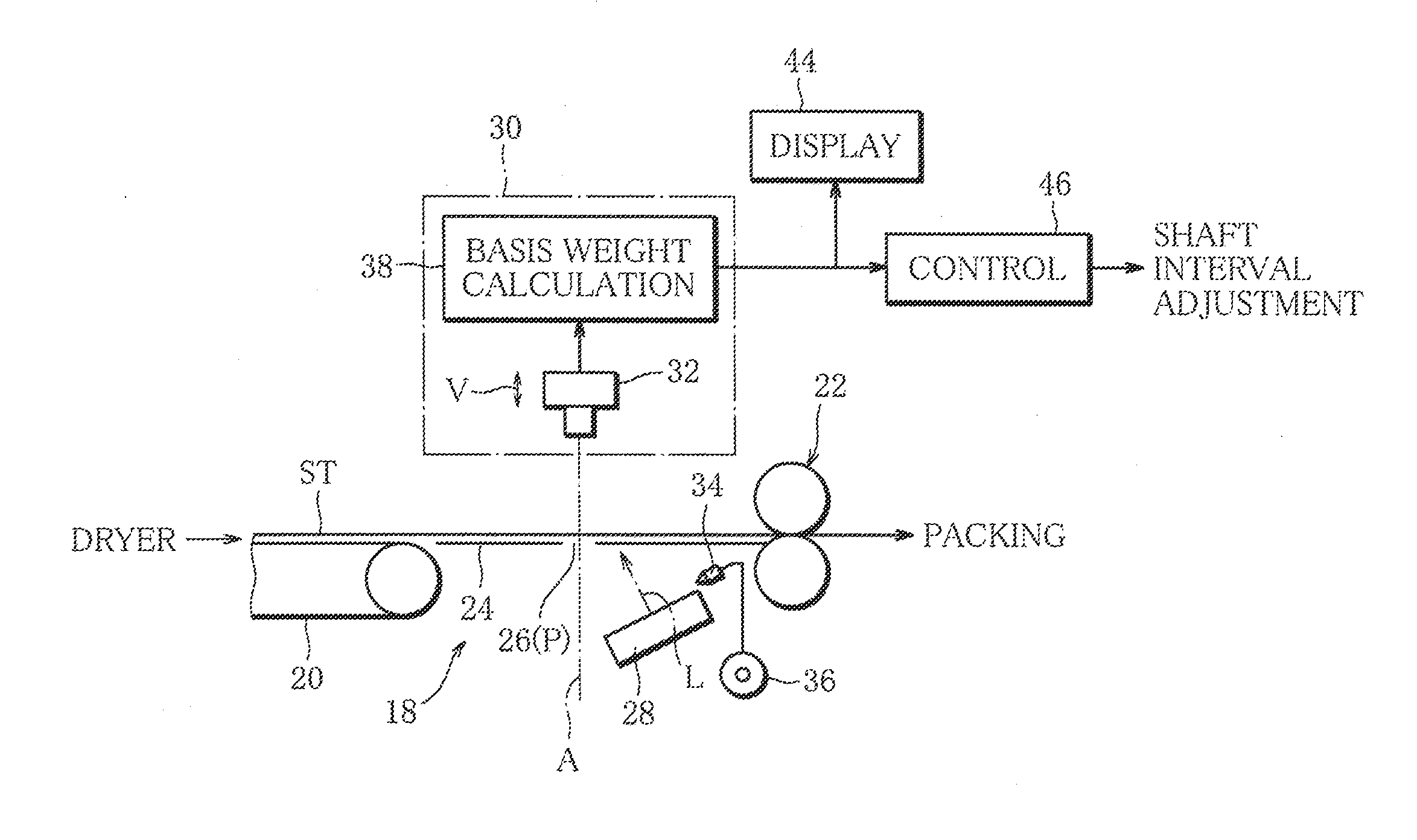

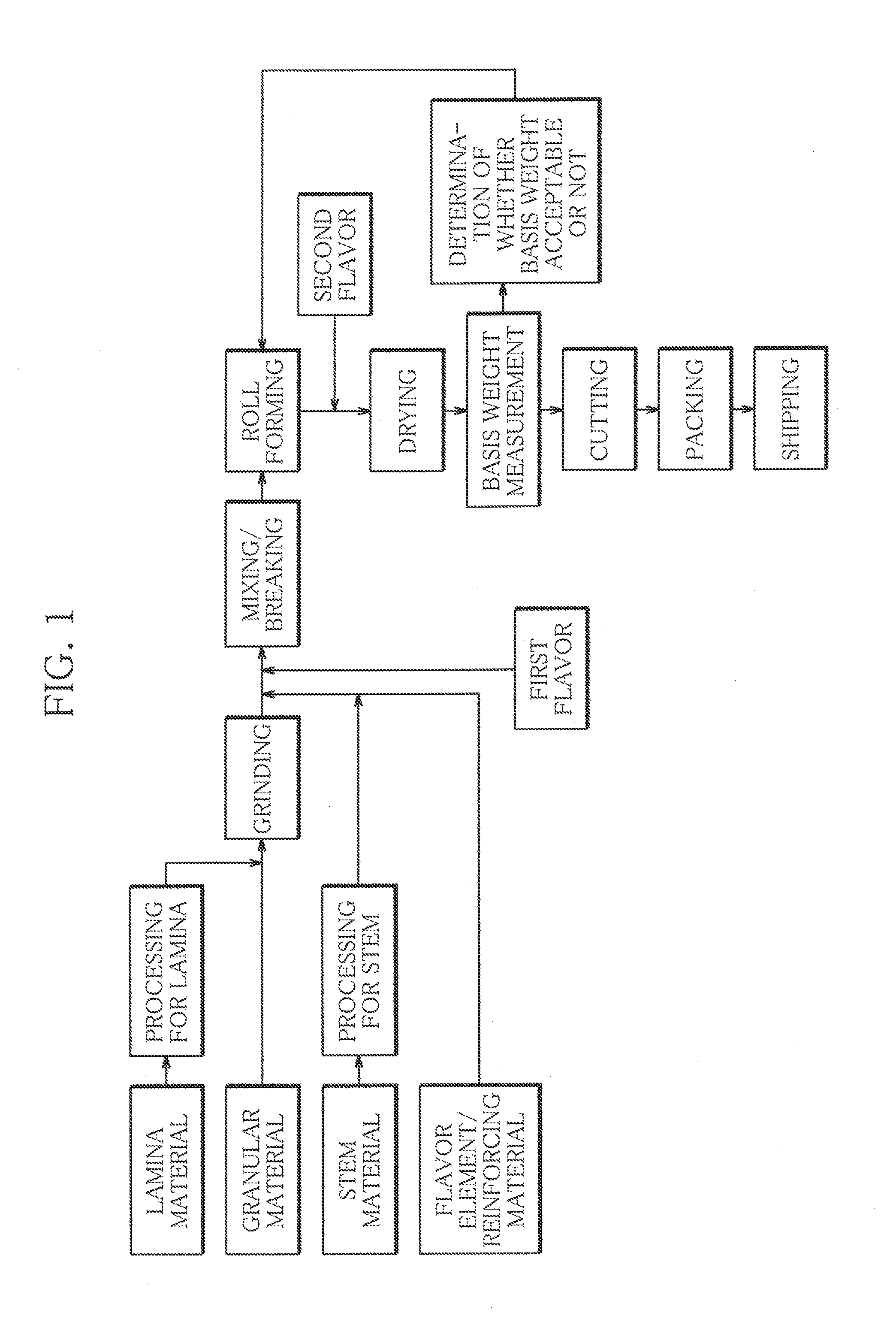

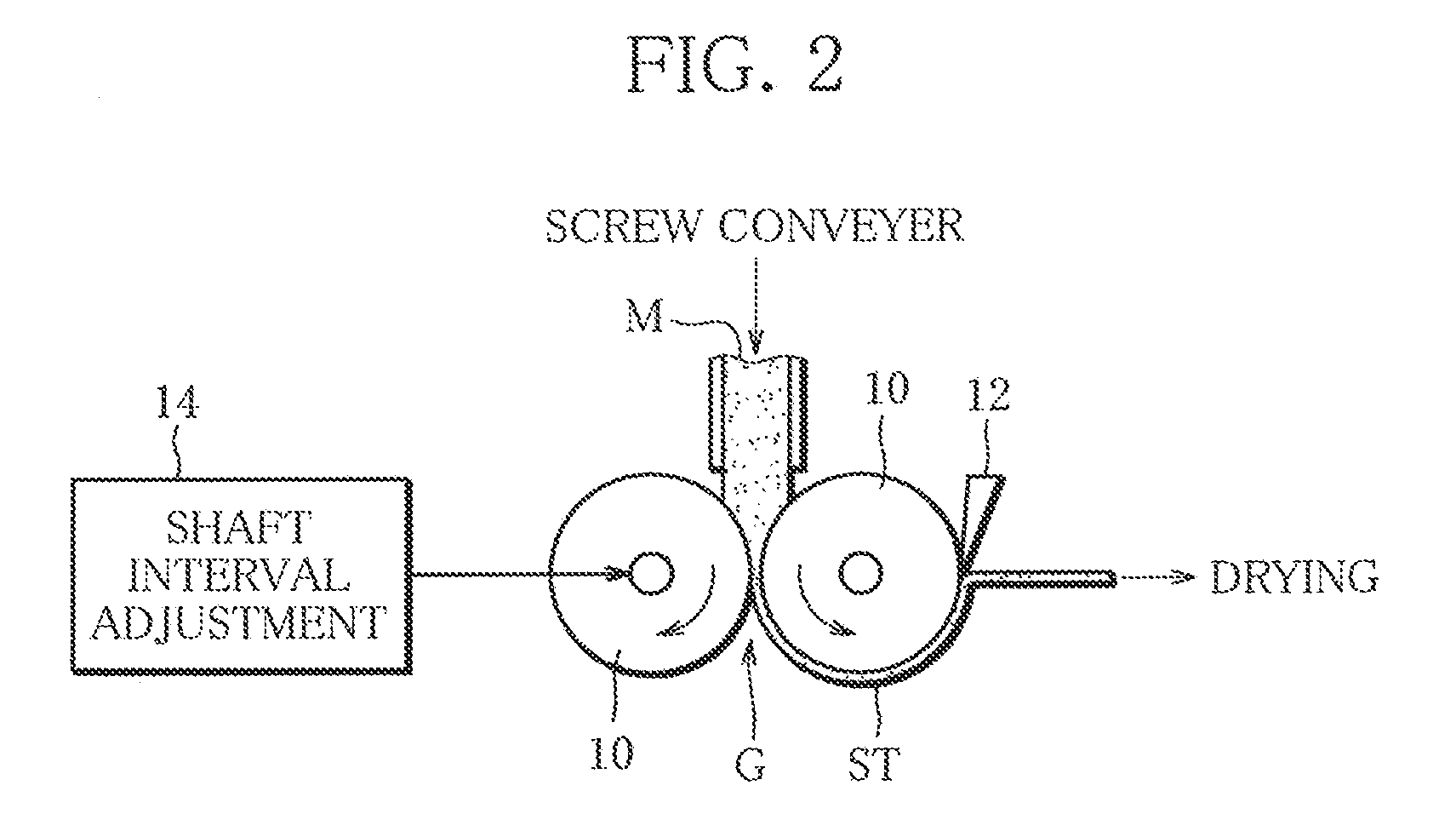

Basis weight measuring apparatus and method for sheet tobacco, and manufacturing system and method for sheet tobacco

ActiveUS20150136161A1Easy to produceReduce productionImage enhancementTobacco preparationColor imageGray level

A measuring apparatus for performing a basis weight measuring method for sheet tobacco according to the present invention includes: a light source (28) that emits light to sheet tobacco (ST) passing through a measurement position (P) on a transport path (18); and a visual sensor (30), the visual sensor (30) having a color camera (32) disposed with the transport path (18) put between the color camera (32) and the light source (28), a processing part (40) that transforms a color image of the sheet tobacco (ST) taken by the camera (32) into a grayscale image, and a conversion part (42) that converts an average gray level of the grayscale image into a basis weight of the sheet tobacco (ST) with reference to a conversion map which indicates a relationship between the average gray level of the grayscale image and an actual basis weight of sheet tobacco (ST).

Owner:JAPAN TOBACCO INC

Weight inspection apparatus and weight inspection system provided therewith

InactiveUS7991110B2Improve accuracyHigh precisionVolume/mass flow measurementWeighing apparatus using radiationEstimated WeightObject based

A weight inspection apparatus includes a weight obtaining unit, an irradiation unit, a detection unit and an estimated weight calculation unit. The weight obtaining unit is configured to obtain an actual weight of an inspection target object. The irradiation unit is configured to irradiate the inspection target object with energy waves. The detection unit is configured to detect the energy waves irradiated at the inspection target object. The estimated weight calculation unit is configured to calculate an estimated weight of the inspection target object based on a result of detection by the detection unit. The deviation amount calculation unit is configured to calculate a difference between the actual weight obtained by the weight obtaining unit and the estimated weight obtained by the estimated weight calculation unit.

Owner:ISHIDA CO LTD

Machine and method for filling and checking capsules

ActiveUS9157784B2Changed rapidly and quicklyAccurate operationLiquid fillingWeighing apparatus using electrostatic balancingBiomedical engineeringDosing units

A machine for dosing a plurality of products in capsules, or similar containers, includes a plurality of dosing units for filling the capsules with respective products and a turret arrangement that rotates intermittently and is arranged for housing and moving the capsules in sequence through the dosing units. The machine further includes a plurality of checking units, each of which is located downstream of a respective dosing unit for measuring a quantity of product dosed in the capsules by the respective dosing units.

Owner:IMA IND MASCH AUTOMATICHE SPA

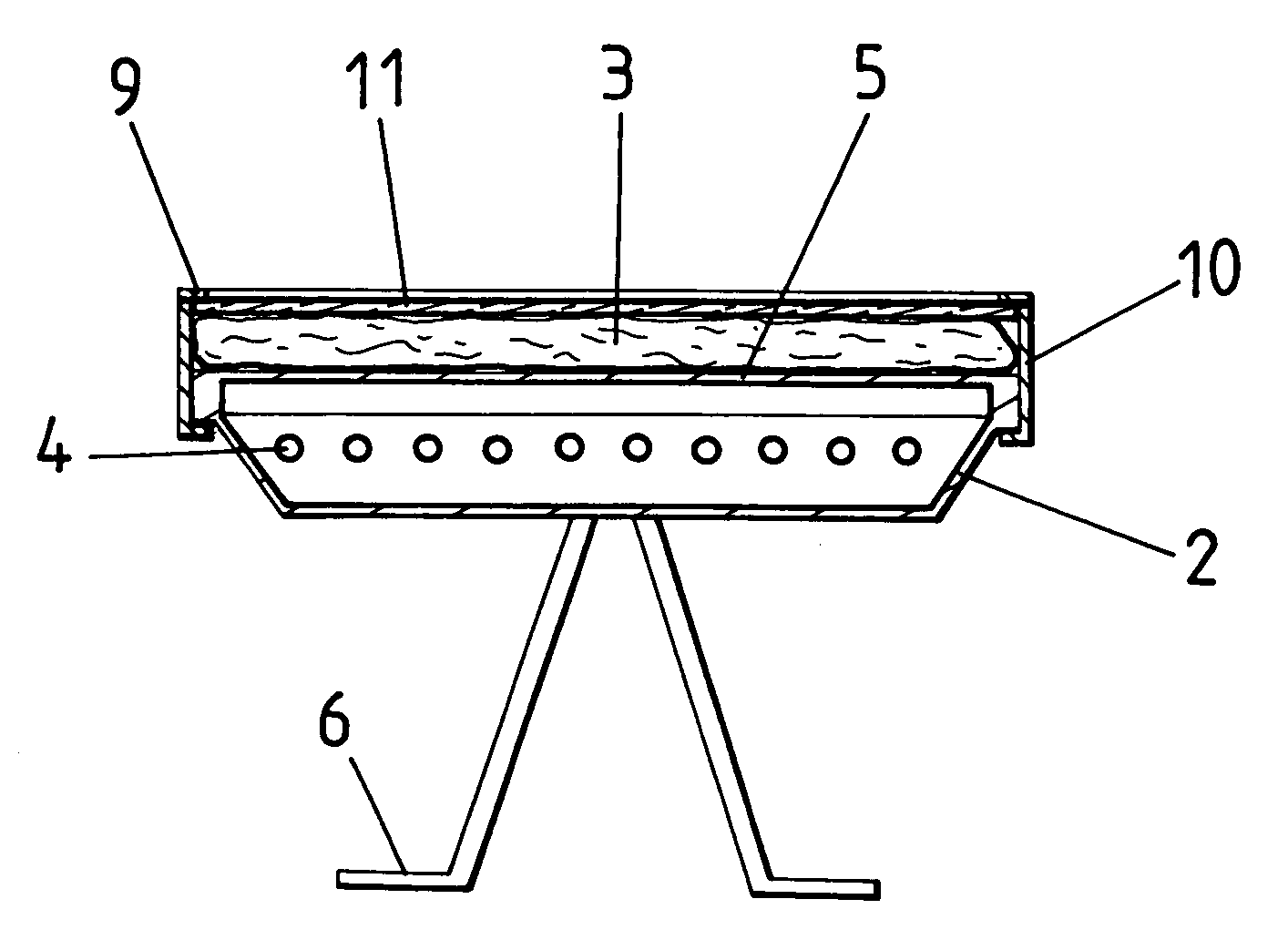

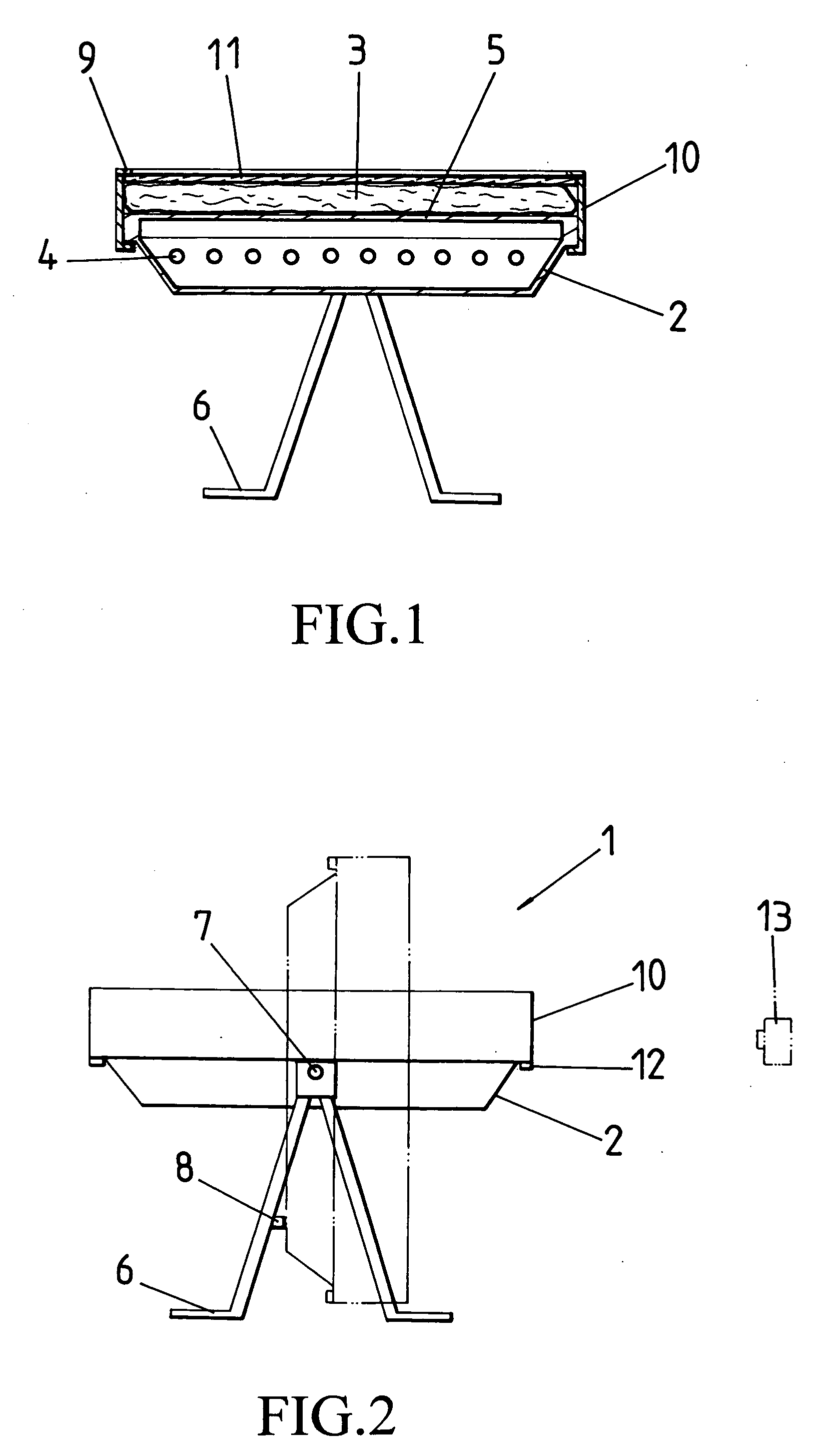

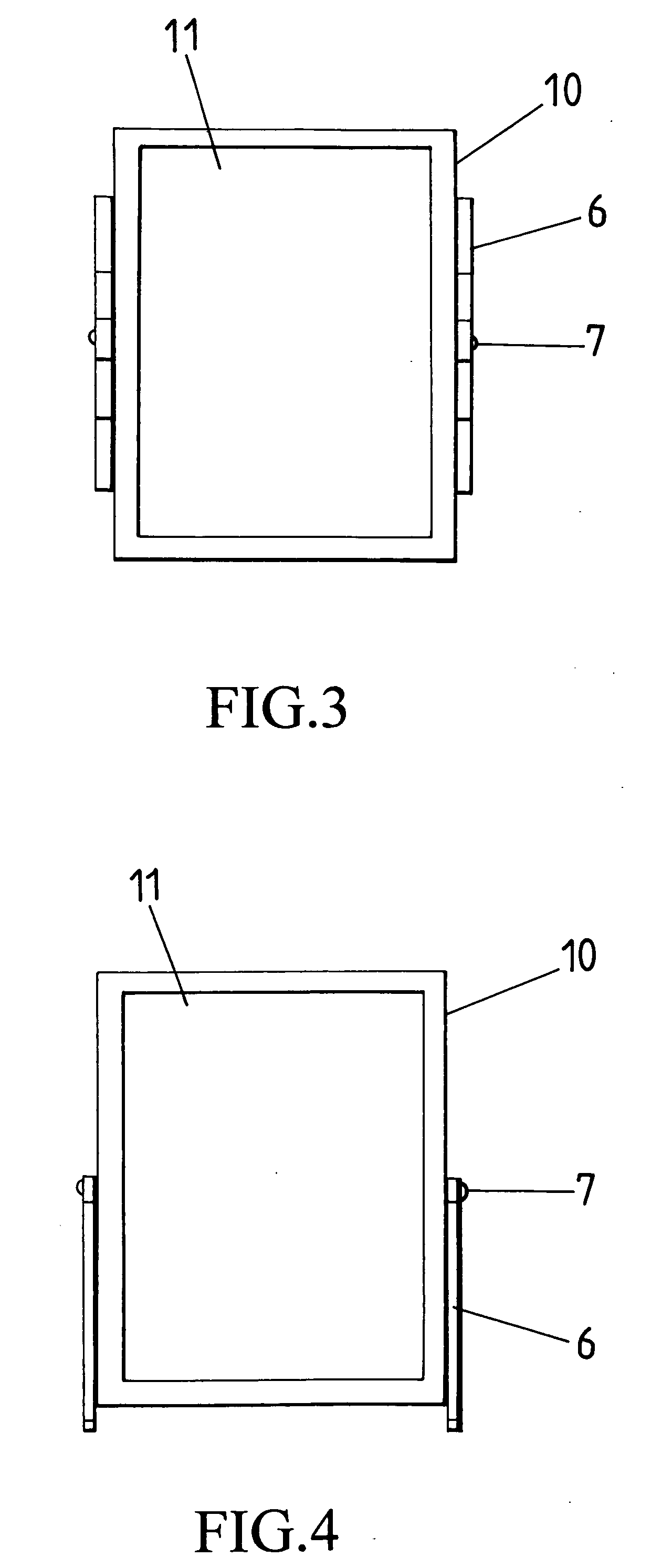

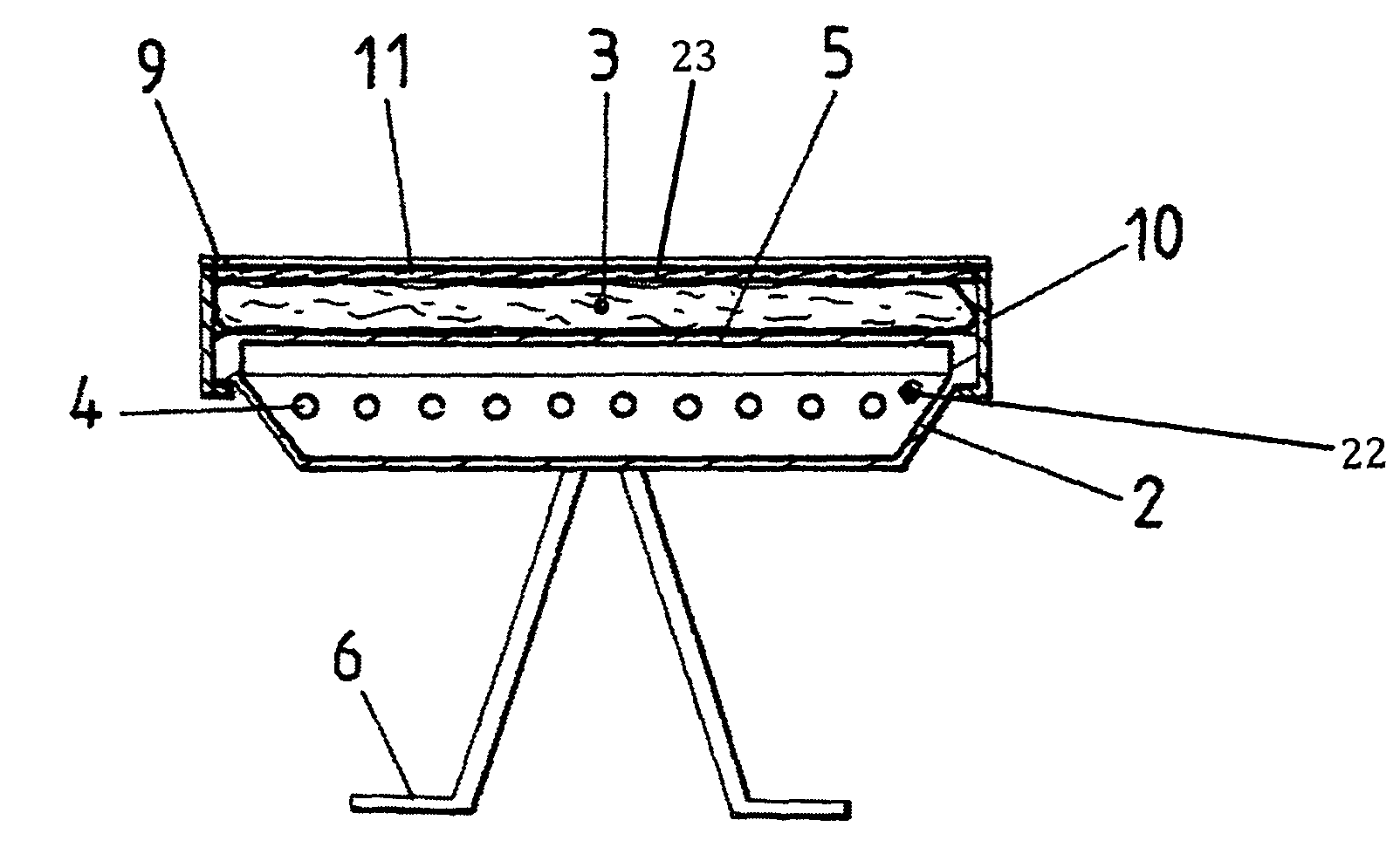

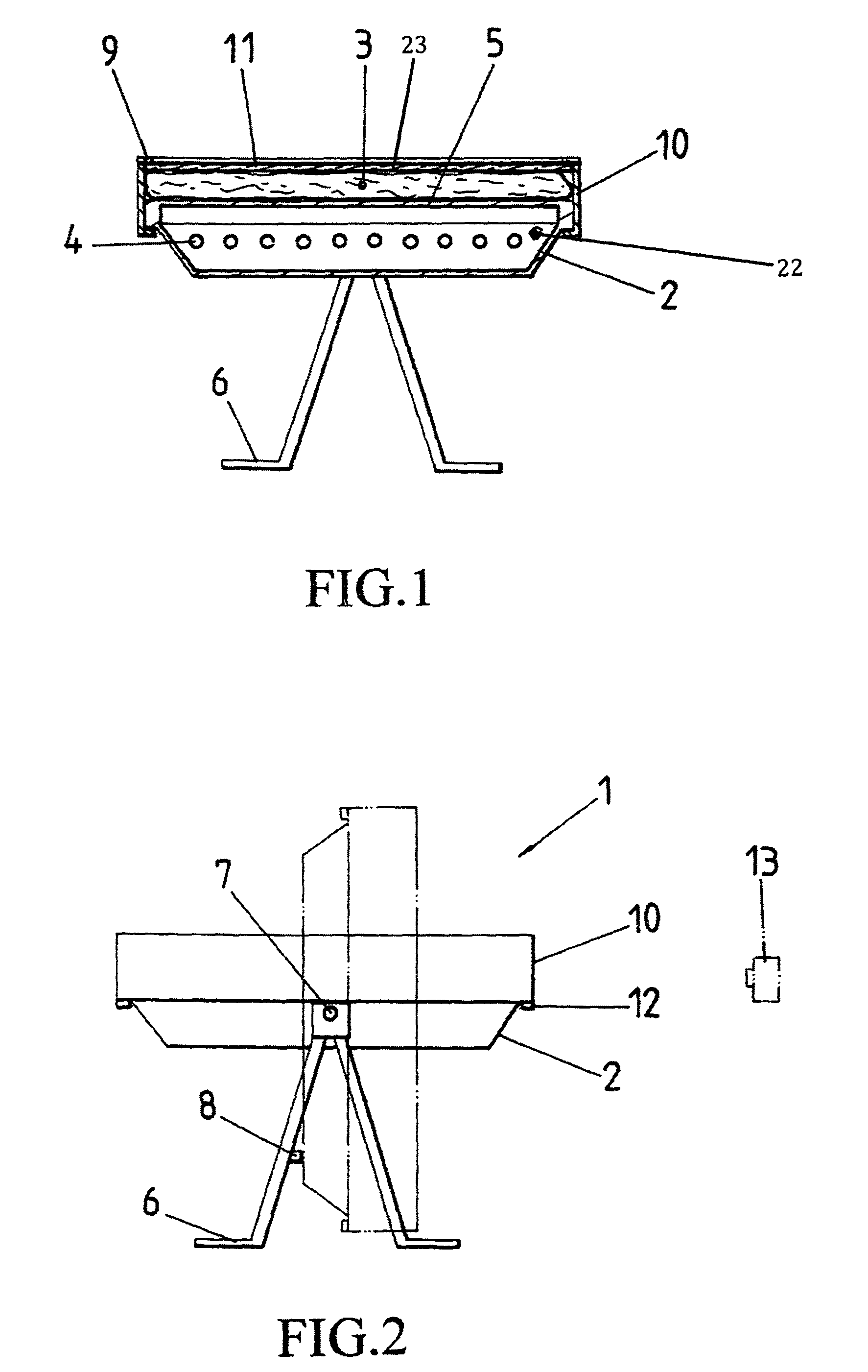

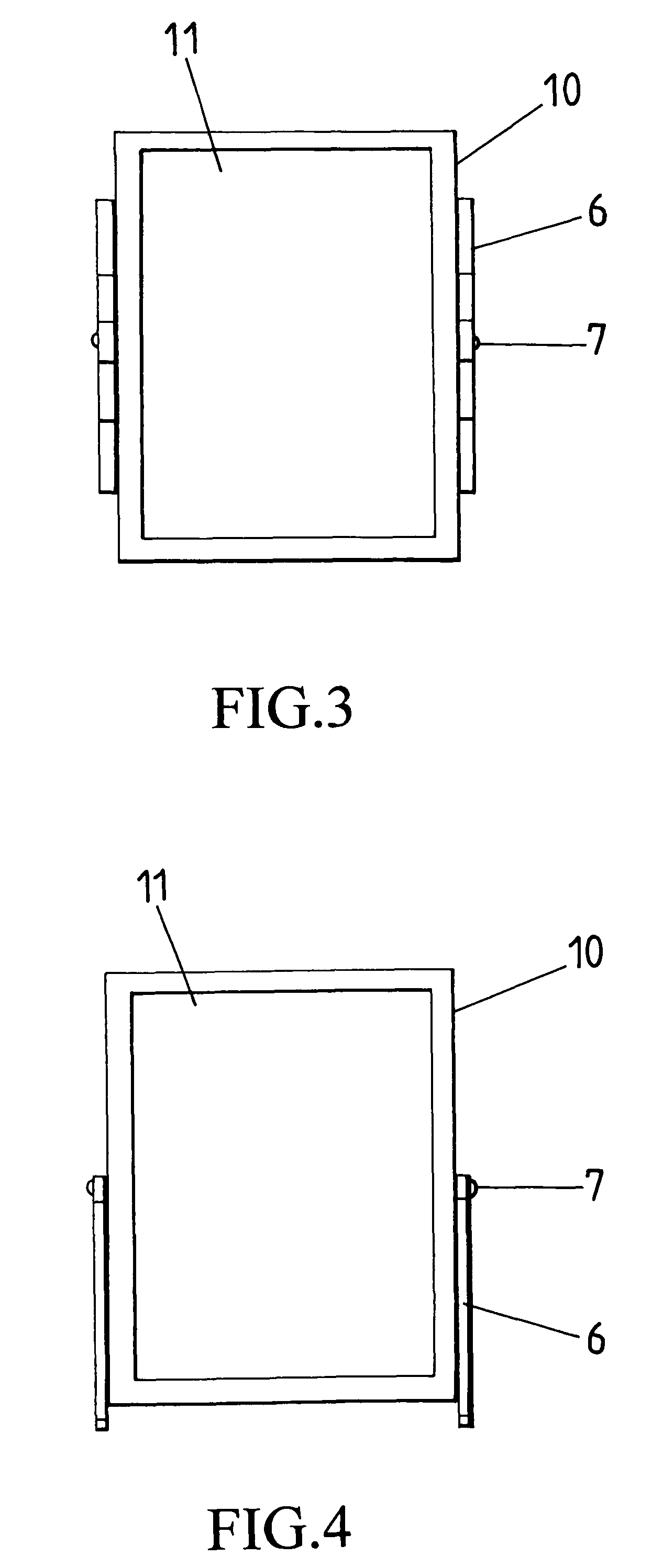

Method and a device for verifying mass inside a quilt

A method and a device for verifying mass inside a quilt is provided. A top of a box of a write-through device is placed with the quilt, which is unfolded and paved, and which is then put with a transparent platen. The quilt is next gently pressed and fixed by a semi-transparent board of the box, and the box rotates twice and stops at a vertical position. When the quilt is photographed under a write-through condition, one photo which is put in a transparent bag, and the other photo which is a locally exploded picture of the quilt, are attached on proper positions of the quilt.

Owner:YUSHO

Method and a device for verifying mass inside a quilt

InactiveUS8286515B2Weighing apparatus using radiationUsing mechanical meansEngineeringSemi transparent

A method and a device for verifying mass inside a quilt is provided. A top of a box of a write-through device is placed with the quilt, which is unfolded and paved, and which is then put with a transparent platen. The quilt is next gently pressed and fixed by a semi-transparent board of the box, and the box rotates twice and stops at a vertical position. When the quilt is photographed under a write-through condition, one photo which is put in a transparent bag, and the other photo which is a locally exploded picture of the quilt, are attached on proper positions of the quilt.

Owner:YUSHO

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com