Basis weight measuring apparatus and method for sheet tobacco, and manufacturing system and method for sheet tobacco

a technology of weight measurement and tobacco, which is applied in the field of basic weight measurement apparatus and method for tobacco, and the manufacturing system and method of tobacco, can solve problems such as affecting the taste of tobacco, and achieve the effect of reducing the production of inferior sheet tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

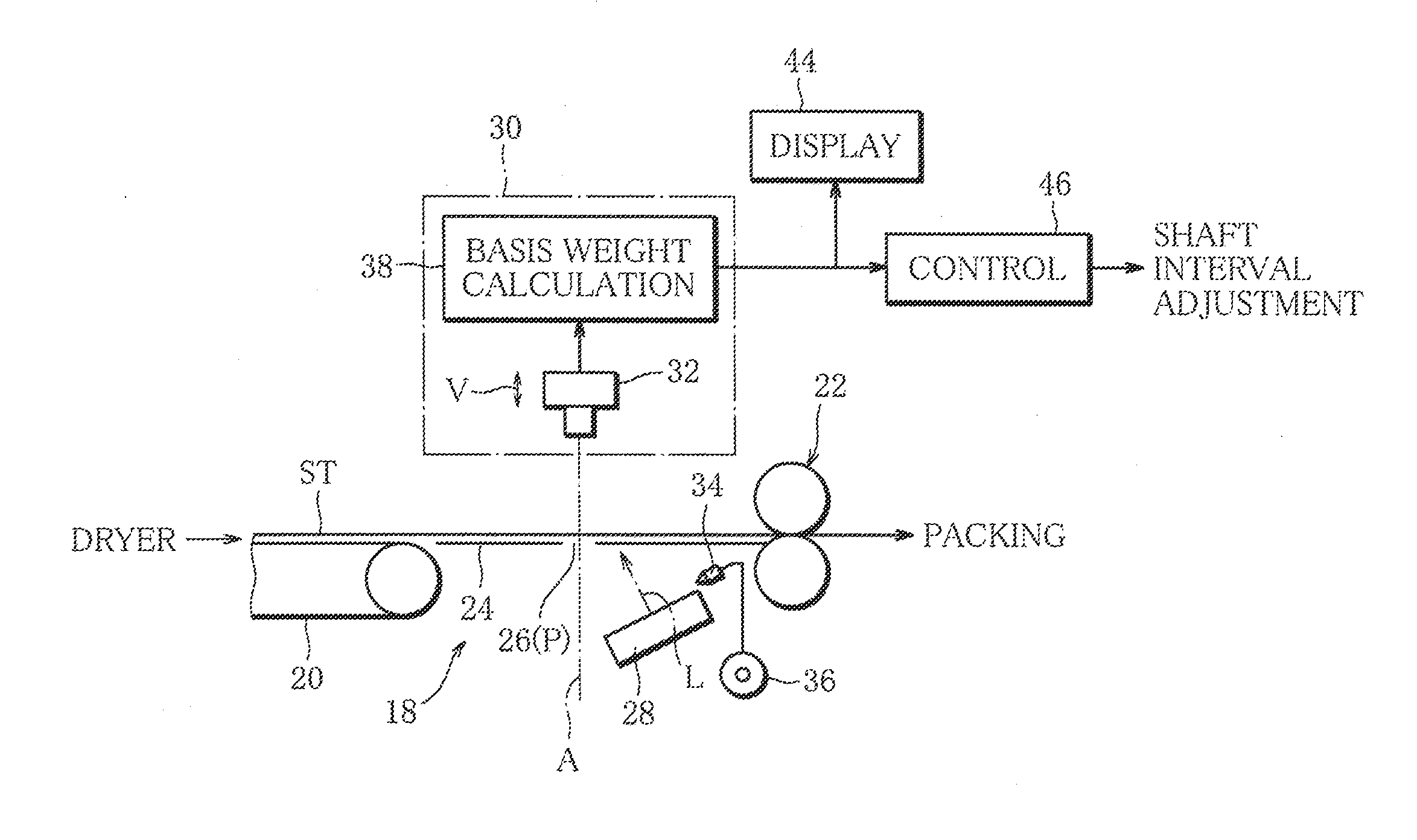

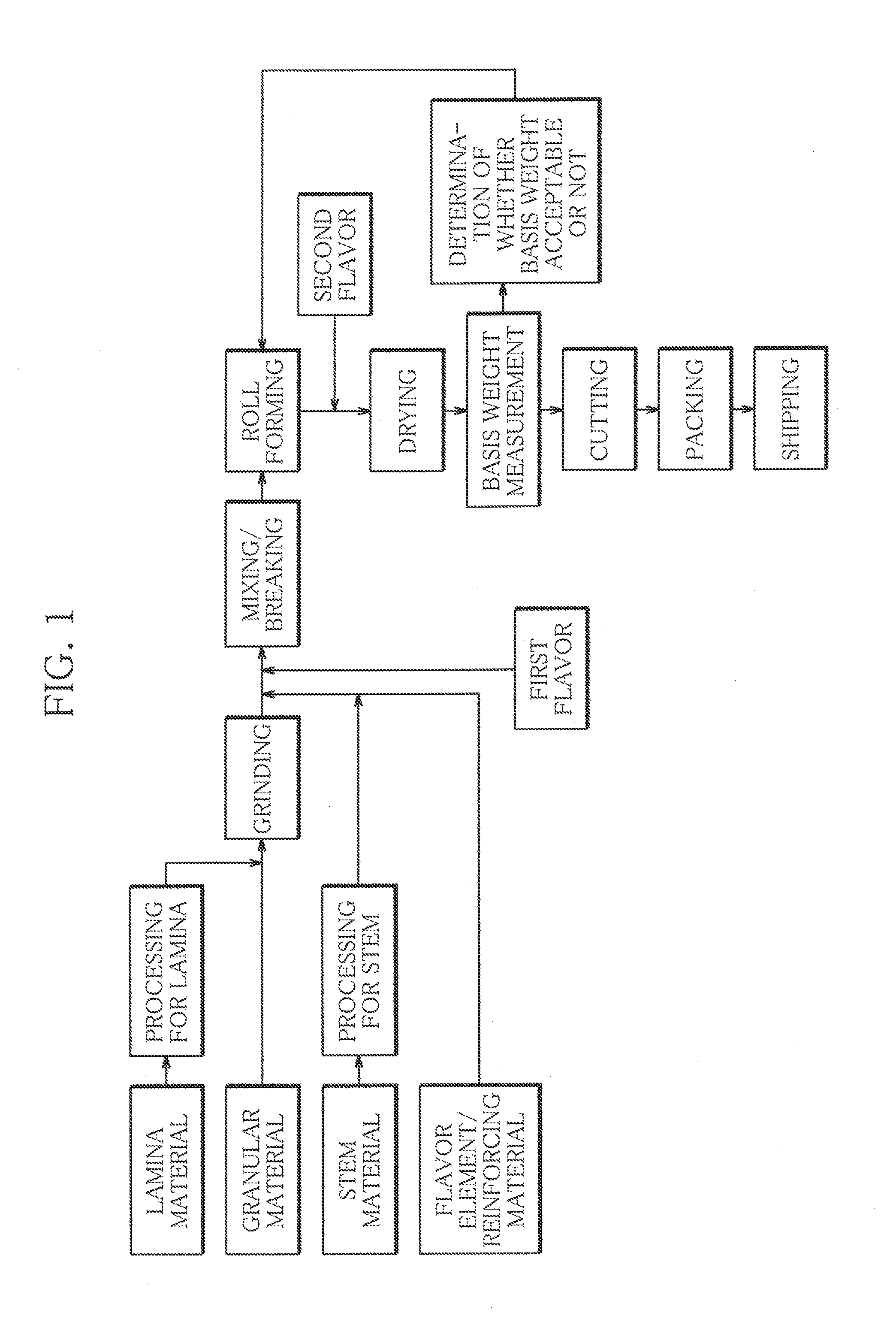

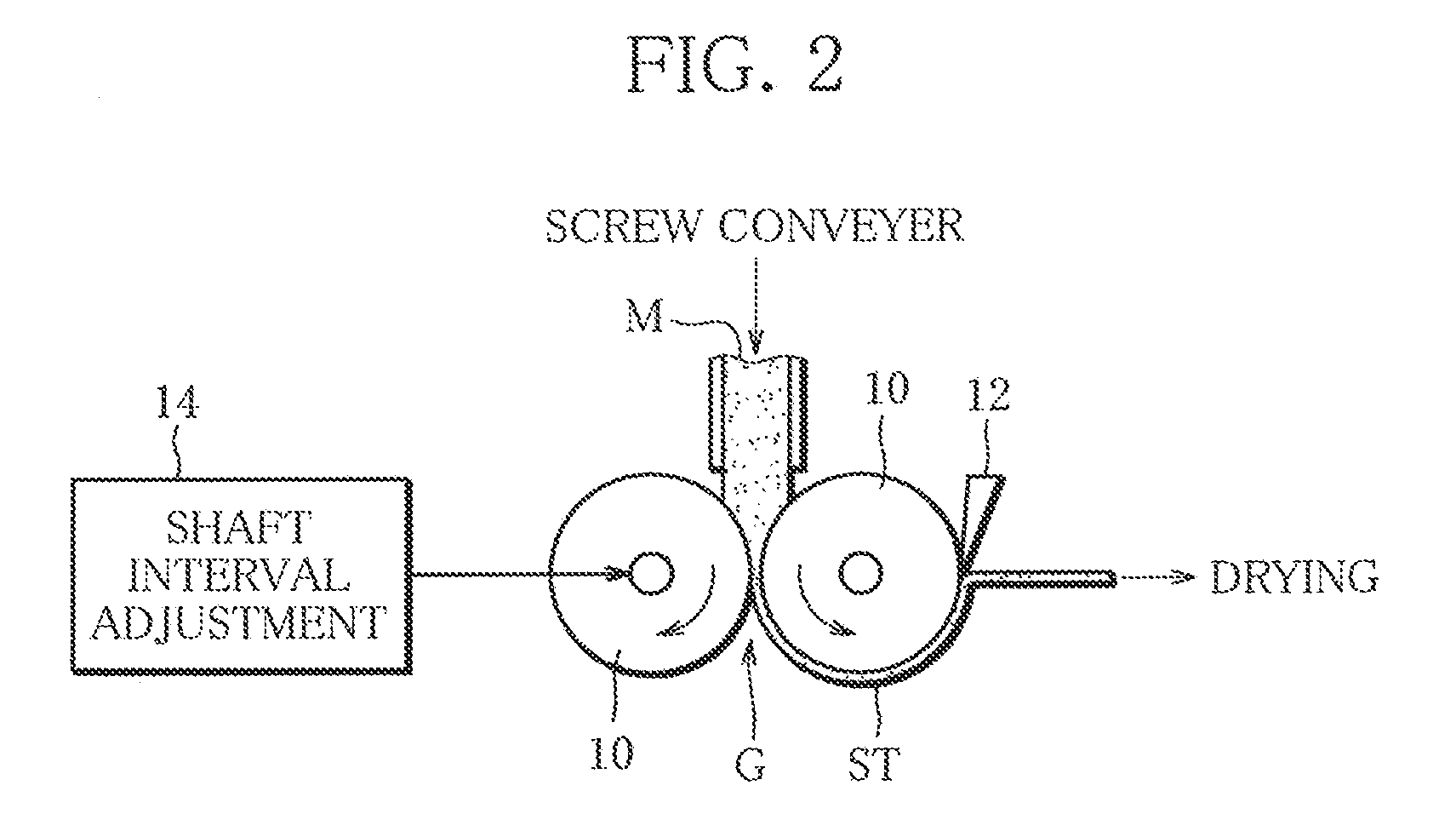

[0035]FIG. 1 schematically illustrates a manufacturing system from, for example, forming of rolled sheet tobacco (hereinafter simply referred to as “sheet tobacco”) from ingredients to shipping of the sheet tobacco through basis weight measurement and basis weight control.

[0036]Sheet tobacco ingredients include a flavor element (cornstarch) and a reinforcing material in addition to lamina material obtained from leaf tobacco, granular material such as cut tobacco and recycled cut tobacco collected from a cigarette manufacturing process and stem material obtained from leaf tobacco.

[0037]The lamina material is subjected to processing for lamina and then added to the granular material, thereby forming first blend material. The processing for lamina includes cracking, humidity control and drying of the lamina material, and the granular material may be subjected to cracking processing before the addition of the lamina material. Subsequently, the first blend material is further ground.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com