Machine and method for filling and checking capsules

A technology for equipment and capsules, which is applied to weighing equipment using electrostatic balance, capsule conveying, weighing equipment for materials with special properties/forms, etc., which can solve problems such as inability to quickly intervene in equipment production and destruction of capsule samples.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

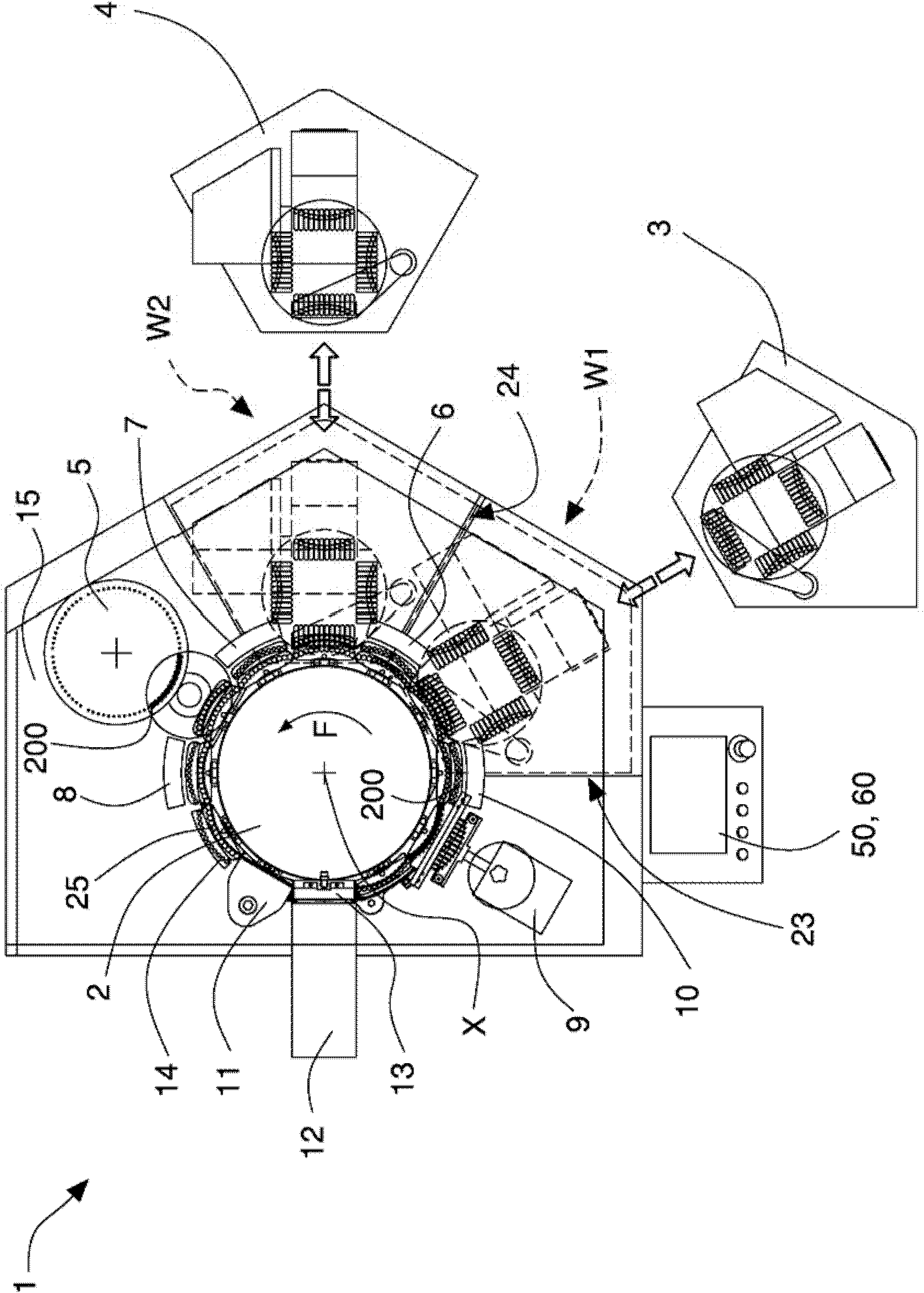

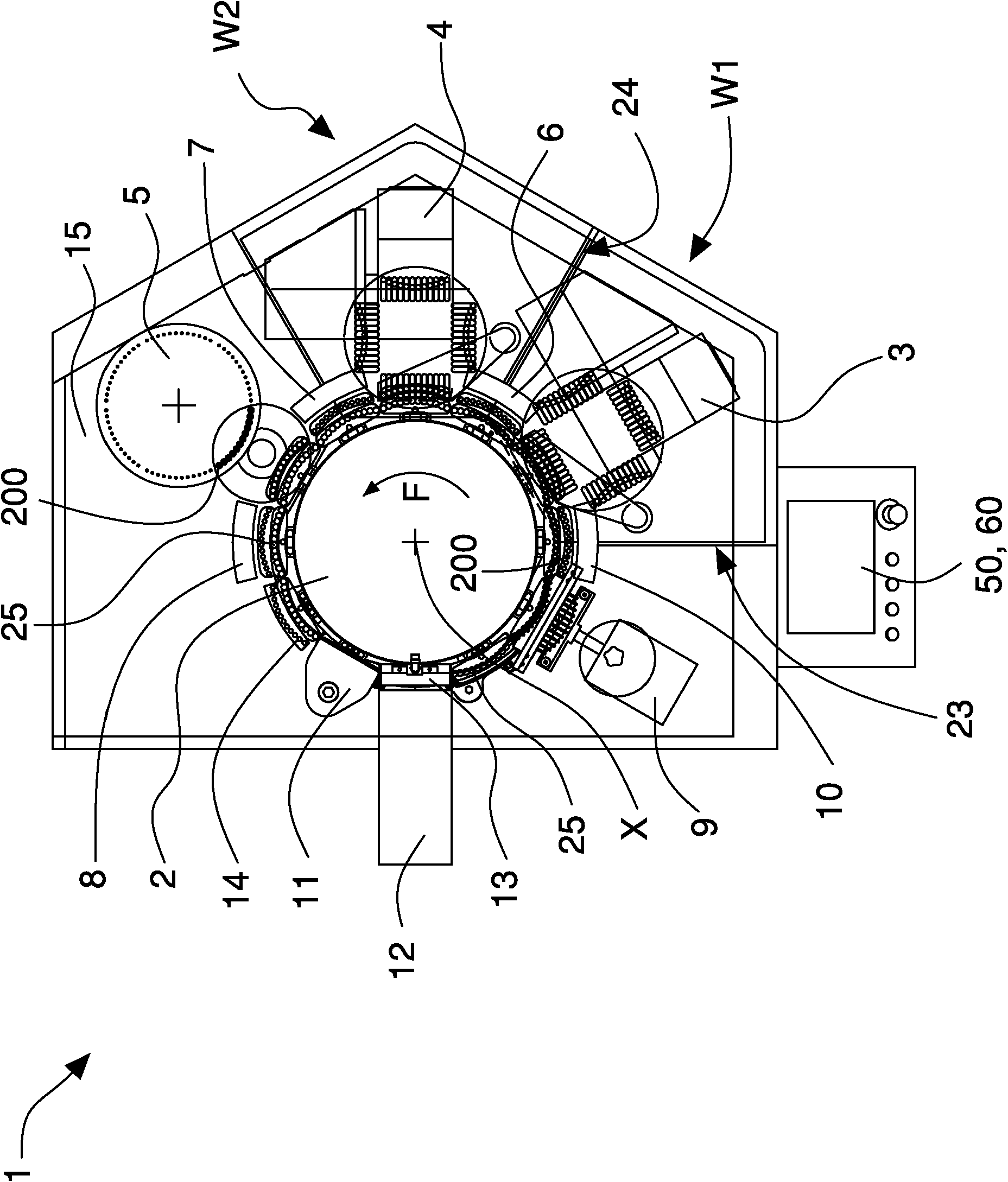

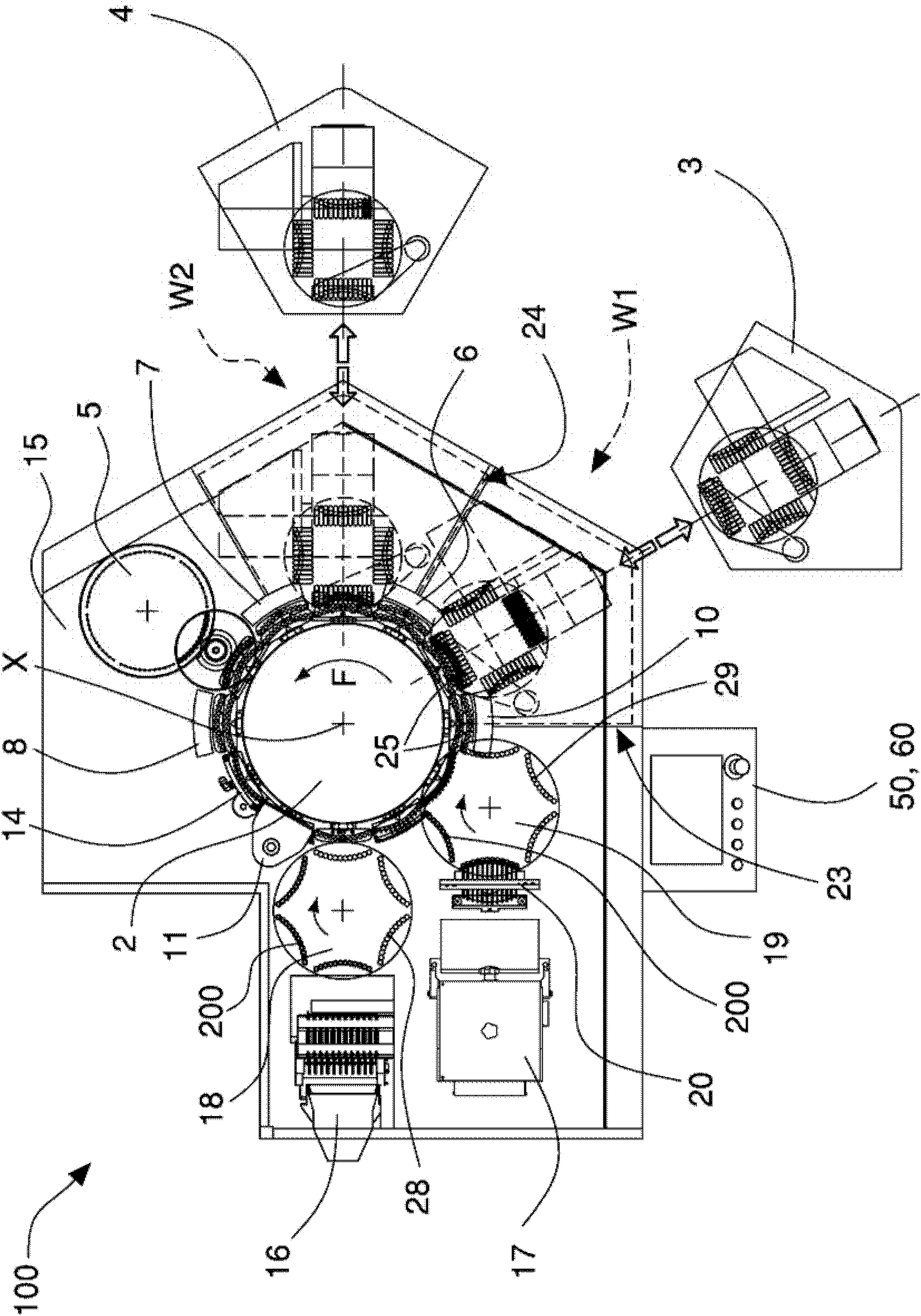

[0031] refer to figure 1 and 2 , shows a filling device 1 for multiple dosing, suitable for dosing a plurality of different products into a capsule 200, or into a similar container, in particular a capsule made of hard gelatin.

[0032] The plant 1 has a turntable arrangement of known type comprising a single operating turntable 2 intermittently rotatable about a vertical axis of rotation X and a plurality of dosing units 3, 4, 5. The dosing unit is used to fill each product into the capsule 200 . exist figure 1 and 2 In the embodiment shown, three dosing units 3, 4, 5 are arranged, but there may be only two or more than three.

[0033] The turntable 2 has a plurality of housings 25 arranged to accommodate capsules 200 . During the operation of the device 1, for example along figure 1 and 2 Rotating intermittently in the direction of the middle arrow F, the turntable 2 continuously transports the capsules 200 through the dosing units 3 , 4 , 5 .

[0034] The device 1 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com