Explosion-proof and dust-proof ventilation equipment for underground engineering

A technology for ventilation equipment and underground engineering, applied in dust prevention, mining equipment, ventilation of mines/tunnels, etc., can solve problems such as gas explosions and polluted equipment, and achieve the effects of avoiding gas explosions, reducing concentration, and reducing wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

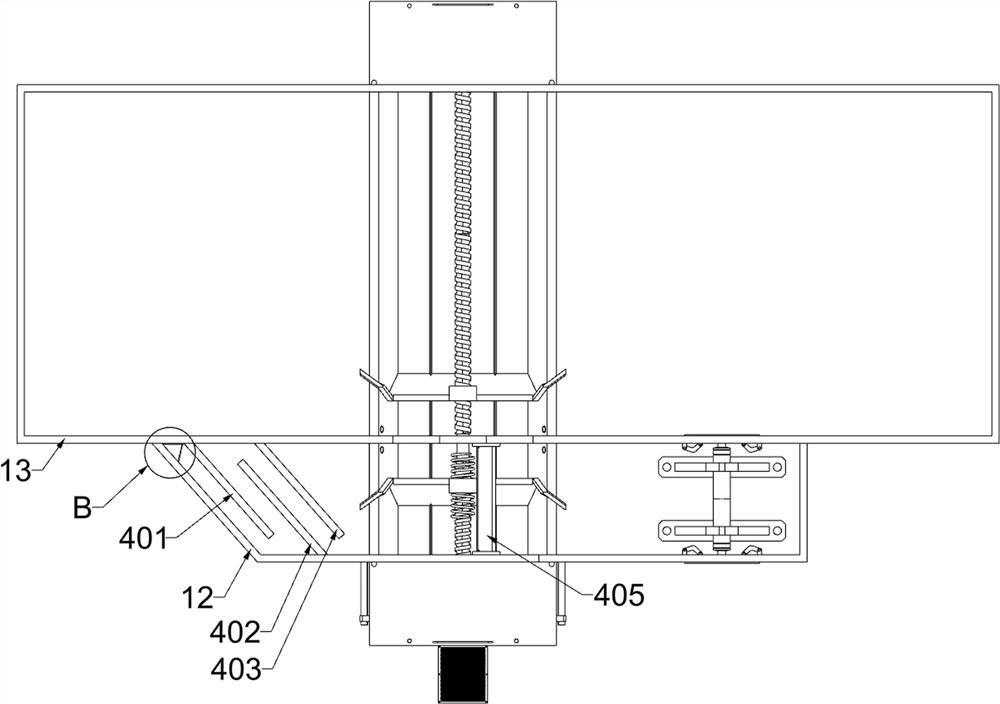

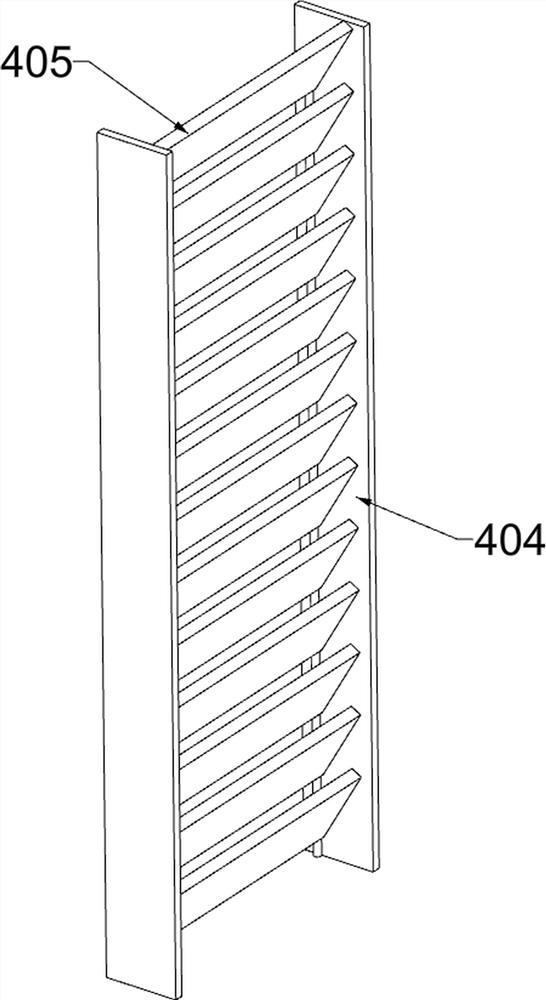

[0040] An explosion-proof and dust-proof ventilation equipment for underground engineering, such as Figure 1-14 As shown, it includes a ventilation pipe body 1, a transfer pipe 2, a fan 3, a sprinkler 4, a combustion unit, a dust removal unit and a flow velocity slowing unit; the upper side of the ventilation pipe body 1 is provided with a top cover plate 11; the top cover plate 11 The front part of the lower side is fixedly connected with the side expansion plate 12; the rear part of the lower side of the top cover plate 11 is fixedly connected with the pipe body plate 13; the rear side of the side expansion plate 12 is fixedly connected with the pipe body plate 13; The transfer pipe 2; the right side of the transfer pipe 2 is connected with the fan 3; the sprinkler 4 is installed on the lower side of the top cover plate 11; The lower side of the side expansion plate 12 is connected with the dust removal unit; the side expansion plate 12 and the tube body plate 13 are connec...

Embodiment 2

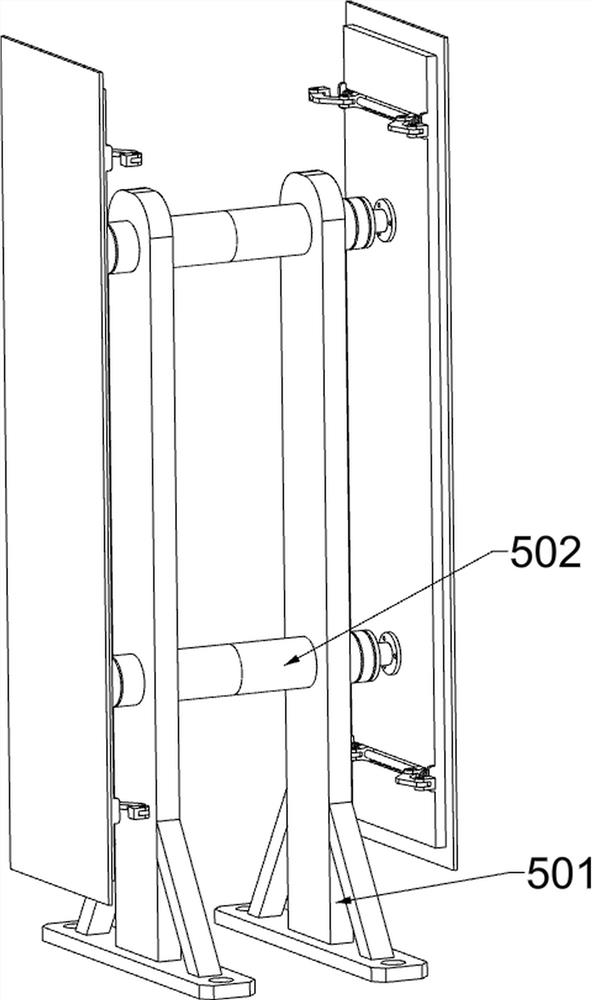

[0054] On the basis of Example 1, as figure 1 and Figure 15-17As shown, it also includes an air supply unit; the side expansion plate 12 is connected with an air supply unit; the tube body plate 13 is connected with the air supply unit; the air supply unit includes a mounting seat 501, a two-way electric push rod 502, a ventilation The door 503, the sliding rod 504, the sliding block 505, the second spring 506 and the connecting turning plate 507; two mounting seats 501 are fixedly connected to the right part of the inner and lower side of the side expansion plate 12; Two-way electric push rod 502; the upper part of the two mounting bases 501 is fixedly connected with another two-way electric push rod 502; the front telescopic ends of the two two-way electric push rods 502 are fixedly connected with a ventilation door 503; two two-way electric push rods The rear telescopic end of 502 is fixedly connected with another ventilation door 503; the opposite sides of the two ventil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com