Double-channel safety ignition mechanism and method

An ignition mechanism, dual-channel technology, applied in the direction of combustion ignition, combustion method, incandescent ignition, etc., can solve the problems of high failure rate, complex production process of DC motor, and high requirements for the use environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

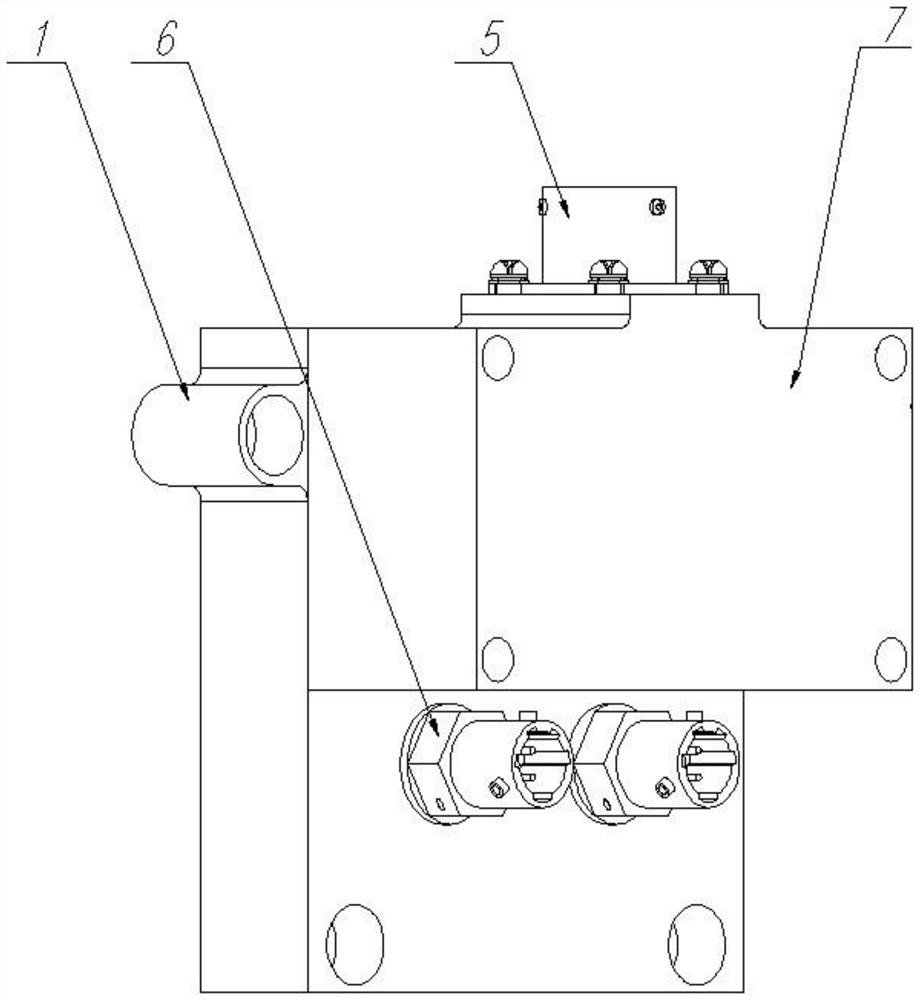

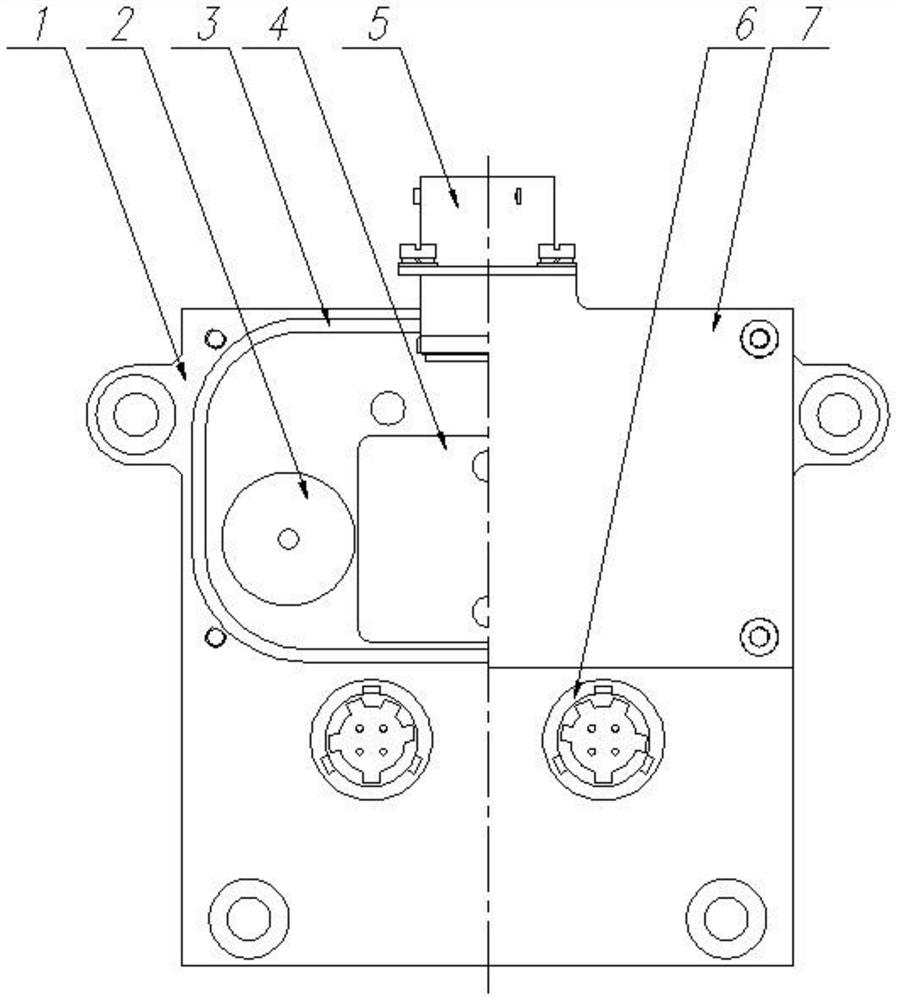

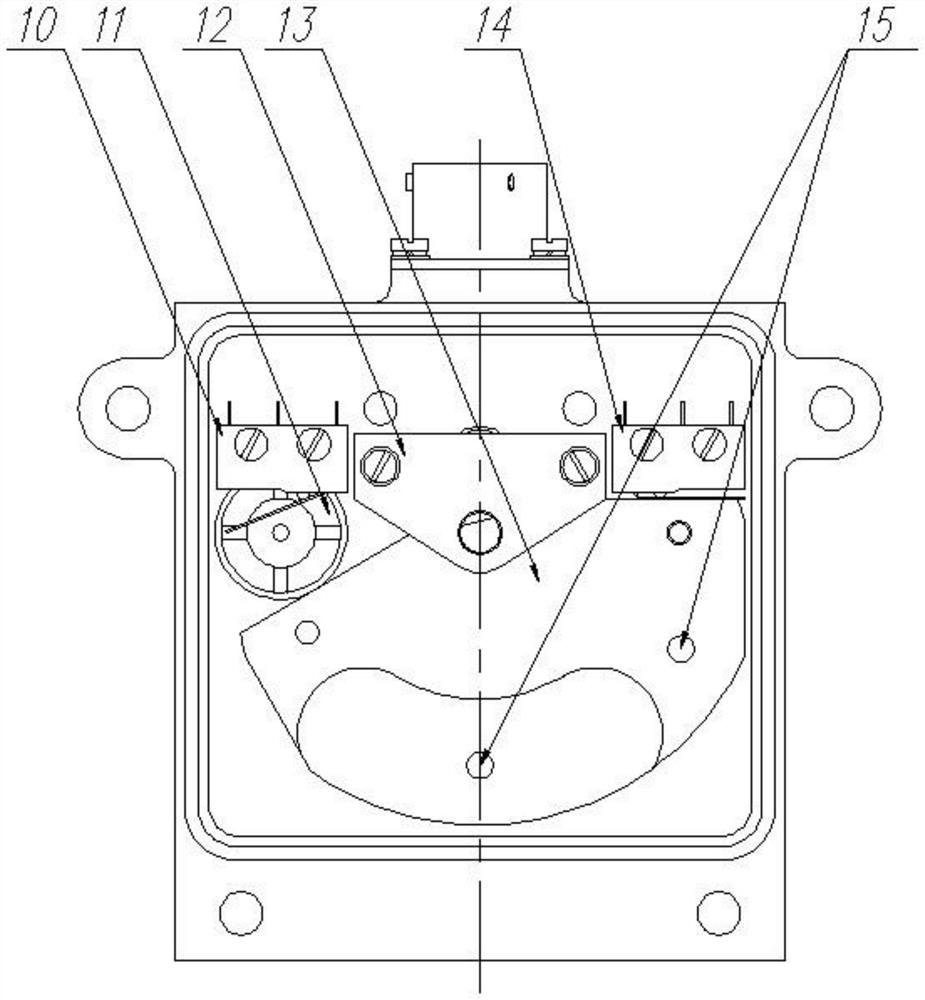

[0031] The first embodiment of the present invention relates to a dual-channel safety ignition mechanism, such as figure 1 As shown, the mounting base 1 is included, and the seat body of the mounting base 1 is provided with an aviation socket 5 for transmitting an ignition command and two electric igniters 6 for executing the ignition command, and a rotating electromagnet is also installed on the base body of the mounting base 1 4 (see figure 2 ), the output shaft of the rotating electromagnet 4 is sleeved with a rotating fan plate 13 that rotates synchronously with it, referring to image 3 and Figure 4 , Two fire holes 15 are provided on the rotating fan plate 13 .

[0032] The rotating electromagnet 4 drives the rotating fan plate 13 to rotate, so that the two fire holes 15 are respectively facing the two electric igniters 6 to form two fire receiving channels, or the closed surface of the rotating fan plate 13 covers two electric igniters. device 6, wherein the electr...

no. 2 approach

[0058] A dual-channel safe ignition method at least includes a dual-channel safe ignition mechanism, the dual-channel safe ignition mechanism has two states, namely a safe state and a working state, wherein the ignition method in the working state is as follows:

[0059] The unit tester sends an ignition command to the aviation socket 5, and the aviation socket 5 controls the two electromagnetic pins to be pulled out at the same time, and at the same time controls the rotation of the rotating electromagnet 4, the rotating fan plate 13 rotates and touches the working switch 10, and the unit tester controls the working electromagnetic pin 11 drop the pin, the pin shaft of the working electromagnetic pin 11 falls into the working pin hole 9 of the rotating fan plate 13, the rotating fan plate 13 stops rotating, and the two fire holes 15 of the rotating fan plate 13 are facing the two electric igniters 6 , forming two sets of fire channels.

[0060] The working principle of the du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com