Engine Oil Lubrication Monitoring and Protection System

A technology of engine oil and protection system, which is applied in the direction of pressure lubricating safety devices, etc., and can solve problems such as broken engine lubrication, locking, engine damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

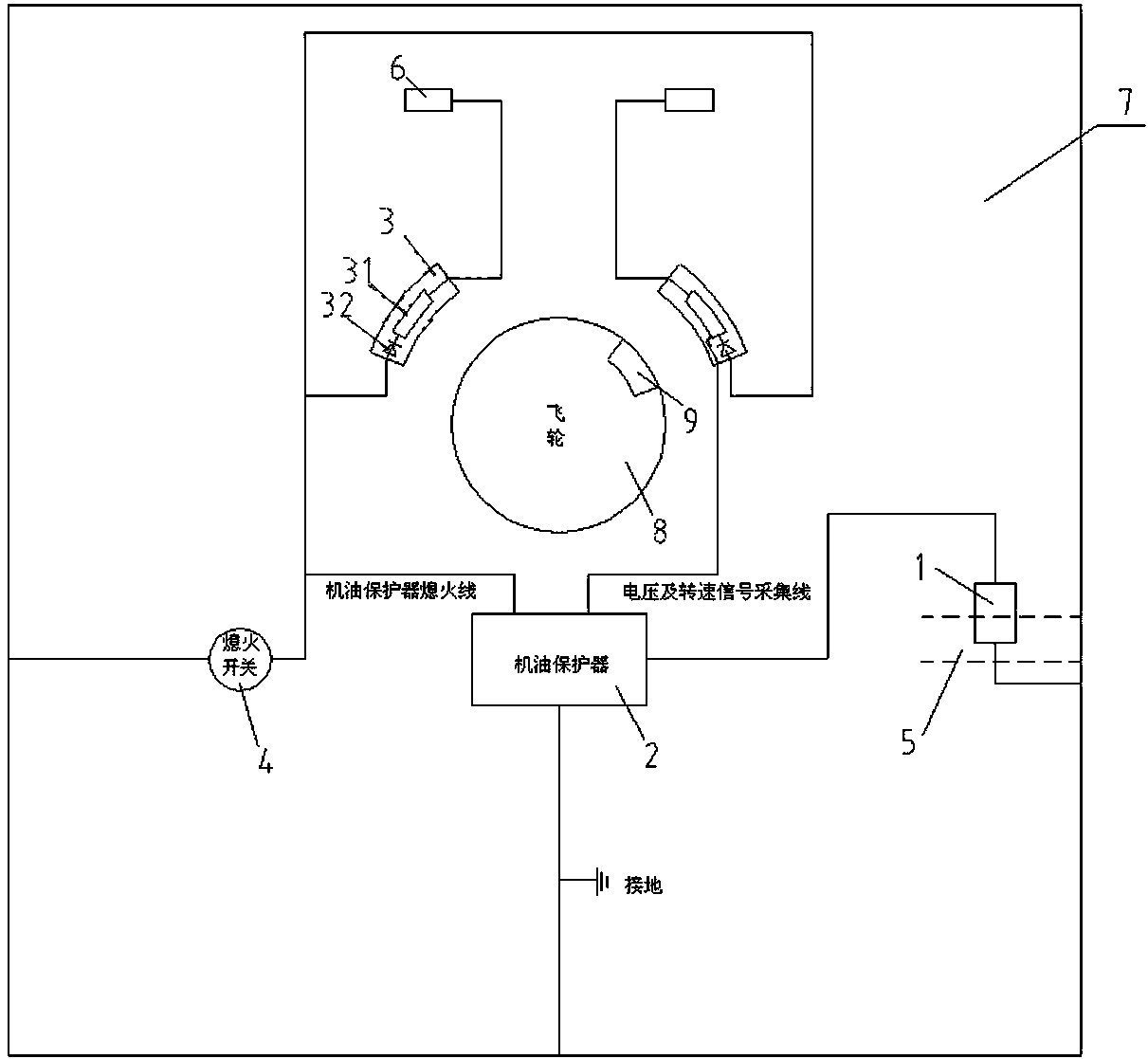

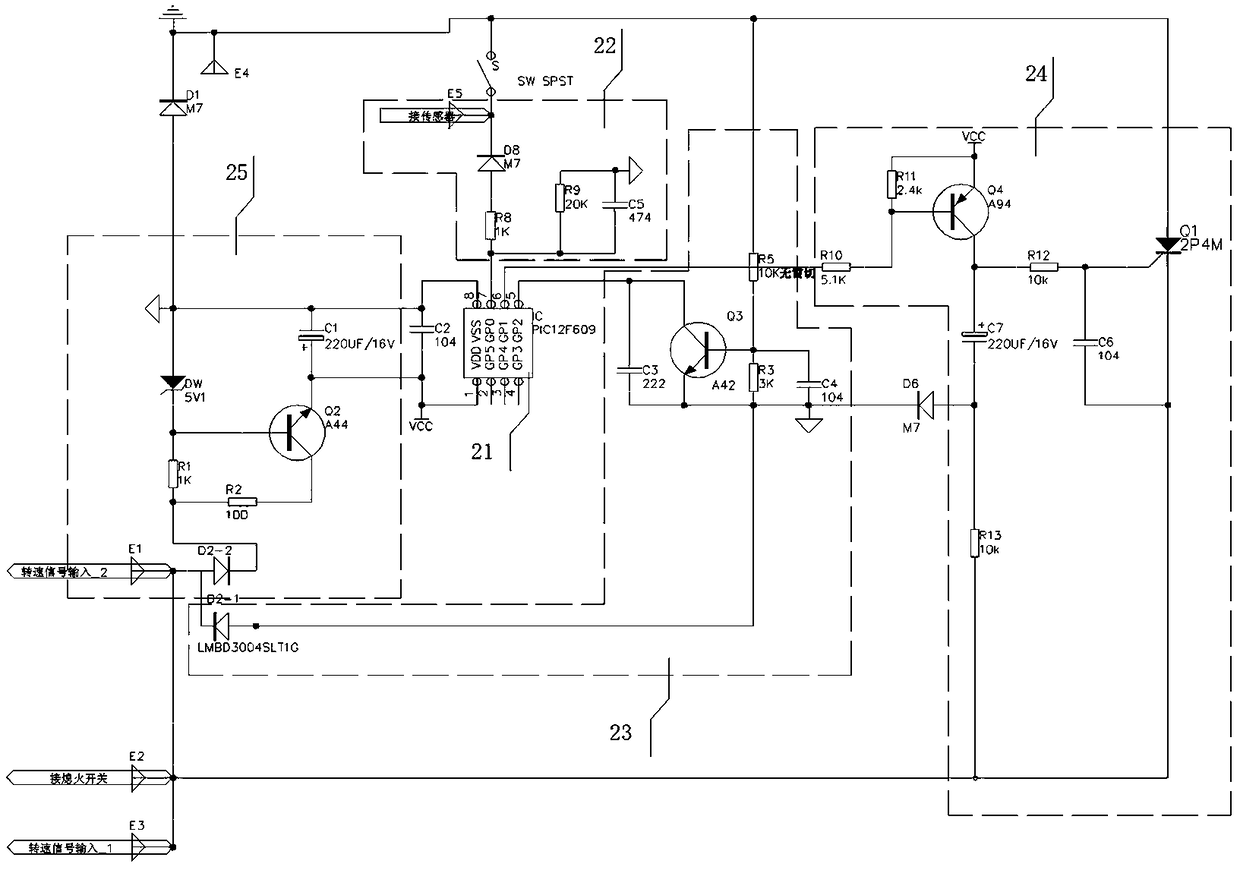

[0015] see figure 1 and figure 2 An engine oil lubrication monitoring and protection system includes a pressure sensor 1, an oil protector 2 and at least two igniters 3, and the igniters 3 are provided with an ignition coil 31 and a one-way isolation diode 32. The pressure sensor 1 is used to monitor the pressure of the main lubricating oil gallery 5 of the engine. A one-way isolation diode 32 is provided in the igniter 3 to prevent the mutual ignition between several igniters 3 from affecting the normal ignition of the engine 7 . There are two igniters 3 in this embodiment, corresponding to the twin-cylinder engine 7 . The ignition coil 31 is electrically connected to the spark plug 6 secondaryly. There are two spark plugs 6 in this embodiment, which are the spark plug 6 for the left cylinder of the engine 7 and the spark plug 6 for the right cylinder of the engine 7 . The primary of the ignition coil 31 is connected to the negative pole of the one-way isolating diode 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com