Water-proof rubber sleeve of sparking plug cap

A technology of spark plug cap and waterproof glue, which is applied in the direction of spark plugs, spark plugs, spark ignition controllers, etc., can solve the problems of adverse effects on normal engine ignition and high assembly precision requirements, achieve improved waterproof effect, easy assembly, and ensure normal operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

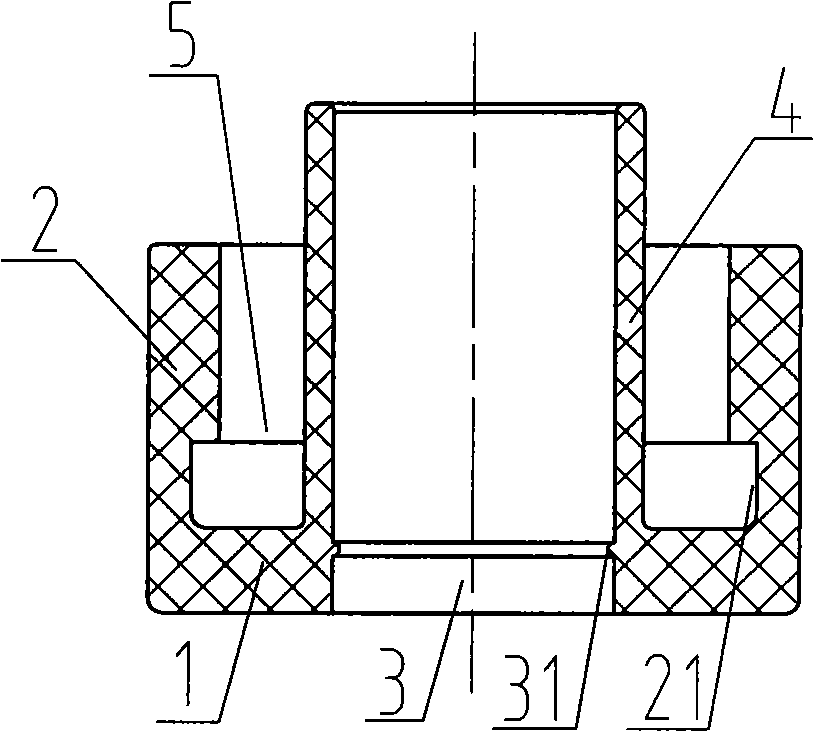

[0014] Such as figure 2 As shown, the spark plug cap waterproof rubber sleeve according to the present invention has a bottom 1 and an outer ring sleeve 2 connected with the outer edge of the bottom 1 as a whole. The center of the bottom 1 is provided with a spark plug installation hole 3. An inner ring sleeve 4 extends integrally from the end of the installation hole, and an annular groove 5 is formed between the inner ring sleeve 4 and the outer ring sleeve 2 .

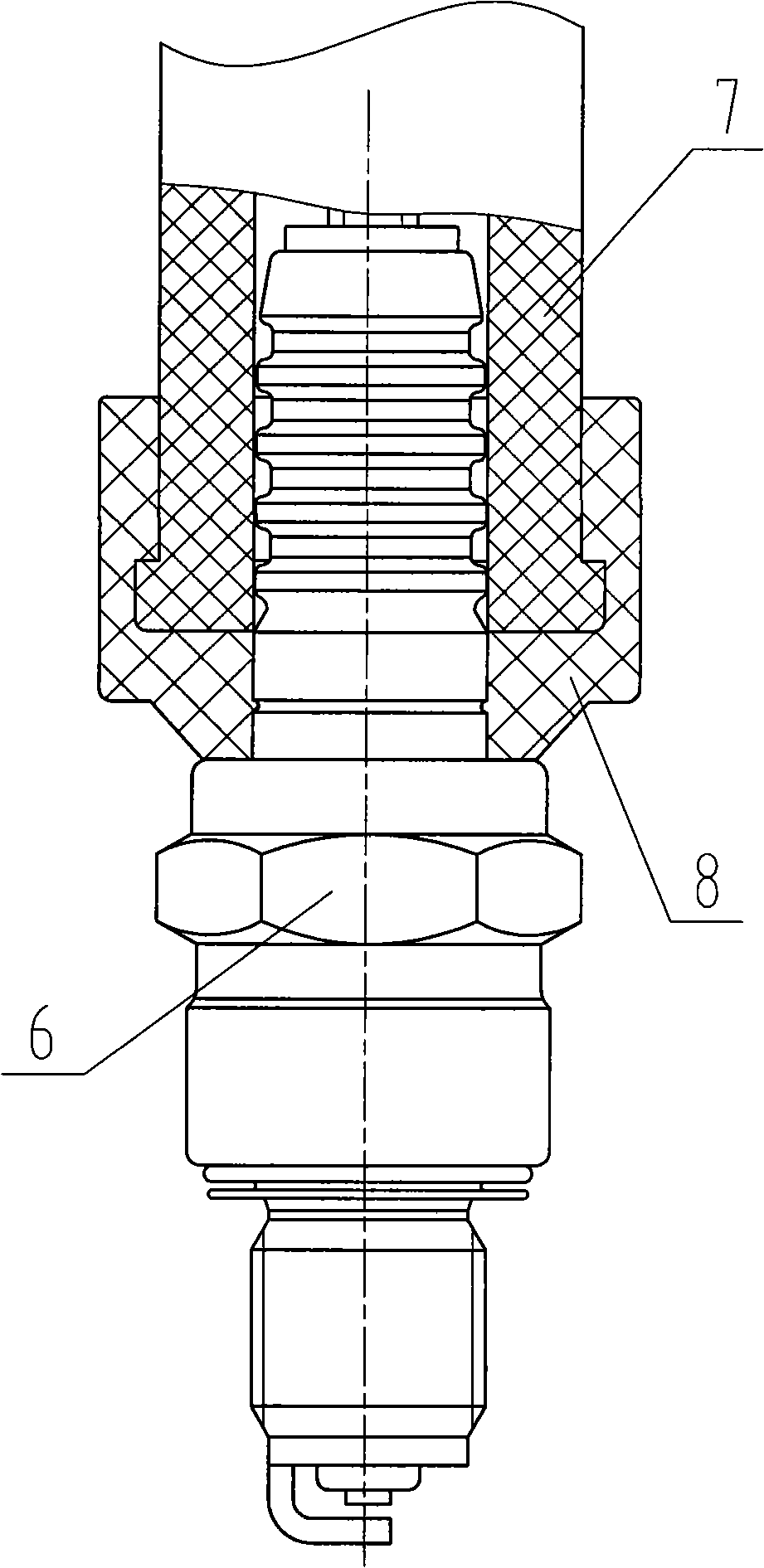

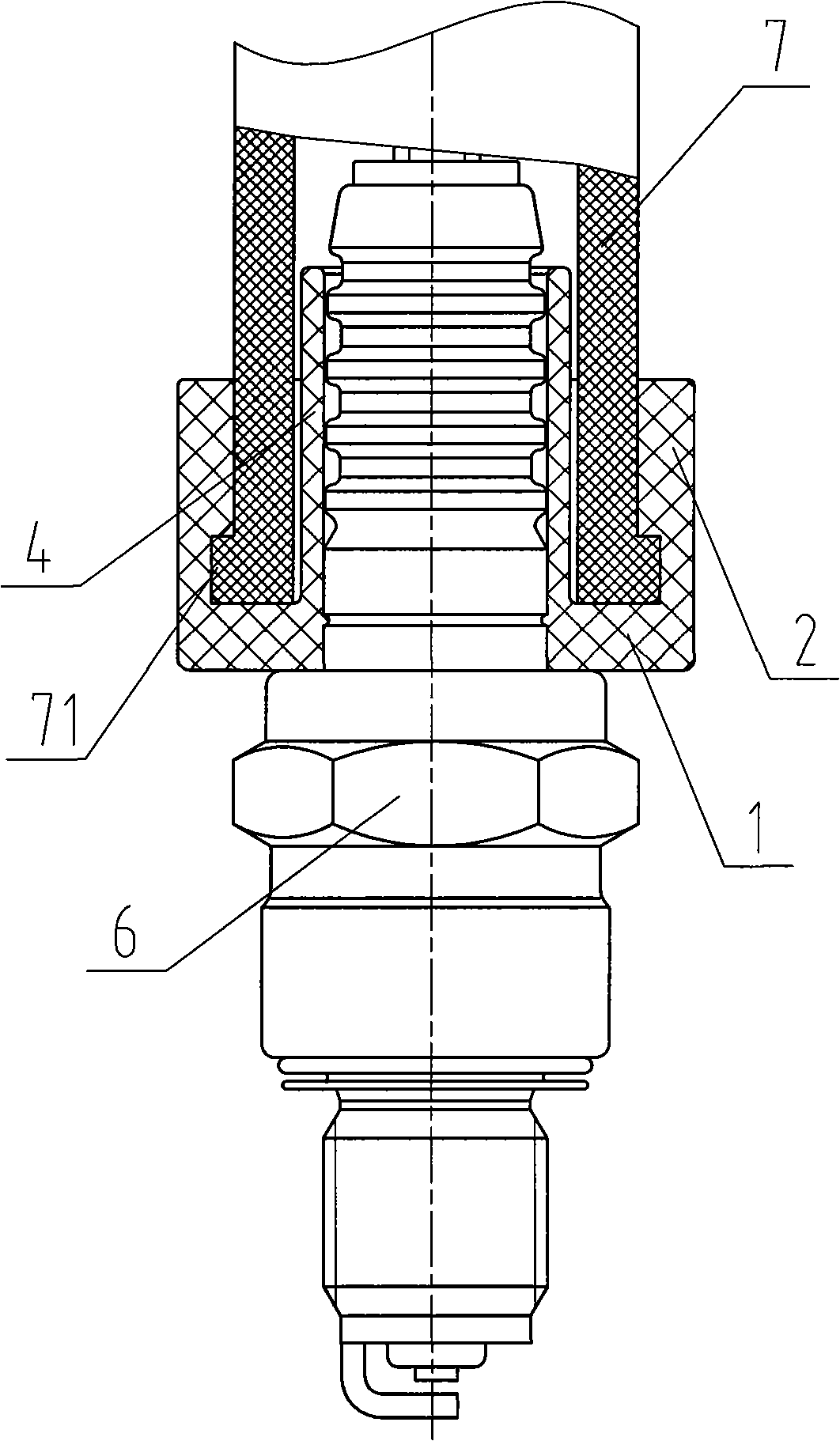

[0015] Such as image 3 As shown, during assembly, the spark plug 6 is set in the inner ring sleeve 4, and one end of the spark plug cap 7 is installed in the annular groove 5 between the inner ring sleeve 4 and the outer ring sleeve 2, and the entire waterproof rubber sleeve is a double-layer structure , even if water enters through the gap between the outer ring sleeve 2 and the spark plug cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com