MVR evaporation crystallizer suitable for high salt concentration and crystallization and production process of MVR evaporation crystallizer

An evaporative crystallizer and crystal precipitation technology, which can be used in evaporation and separation crystallization, evaporators heated by serpentine tubes, evaporation, etc., and can solve problems such as normal production and blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

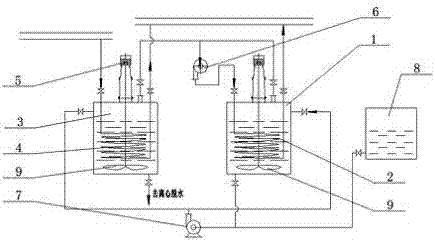

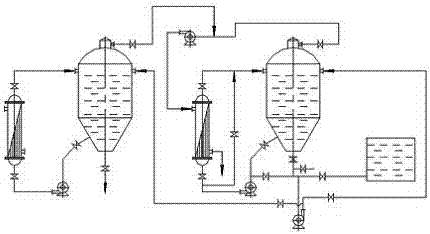

[0010] see Figure 1-2 As shown, the technical solution adopted in this specific embodiment is: it comprises a first evaporation chamber 1, a first heat exchanger 2, a second evaporation chamber 3, a second heat exchanger 4, a mixer power unit 5, and a steam compressor 6 , liquid delivery pump 7, liquid storage tank 8, stirring device 9, the first heat exchanger 2 and the second heat exchanger 4 are respectively arranged in the first evaporation chamber 1 and the second evaporation chamber 3, the second evaporation chamber 3 The steam inlet end is connected to the steam main pipe 10, the steam outlet end of the second evaporation chamber 3 is connected to the steam inlet of the first evaporation chamber 1 through the compressor 6, and the steam outlets of the first evaporation chamber 1 and the second evaporation chamber 3 are connected to On the condensed water main pipe 11, the liquid delivery pump 7 is connected between the liquid storage tank 8 and the first evaporation ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com