Patents

Literature

210results about How to "Improve supply efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

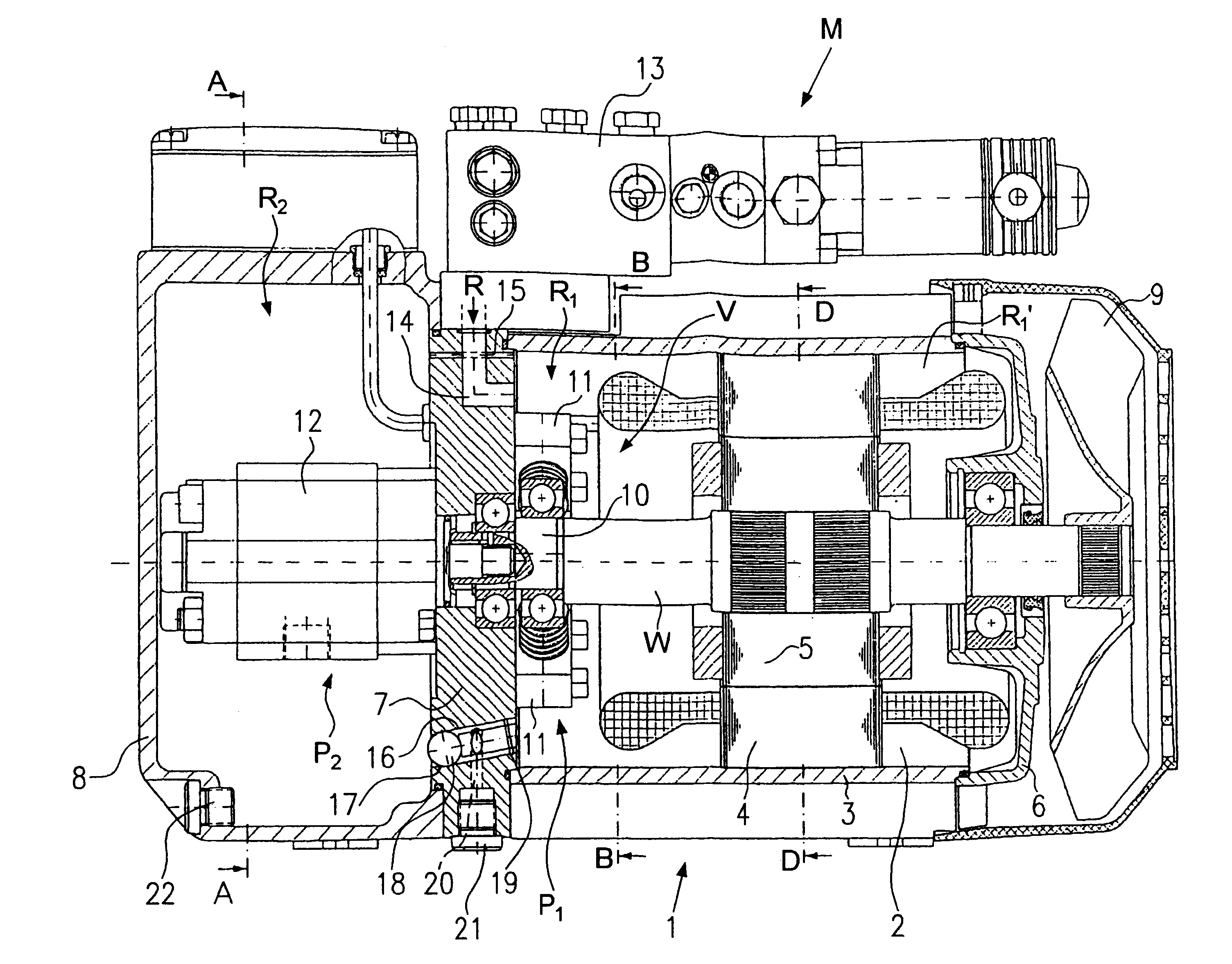

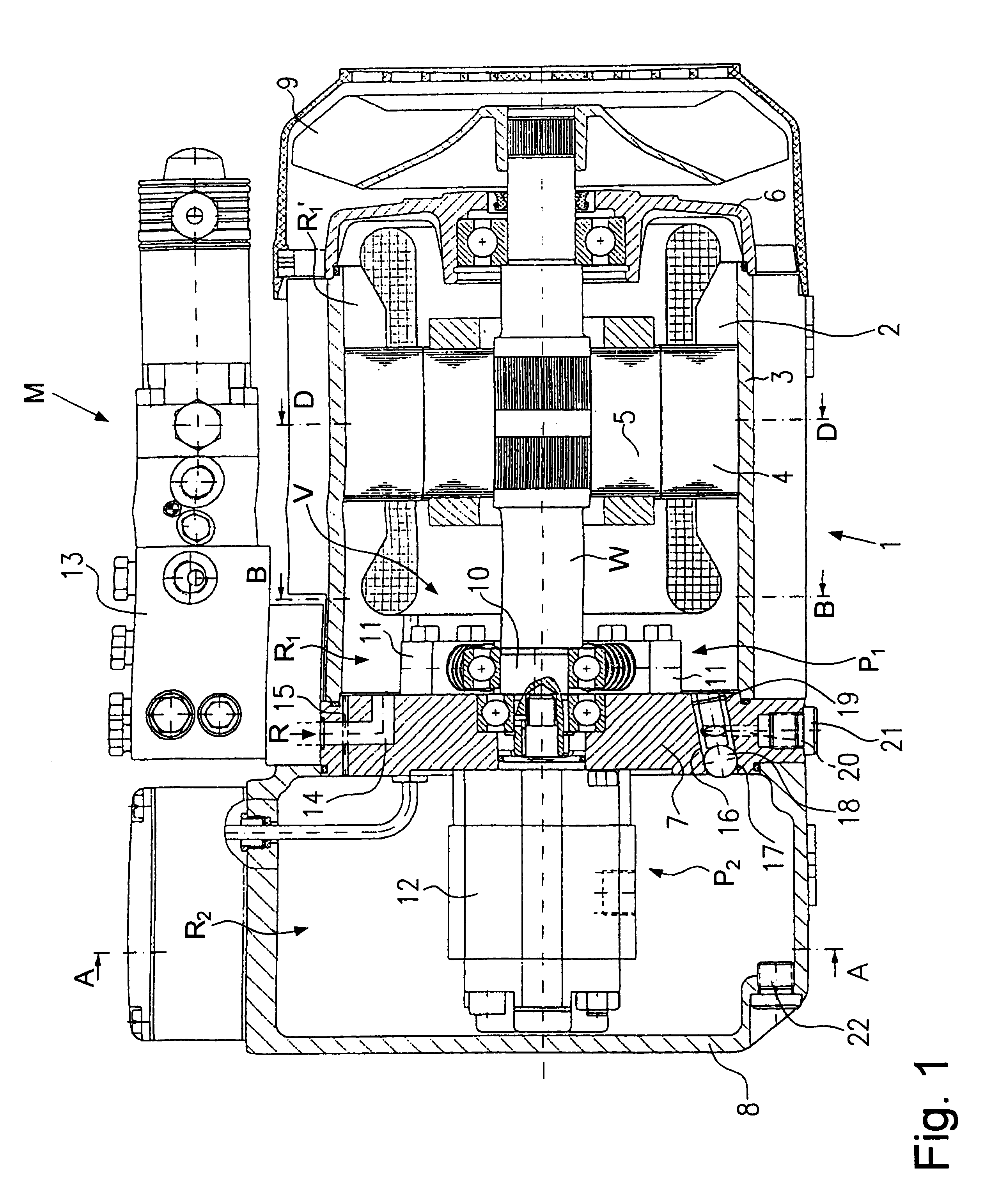

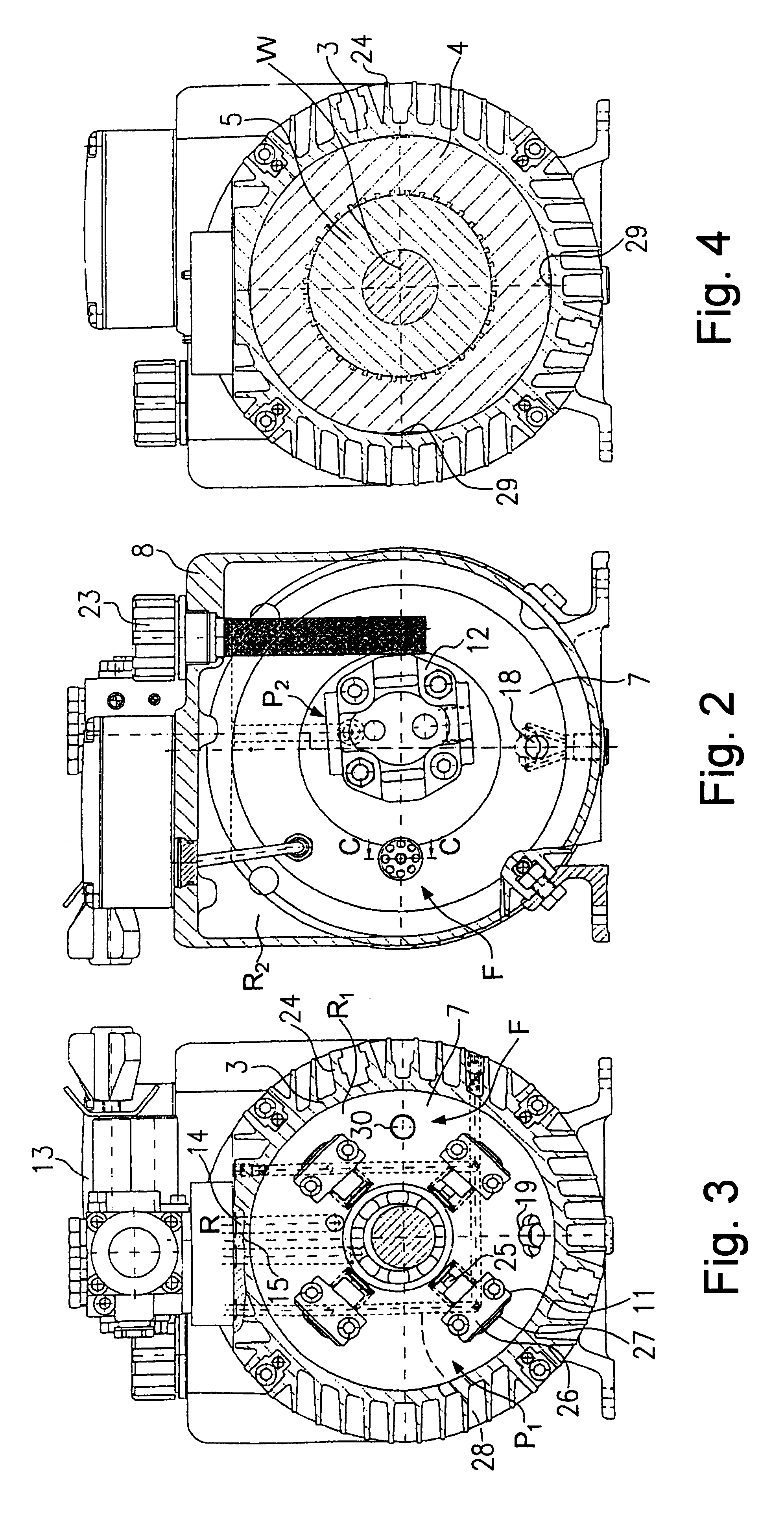

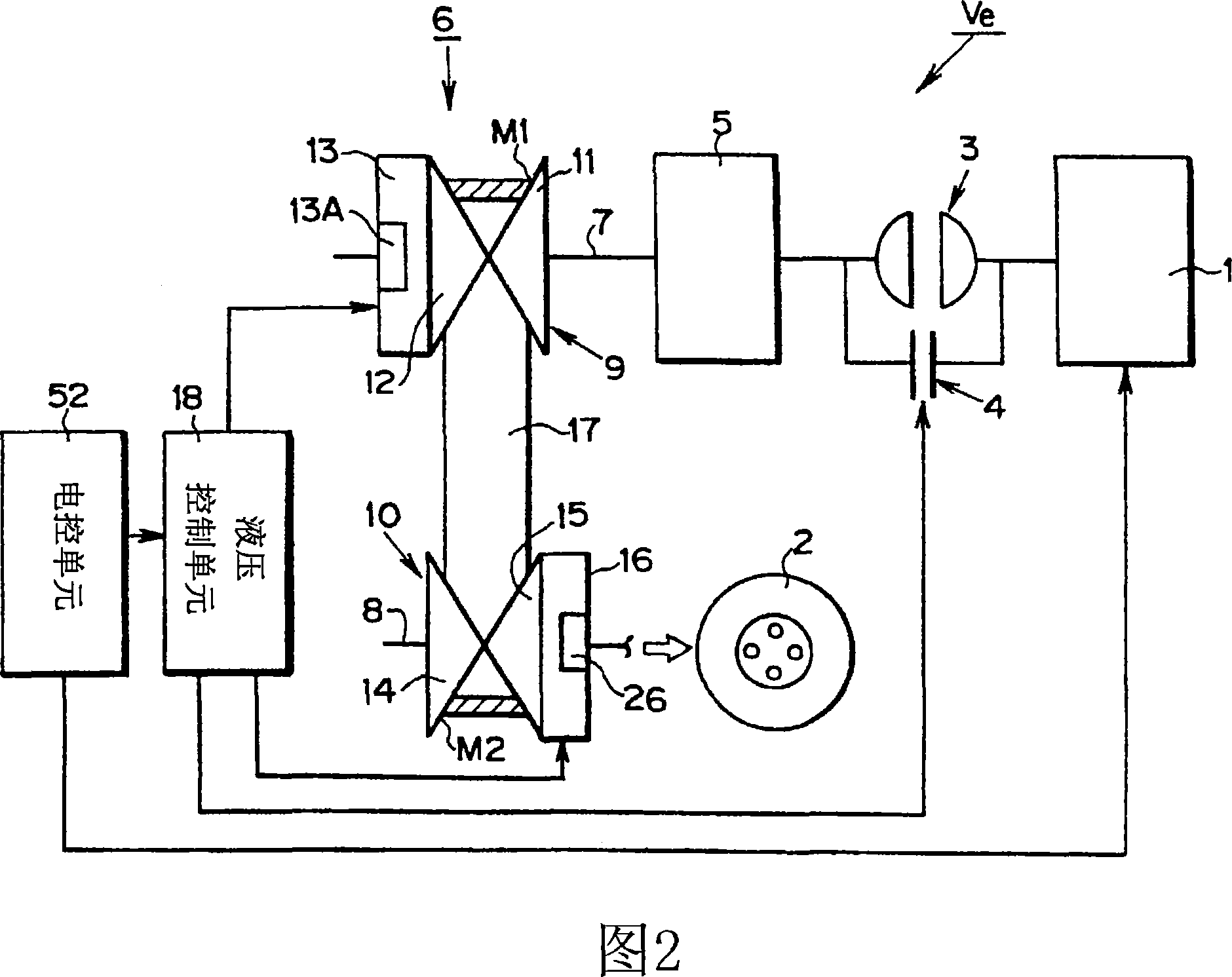

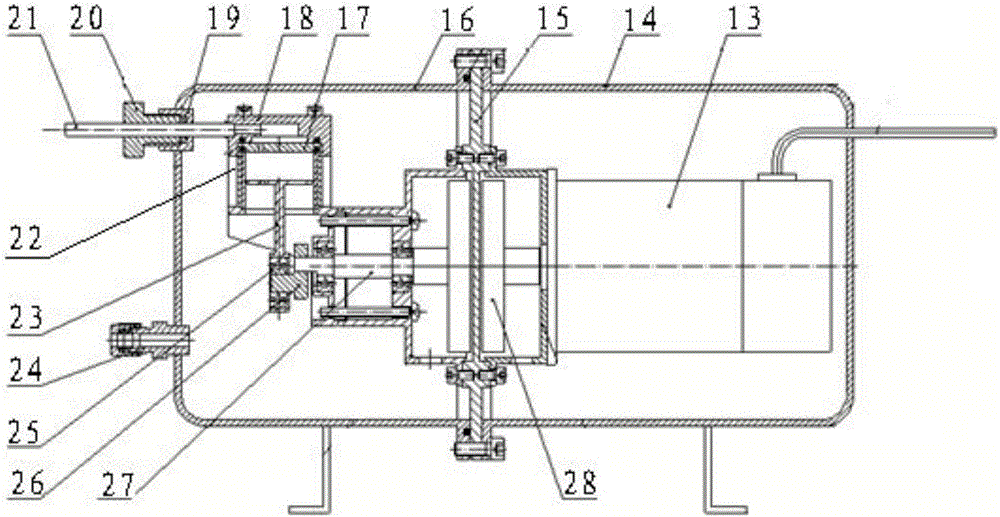

Motor pump unit

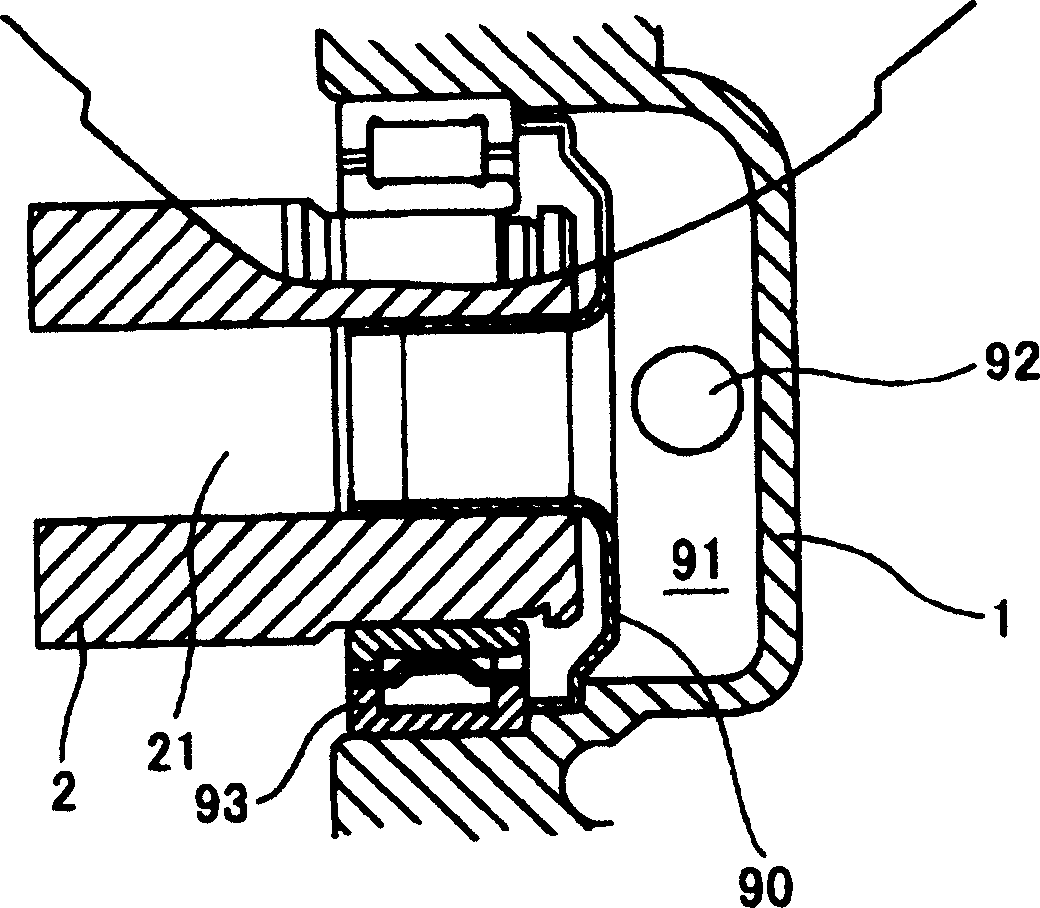

InactiveUS6524084B2Improve supply efficiencyAvoids getting trappedPositive displacement pump componentsPiston pumpsRadial piston pumpEngineering

A motor pump aggregate M has a housing 1 defining an oil reservoir with first and second chambers R1, R2. An electromotor 2 is driving via its motor shaft W at least one radial piston pump arrangement P1 provided within said first chamber R2. Both chambers R1, R2 are separated by a separation wall 7. A filling and pressure biasing system V is provided for said first chamber R1 in order to adjust within said first chamber R1 a predetermined oil filling level and a pre-selected oil pressure pre-biasing for said radial piston pump arrangement P1.

Owner:HEILMEIER & WEINLEIN FAB FUR OEL HYDRAULIK

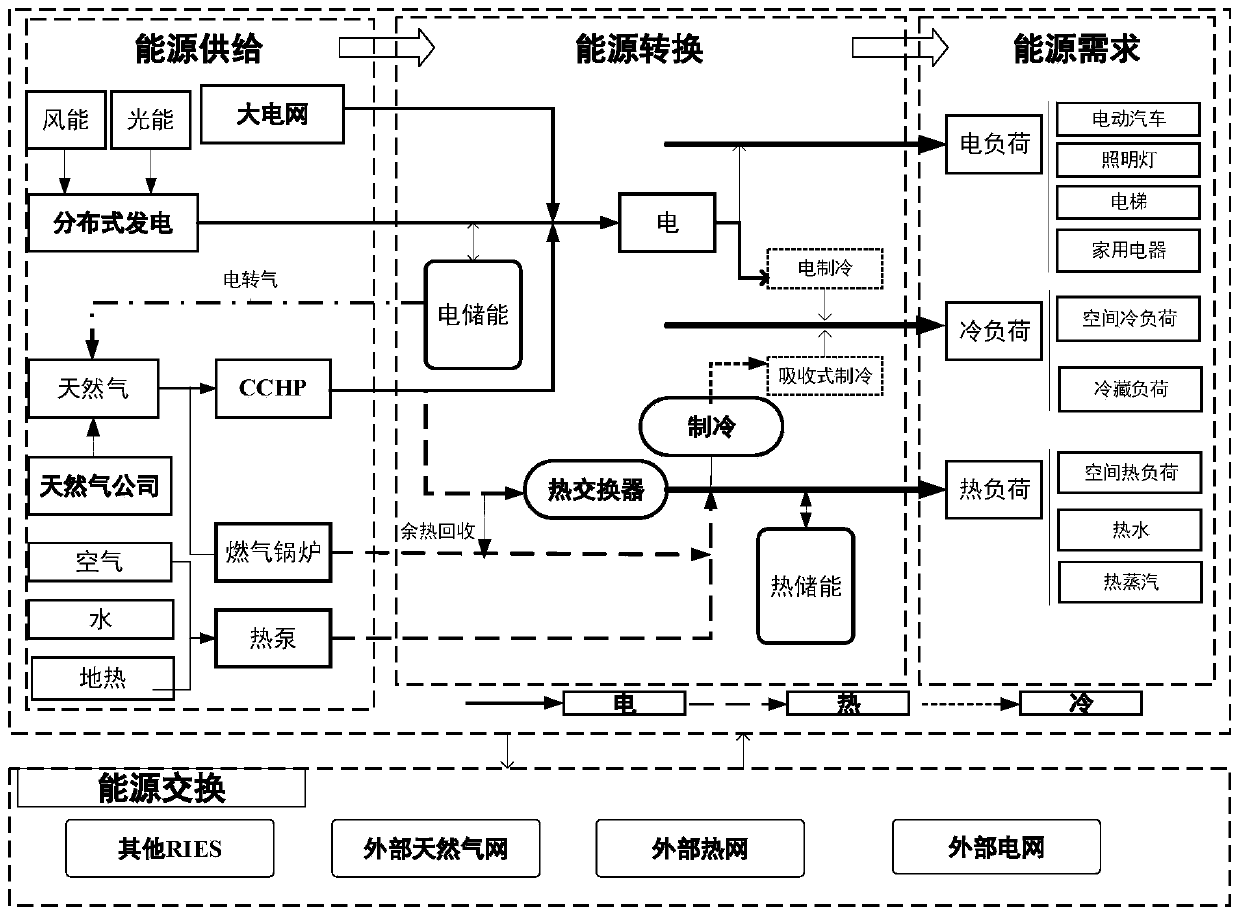

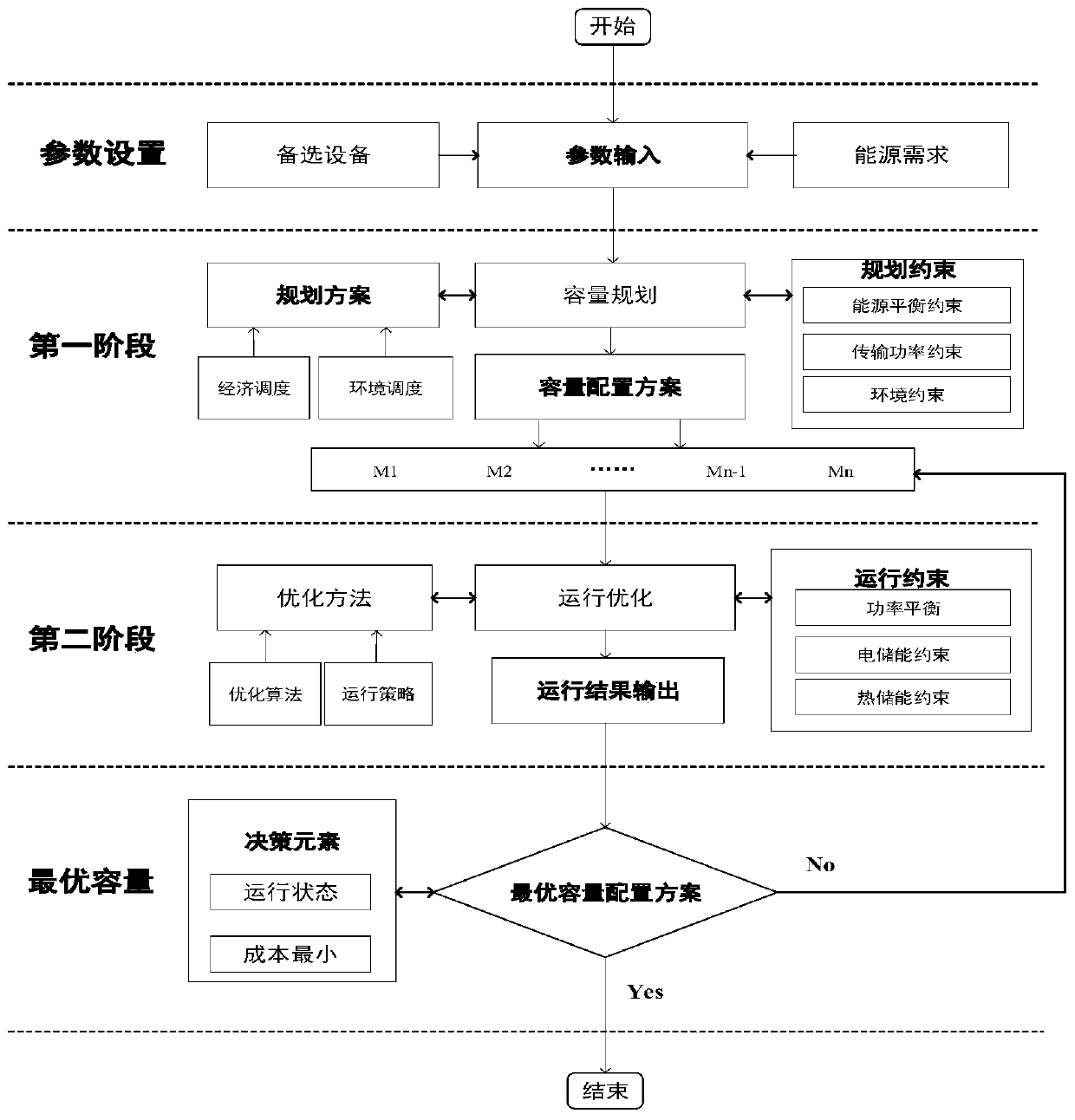

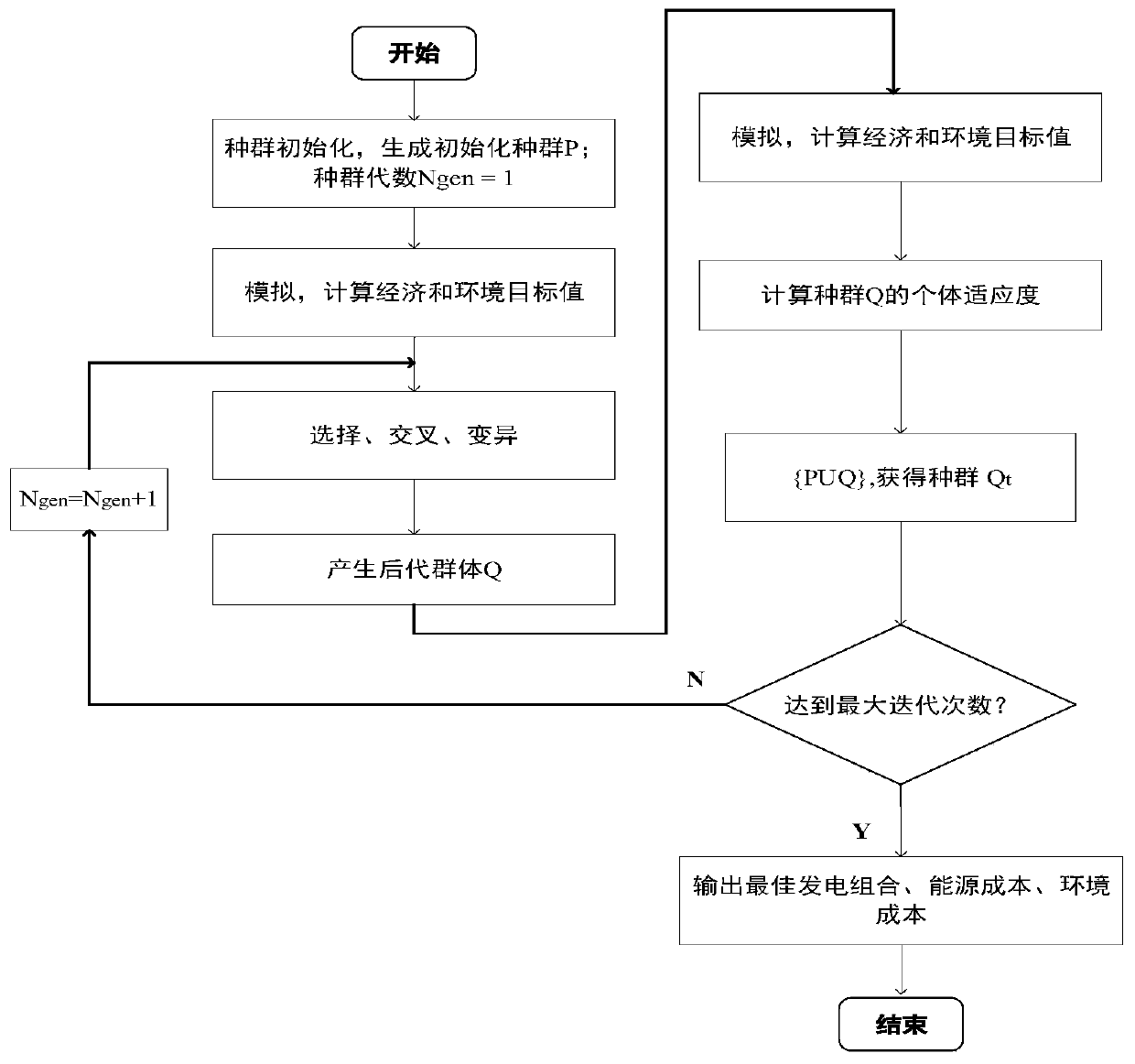

A regional comprehensive energy system planning optimization method based on double-layer optimization

InactiveCN109740827AAchieve interactionSolving Capacity Planning ProblemsForecastingResourcesBilevel optimizationVector optimization

The invention discloses a regional integrated energy system planning optimization method based on double-layer optimization, and the method comprises the following steps: S1, selecting a plurality ofgroups of capacity schemes to carry out the capacity optimization of a regional integrated energy system, and finding out a plurality of groups of capacity optimization configuration schemes of the regional integrated energy system; S2, performing optimization operation on the plurality of groups of capacity optimization configuration schemes planned in the step S1 to obtain a plurality of groupsof operation output results of the regional integrated energy system, and then solving an optimization operation problem of the system by utilizing mixed integer linear programming (MILP); S3, carrying out capacity selection, and comparing multiple groups of operation output results in the step S2 with load requirements to obtain the load supply reliability of each group of planning schemes; S4, feeding the obtained reliability back to the capacity optimization planning in the step S1, reselecting and optimizing the capacity optimization of the regional integrated energy system, and repeatingthe steps S1 to S1; and S3, selecting a capacity planning scheme with the strongest power supply reliability.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

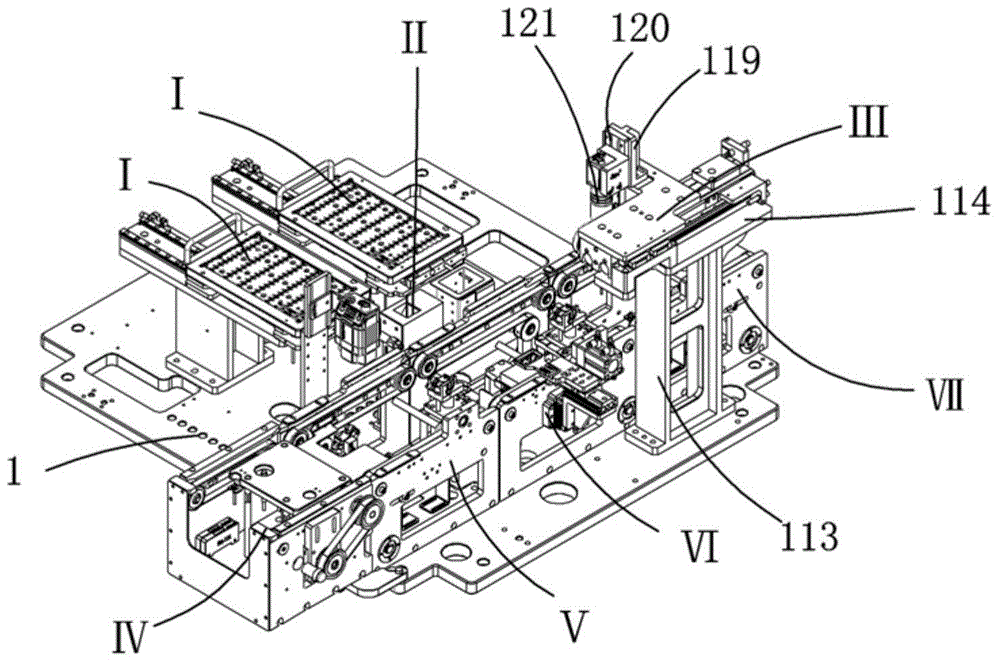

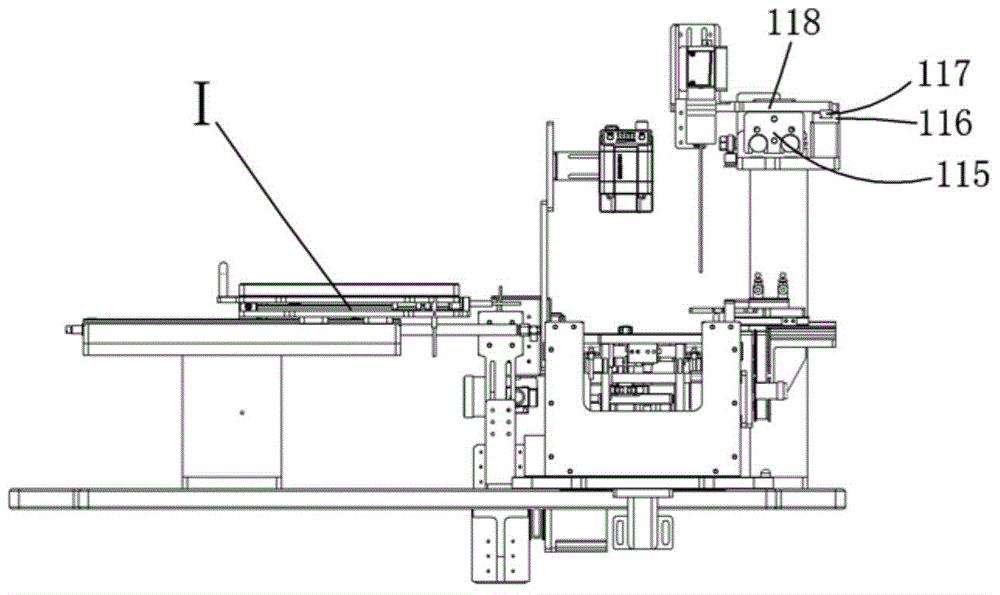

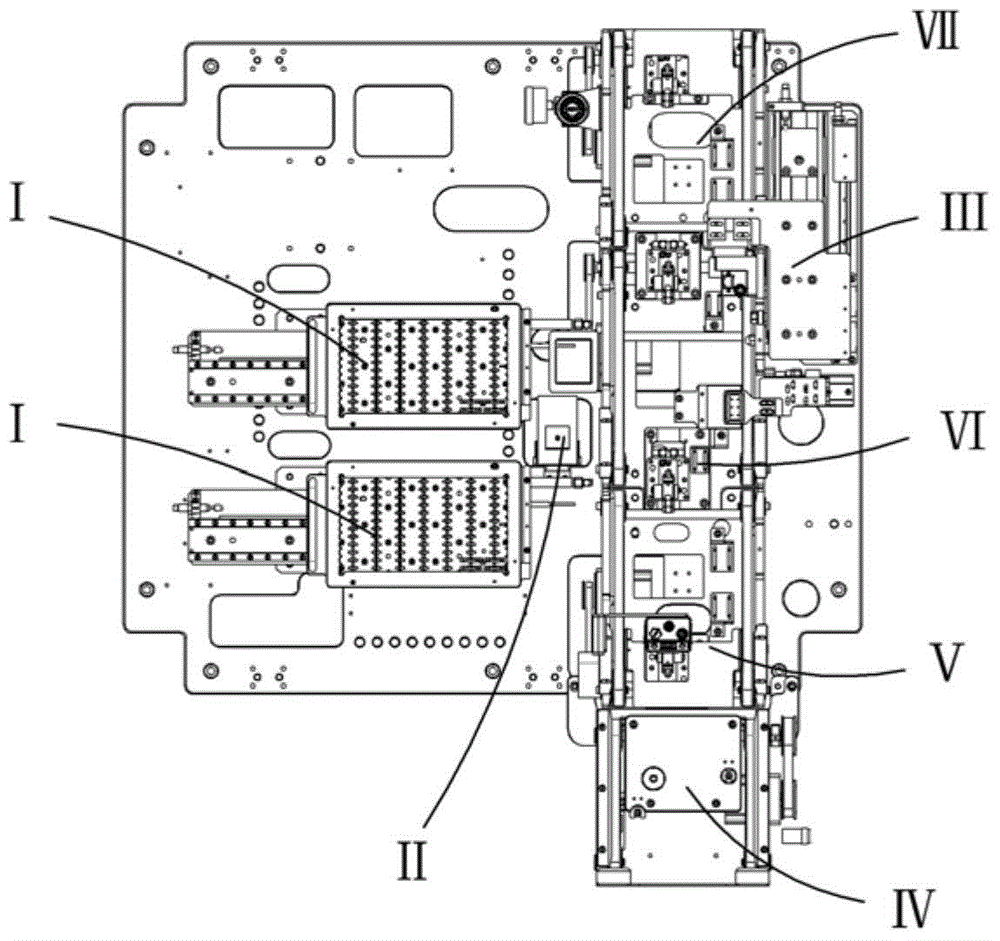

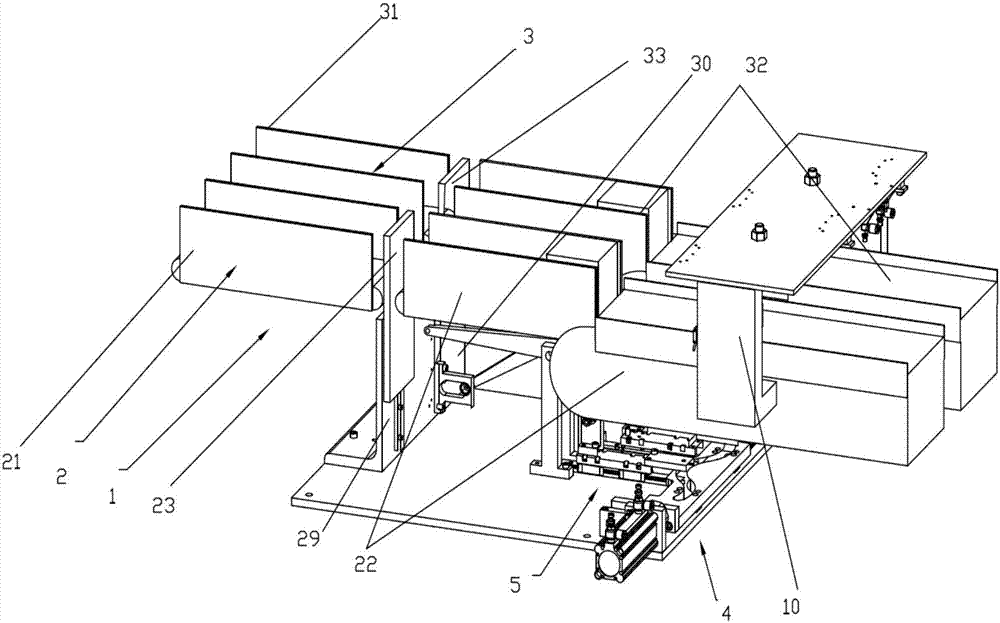

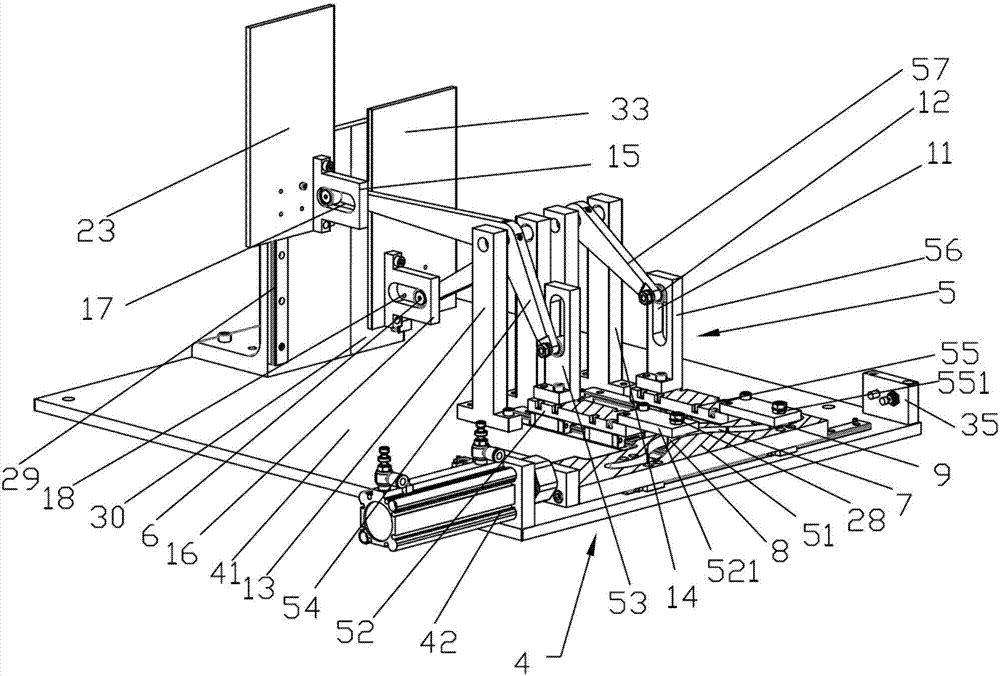

Component height difference detecting device

ActiveCN104567697AImprove supply efficiencyReduce labor intensityUsing optical meansHeight differenceAssembly line

The invention relates to a component height difference detecting device. Material is fed in a material feeding assembly line mechanism, and a first assembly line mechanism is capable of blocking a carrier and scanning a serial number of a component through a bar-code scanner; the component is driven by a manipulator to move to the position of a CCD mechanism and to take a picture, and the component position is calibrated; a second assembly line mechanism is capable of separating the carrier from a conveyer belt and blocking the forward movement of the carrier, and the carrier is capable of maintaining level after the carrier is lifted up; the component is placed on the carrier through the manipulator, a material pressing mechanism is driven by a driving air cylinder and a lifting air cylinder to drive a material pressing plate to press the component after the component is placed, a detecting counterpoint mechanism is driven by the manipulator and is transported to the position above the component, a height difference between the component and the datum on the carrier is detected, and after the height difference is detected, the material pressing mechanism is moved out, a mandril is retreated, and the carrier is continuously transported forward to a material discharging assembly line mechanism for material discharging. The component height difference detecting device is used for detecting the height difference on small components of electronic products, the height difference can be confirmed, and the next step of operation is prepared.

Owner:BOZHON PRECISION IND TECH CO LTD

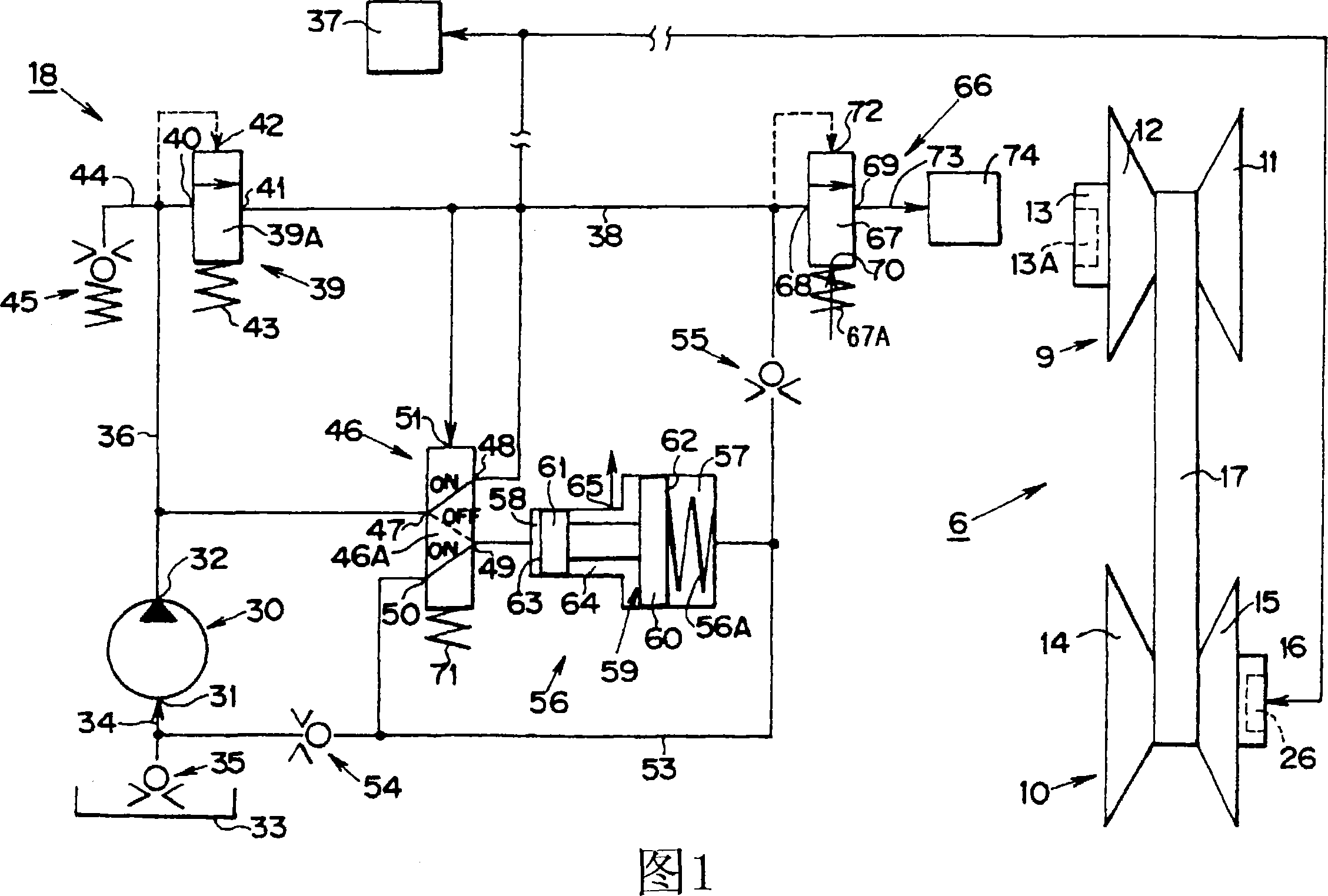

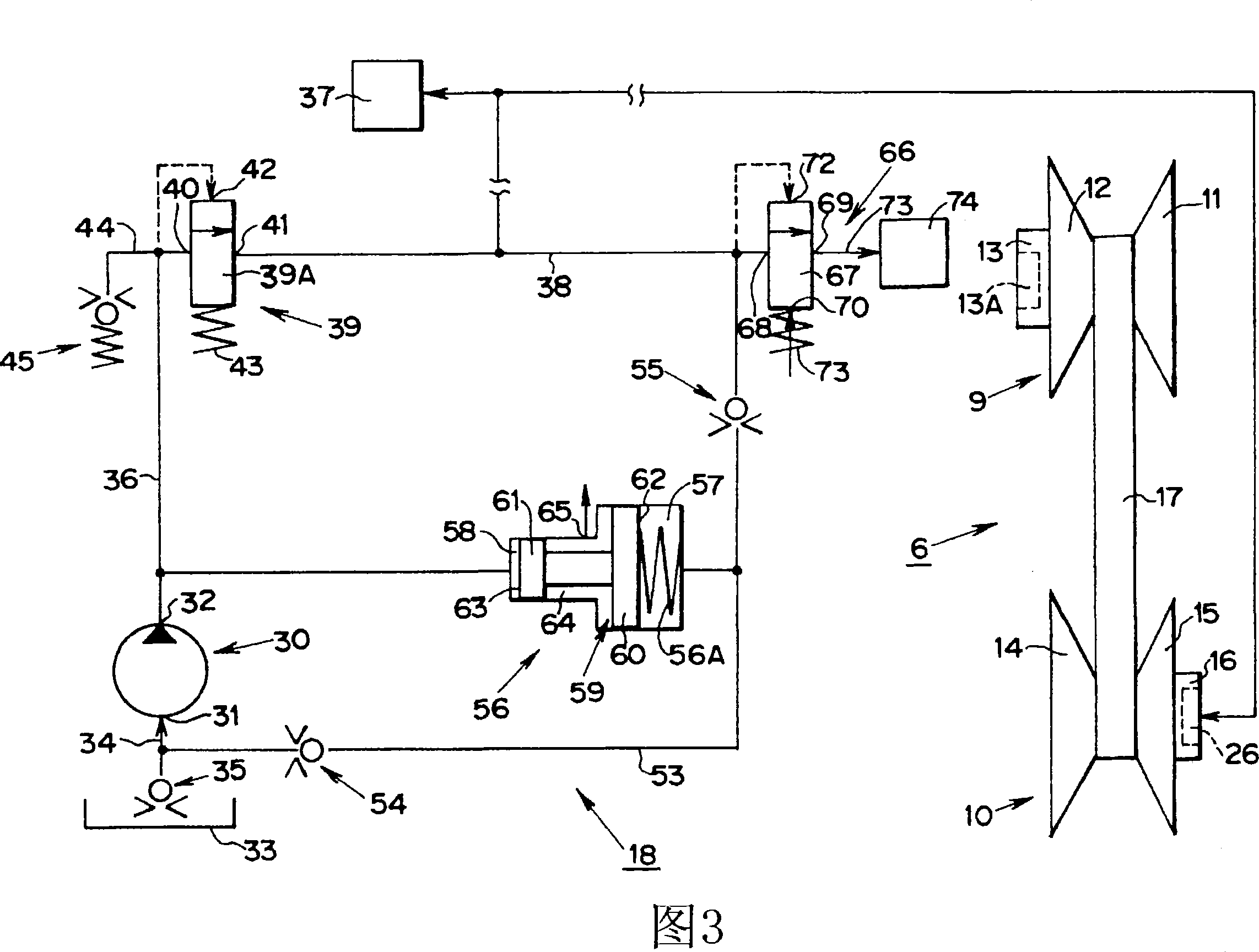

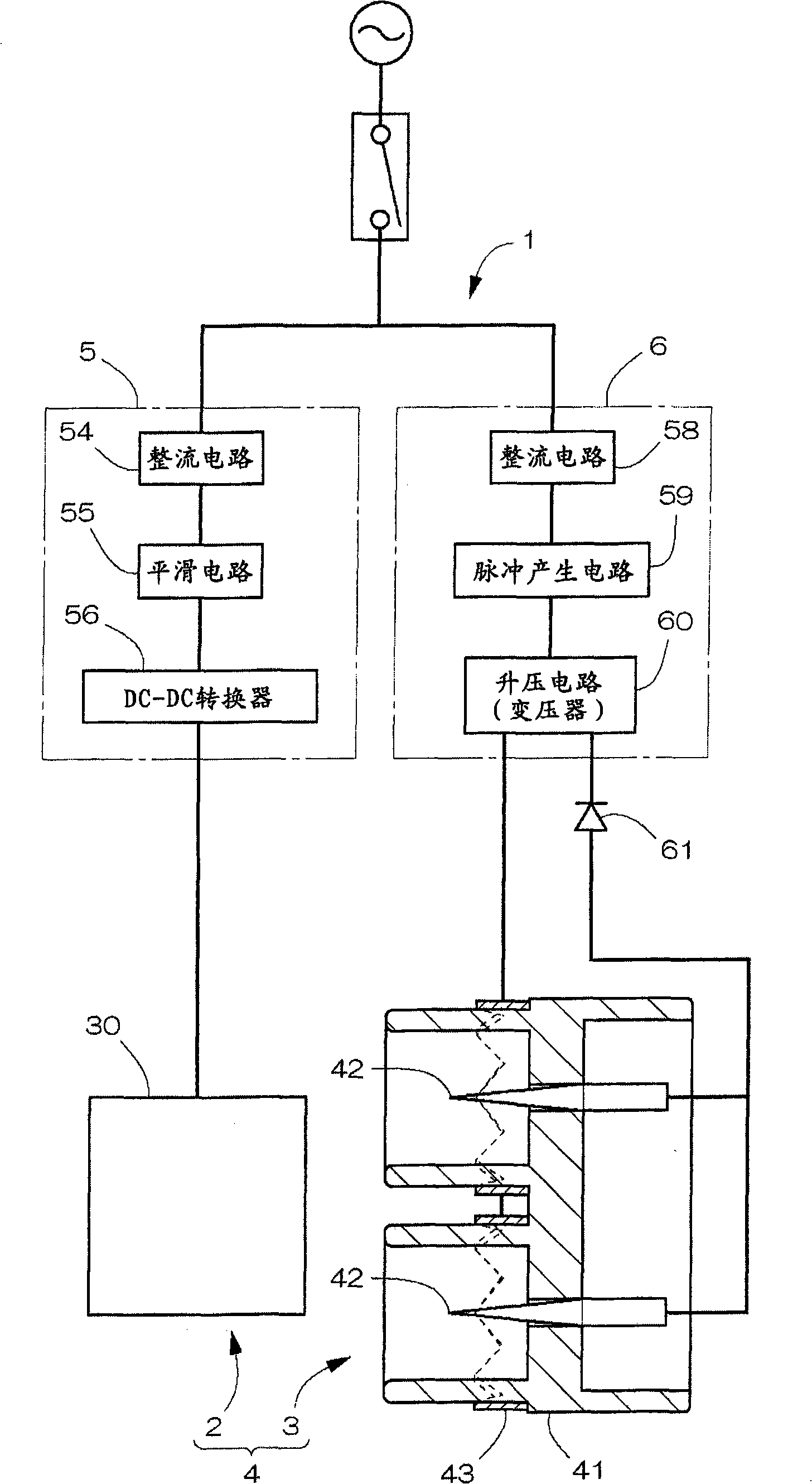

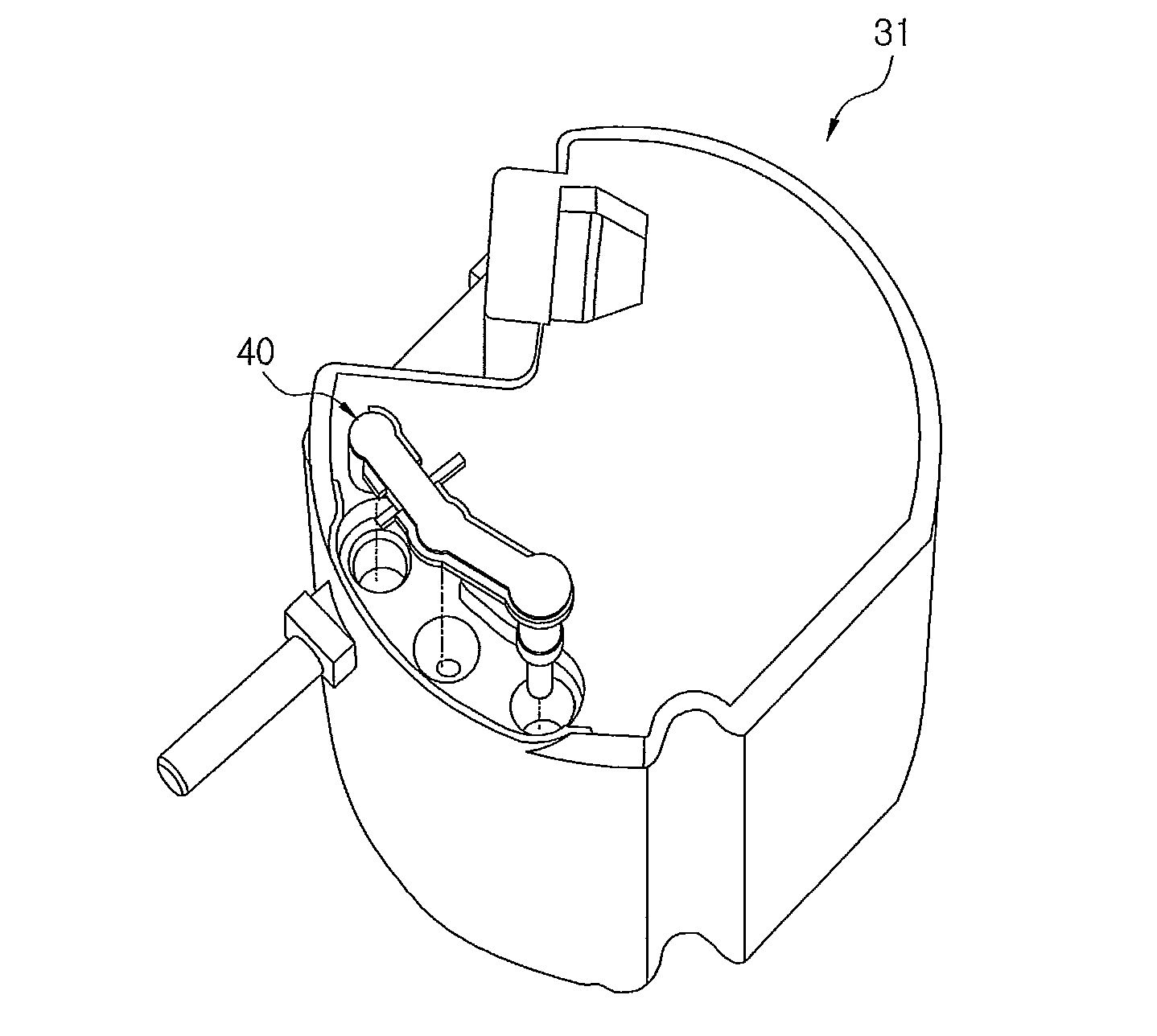

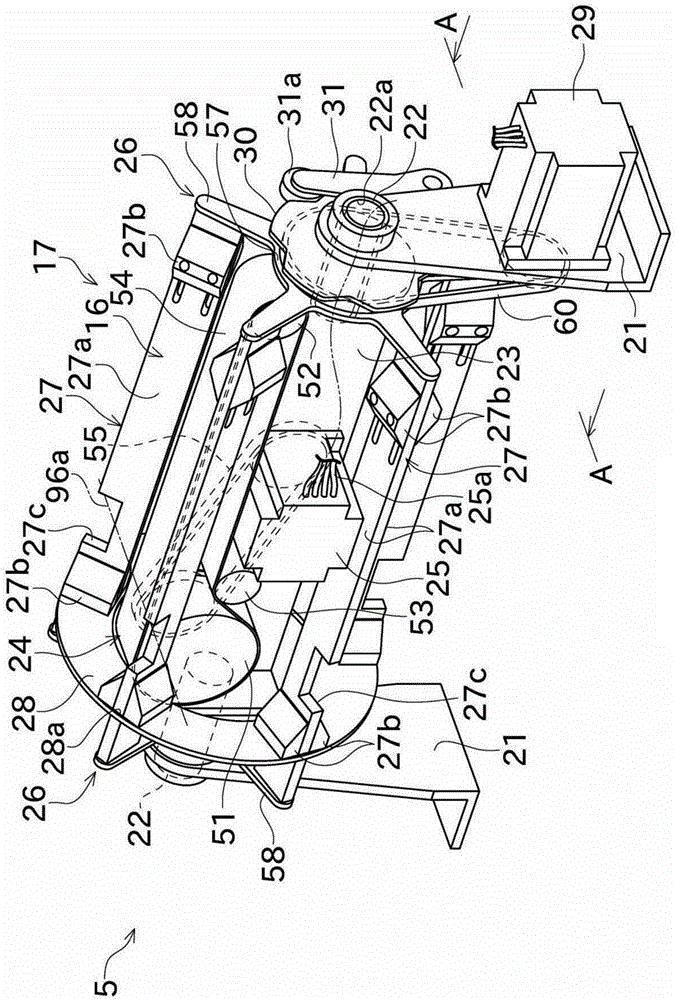

Hydraulic control unit

InactiveCN1973152AFast supplyImprove supply efficiencyGearingGearing controlHydraulic control unitDrivetrain

A hydraulic control unit, has a power transmission system arranged on the line from the prime mover to the vehicle wheel; an oil reserving device for feeding the oil to the oil receiving device, which controls a power transmitting condition of the power transmission system based on oil feeding condition; an oil storing device for feeding the oil to the oil receiving devices, the characteristic of the hydraulic control unit is that, in which, the oil storing device comprises a piston where large diameter potion and small diameter potion are arranged coaxially and integrately; a first hydraulic chamber in which the large diameter potion are accommodated with liquid-tight and can move backwards and forwards; a second hydraulic chamber in which the small diameter potion are accommodated with liquid-tight and can move backwards and forwards; wher, the bearing area of the first bearing surface in the first hydraulic chamber which the large diameter potion faces towards is larger than the bearing area of the second bearing surface in the second hydraulic chamber which the small diameter potion faces towards; the characteristic of which is including an oil feed quantity control device for operating the piston by improving oil pressure in the second hydraulic chamber, feeding oil in the first hydraulic chamber to the oil receiving device.

Owner:TOYOTA JIDOSHA KK

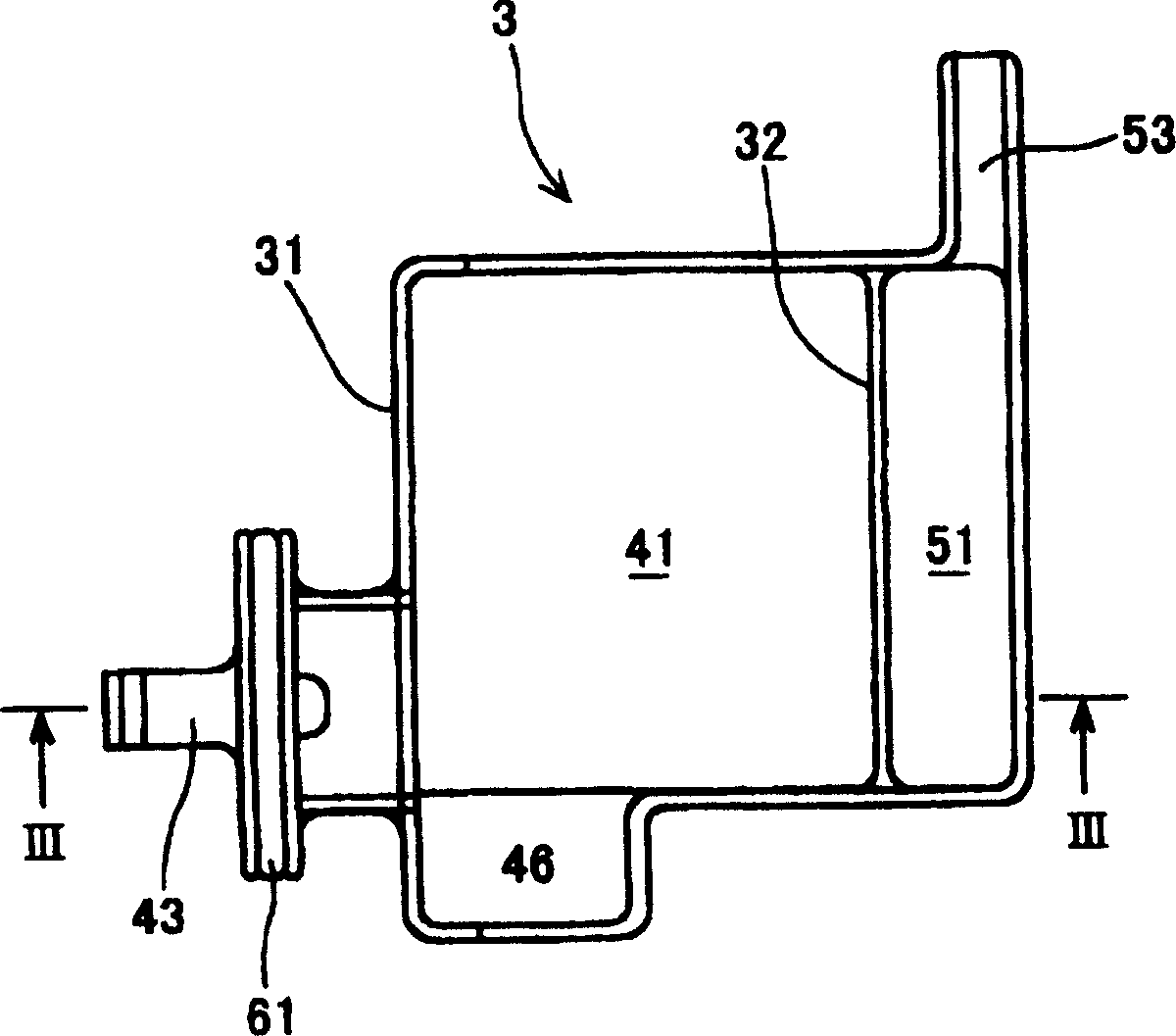

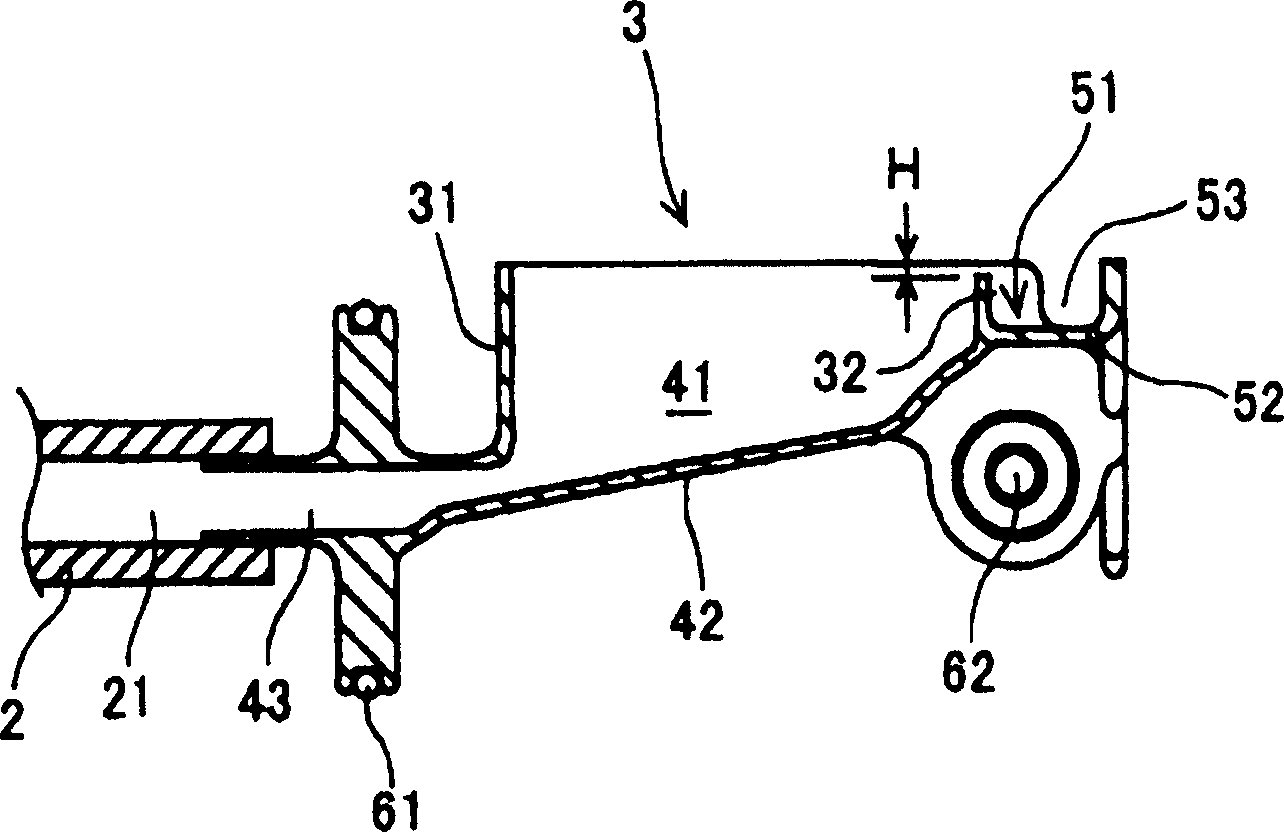

Transmission

ActiveCN1824975AImprove supply efficiencyLight supply efficiencyGearboxesGear lubrication/coolingEngineeringSpur gear

A transmission includes: a casing of the transmission; a shaft rotatably supported by the casing and having an oil passage; plural gears mounted on the shaft. The lubricant is partly lifted and stirred in response to a shift operation implemented by selectively engaging and rotating the gears. The transmission further includes a lubricating mechanism placed at a position higher than the shaft and having an upper end opening in an upward direction so as to collect and store the lifted lubricant. The lubricating mechanism is provided with an oil supply port through which the lubricant is guided to the oil passage of the shaft.

Owner:AISIN AI CO LTD +1

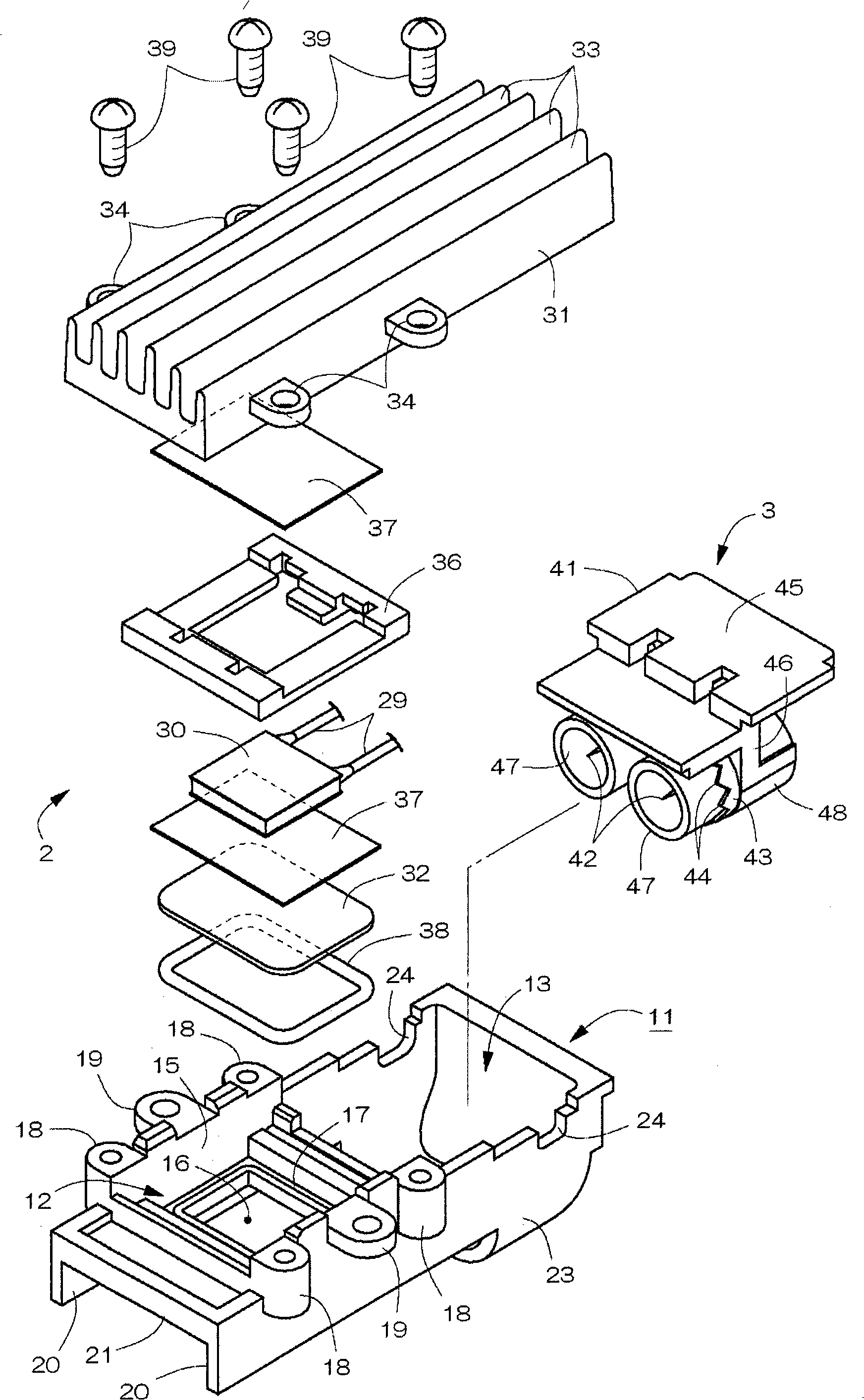

Ion generating device

ActiveCN101335427AIncrease productionEliminate Discharge State DisordersCorona dischargeLitterCorona discharge

The present invention relates to an ion generating device, and provides an ion generating device which can not be influenced by litter deviation of machining precision or assembly precision and can stably execute corona discharge. The ion generating device of the invention is provided with a barrel wall (47), an acicular discharge electrode (42) arranged at the center of the barrel wall (47), and a barrel relative electrode (43) arranged at the circumference of the barrel wall (47). The edge of the relative electrode (43) is formed with a group of sharp convex parts (44).

Owner:MAXELL HLDG LTD

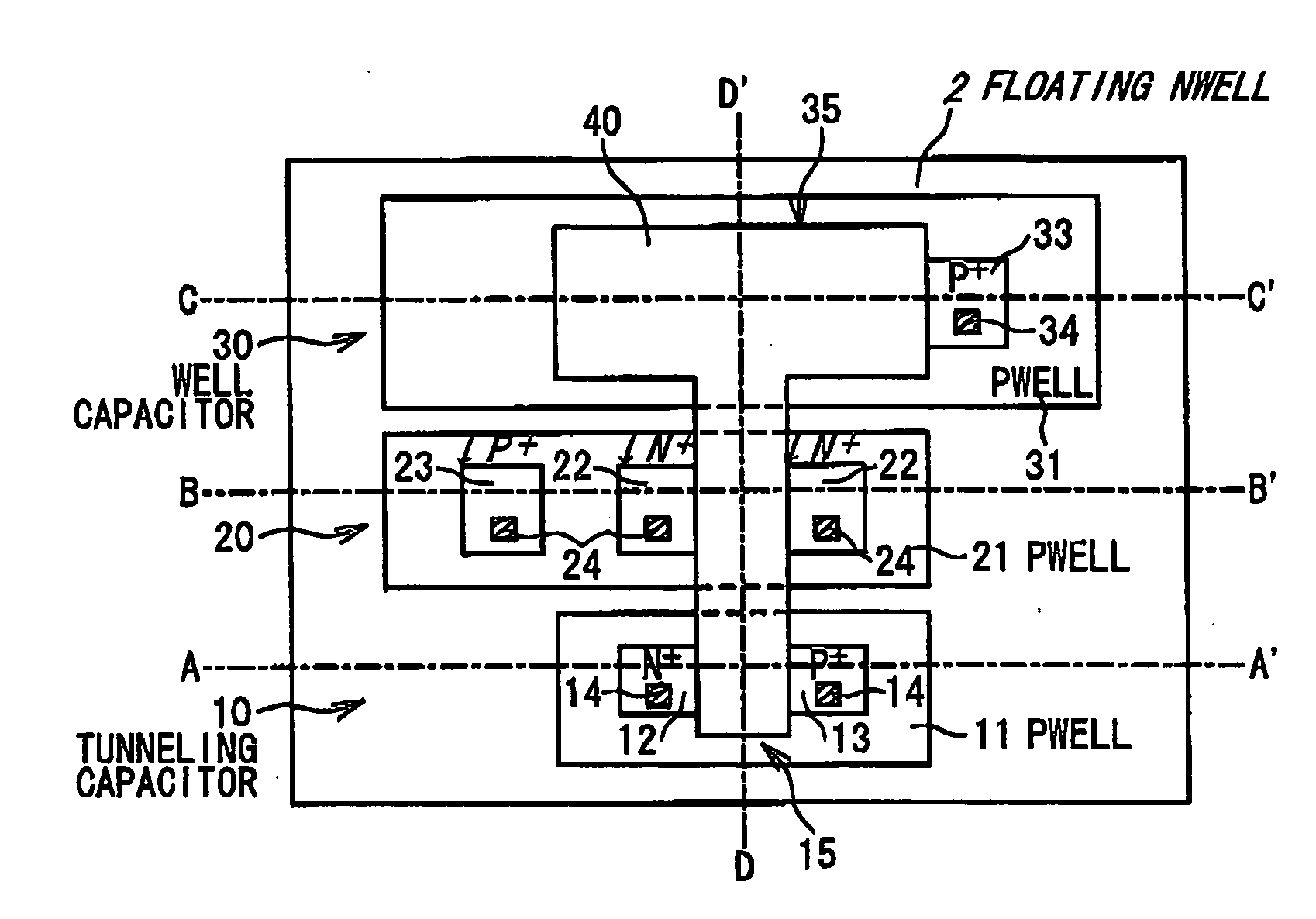

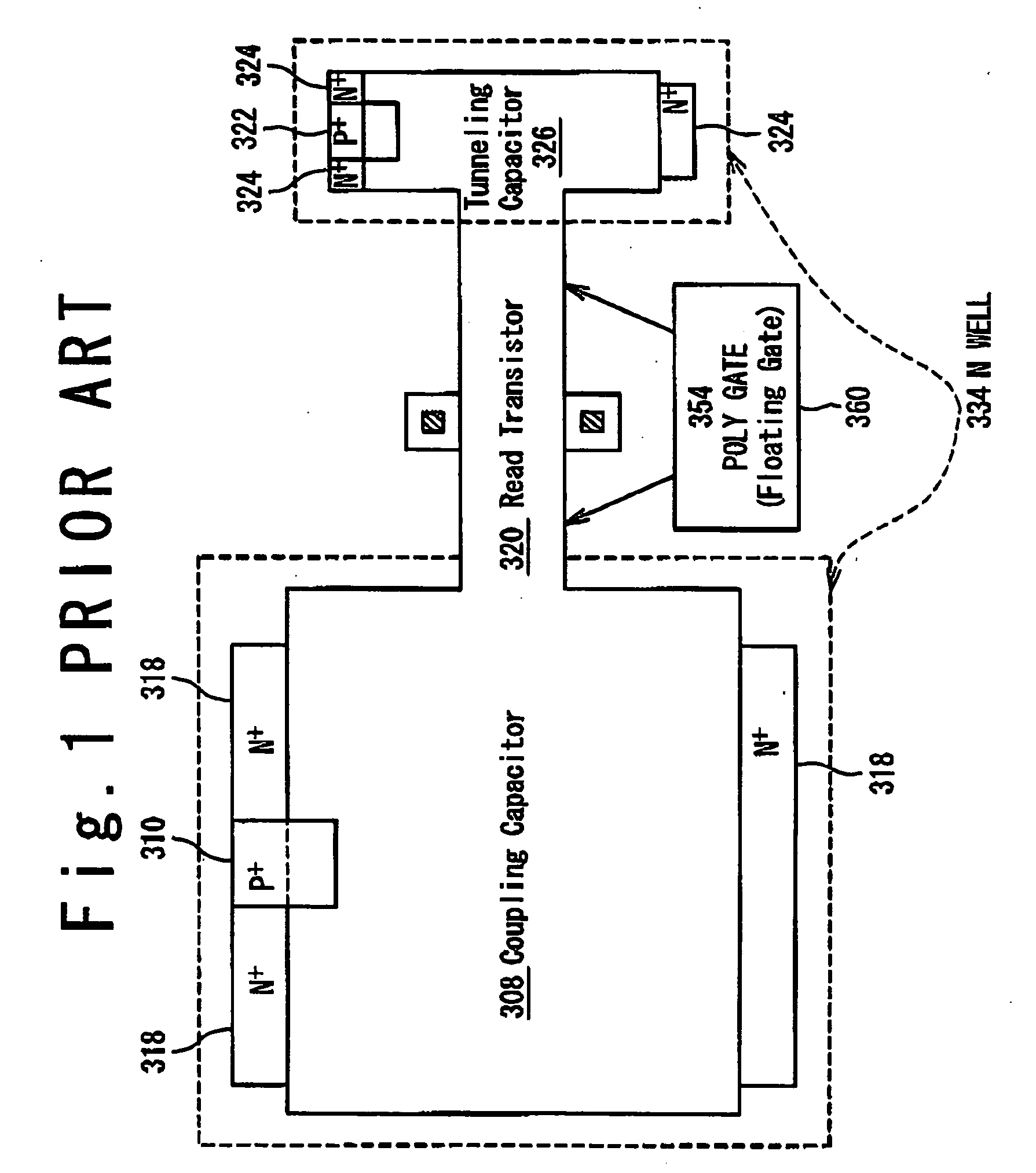

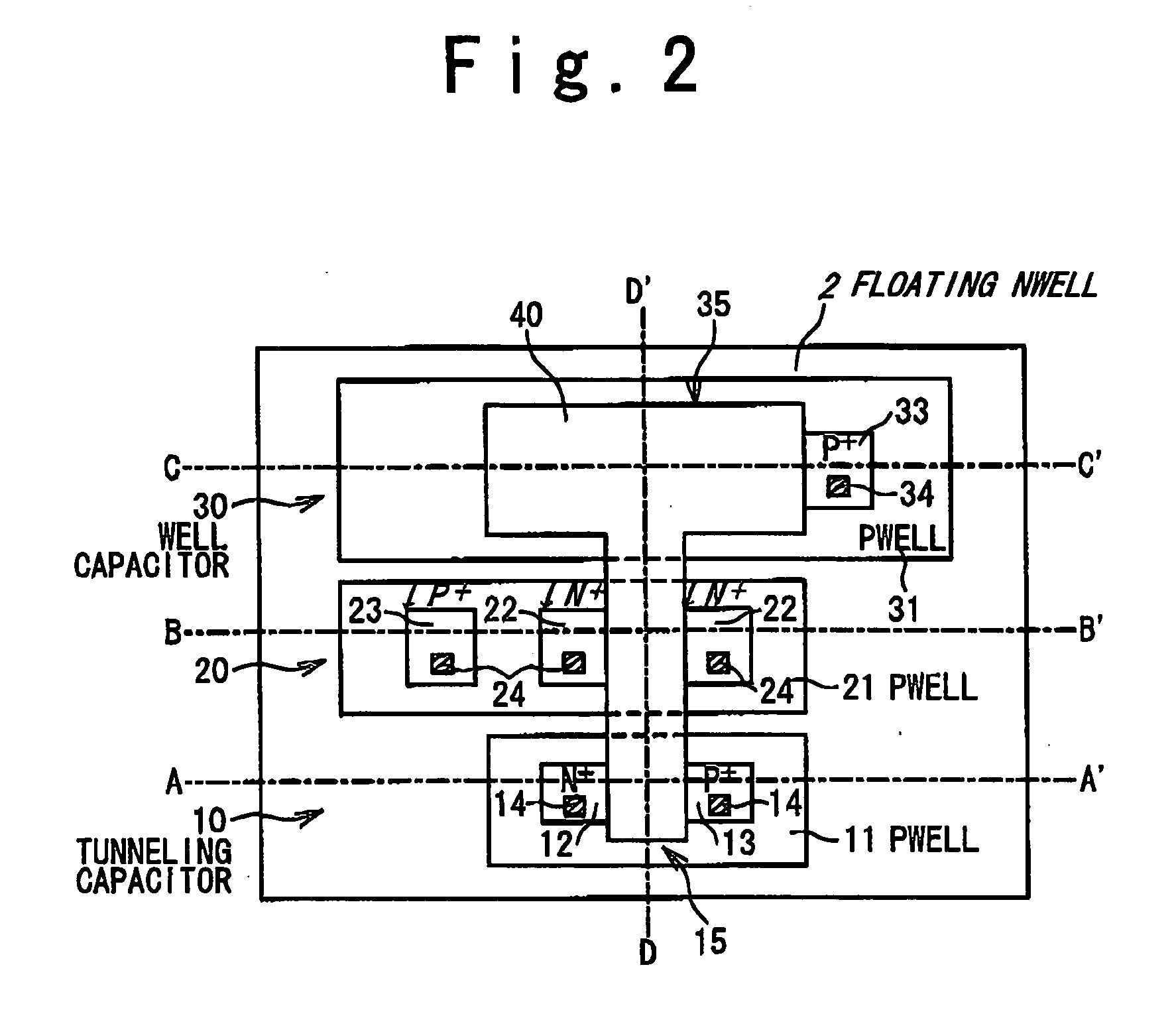

Eeprom

InactiveUS20070120176A1Increase supplyImprove supply efficiencyTransistorDiffusion layerNon-volatile memory

An EEPROM having a nonvolatile memory cell is provided. The nonvolatile memory cell has: a first well formed in a substrate; a floating gate formed on the substrate through a gate insulating film to overlap a first region of the first well; and first and second diffusion layers formed in the first well to contact the first region. A charge supply to the floating gate is performed through the gate insulating film between the first region and the floating gate. The first diffusion layer and the second diffusion layer are of opposite conductivity types and are provided such that efficiencies of the charge supply to the floating gate from respective of the first diffusion layer and the second diffusion layer are equal to each other.

Owner:NEC ELECTRONICS CORP

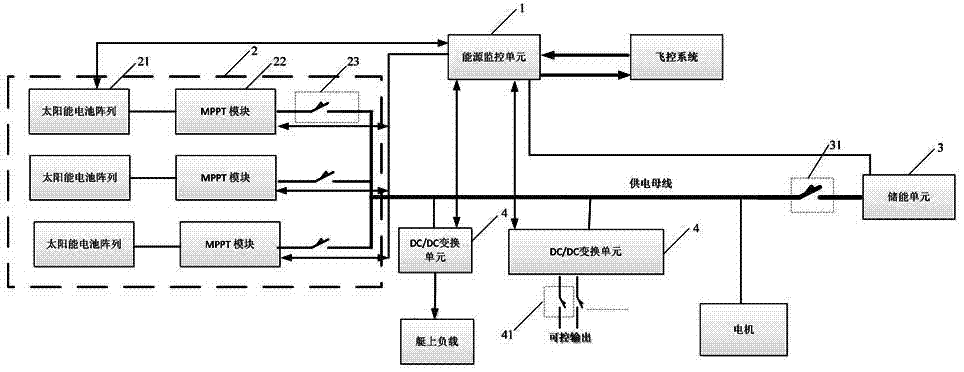

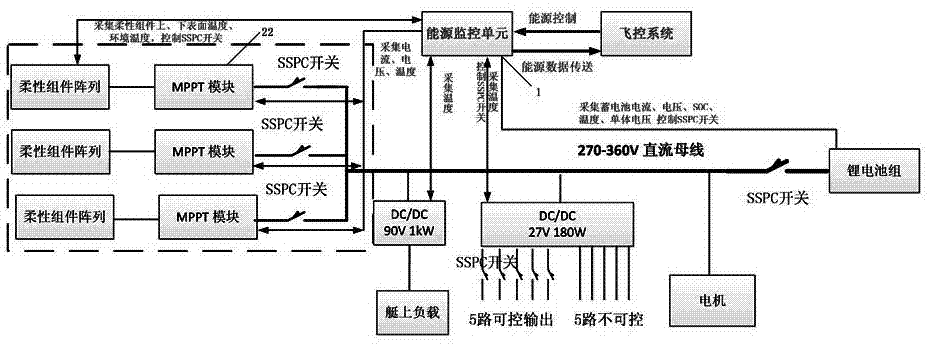

Energy supply system of stratosphere solar energy airship and control method thereof

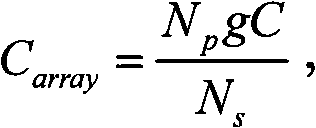

InactiveCN107979157AEliminate performance differencesFlexible control on-offBatteries circuit arrangementsSingle network parallel feeding arrangementsStratosphereEnergy supply

The present invention discloses an energy supply system of a stratosphere solar energy airship and a control method thereof. The system comprises an energy monitoring unit and a solar generation unitand an energy storage unit which are connected with the energy monitoring unit. The solar generation unit is connected with a power supply bus in an airship through the energy storage unit, the energymonitoring unit comprises multiple generation paths, each generation path comprises one solar cell array, one MPPT module and one control switch module which are connected in order, and the energy monitoring unit controls output of each MPPT module and charge and discharge of the energy storage unit according to the power required by a load, and controls on-off of each control switch module according to the residual energy of the energy storage unit. The control method is configured to control the system mentioned above. The energy supply system of the stratosphere solar energy airship and the control method thereof are simple in structure, low in cost and high in energy supply efficiency and utilization rate, can meet the long-term continuous power supply demand of the stratosphere airship, and are stable and reliable, etc.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

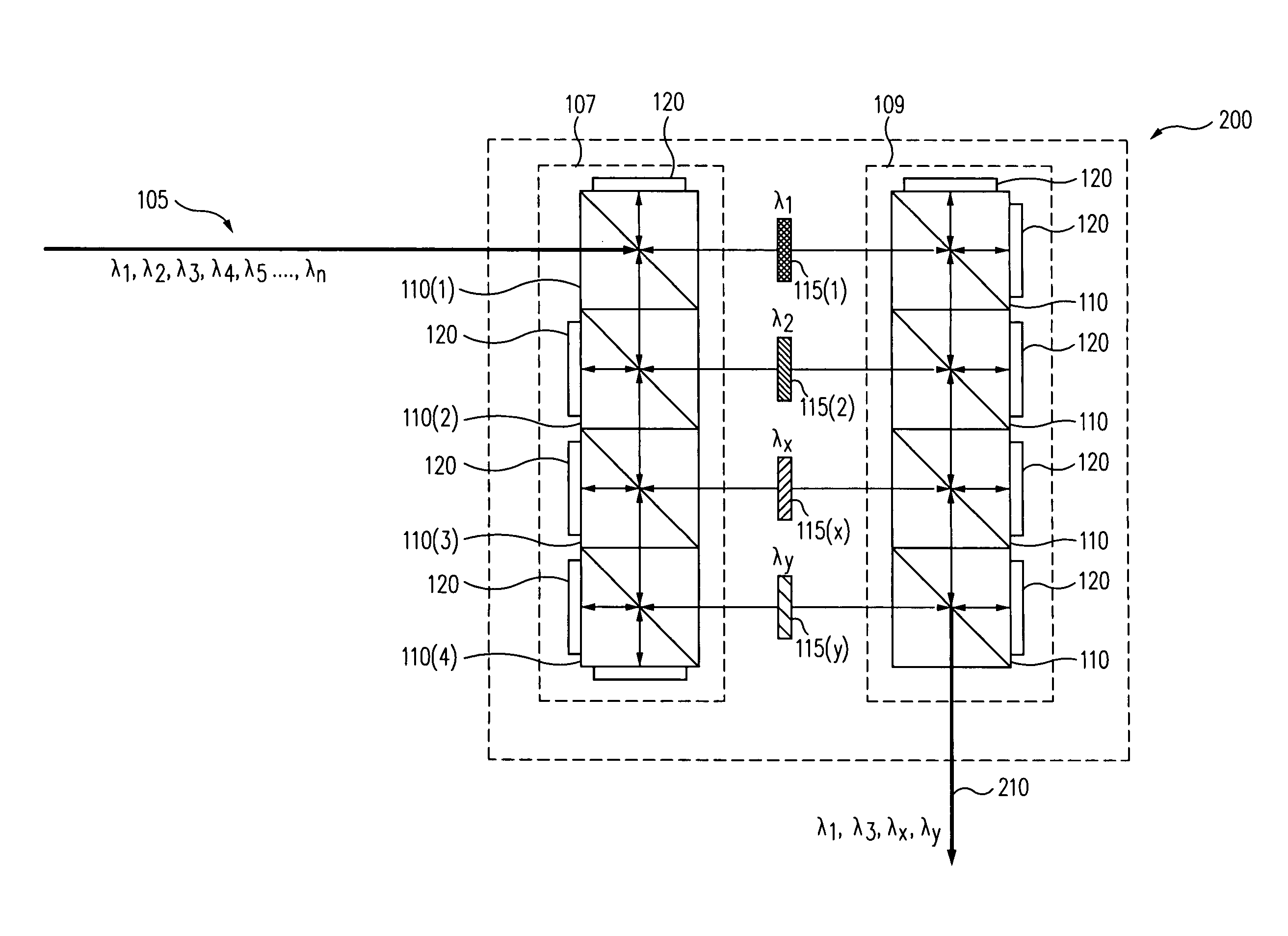

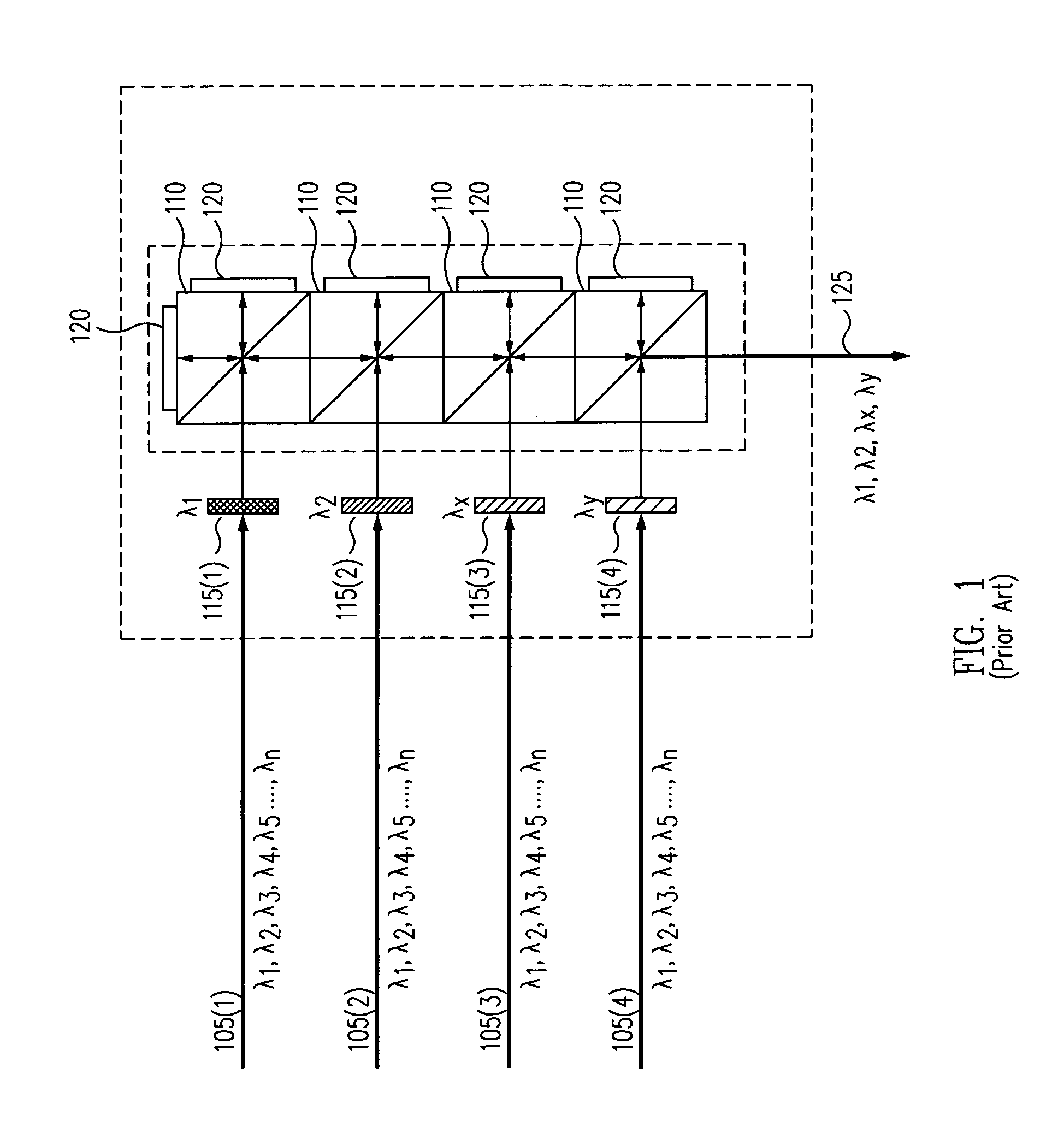

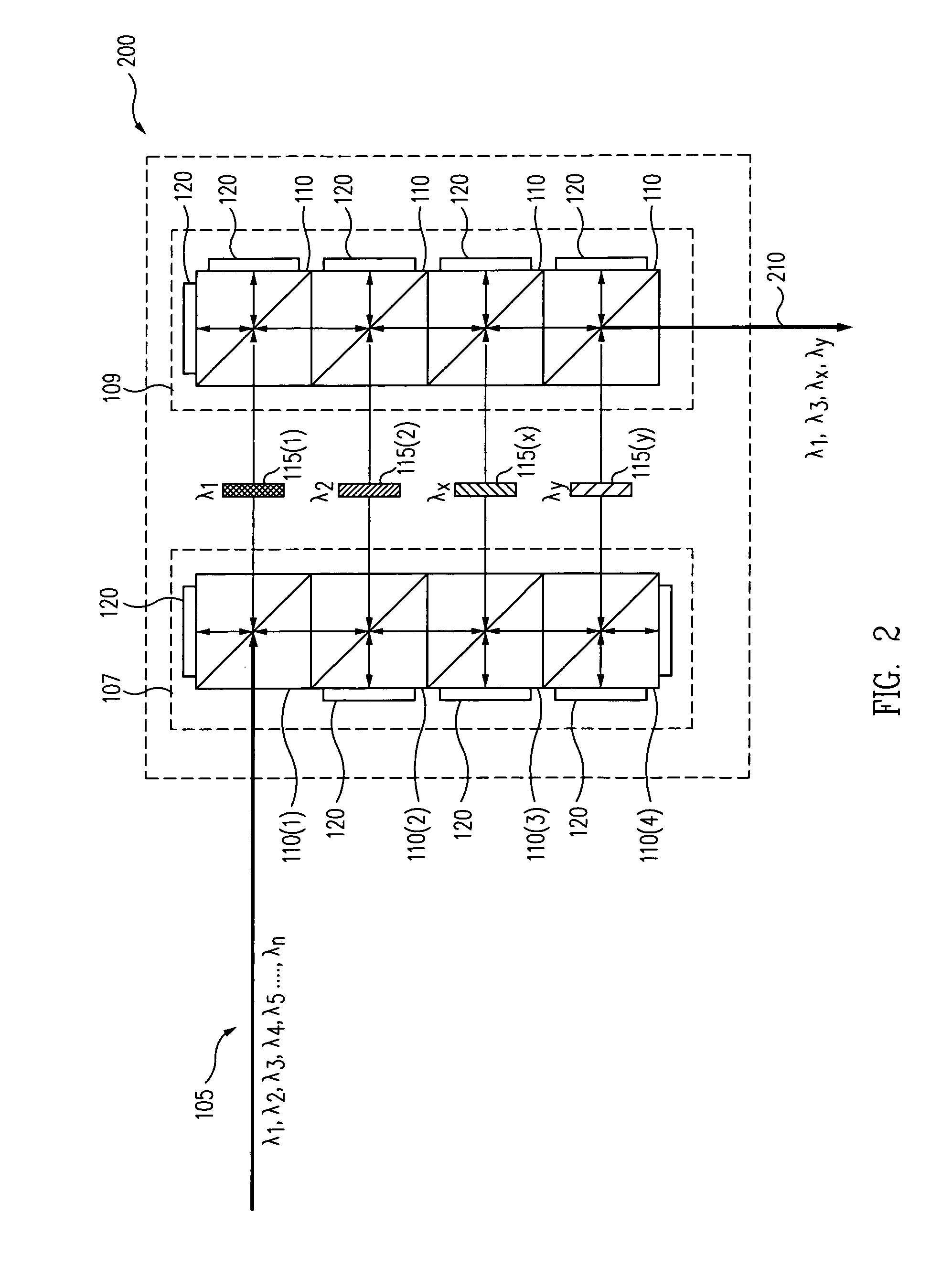

Light beam conditioner

InactiveUS7262918B1Efficient provisionImprove supply efficiencySpectrum generationOptical devices for laserMulti wavelengthLight source

A system and method for conditioning a beam of light comprised of several wavelengths by means of selecting from among the plurality of available wavelengths, a desired set of wavelengths simultaneously. A small number of multi-wavelength lasers or continuous spectra light sources, or both, may be the source for the plurality of light wavelengths, and a configuration of beam splitters / combiners, mirrors and wavelength selectable pass- and stop-filters provide a combined beam of light wavelengths selected from among the available wavelengths.

Owner:WAFERMASTERS

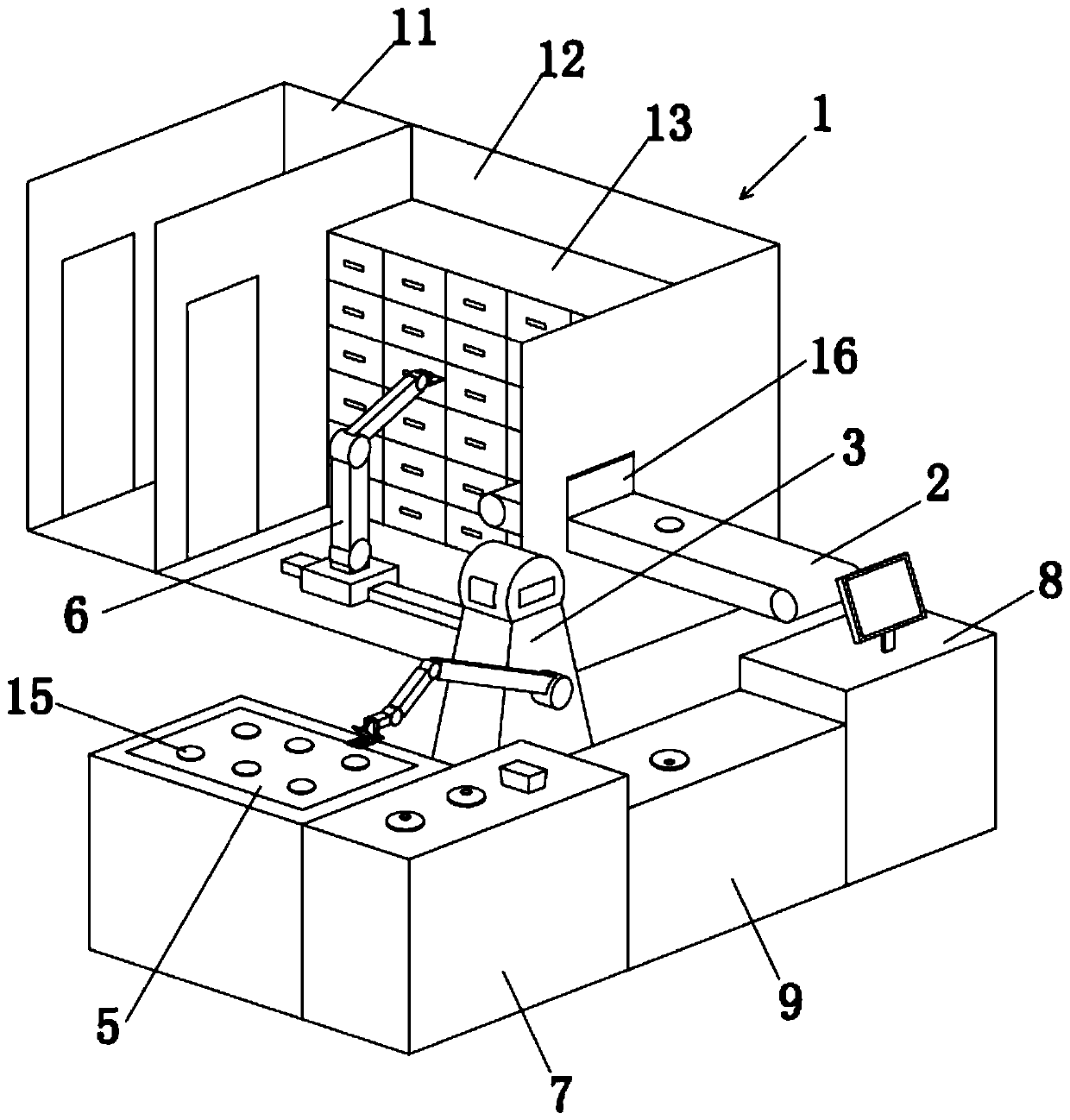

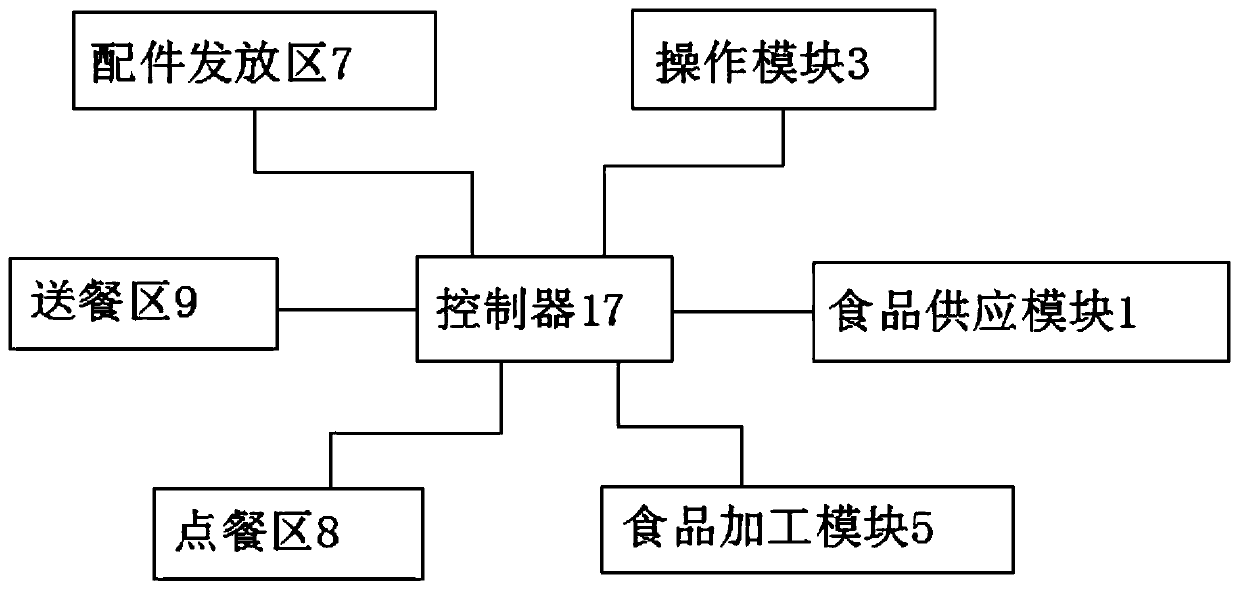

Unmanned system for automatic food processing and sales

ActiveCN110412959AReduce dependencyImprove operational efficiencyProgramme-controlled manipulatorData processing applicationsComputer moduleEngineering

The invention discloses an unmanned system for automatic food processing and sales. The system comprises an operation module, a food supply module and a food processing module, wherein the food supplymodule and the food processing module are arranged along the food moving path in sequence. The operation module is located on one side of the food processing module. The unmanned system further comprises a controller, a food ordering area and a food taking area, wherein the food taking area is located on one side of the food processing module; the controller is in signal connection with the foodordering area, the food supply module, the operation module and the food processing module. According to the unmanned system for the automatic food processing and sales, manual carrying, cooking and sales are not needed, the labor cost is reduced to the greatest extent, optimal standardized cooking procedures are provided, it is ensured that an unmanned store using the system achieves an optimal cooking effect, the situation that food quality differences are caused by human factors in an ordinary chain store is avoided, the speed of operation in the store is increased, and the unmanned systemcan be independently managed in various places.

Owner:李绍汉 +1

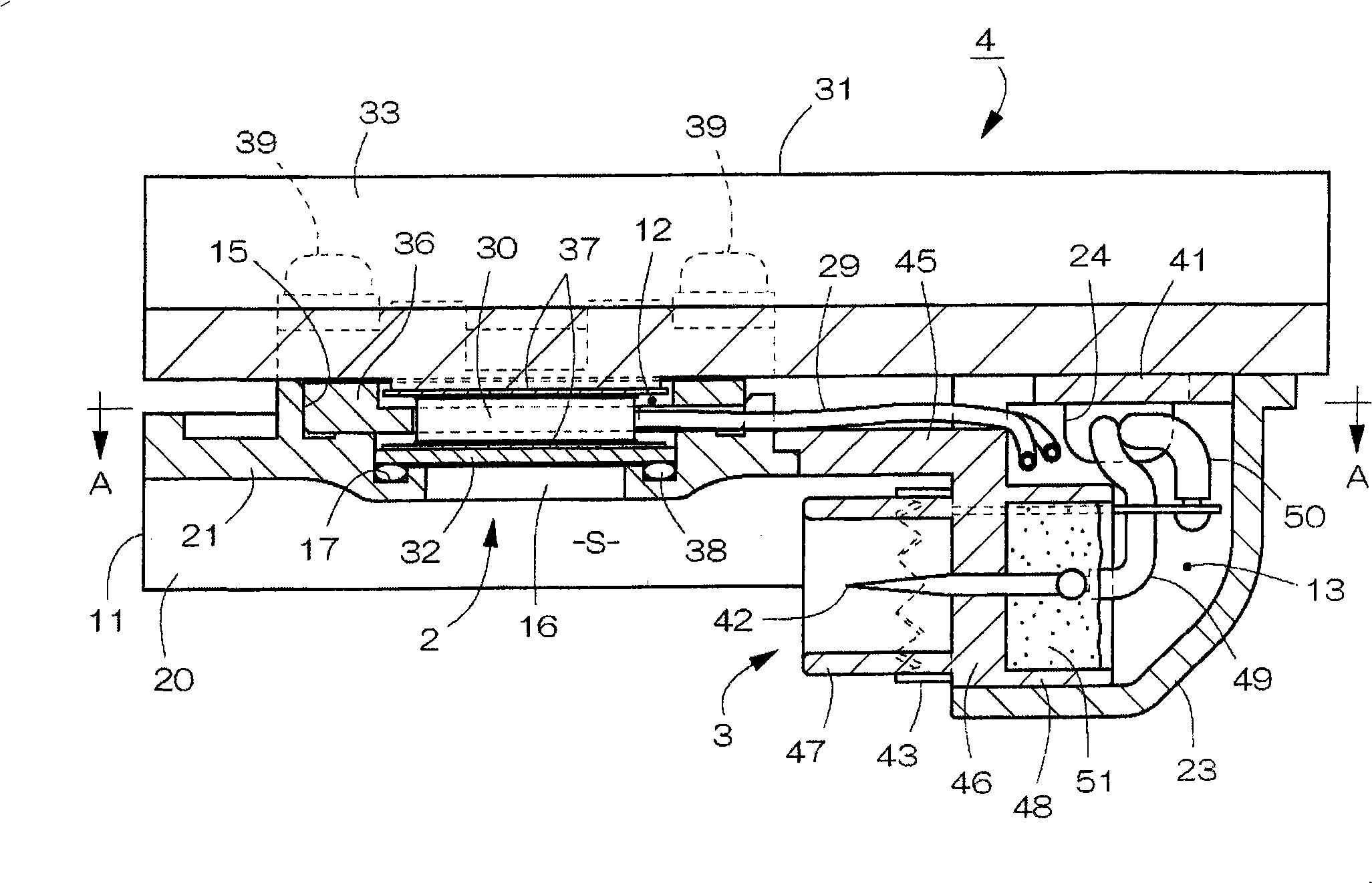

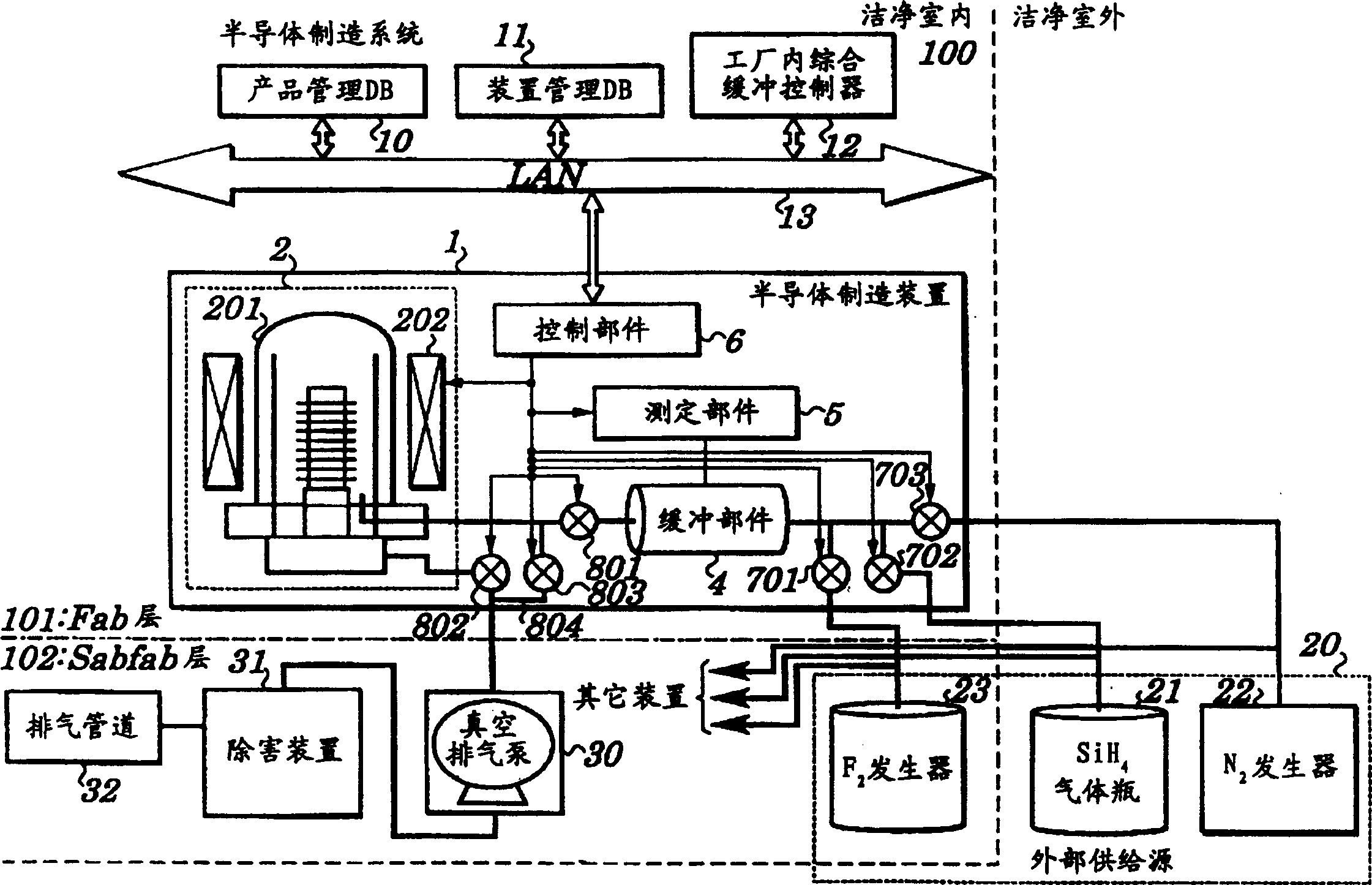

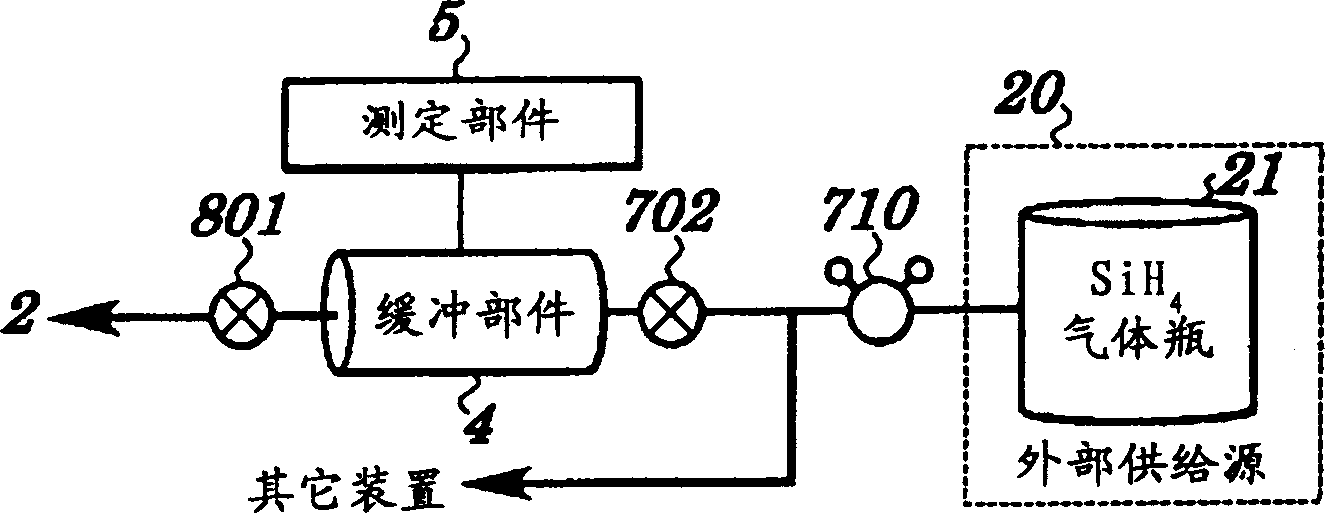

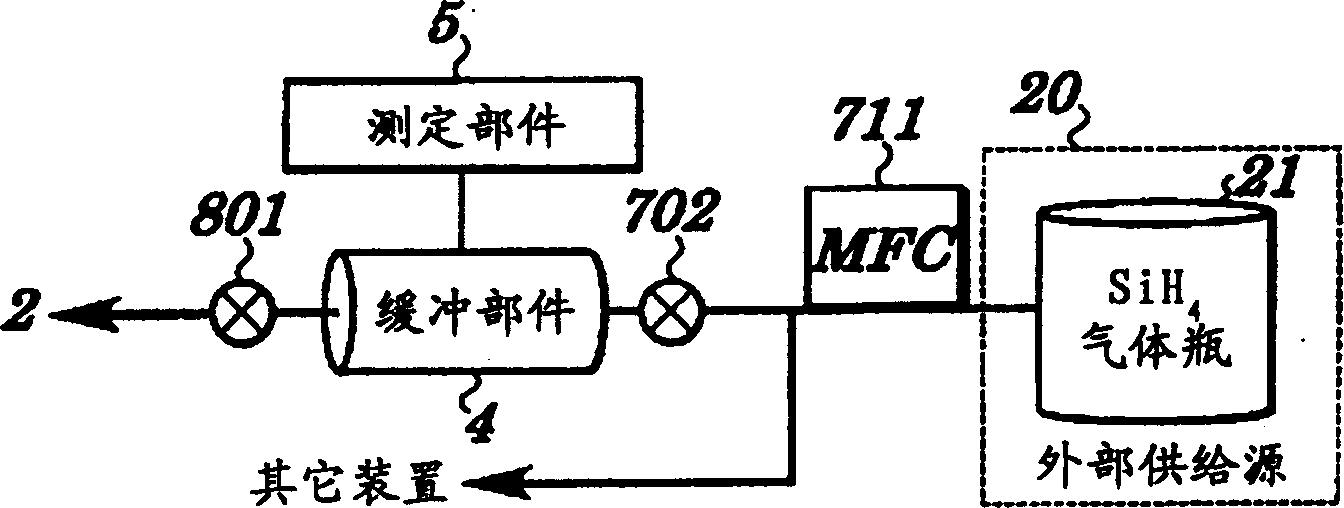

Semiconductor manufacturing device, semiconductor manufacturing system and substrate processing method

InactiveCN1445822AMiniaturizationImprove supply efficiencyCellsSemiconductor/solid-state device manufacturingMiniaturizationManufacturing systems

The present invention provides a semiconductor manufacturing device, a semiconductor manufacturing system, and a semiconductor manufacturing device, a semiconductor manufacturing system, and a substrate that can supply only a required amount of liquid, gas, or solid used directly or indirectly in substrate processing when necessary, and can realize miniaturization of supply equipment or conveying equipment. Bottom treatment method. The semiconductor manufacturing apparatus 1 and the semiconductor manufacturing system include a buffer member 4 . The buffer member 4 temporarily stores substances required for substrate processing supplied from the external supply source 20 , and supplies the stored substances to the processing chamber 2 . The supply of the substance is controlled by the CIM through the control unit 6 and the LAN 13 .

Owner:KK TOSHIBA

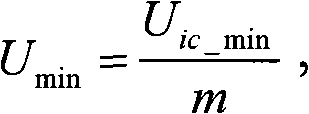

Device and method for intelligently supplying power to node based on wireless sensor network

InactiveCN101951033AImprove supply efficiencyEfficient use ofElectrical storage systemEnergy efficient ICTCapacitanceHigh energy

The invention relates to a device and a method for intelligently supplying power to a node based on a wireless sensor network, which belongs to the technical field of low-energy consumption power supply of the node of the wireless sensor network, and aims to solve the problem that the energy supplies and management of the node are inconvenient because the distribution of the node in the field wireless sensor network is wide and the layout environment thereof is complicated. In the technical scheme of the invention, a MCU microprocessor selects the power supply mode of supplying power directly by a solar battery or releasing energy by a super capacitor by collecting external voltages and through internal comparison and judgment so as to intelligently control charging and power supply circuits, and control the node to enter different working modes according to the energy state so as to improve the efficiency of energy utilization. The device and the method of the invention can solve the intrinsic power supply problem of the nodes of the wireless sensor network, and extend the lifecycle of the whole wireless sensor network.

Owner:CHINA AGRI UNIV

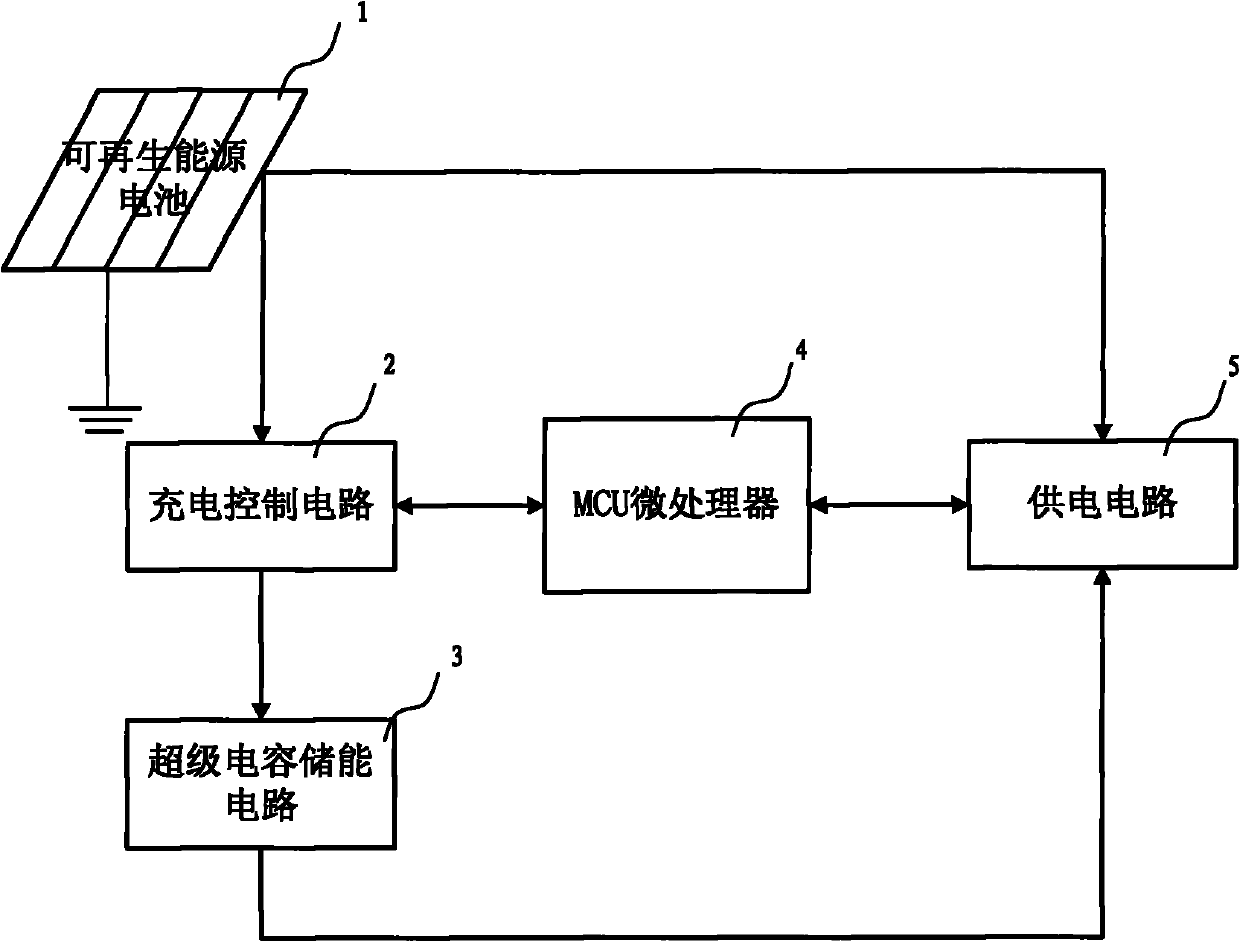

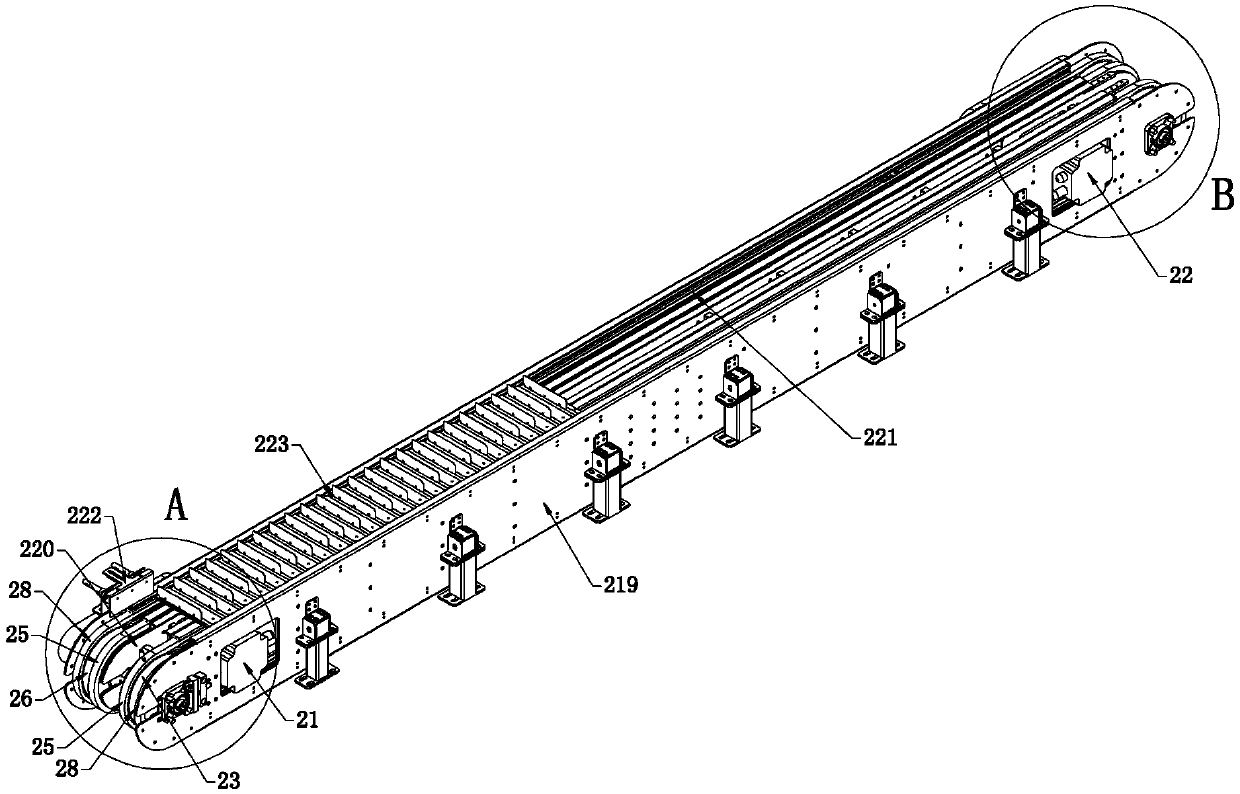

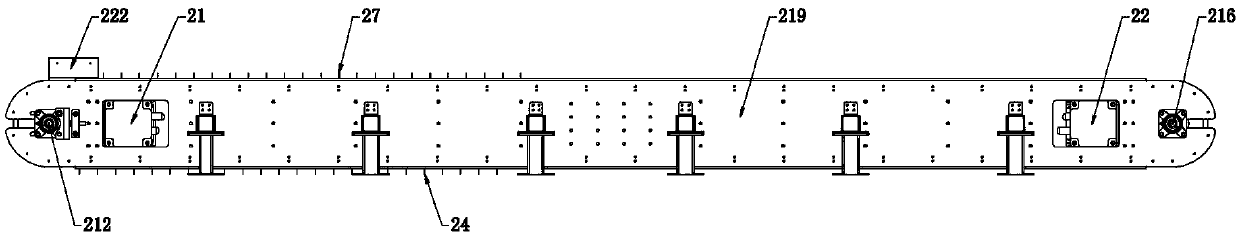

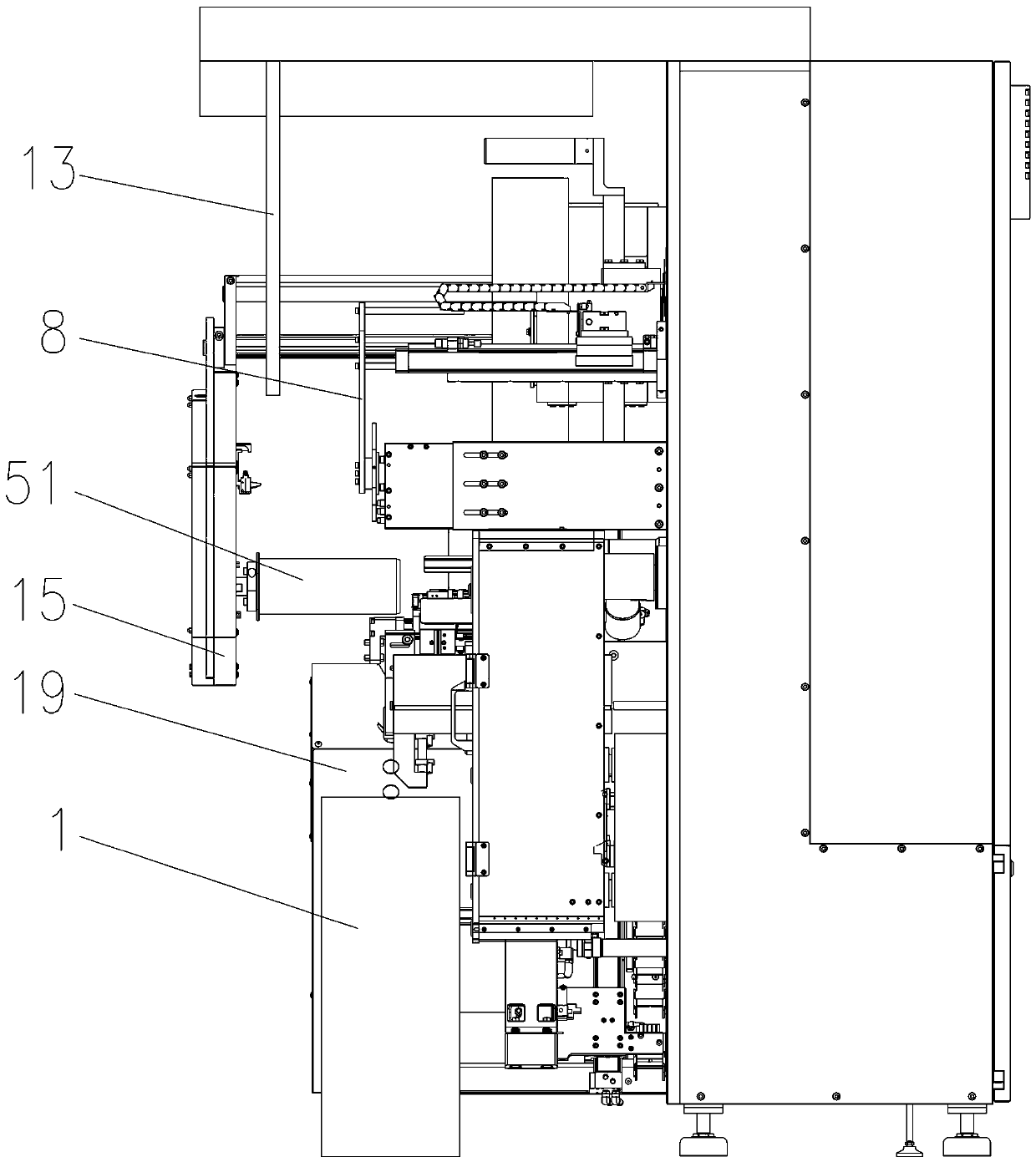

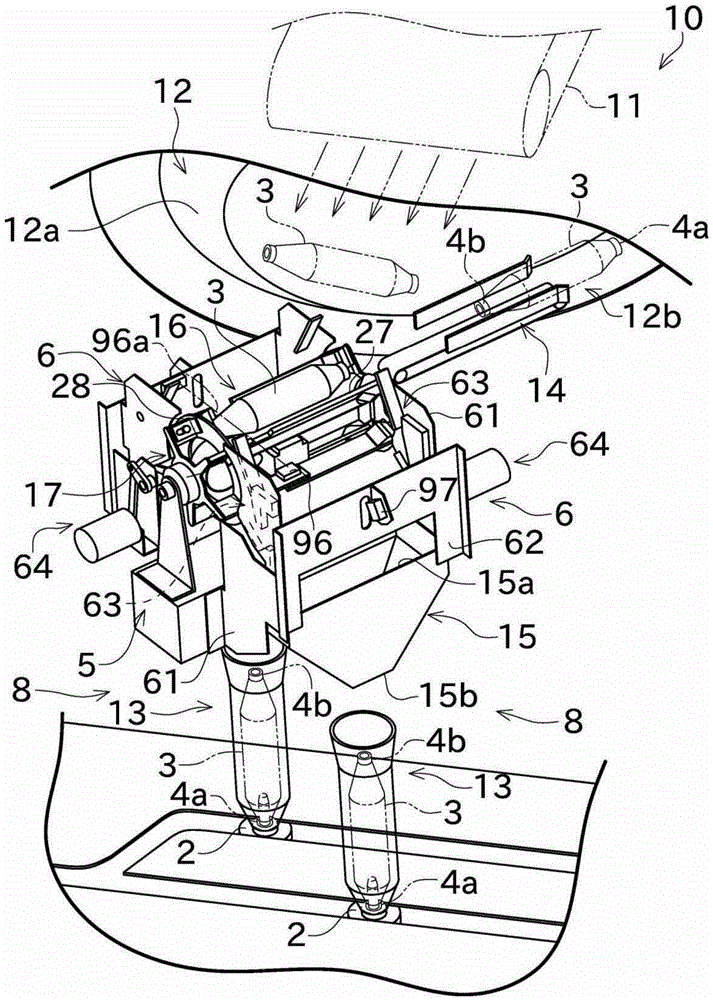

Automatic ice cream packaging system

ActiveCN105501544ASimple and fast deliveryImprove packaging efficiencyShock-sensitive articlesPackaging machinesElectric machineryEngineering

The invention discloses an automatic ice cream packaging system which comprises an ice cream feeding mechanism (1), an integrated conveying mechanism (2), a rack (3) and a box packaging line (5), wherein the integrated conveying mechanism (2) is vertically arranged at the tail end of the ice cream feeding mechanism (1), and the box packaging line (5) is parallel to the integrated conveying mechanism (2). Ice cream is quickly shot into ice cream grooves in integrated conveying belts (223) on the integrated conveying mechanism (2) one by one through an accelerating belt (13) at the rear end of the ice cream feeding mechanism (1); after the ice cream grooves in one integrated conveying belt (223) is full of ice cream, the integrated conveying belt (223) is driven by a corresponding servo motor to quickly run to the position under a robot grabbing mechanism (4) fixed on the rack (3), and the ice cream is simultaneously grabbed through the robot grabbing mechanism (4) to be put in a packaging box on the box packaging line (5). The system has the advantages of being simple and quick in running, high in automatic box packing efficiency and high in precision.

Owner:苏州澳昆智能机器人技术有限公司

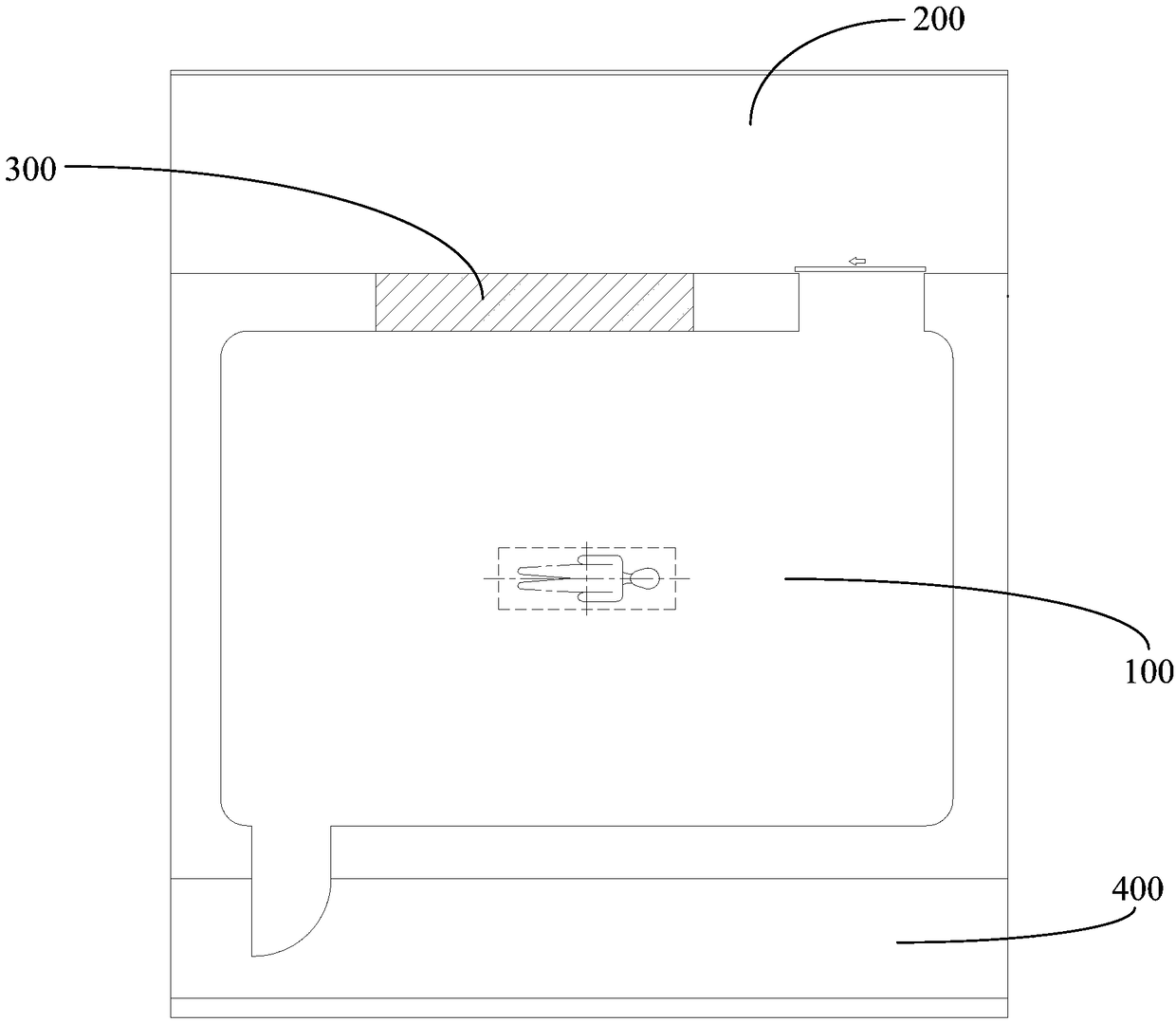

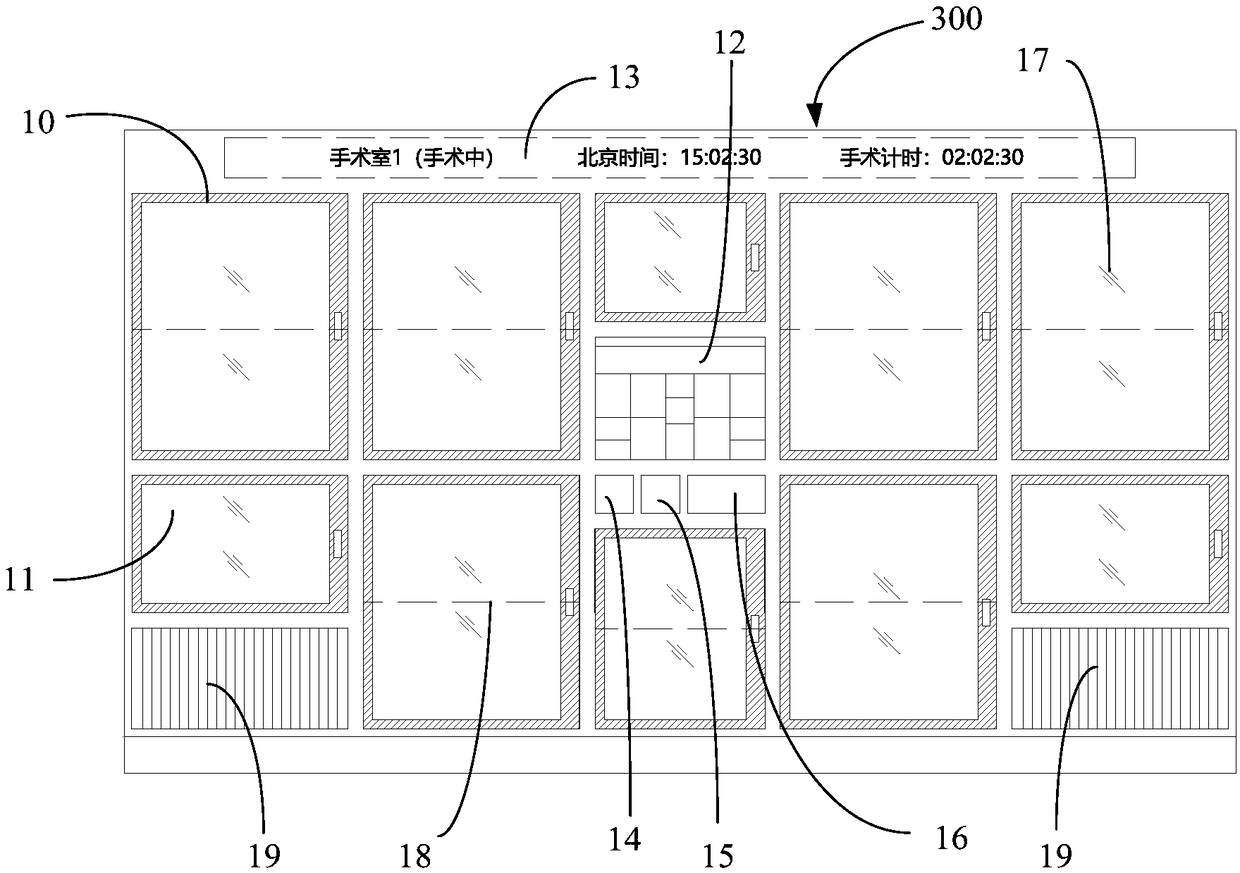

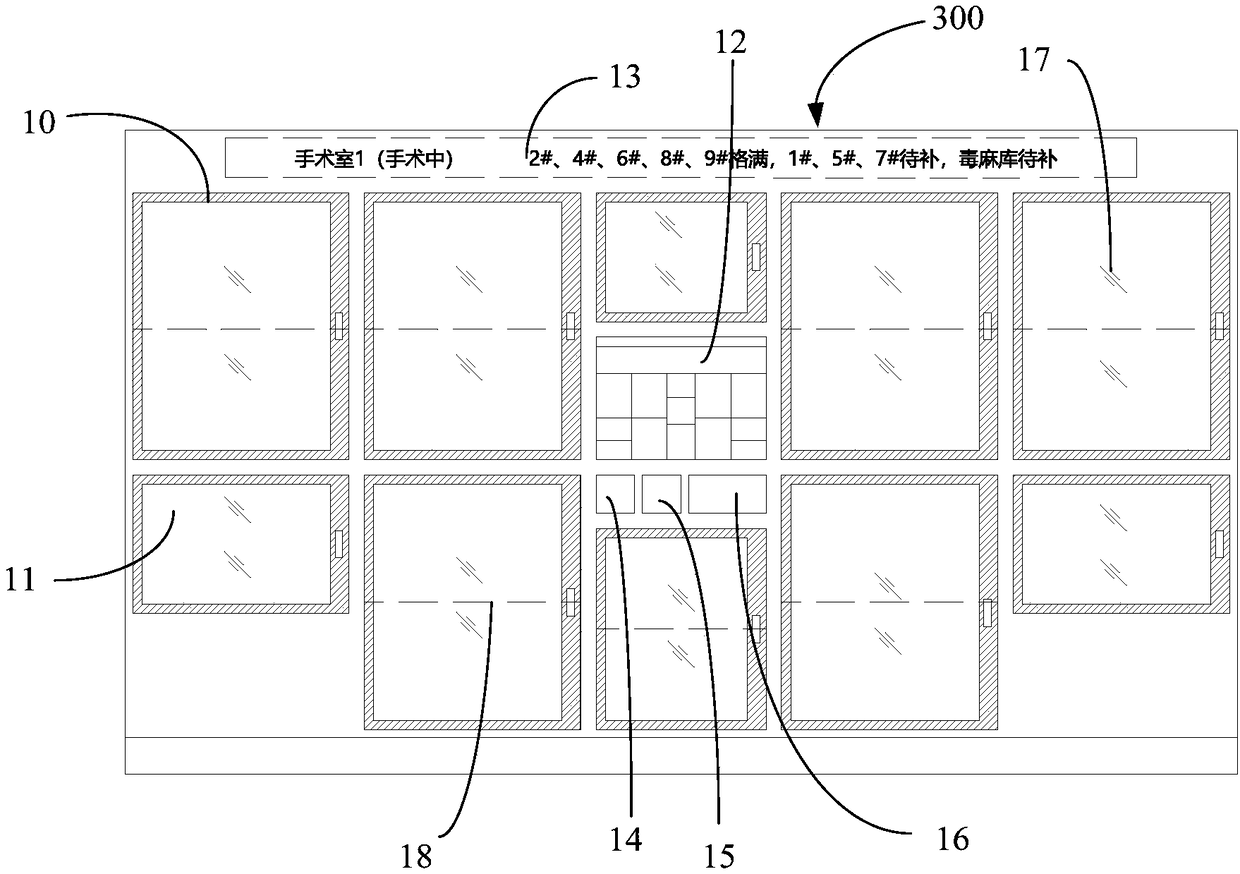

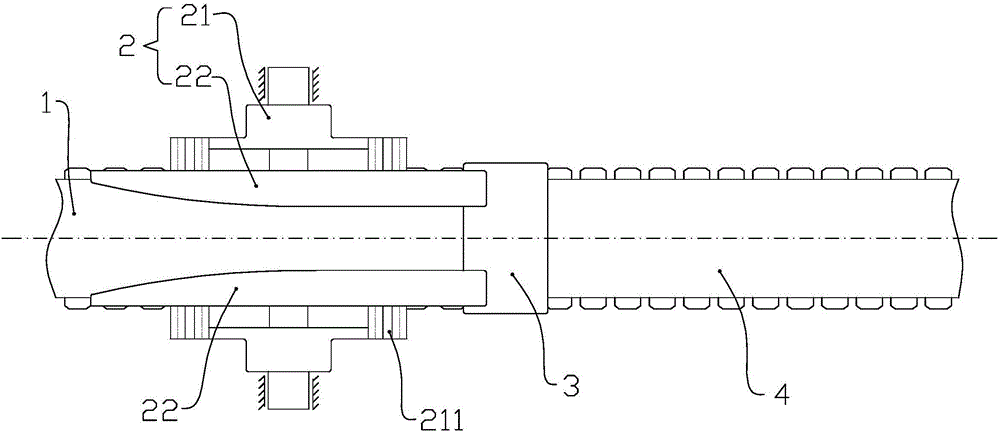

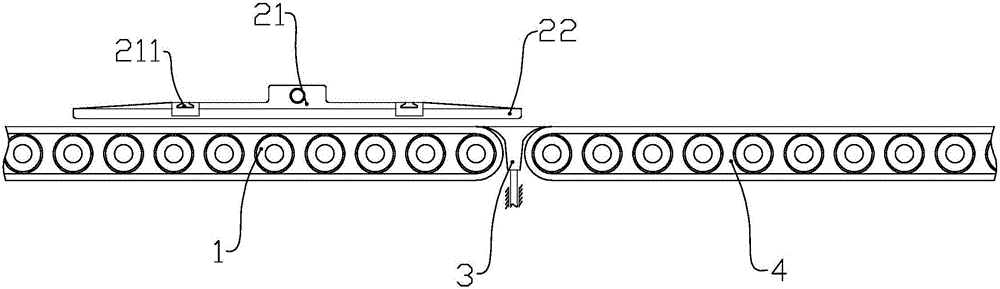

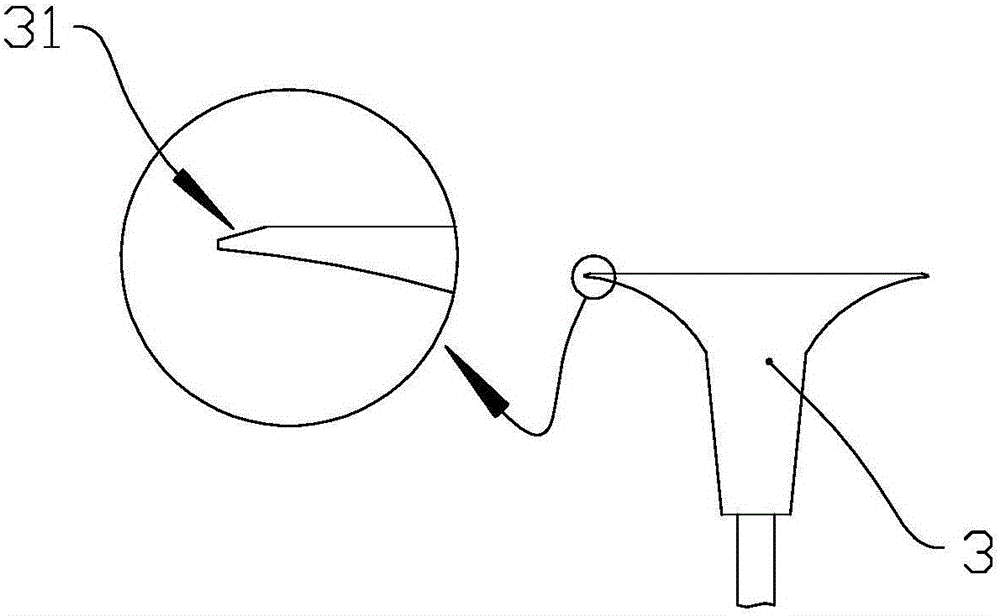

Medical wall system, surgical article management method and device, server and medium

InactiveCN109184279AImprove supply efficiencyFaster turnaroundWallsHospitalsSurgery schedulingEngineering

The invention discloses an operating room medical wall system. An operating room medical wall is arranged by using a space between an operating room and a clean passage, a locker is arranged on the medical wall to store surgical articles, the locker has first openings facing the clean passage and second openings facing the inside of the operating room. Warehouse management personnel can supply thesurgical articles to the operating room during the use of the operating room and is no longer limited by the operation time. The invention also discloses a surgical article management method and device, a server and a storage medium, the warehouse management personnel is notified to supply according to surgical article inventory information in the locker and operation plan information. Accordingto the operating room medical wall system and the surgical article management method provided by the invention, the supply efficiency of the surgical articles can be effectively improved, the turnoverof the operating room is accelerated, and the workload of the warehouse management personnel is reduced.

Owner:WUHAN LEIRUAN TECH

Cable coil integral discharging, delivering and transferring line

ActiveCN105151642AReduce the number of manpowerReduce labor intensityConveyorsVertical planeEngineering

A cable coil integral discharging, delivering and transferring line comprises a first conveying belt, a guide unit, a transition supporting platform and a second conveying belt. The guide unit comprises driving slide seats and guide arms. The driving slide seats and the guide arms are arranged at the front side and the rear side of the first conveying belt respectively after being connected, so that the lower end face of each guide arm is located at the upper end of the first conveying belt. Each driving slide seat is matched with a rack through a guide rail. Each guide arm is in a strip-plate shape, and the end face, corresponding to each guide arm, of the guide arms is a vertical plane after assembly. The left end of each vertical plane is closed up gradually from the left end to the right end to form an arc surface, and the right end of each arc surface is tangent to the corresponding vertical plane. The first conveying belt is in butt joint with the second conveying belt, and the transition supporting platform is arranged between the first conveying belt and the second conveying belt. The upper end plane of the transition supporting platform is flush with the upper end face of the right end of the first conveying belt, and the left end and the right end of the transition supporting platform are each provided with a slope which inclines inwards from the outer side. By means of the cable coil integral discharging, delivering and transferring line, the quantity of labors required in the discharging and transferring process of cables is reduced in the cable supplying process, the labor intensity of workers is reduced, and the delivering efficiency is improved.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

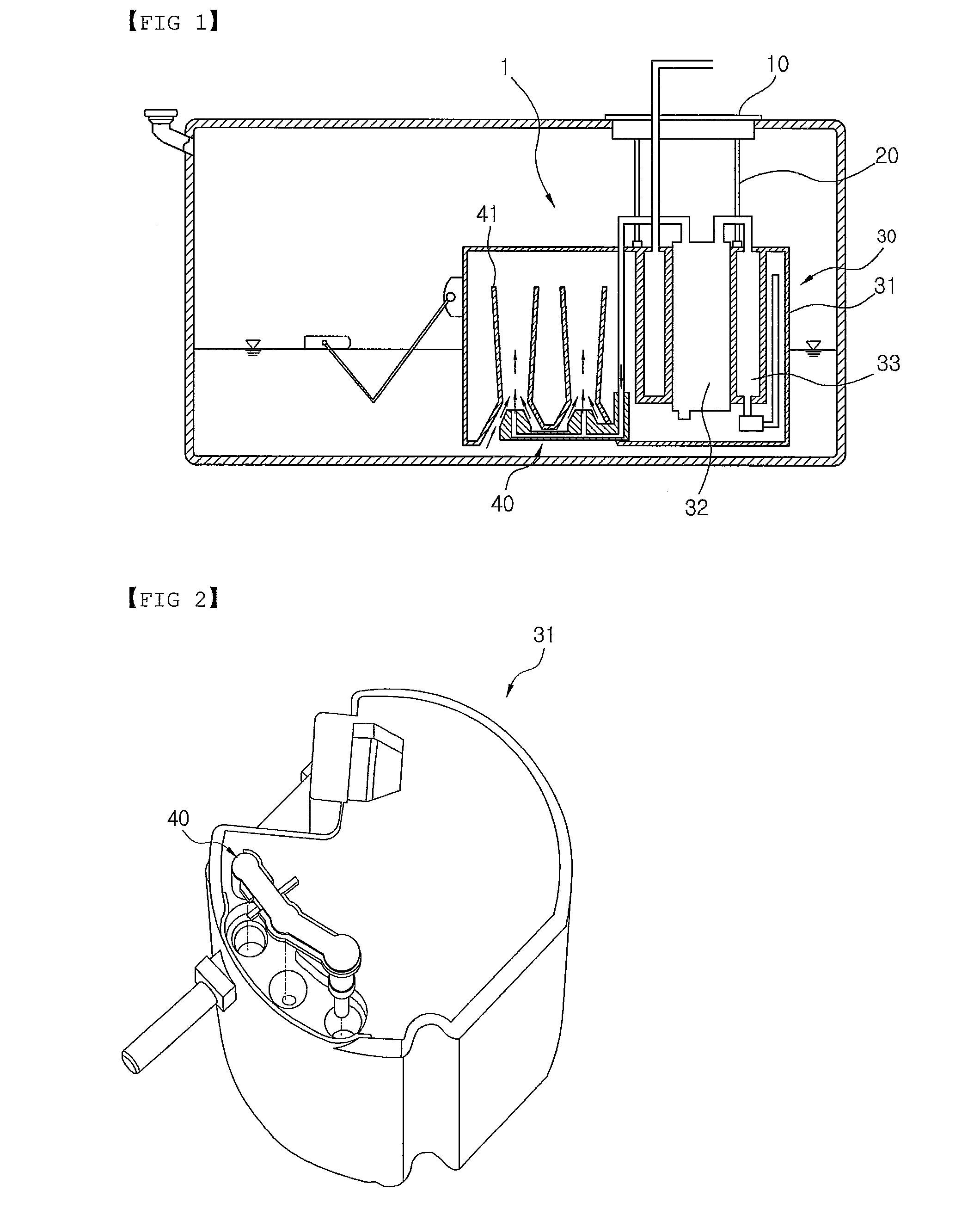

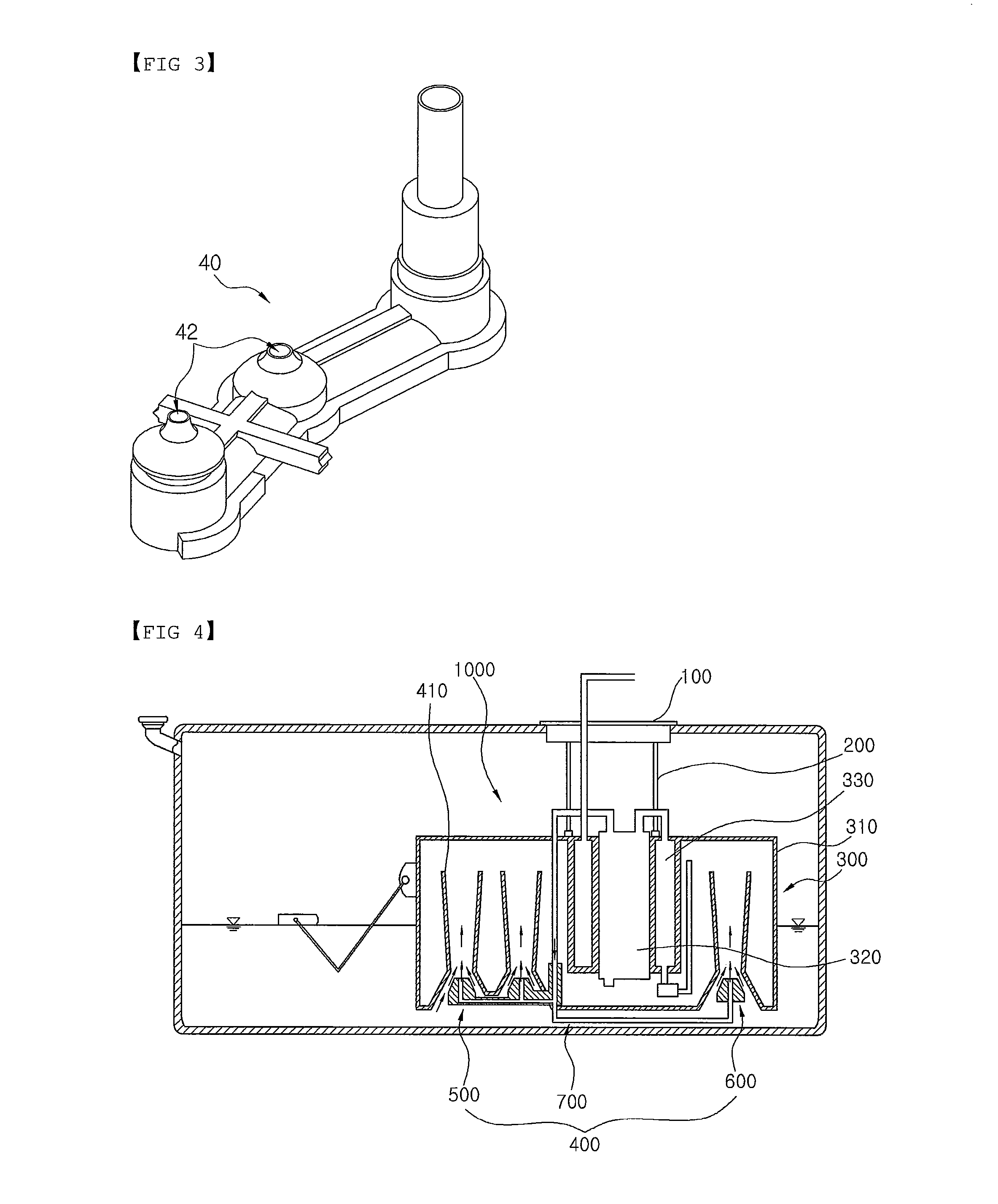

Dual Jet System

InactiveUS20110250079A1Improve supply efficiencyPreventing engine hesitationJet pumpsMachines/enginesFuel tankSteep slope

Provided is a dual jet system mounted at a bottom end of a reservoir in a fuel pump module, and more particularly, to a fuel pump module mounted with a dual jet system capable of preventing a phenomenon that fuel is not smoothly filled in a reservoir due to fuel inclined to one side caused by an inclination of a fuel tank when a vehicle travels a steep slope section by mounting two jet pumps at both edges of a bottom end of a reservoir.

Owner:COAVIS

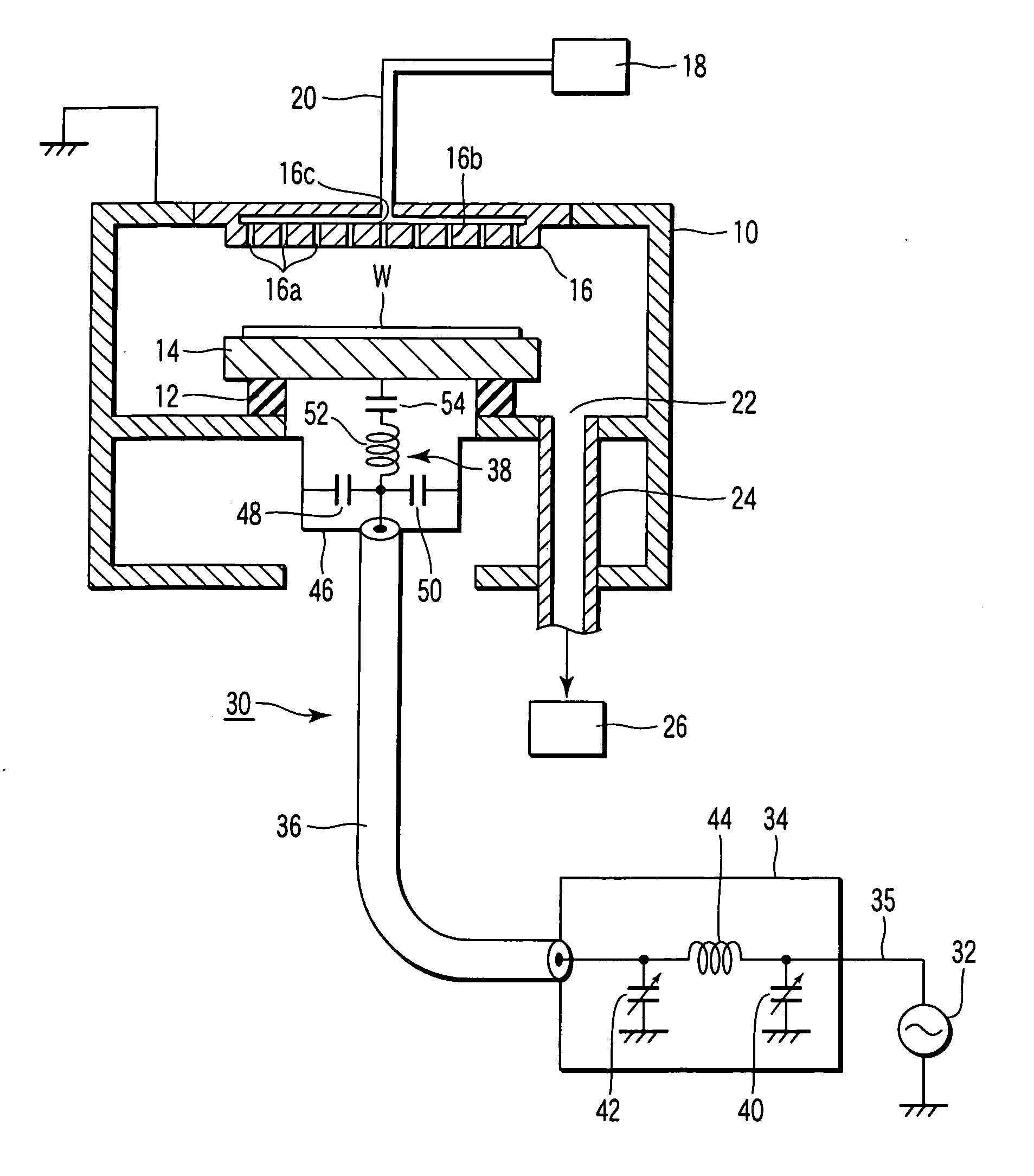

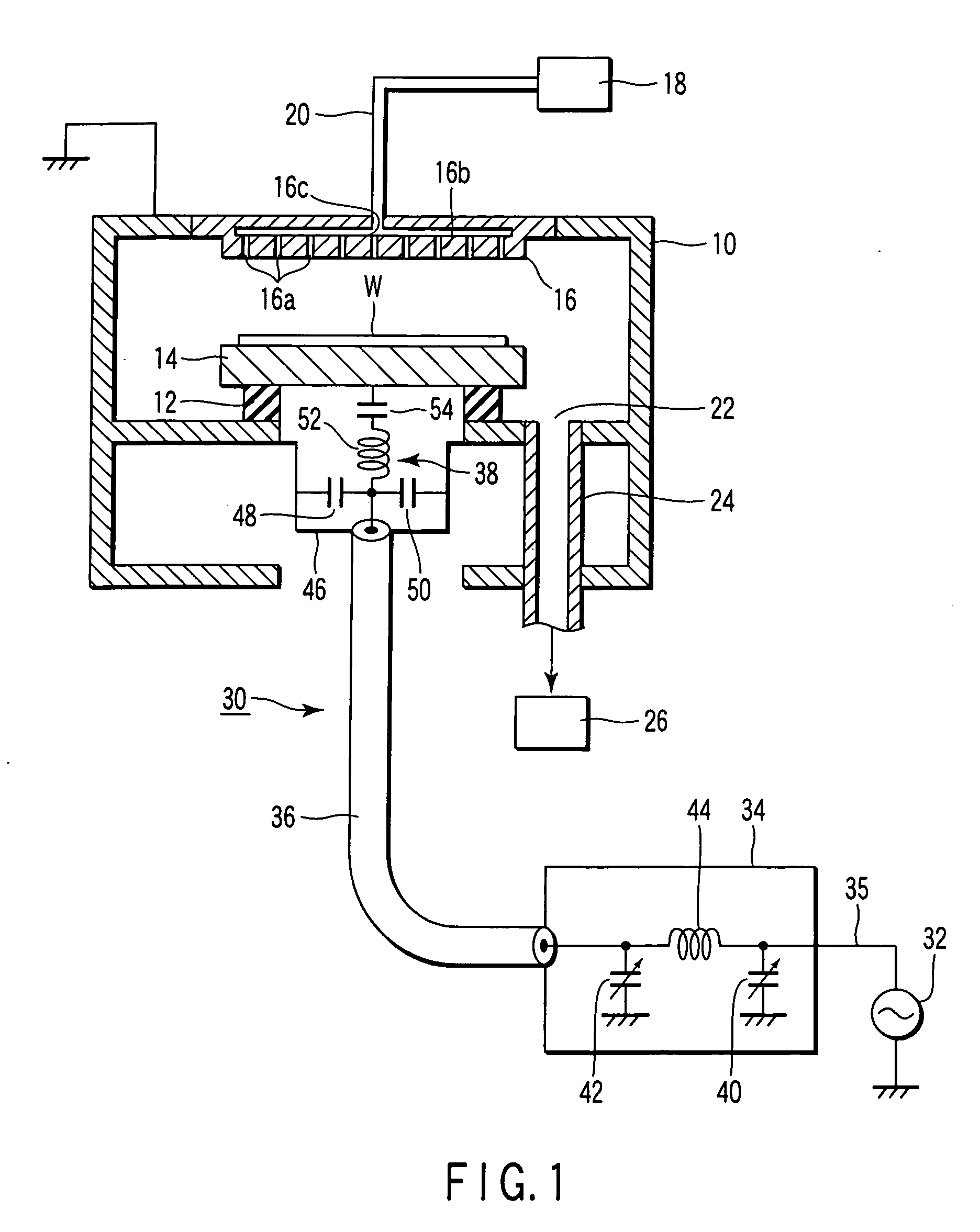

RF supply system and plasma processing apparatus

ActiveUS20060090854A1Low heat generationReduce transmission lossElectric discharge tubesSemiconductor/solid-state device manufacturingImpedance ConverterThrough transmission

An RF supply system is to be connected to an RF electrode disposed outside or inside a process chamber to assist a plasma process performed in the process chamber. This system includes an RF power supply, a matching unit, and an impedance converter. The RF power supply is configured to supply an RF power for plasma generation to the electrode through a transmission path. The matching unit is disposed on the transmission path between the RF power supply and the electrode, and configured to match a load impedance viewing from the RF power supply with an impedance of the RF power supply side. The impedance converter is disposed on the transmission path between the matching unit and the electrode, and configured to convert a load impedance viewing from the matching unit to an impedance higher than an actual impedance on the electrode side.

Owner:TOKYO ELECTRON LTD

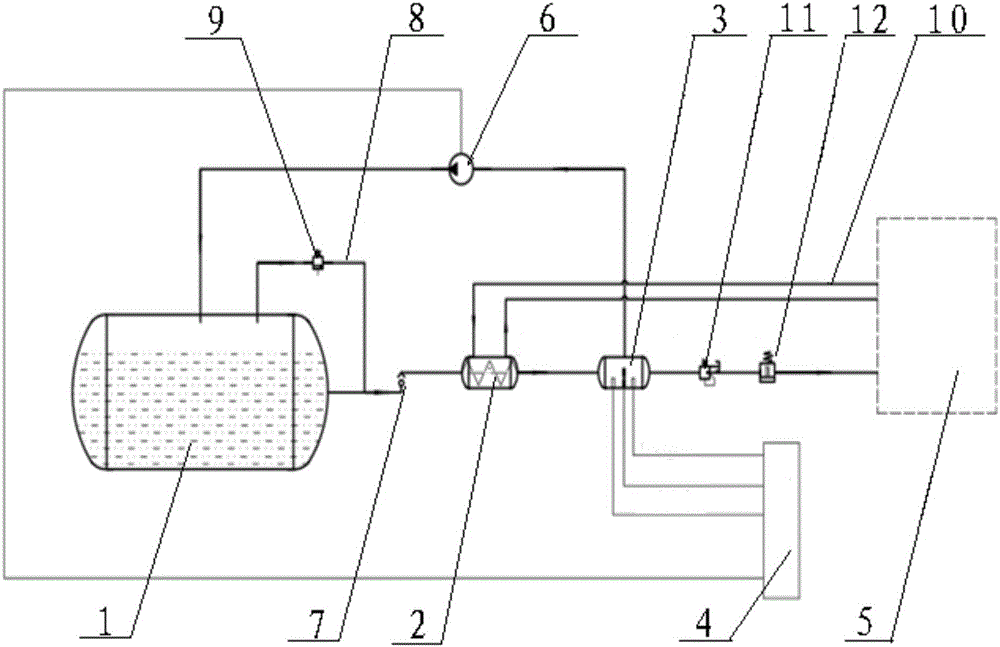

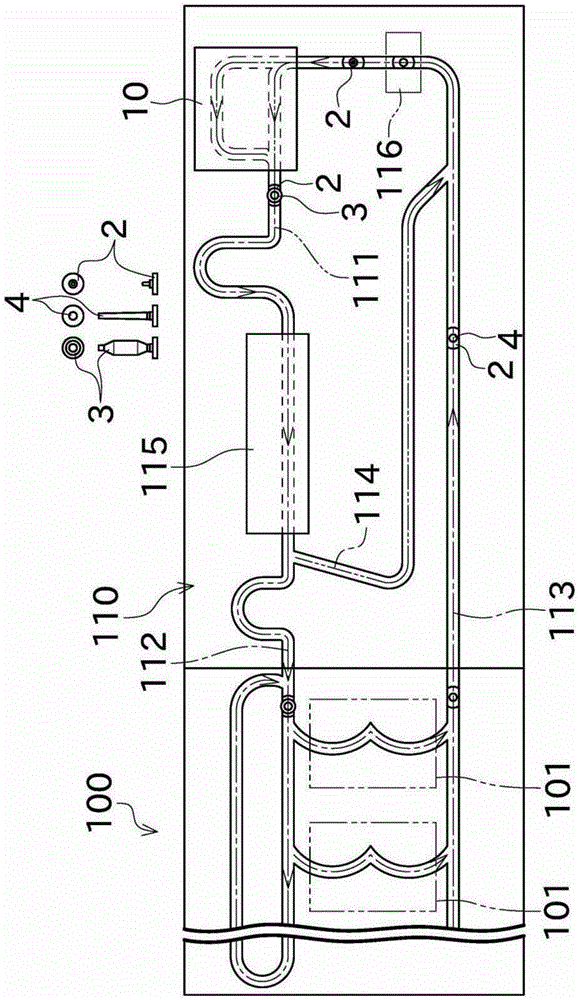

LNG (Liquefied Natural Gas) vehicle-mounted gas cylinder supercharging system

InactiveCN105673258AImprove the safety of useStable jobInternal combustion piston enginesFuel supply apparatusElectricityGas cylinder

The invention discloses an LNG (Liquefied Natural Gas) vehicle-mounted gas cylinder supercharging system. The LNG vehicle-mounted gas cylinder supercharging system comprises a gas cylinder, a vaporizer, a buffer tank and a controller. The LNG vehicle-mounted gas cylinder supercharging system is characterized in that one end of the vaporizer is connected to the gas cylinder via a pipeline; the mounting height of the vaporizer is lower than the lowest liquid level of the gas cylinder; the other end of the vaporizer is connected to the buffer tank; one output of the buffer tank is connected to an engine and the other output of the buffer tank is connected to the gas cylinder via a circulating pump; a temperature sensor, an electric heater and a pressure sensor are arranged in the buffer tank and are connected with the controller via a circuit; meanwhile the controller is connected with the circulating pump to control the working state of the circulating pump. The LNG vehicle-mounted gas cylinder supercharging system disclosed by the invention is not affected by any use condition and environment temperature, the pressure is stably controlled, the stable working of the engine is guaranteed, meanwhile the fuel waste is reduced, the environmental protection is improved and the use safety is enhanced.

Owner:任焕轩

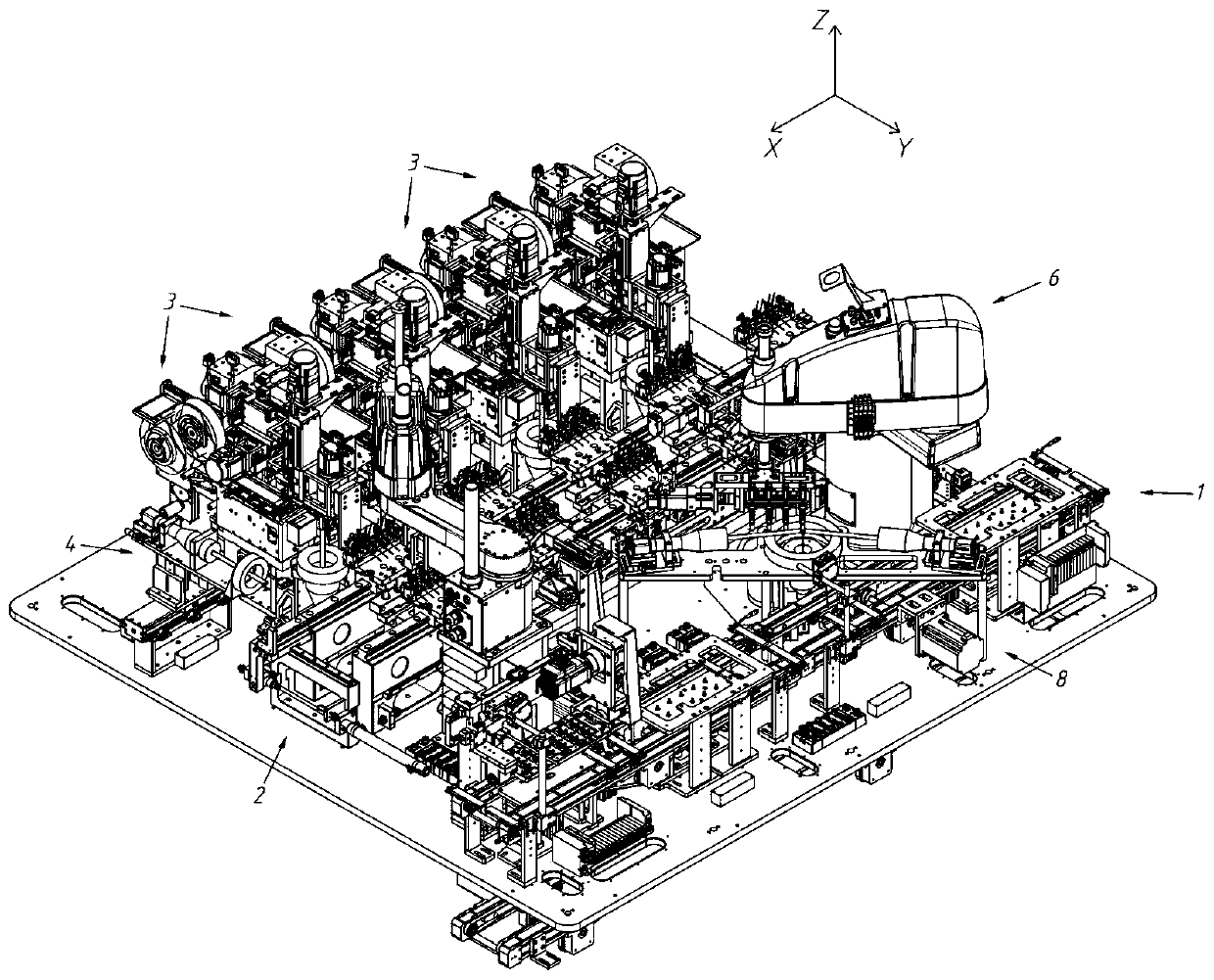

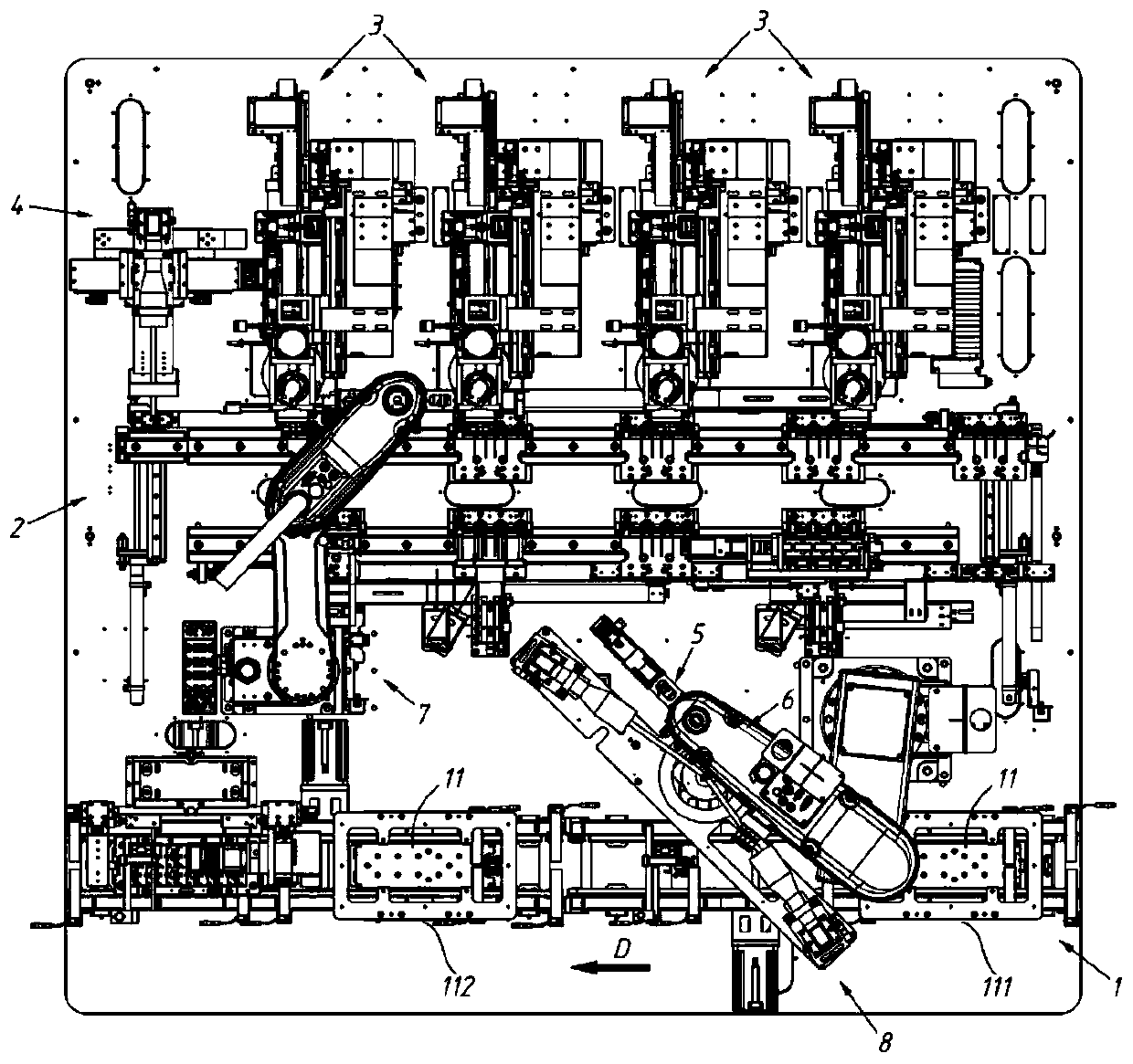

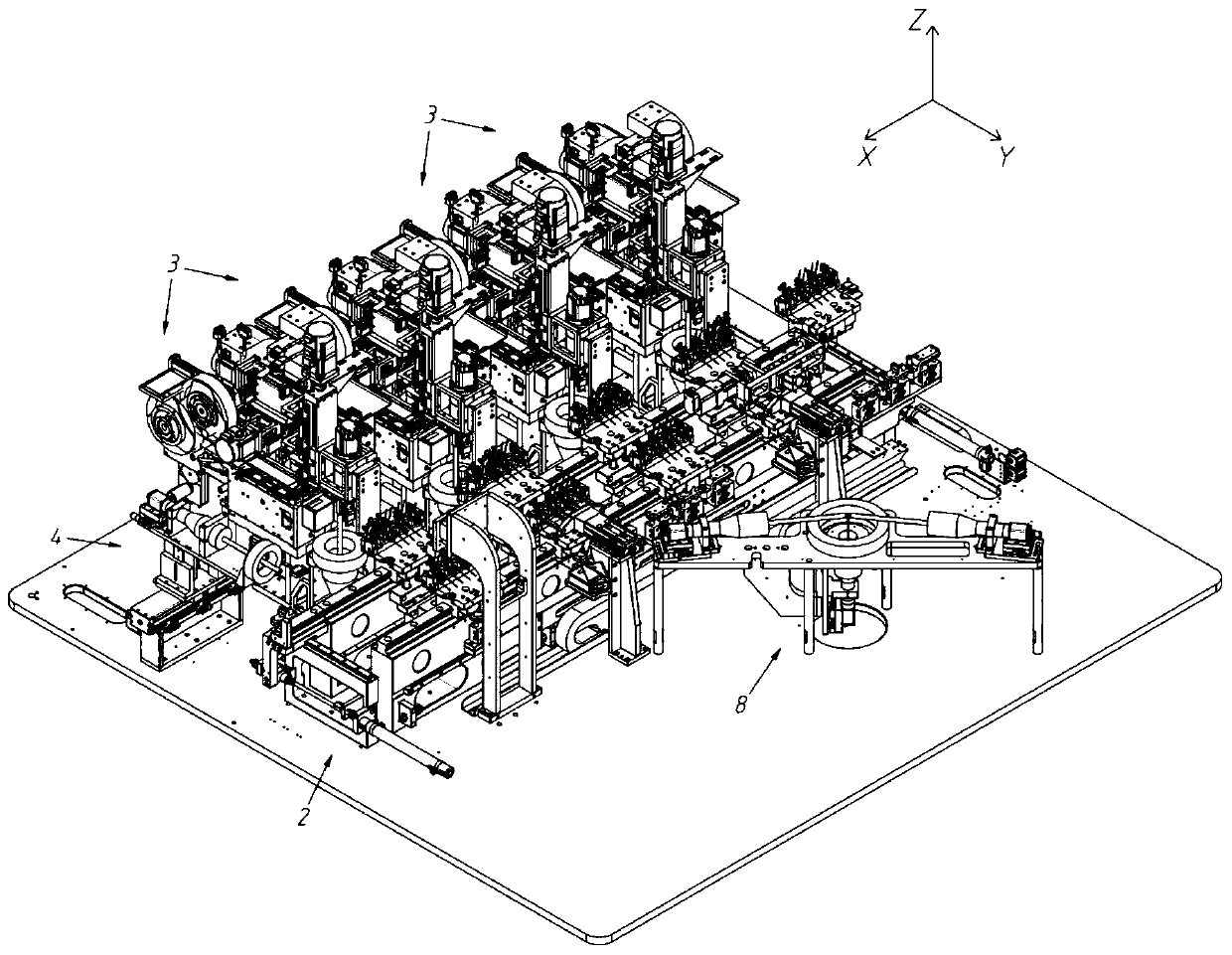

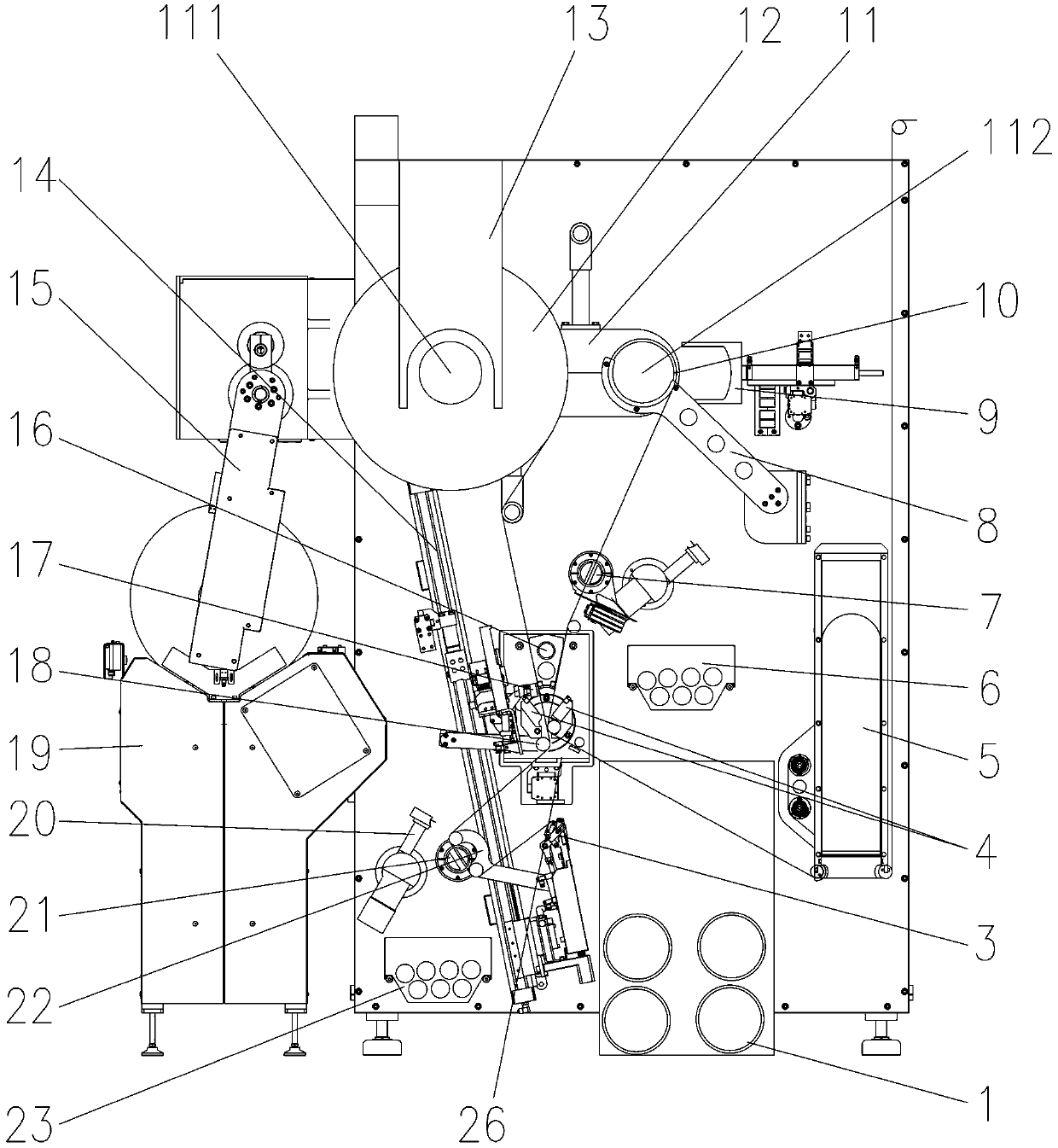

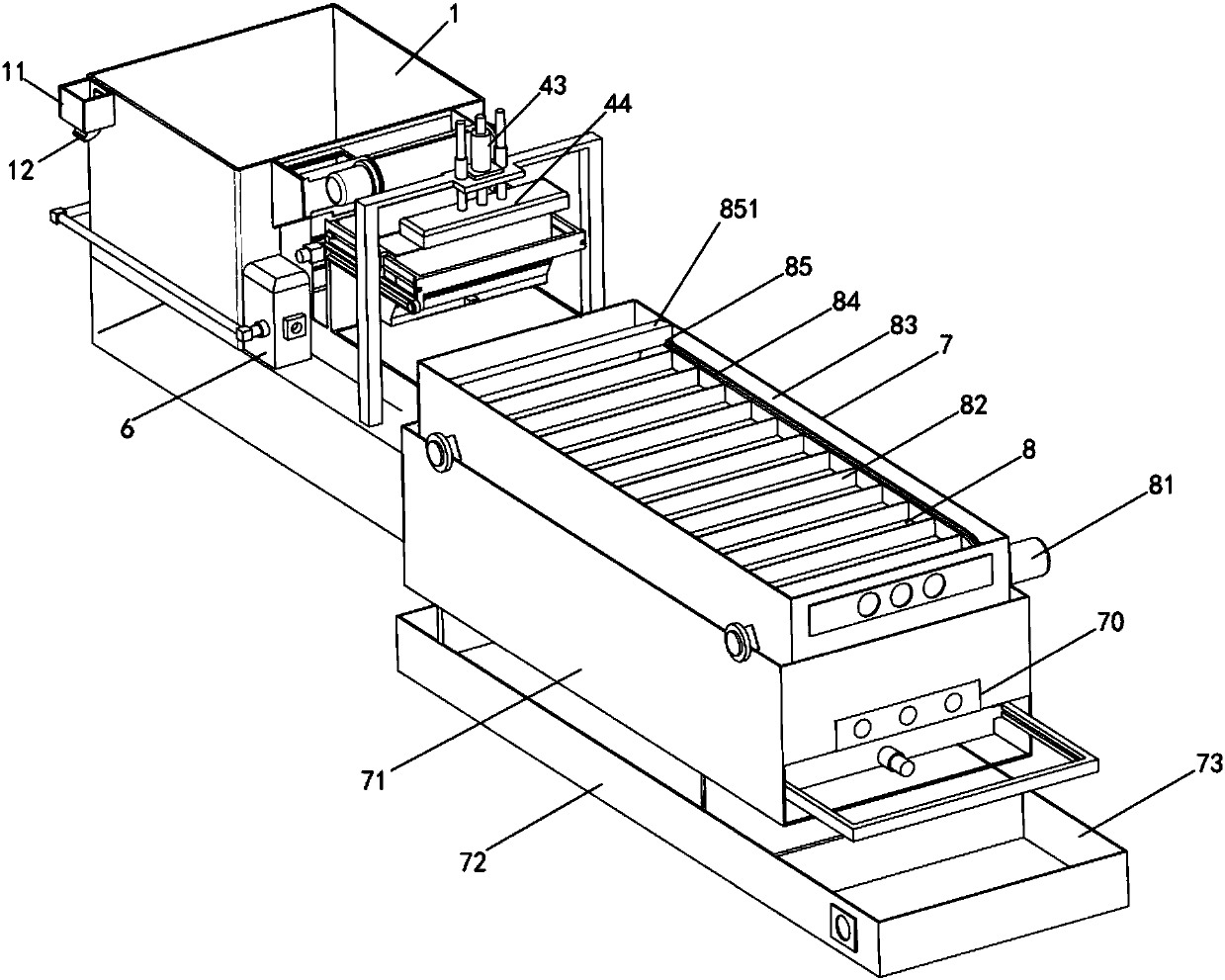

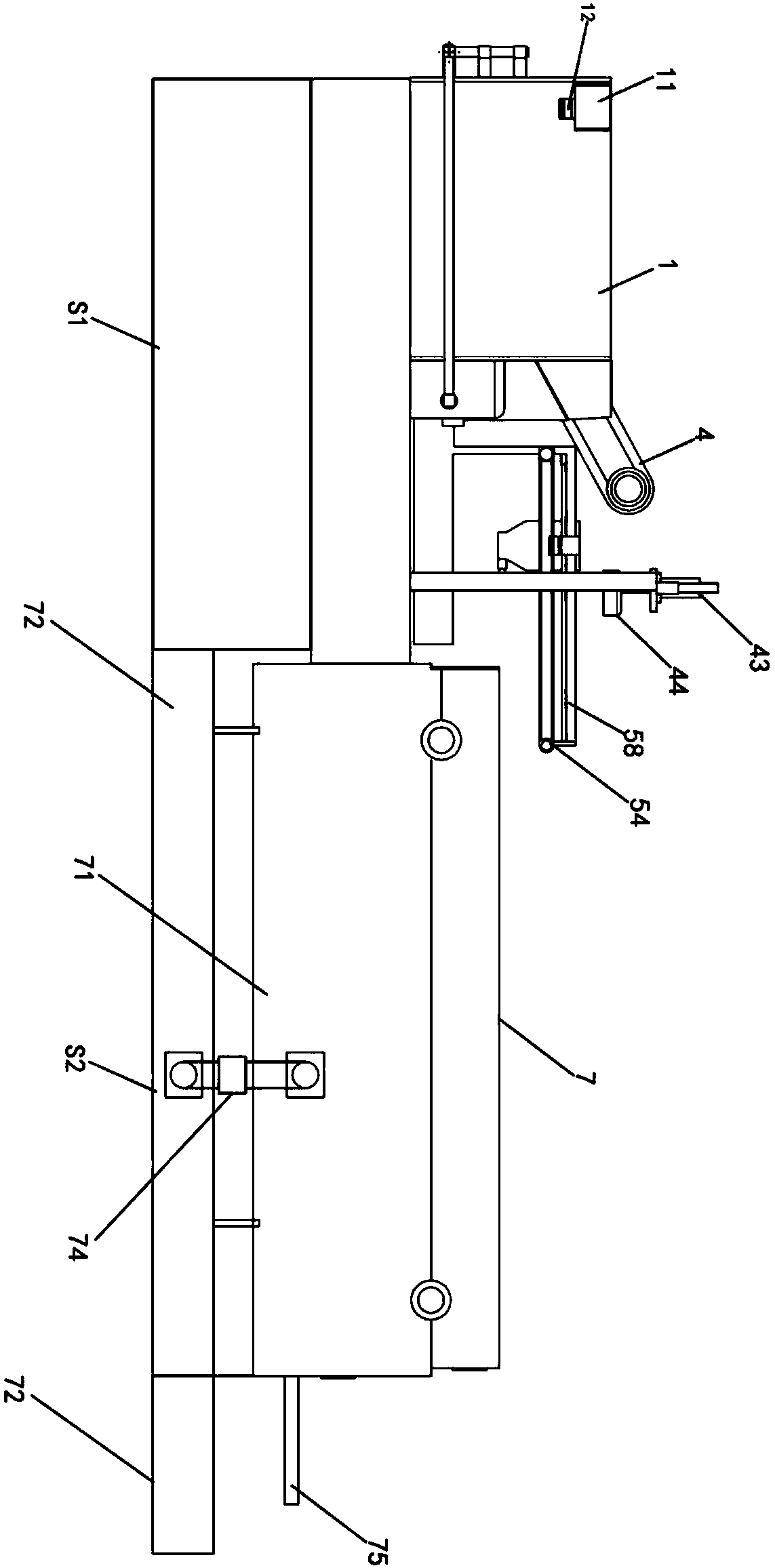

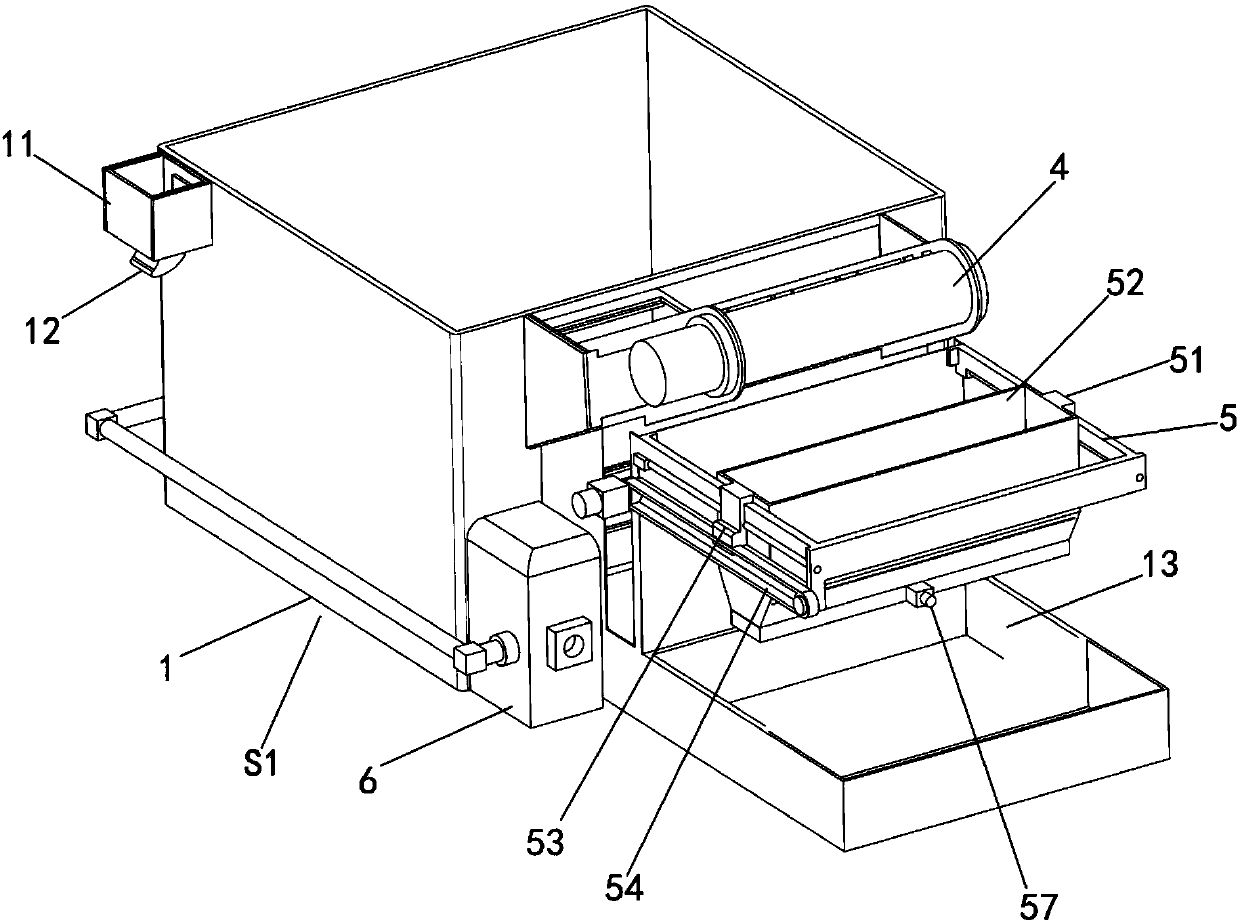

Full-automatic assembly line integrating feeding, positioning, film pasting and discharging

ActiveCN111115189AShorten the transmission strokeImprove film application efficiencyFinal product manufactureConveyor partsRobot handThin membrane

The invention discloses a full-automatic assembly line integrating feeding, positioning, film pasting and discharging. The full-automatic assembly line comprises a feeding assembly line, a film pasting assembly line, a feeding mechanical arm, a discharging mechanical arm and a visual positioning mechanism, wherein the film pasting assembly line is opposite to the feeding assembly line, the film pasting assembly line and the feeding assembly line are arranged at an interval to form a transferring space between the film pasting assembly line and the feeding assembly line; and the feeding mechanical arm, the discharging mechanical arm and the visual positioning mechanism are arranged in the transferring space. According to the full-automatic film sticking machine, material supply, positioning, feeding, thin film supply, film pasting and stacking operation are integrated on a unified assembly line for rhythmic and ordered operation through high-integration-degree design thinking, so that the transferring stroke of transferring materials back and forth among a plurality of assembly lines is greatly shortened, time waste caused in the transferring process is greatly reduced, the automation degree and the film and material supplying and stacking efficiency are remarkably improved, and the film pasting efficiency of the assembly line is greatly improved.

Owner:SUZHOU RS TECH

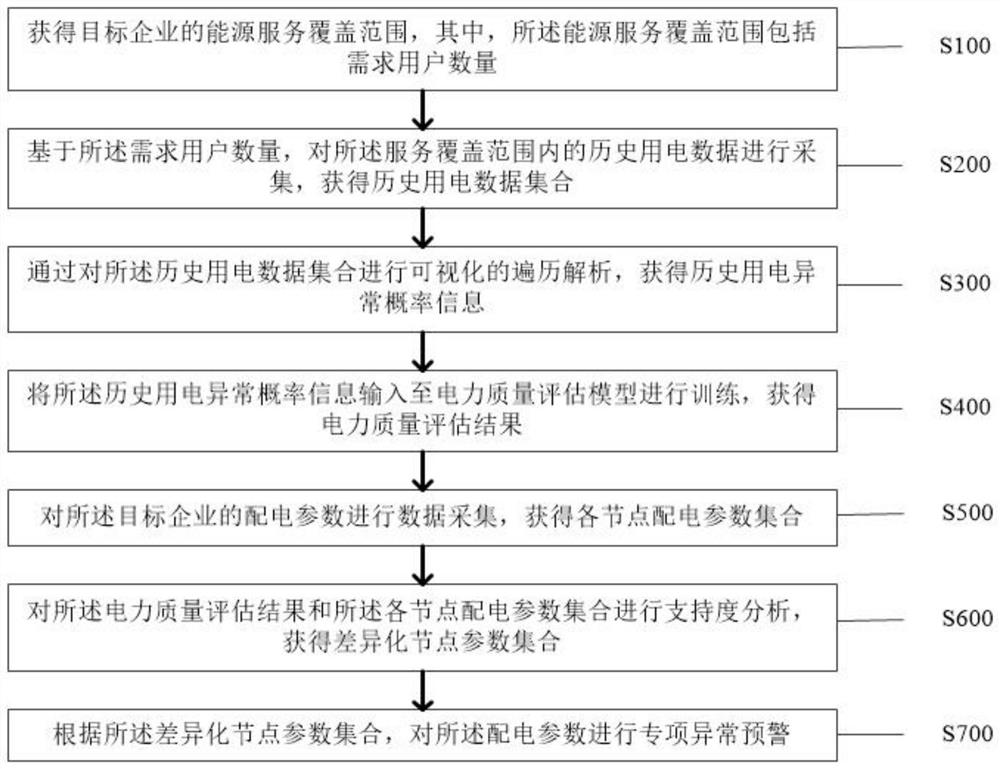

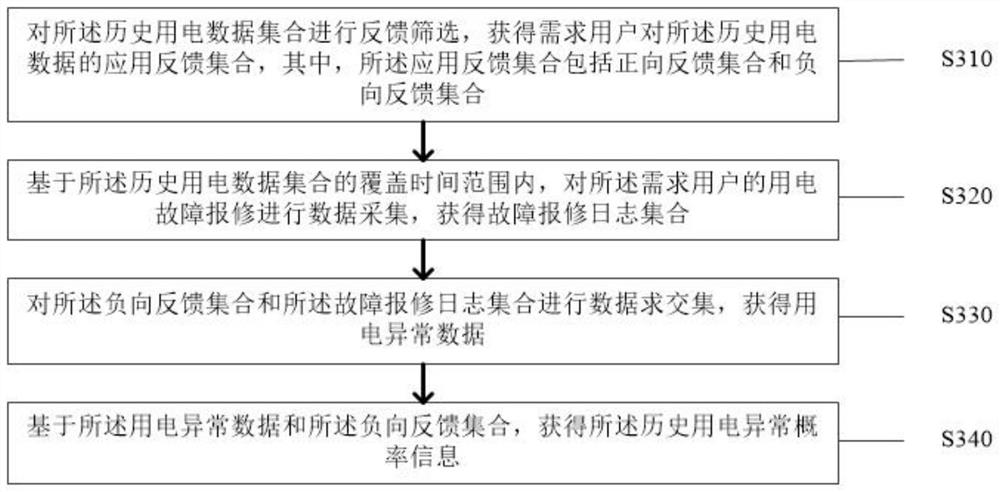

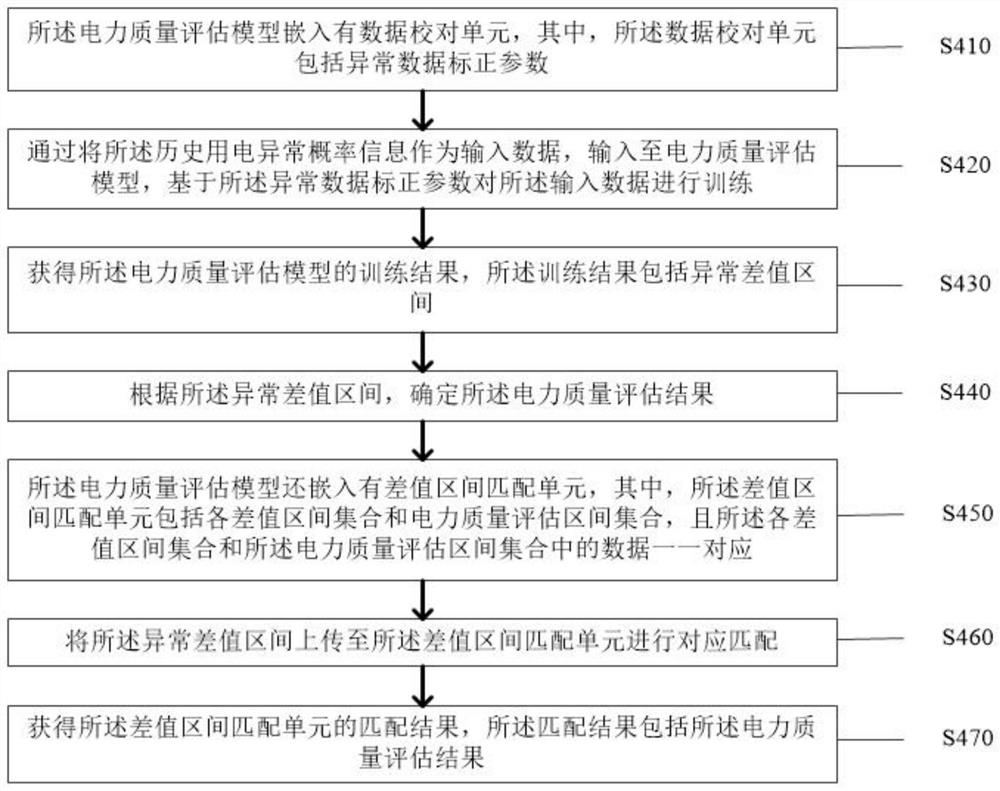

Abnormity early warning method and system based on distributed energy management

The invention discloses an abnormity early warning method and system based on distributed energy management. The method comprises the steps of obtaining an energy service coverage range of a target enterprise; on the basis of the number of required users, historical power consumption data in the service coverage area is collected, and a historical power consumption data set is obtained; performing visual traversal analysis on the historical electricity consumption data set to obtain historical electricity consumption abnormal probability information; inputting the historical power utilization abnormal probability information into a power quality evaluation model for training to obtain a power quality evaluation result; performing data acquisition on the power distribution parameters of the target enterprise to obtain a power distribution parameter set of each node; performing support degree analysis on the power quality evaluation result and the power distribution parameter set of each node to obtain a differentiated node parameter set; and performing special abnormality early warning on the power distribution parameters according to the differentiated node parameter set.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD NANTONG POWER SUPPLY BRANCH

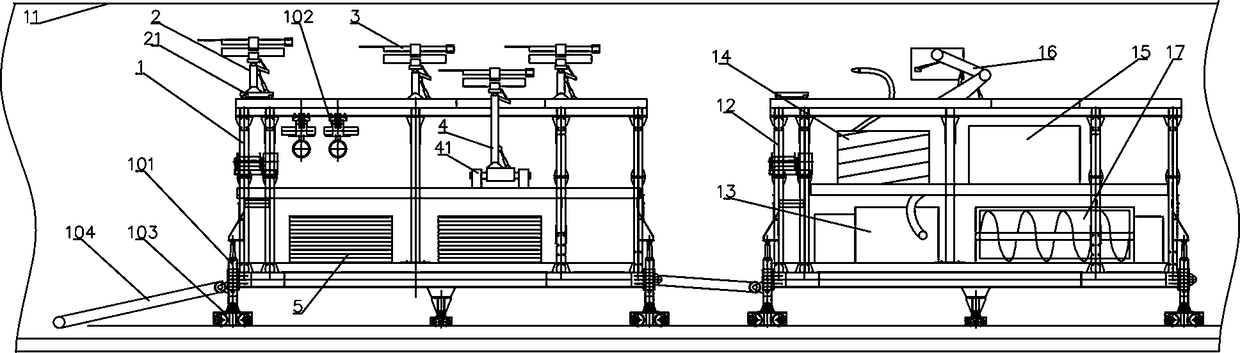

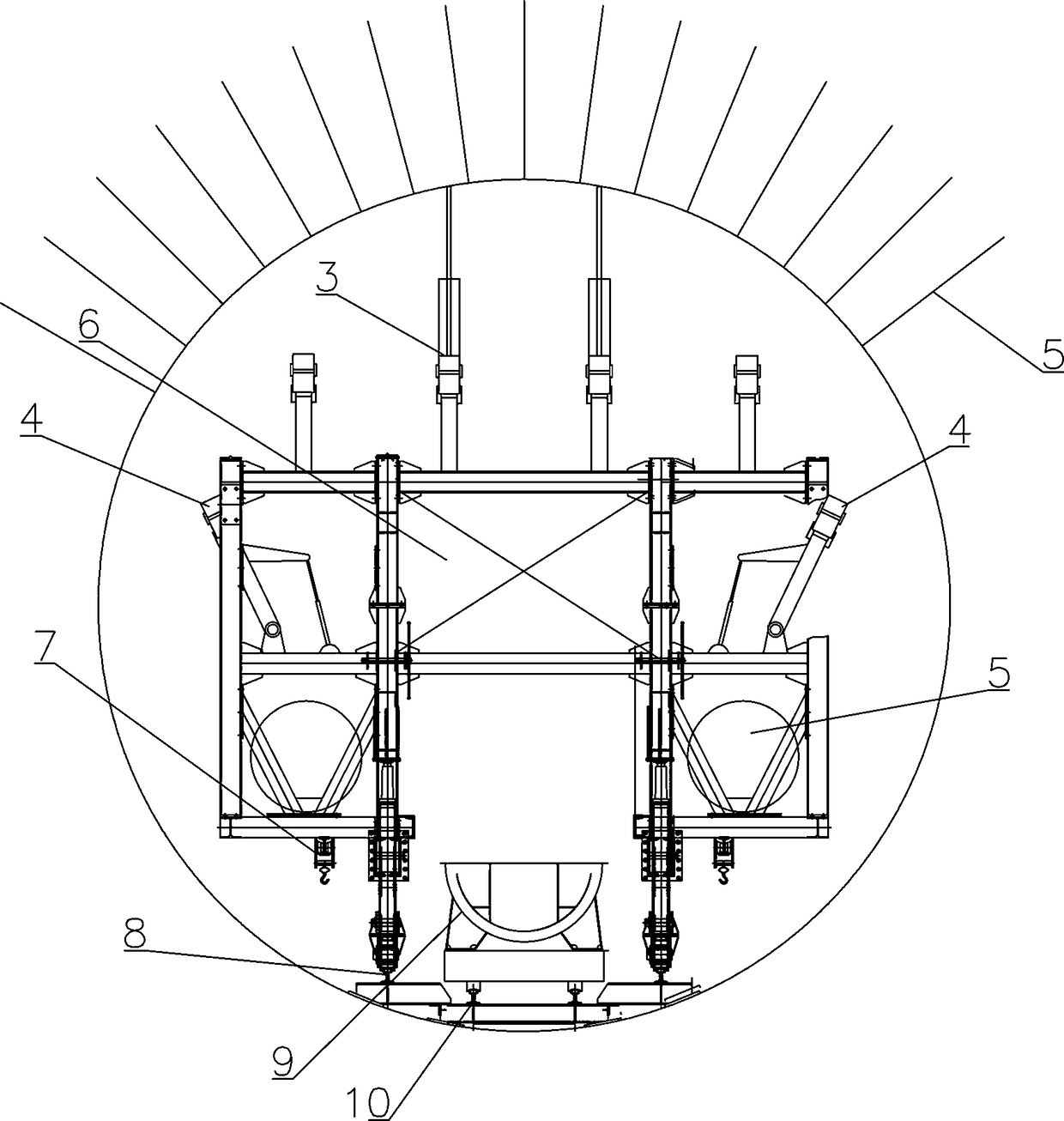

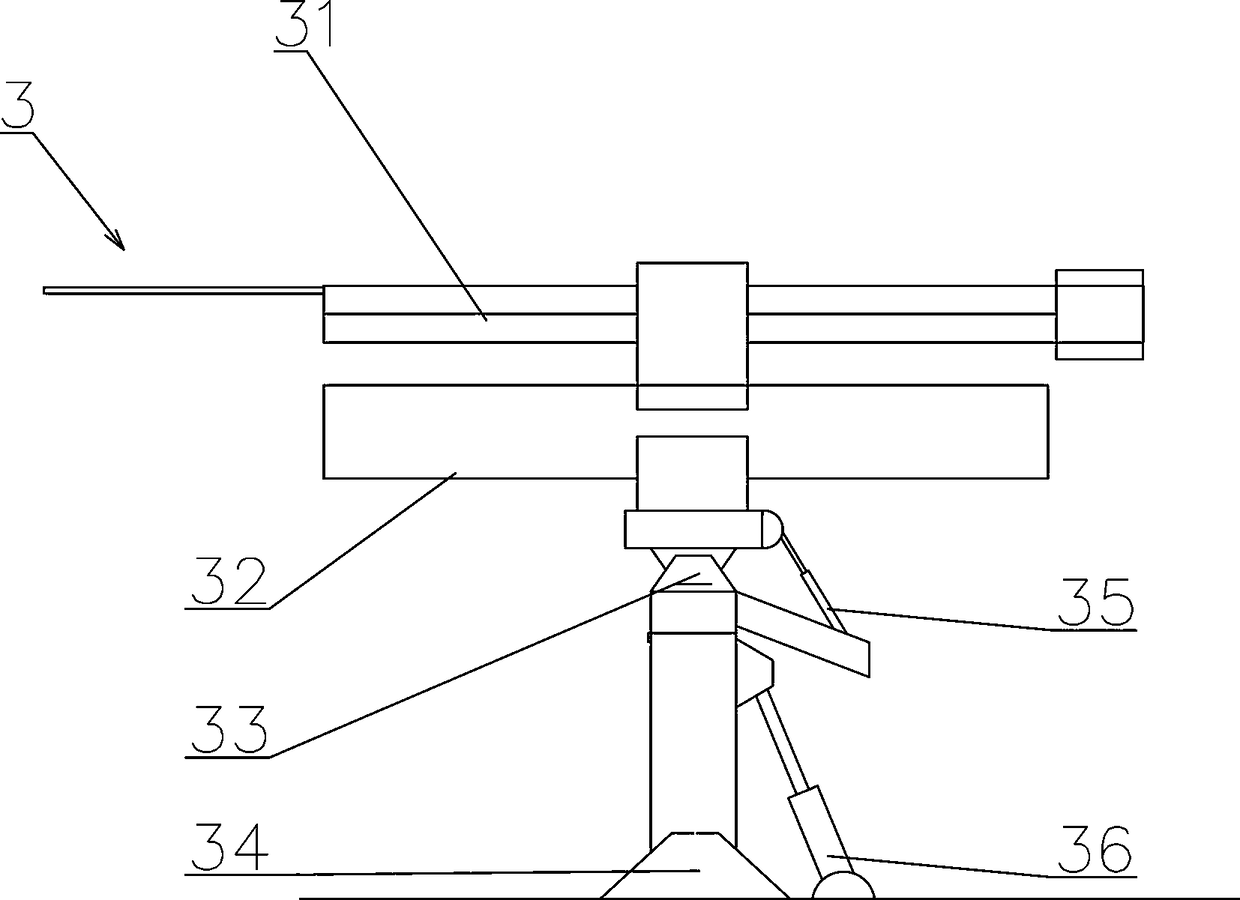

Tunnel anchor rod grouting construction trolley

PendingCN108756972ADrilling a single hole cost-effectiveImprove supply efficiencyAnchoring boltsArchitectural engineeringDrilling machines

The invention provides a tunnel anchor rod grouting construction trolley which comprises a trolley frame, wherein a plurality of anchor rod drilling machines are arranged on the trolley frame. The anchor rod drilling machines at least comprise mechanical arms each with two joints, and drilling mechanisms are mounted at the top ends of the mechanical arms. The anchor rod drilling machines compriseone or more of a horizontal moving type anchor rod drilling machine, a fixed type anchor rod drilling machine and a swing type anchor rod drilling machines. The tunnel anchor rod grouting constructiontrolley is further provided with a grouting trolley which is connected with the trolley frame. A stirring tank is arranged on the grouting trolley and connected with a grouting pump, wherein the grouting pump is connected with a grouting pipe. The multiple anchor rod drilling machines are arranged on one trolley frame, and the multiple anchor rod drilling machines can carry out construction at the same time, so that the efficiency of construction is greatly improved. Matched grouting construction can be realized through the arrangement of the grouting trolley, and the efficiency of the integral construction is greatly improved.

Owner:呼和浩特市市政工程技术服务中心

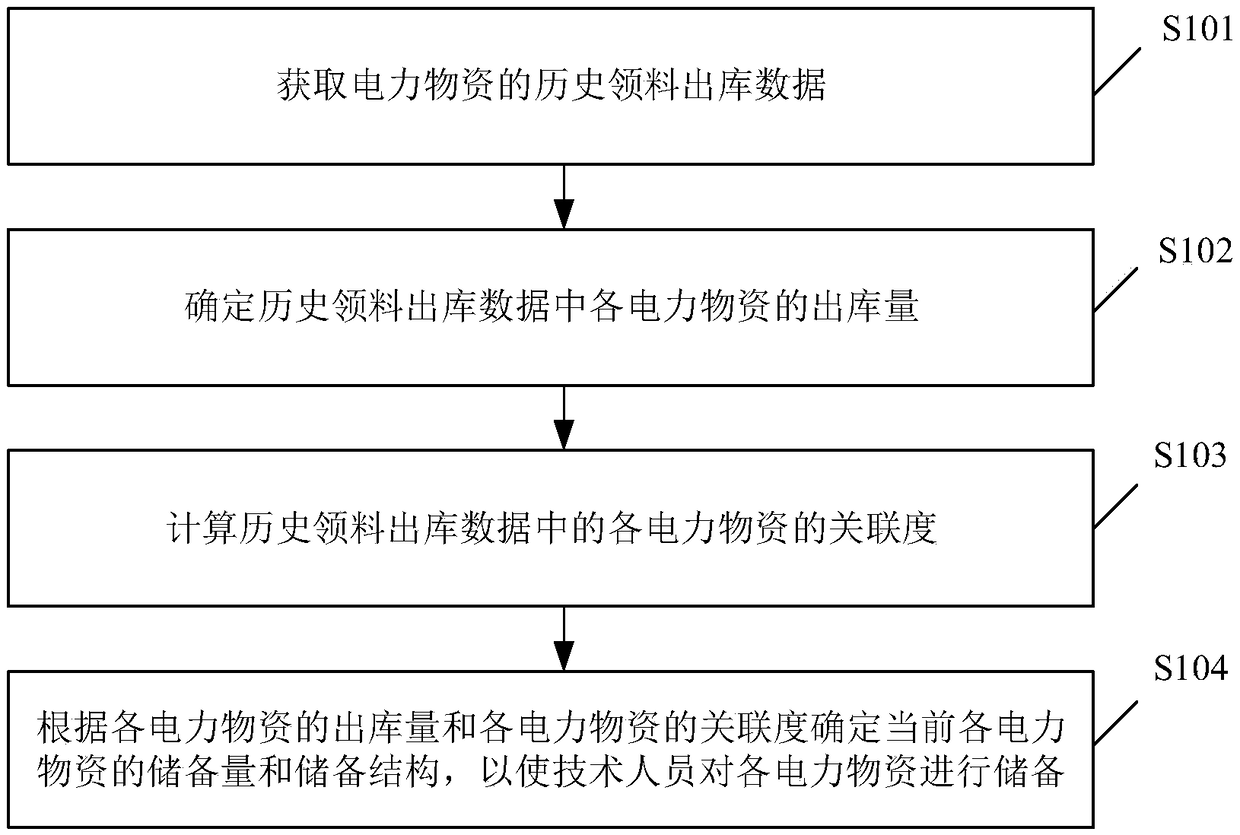

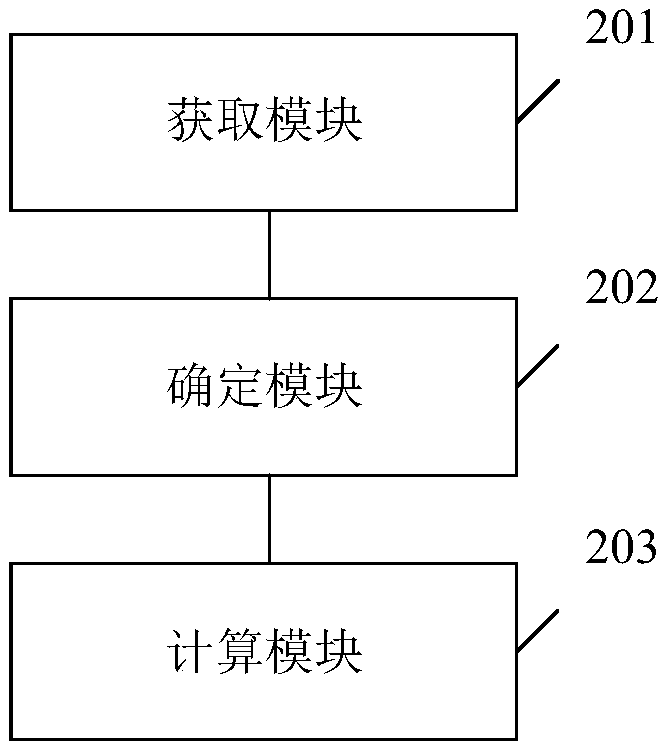

Method and device for storing electric power materials, apparatus and storage medium

The invention discloses a storage method for electric power material. The method comprises the steps of first acquiring the historical picking and warehousing data of the electric power materials, andthen determining the discharge quantity of each electric power material in the historical picking and outputting data; secondly, the correlation degree of each electric power material in the historical picking and outputting data is calculated, and finally, the reserve quantity and reserve structure of each electric power material are determined according to the correlation degree of each electric power material and the outputting quantity of each electric power material, so that the technicians can reserve each electric power material. Considering the relevance of each electric power material, the storage structure of electric power material determined according to the relevance degree is more reasonable (the related electric power material is stored in the same area), and the electric power material associated with a certain electric power material need not be searched from other areas, which improves the supply efficiency of electric power material. In addition, the invention alsodiscloses a storage device, an apparatus and a storage medium for electric power materials, and the effect is as above.

Owner:GUANGDONG POWER GRID CO LTD +1

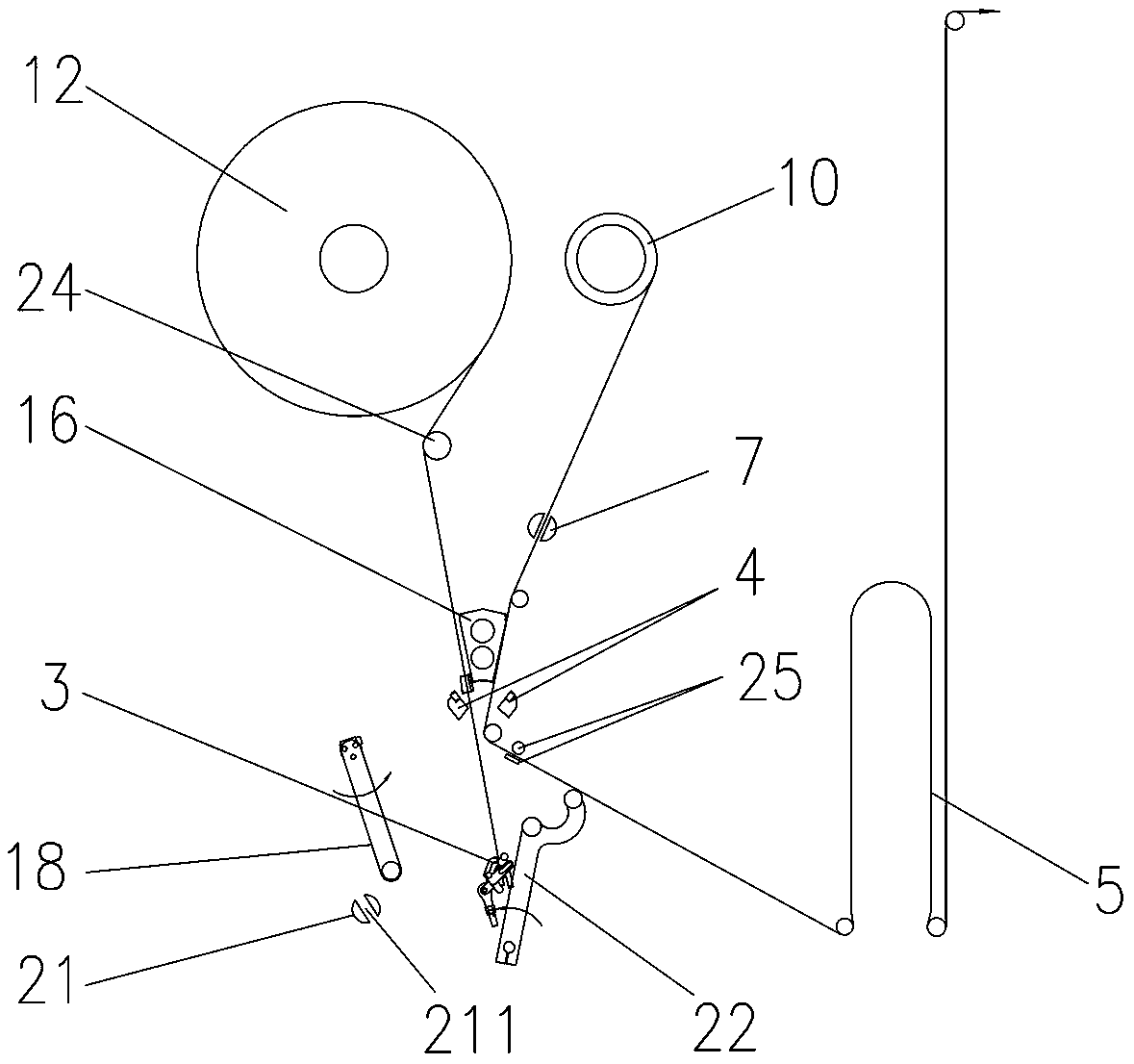

Whole-roll paper reel feeding device of packing machine

ActiveCN107804729ARealize non-stop replacementHighlight substantive featuresWebs handlingBobbinRolling paper

The invention provides a whole-roll paper reel feeding device of a packing machine. The device comprises a paper roll rotary table and a bobbin paper splicing device, wherein a first paper roll is arranged on one end of the paper roll rotary table; a second paper roll is arranged on the other end of the paper roll rotary table; the first paper roll is driven by a first servo motor to rotate; the second paper roll is driven by a second servo motor to rotate; through the rotation of the paper roll rotary table, the first paper roll and the second paper roll can alternatively appear on a left paper roll position and a right paper roll position; the bobbin paper splicing device comprises a fixed cutting tool, a swinging cutting tool and a packaging tape frame. The whole-roll paper reel feedingdevice of the packing machine has the advantages of scientific design, high automation degree, high feeding efficiency, and low human cost.

Owner:XUCHANG TOBACCO MACHINERY

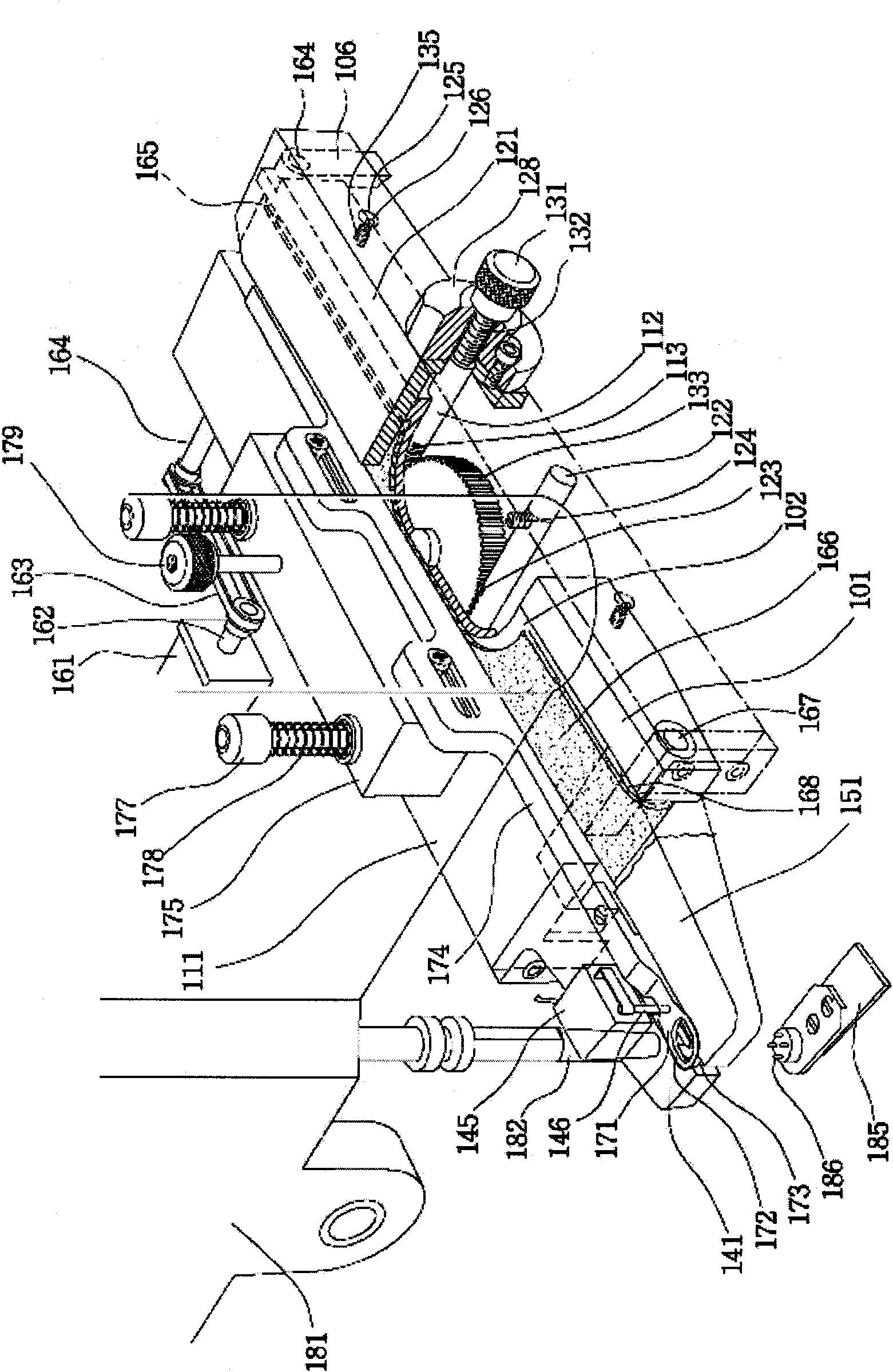

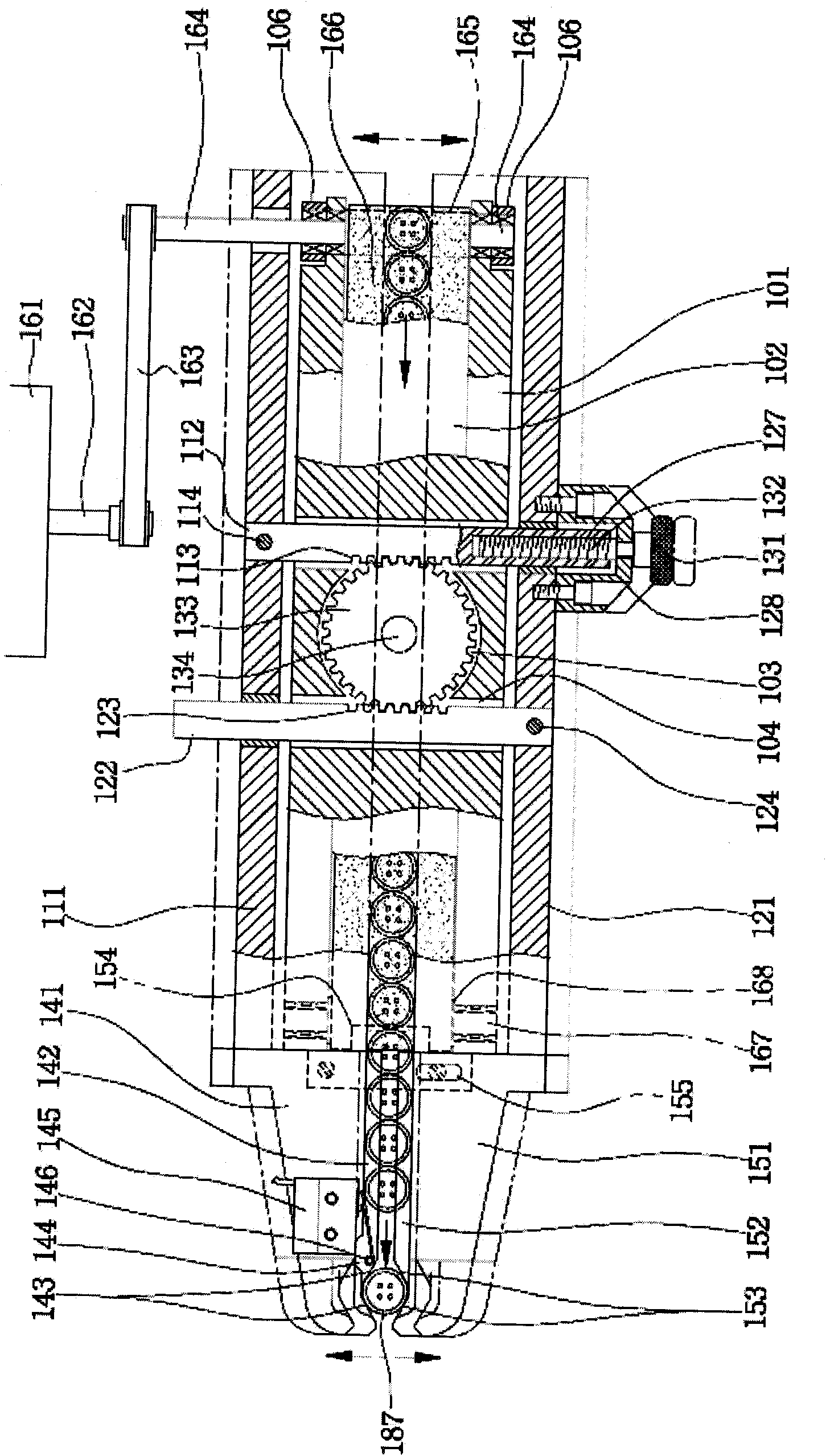

Button arrangement platform for automatic button feeder

ActiveCN101838889AImprove supply efficiencyTransmission is precise and fastSewing-machine elementsEngineeringConveyor belt

The present invention relates to a button arrangement platform for an automatic button feeder, which linearly conveys a conveyor belt which is combined with a guiding groove formed at the central part of a fixing member. Furthermore a distance adjustment mechanism is used for simultaneously adjusting the distance between two side adjustment platforms combined with two sides of the fixing member. After one side guiding surface formed at the end of one side supporting surface of one side supporting platform and the other side guiding surface formed at the end of the other side supporting surface of the other side supporting platform cause consistency of the center of button conveyed by the conveyor belt along two side supporting surfaces and the center of a rotating rubber member combined with the body, a limit switch which causes the contact of a second conveyed button and a movable sheet and detects the state is used for stopping the conveyor belt when the first button is supplied forthe guiding surface. After the contact between a pressing platform between two side adjustment platforms and the upper surface of the button, an elastic force application mechanism of the pressing platform is used for supporting the pressing platform. Furthermore a projection is formed at the lower side of the front end of a guiding sheet combined with the pressing platform. An insertion hole is formed on the upper surface of the guiding sheet for the insertion of the rotating rubber member of the body.

Owner:黄一燮

Automatic-cleaning machine and olive vegetable production process thereof

The invention relates to the field of development and design of precleaning machines for food processing, and especially relates to an automatic-cleaning machine and an olive vegetable production process thereof. The invention adopts a following technical scheme: the olive vegetable production process comprises the following steps: weighing the following raw materials in parts by weight: 0.5-2 parts of scallions, 1-3 parts of garlic, 4-10 parts of olives, 20-30 parts of edible oil, 8-15 parts of salt and 40-70 parts of mustard leaves; pickling the mustard leaves: adding salt to the thoroughlycleaned mustard leaves and putting the mustard leaves into a pickling tank or a pickling jar and conducting pickling for 7-10 days; cleaning impurities and cutting the mustard leaves: cleaning the mustard leaves after completion of pickling to remove impurities and cutting the mustard leaves; dewatering the mustard leaves: drying and dewatering the mustard leaves after cleaning of the impurities to obtain dewatered pickled mustard leaves; preparing scallion and garlic oil: frying thoroughly cleaned and drained scallions and garlic in the edible oil to obtain the scallion and garlic oil; and boiling the dewatered mustard leaves and the scallion and garlic oil for 3.5-6.5 hours to obtain the olive vegetable finished product. The automatic-cleaning machine and the olive vegetable production process thereof have the advantages: the production processes are simple and easy to operate, and the produced olive vegetable is more in line with the favor of people, unique in flavor and good in taste.

Owner:广东蓬盛味业有限公司

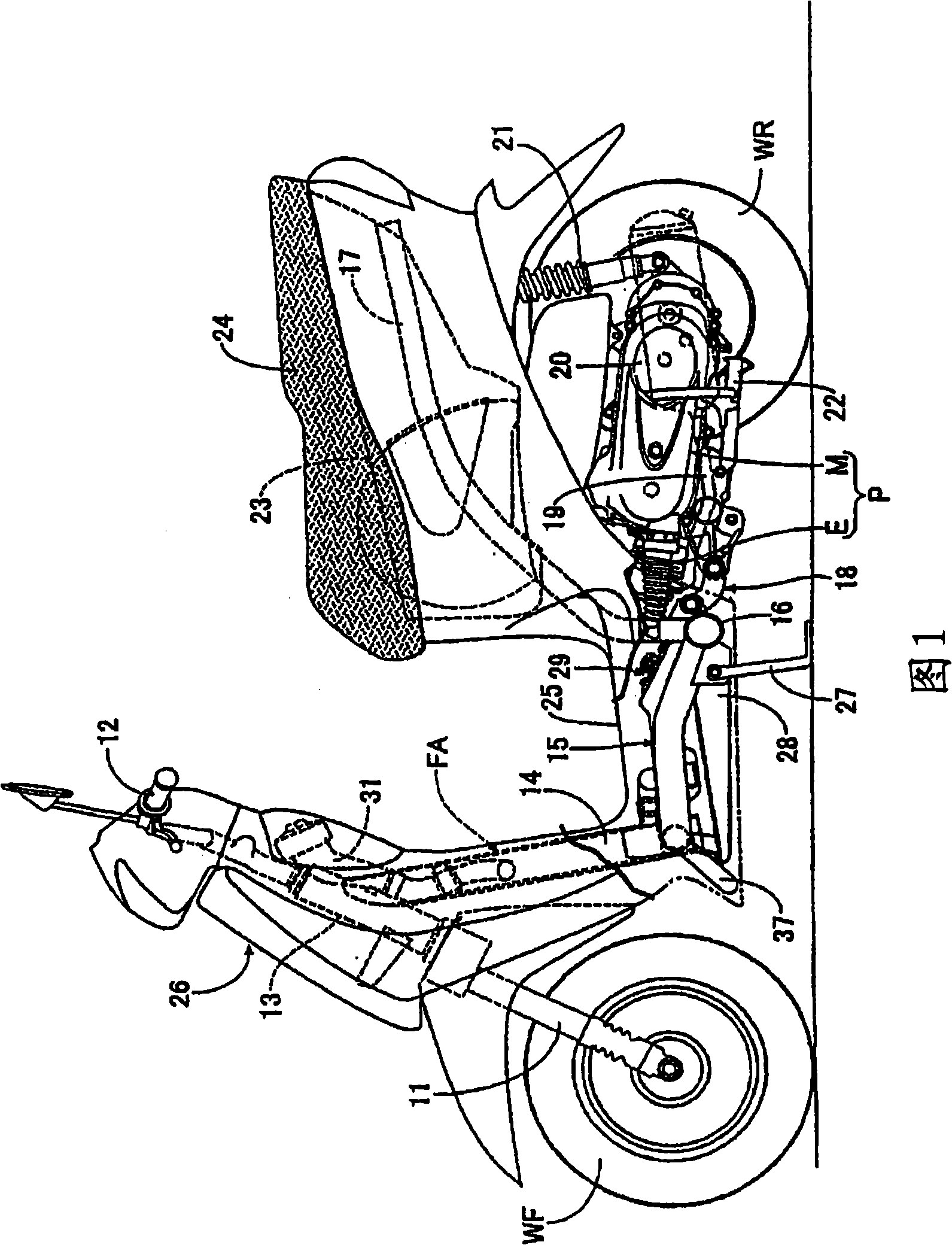

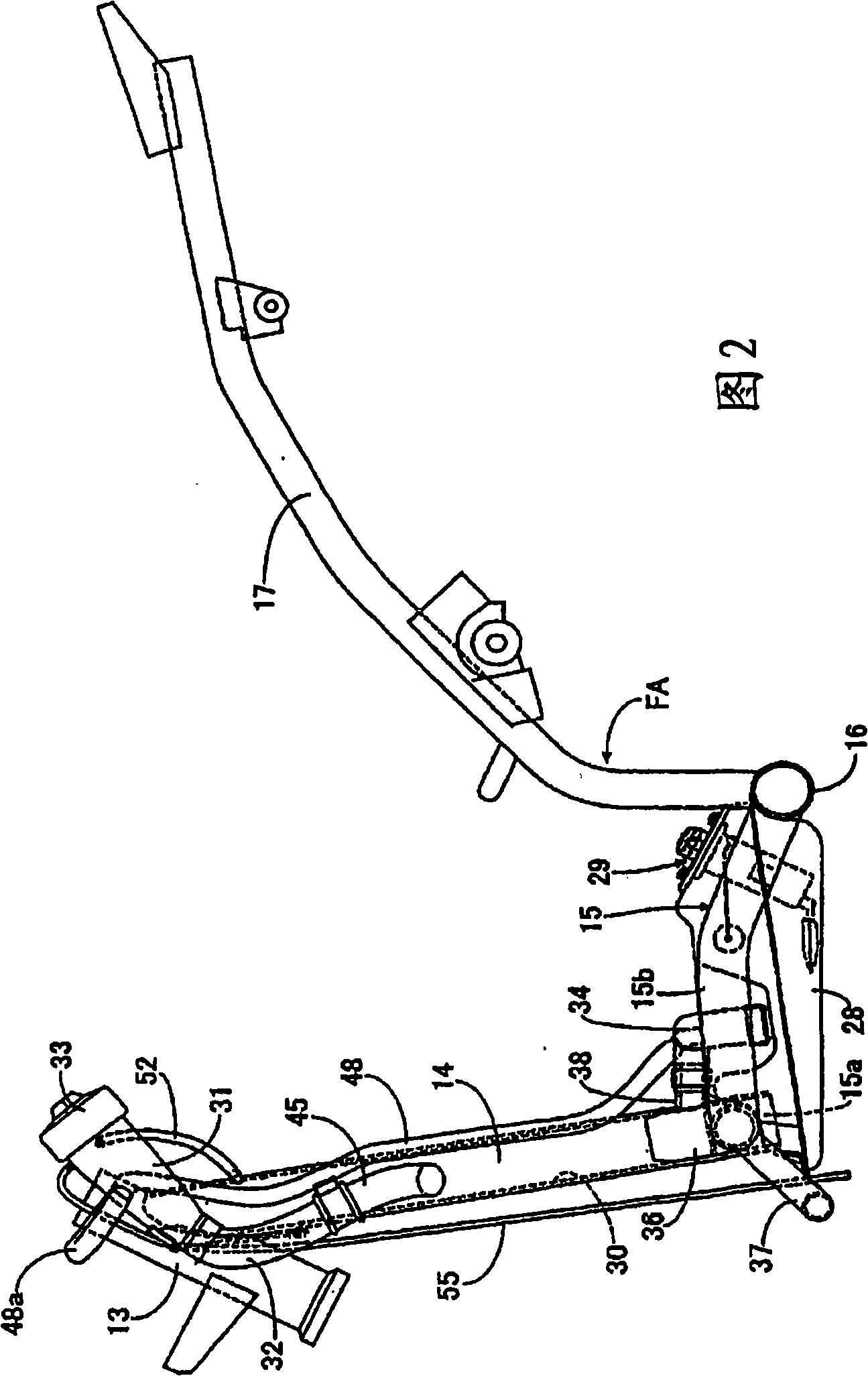

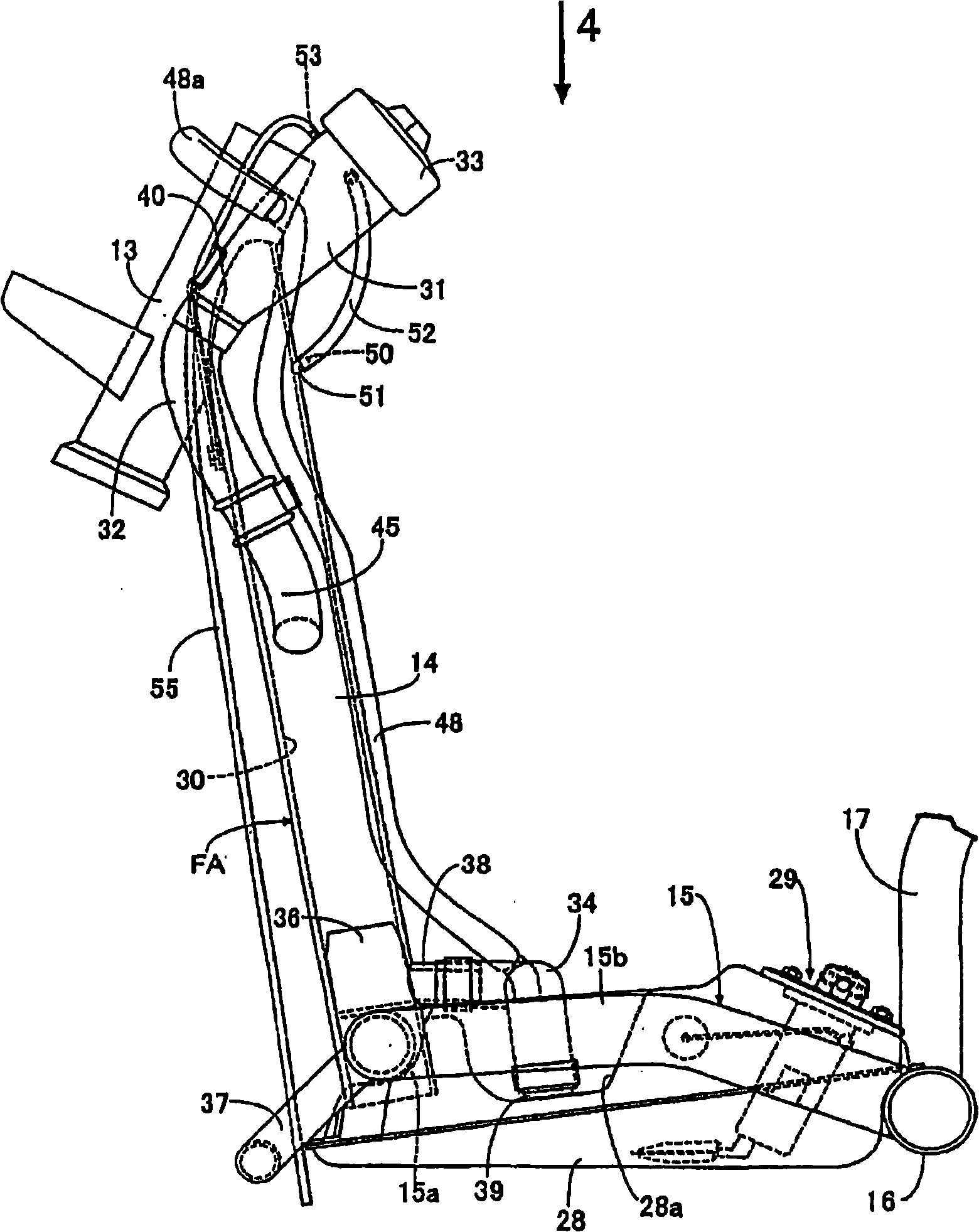

Fuel supply structure for small-type vehicle

In a small-type vehicle in which front parts of frame members (15) extending rearwards are connected to a hollow main pipe (14) extending rearwardly downwards from a head pipe (13) and forming a fuel passage (30) at least at a part thereof and a fuel tank (28) supplied with an oil from an oil supply pipe (31) through the fuel passage is connected to a lower part of the main pipe, to enhance the degree of freedom in designing the shape and layout of a fuel tank and to enhance maintainability. One end of a flexible lower connecting tube (34) is connected to the main pipe (14) so as to communicate with the fuel passage (30), and the other end of the lower connecting tube (34) is connected to the fuel tank (28).

Owner:HONDA MOTOR CO LTD

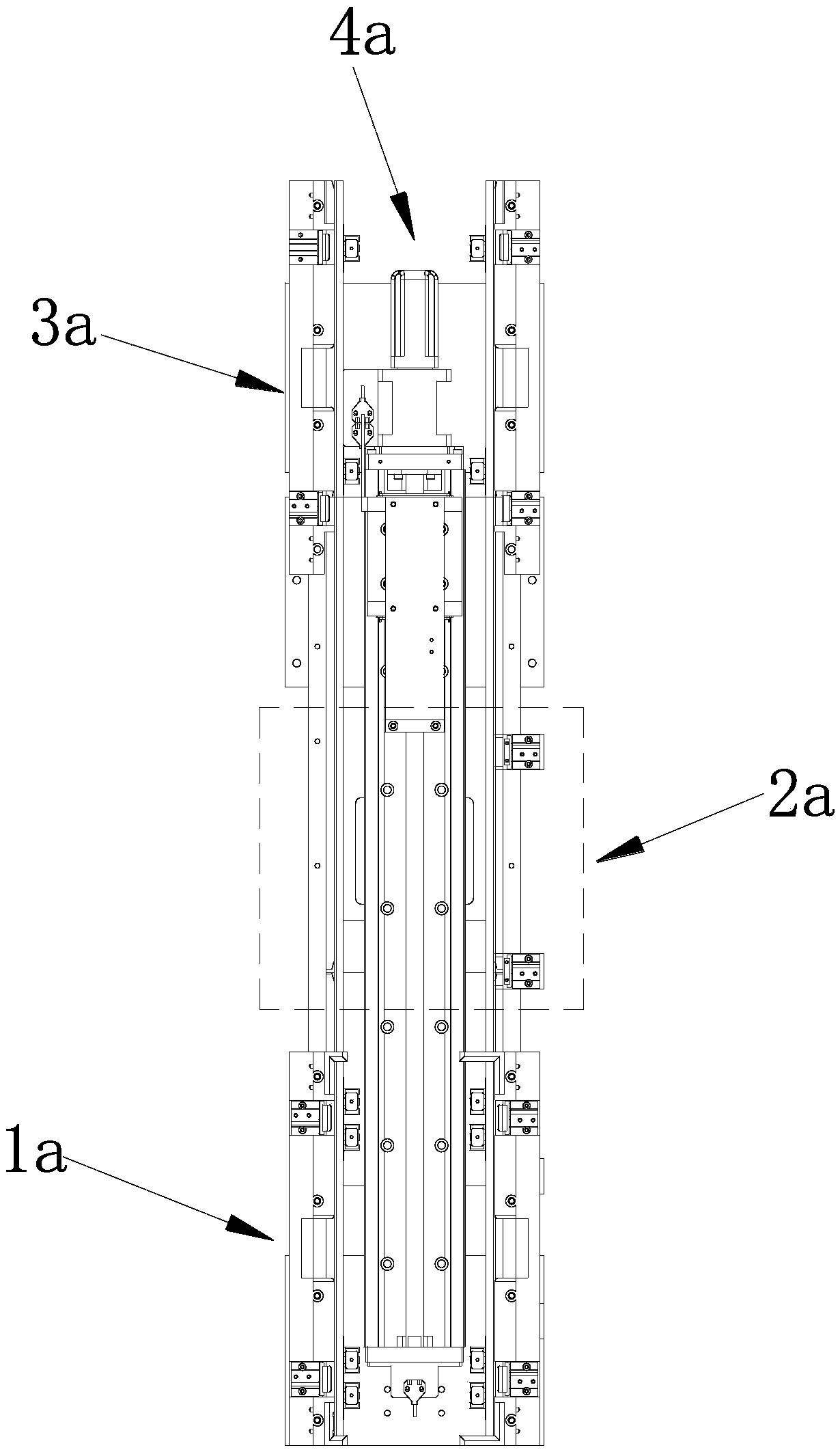

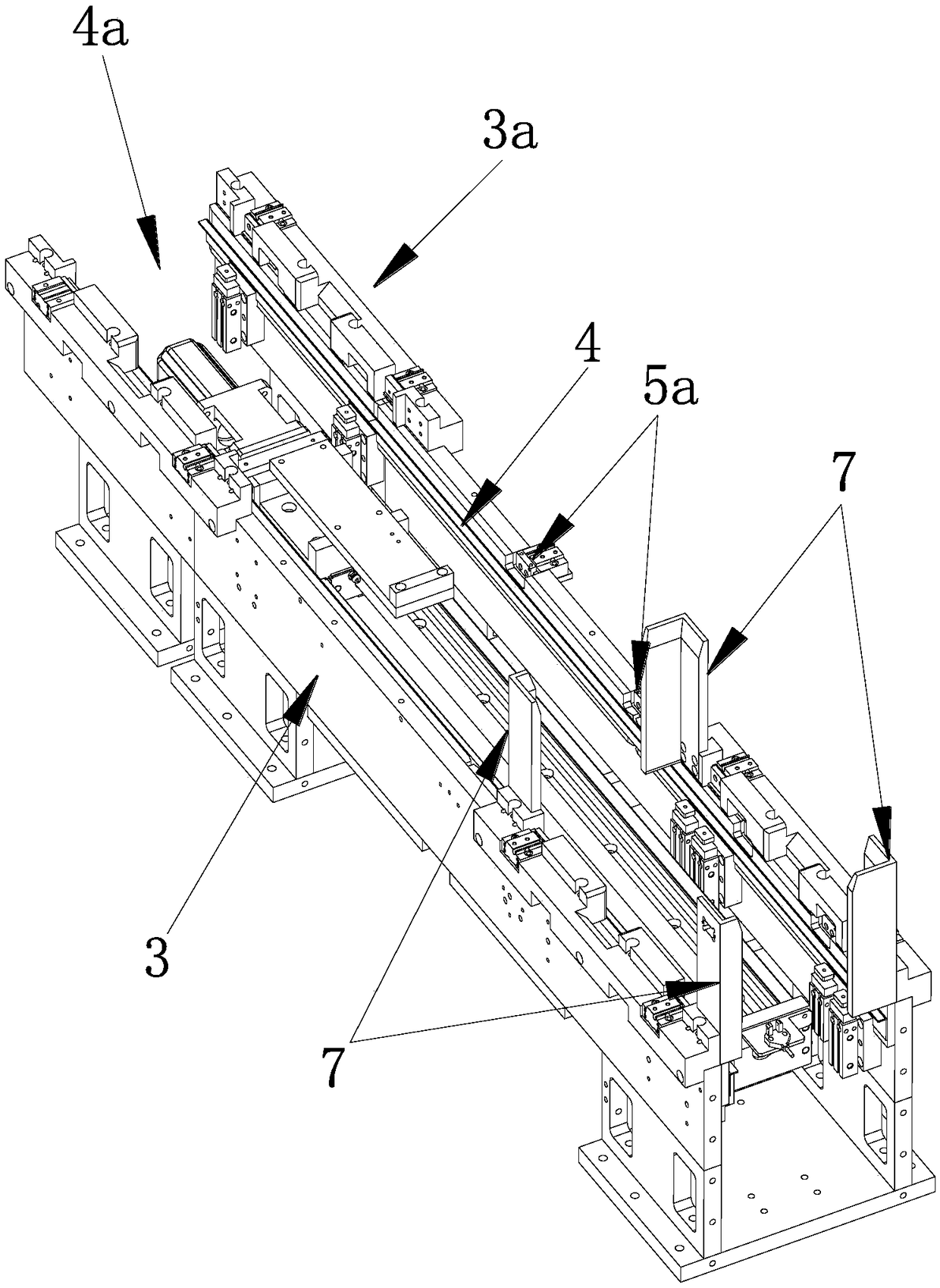

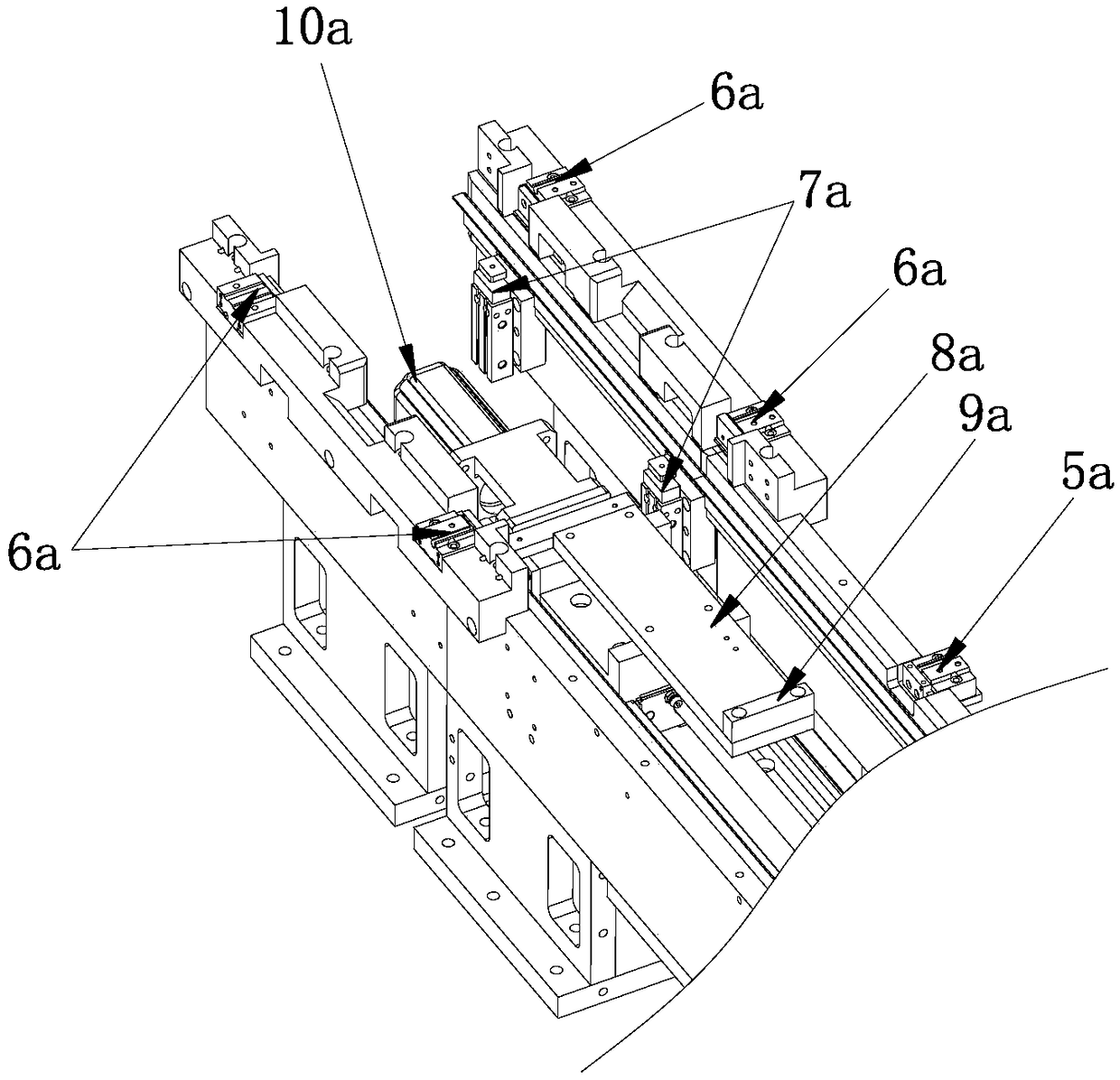

Conveying line for alternately conveying workpieces

InactiveCN107416510ARealize alternate conveyingImprove supply efficiencyConveyor partsMechanical engineeringEngineering

The invention discloses a conveying line for conveying workpieces alternately, comprising a conveying mechanism and a centering mechanism. The conveying mechanism includes a left conveyor belt group and a right conveyor belt group distributed side by side; the centering mechanism includes a left conveyor belt set on the left rear conveyor belt. The centering mechanism and the right centering mechanism arranged on the right rear conveyor belt, the left centering mechanism and the right centering mechanism both include a fixing frame, two gripping hands slidably connected with the fixing frame and in opposite directions of travel, and a driving gripping hand Linear motion cylinder; the left and right conveyor belt groups are respectively provided with left and right lifting baffles that can be raised and lowered, and the left and right lifting baffles are alternately raised and blocked to realize the alternate transportation of workpieces, and through the centering mechanism The mutual movement of the two grippers clamps the workpiece, realizes the correction of the position and angle of the workpiece, and improves the accuracy of conveying the workpiece.

Owner:广州市康超信息科技有限公司

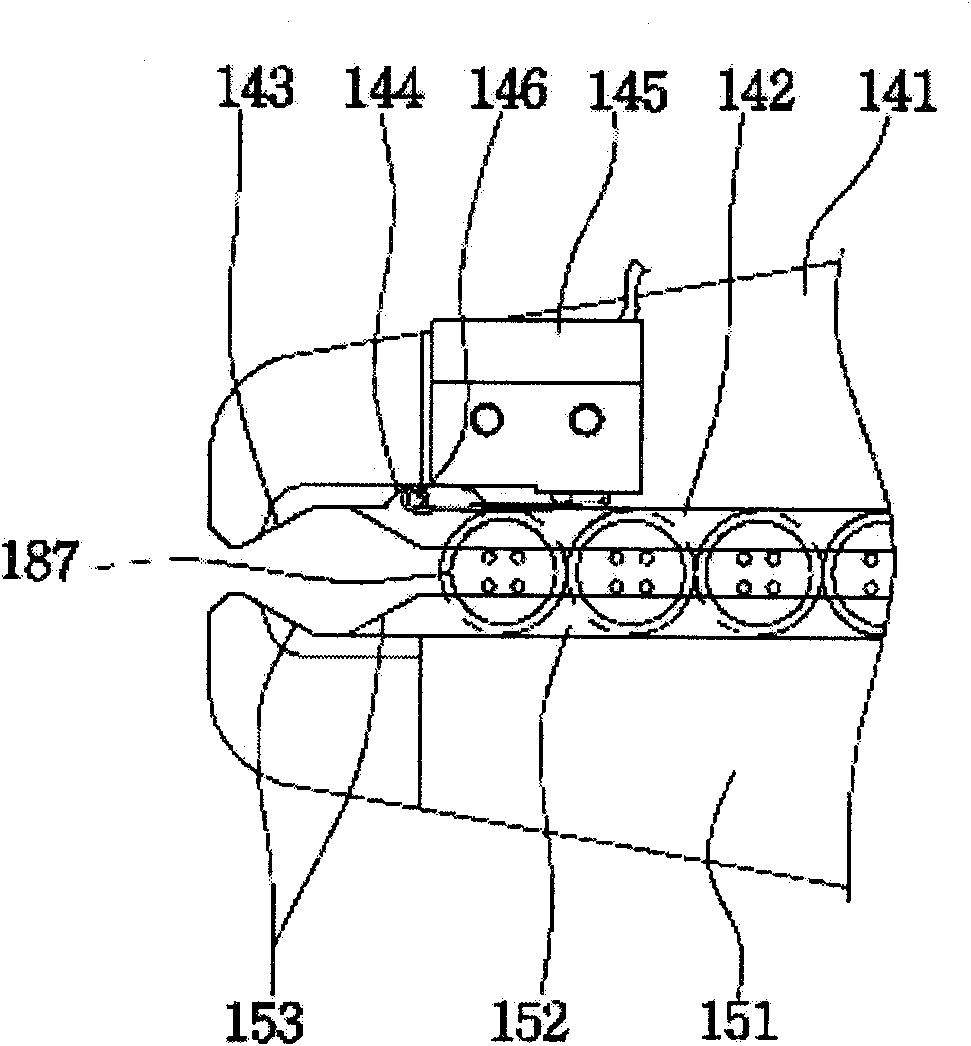

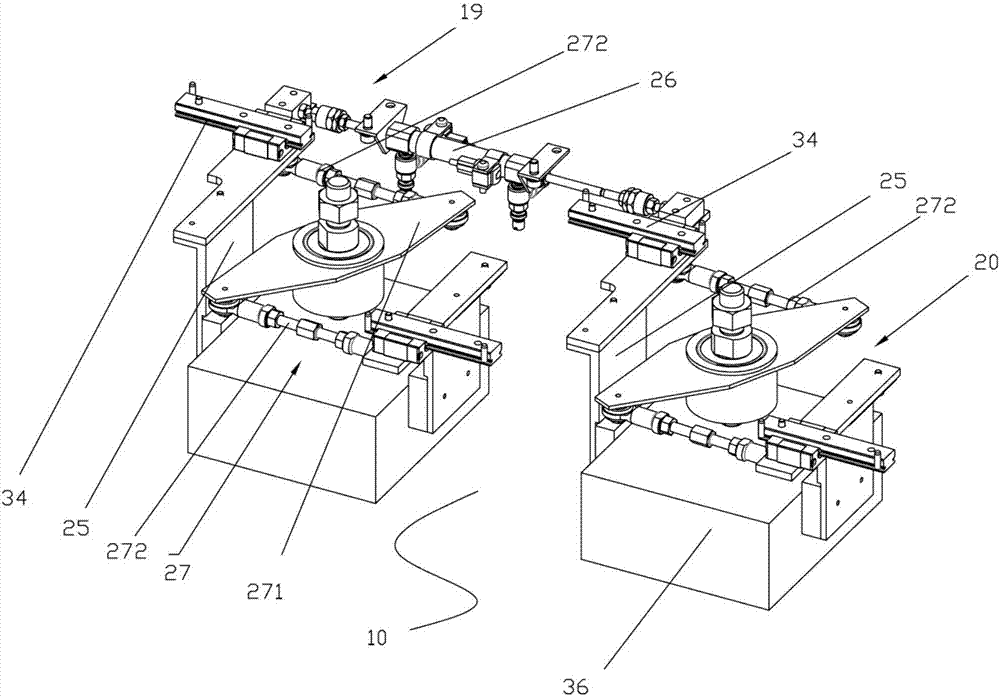

Yarn feeding bobbin direction changing deivce and bobbin supply system

A bobbin aligning device (6) changes the direction of a yarn feeding bobbin (3) in which a yarn is wound around a cylindrical winding core (4) having a bottom portion (4a) and an upper portion (4b) having a smaller diameter As the bottom portion (4a). The coil aligning means (6) includes two winding core guide paths (63) formed in an inclined manner. Each of the guide paths (63) has a bottom region (71) and an upper region (72). The receiving area (71) at the bottom of the area area passes through the upper area (4b) of the winding core (4) and receives the lower area (4a). The upper area-side receiving area (72) is located downstream of the receiving area (71) on the ground area side and receives the upper area (4b). The receiving area (71) on the base area side is designed in such a way that a receiving surface (84a) for receiving the end of the winding core (4) can be opened on the lower side.

Owner:MURATA MASCH LTD

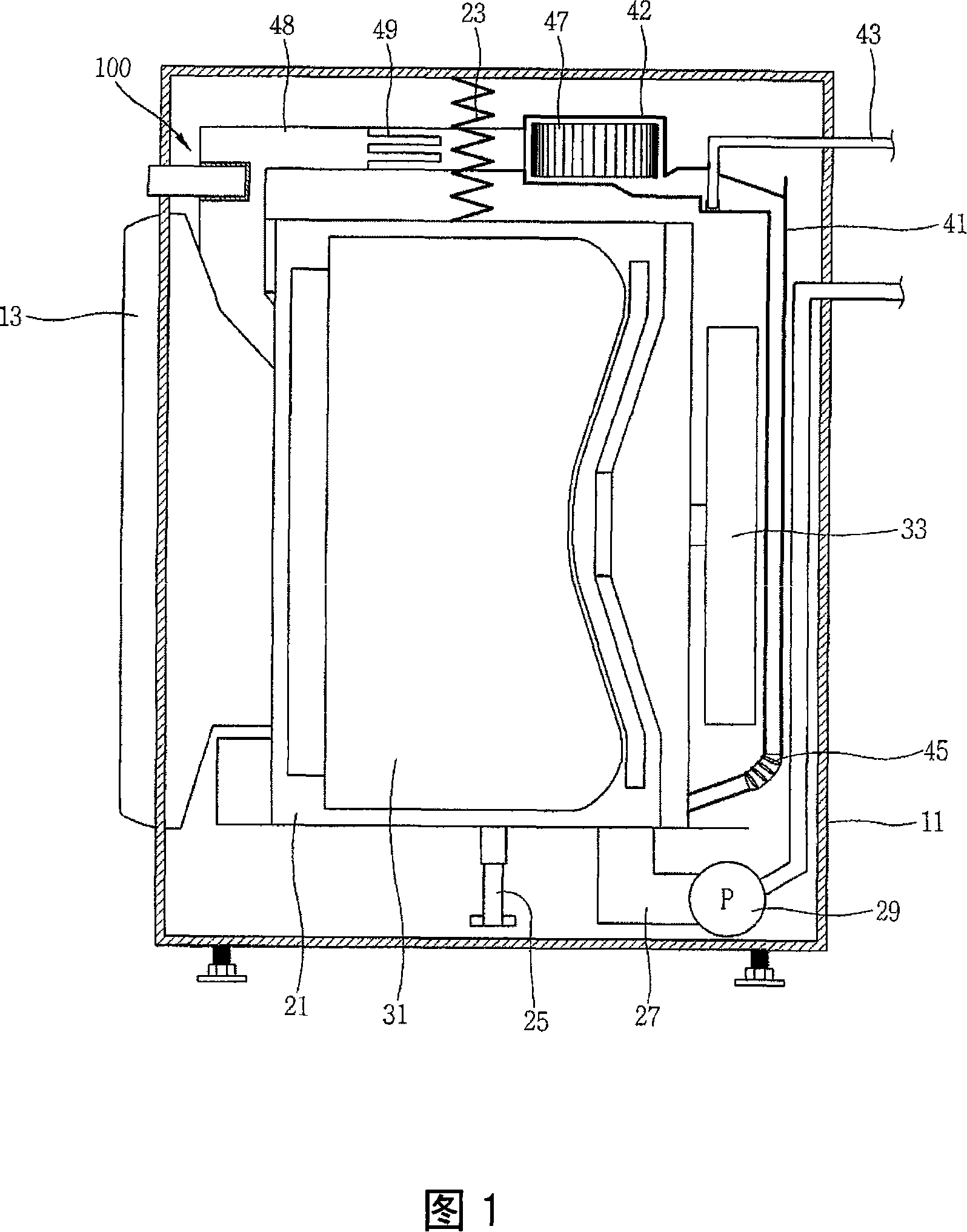

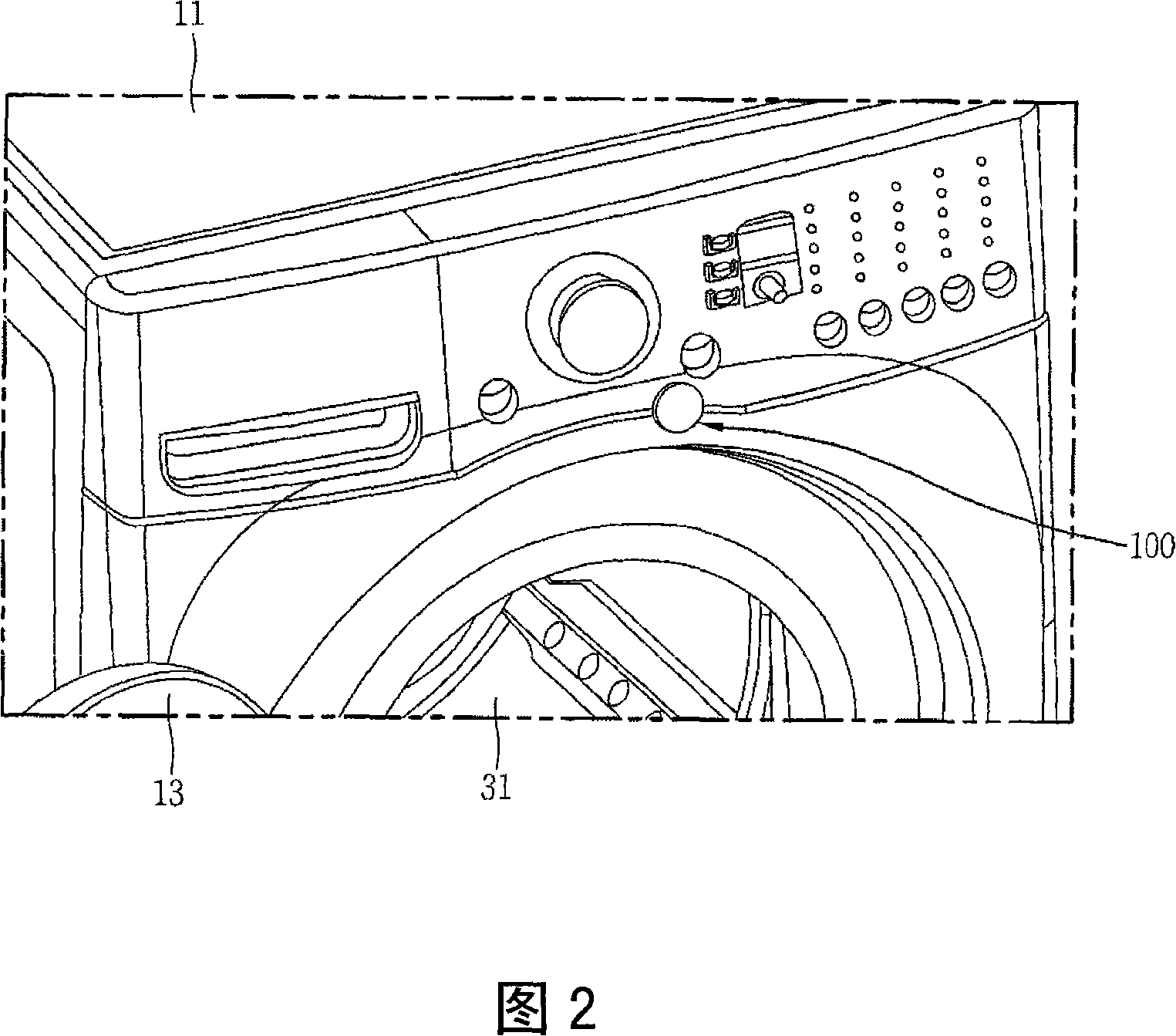

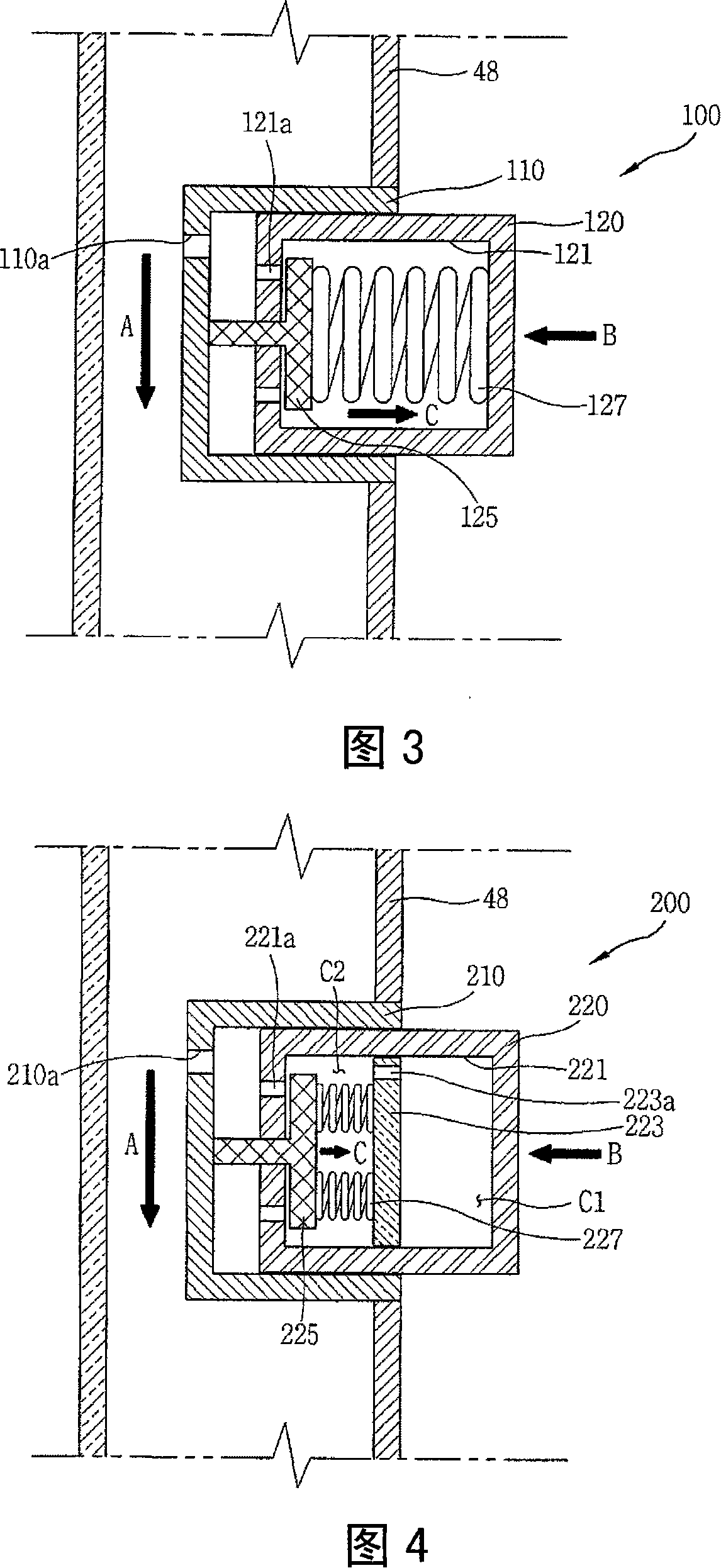

Scent supply apparatus and washing/drying machine having the same

InactiveCN101153447AHigh aroma supply efficiencyImprove supply efficiencyOther washing machinesGaseous substancesEngineeringGuide tube

Provided are a scent supply apparatus and a washing / drying machine including the same. The scent supply apparatus of a washing / drying machine including a tub in a casing, and a guide duct carrying air into the tub, is detachably installed at one side of the guide duct and supplies a scent into the tub. Because the scent supply apparatus is installed in the guide duct, the scent may be forcibly supplied into the washing / drying machine by the air being introduced into the tub from the guide duct. Accordingly, the scent may be actively supplied into the washing / drying machine, without depending only on its own diffusion, thereby improving scent supply efficiency. Also, when the scent source is exhausted and there is a need for replenishment thereof, a user may easily perform the replenishment of a scent source.

Owner:LG ELECTRONICS INC

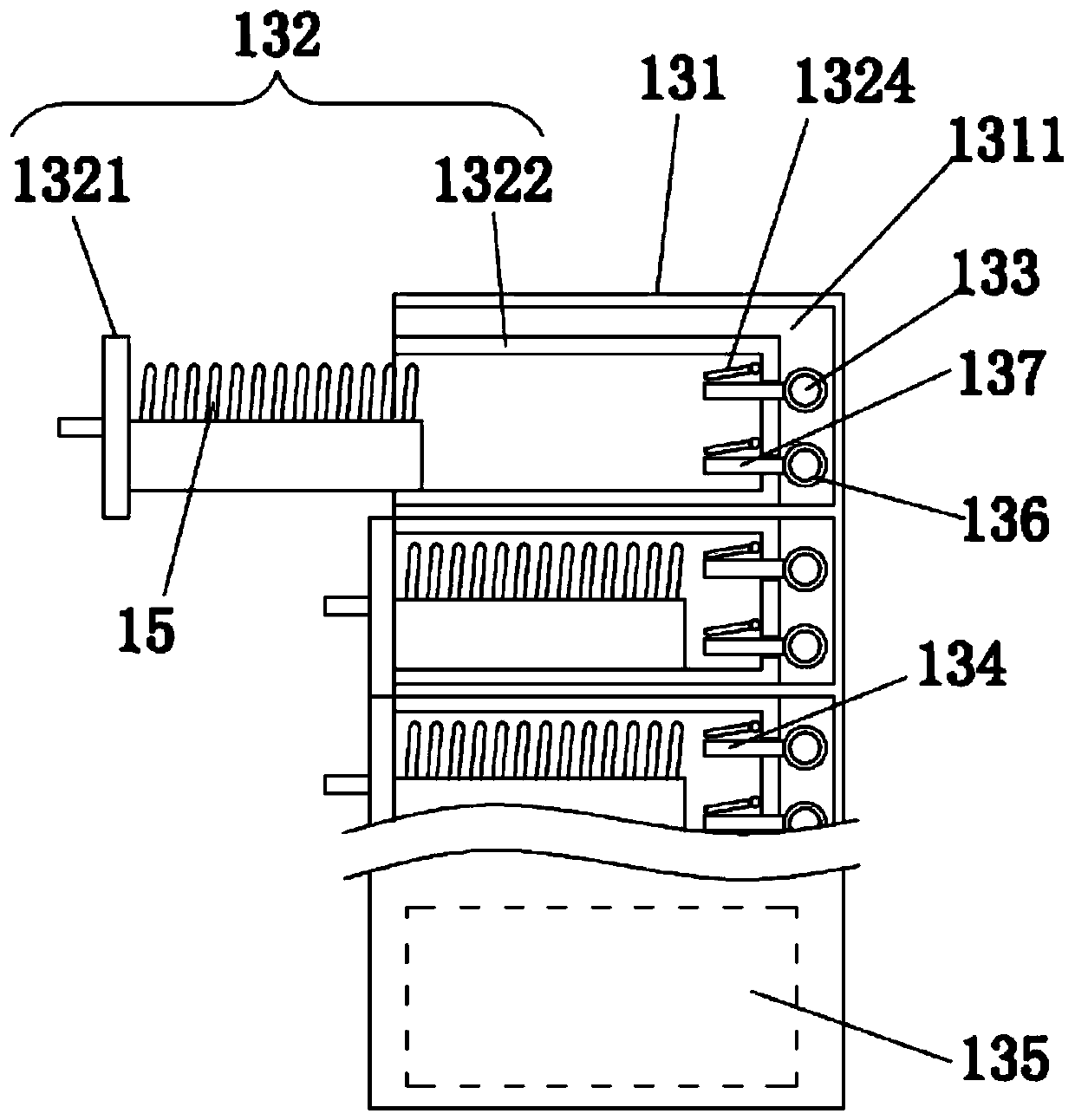

Material tray supply device for chip recording equipment

PendingCN109230574ARealize the supplyImprove supply efficiencyConveyorsDe-stacking articlesElectrical and Electronics engineering

The invention discloses a material tray supply device for chip recording equipment. The device comprises a material tray send-out module and a material tray conveying module; the material tray send-out module comprises a support mechanism and a material tray distribution mechanism; the support mechanism comprises support plates and transverse driving mechanisms for driving retractable movement ofthe support plates, and chip material trays to be sent out are sequentially stacked on the support plates; the material tray distribution mechanism is disposed below the chip material trays and comprises supporting plates and vertical driving mechanisms for driving the supporting plates to move vertically; the material tray conveying module includes a longitudinal moving plate and a longitudinal driving mechanism for driving the longitudinal moving plate to move. The chip material trays which are stacked together are sent out one by one and then conveyed to feeding stations, supply of the chipmaterial trays is achieved, the structure is simple, the occupied space is small, convenience is provided for cooperative installation with a processing module of the chip recording equipment, and improvement of the supply efficiency and transport efficiency of chips is facilitated.

Owner:广州明森合兴科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com