Tunnel anchor rod grouting construction trolley

A technology for construction trolleys and tunnel anchors, which can be used in the installation of bolts, mining equipment, earthwork drilling and mining, etc. It can solve the problems of insufficient site layout space, inconvenient use of tunnels, and slow down the construction period, so as to improve the overall construction efficiency. The effect of improving construction efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

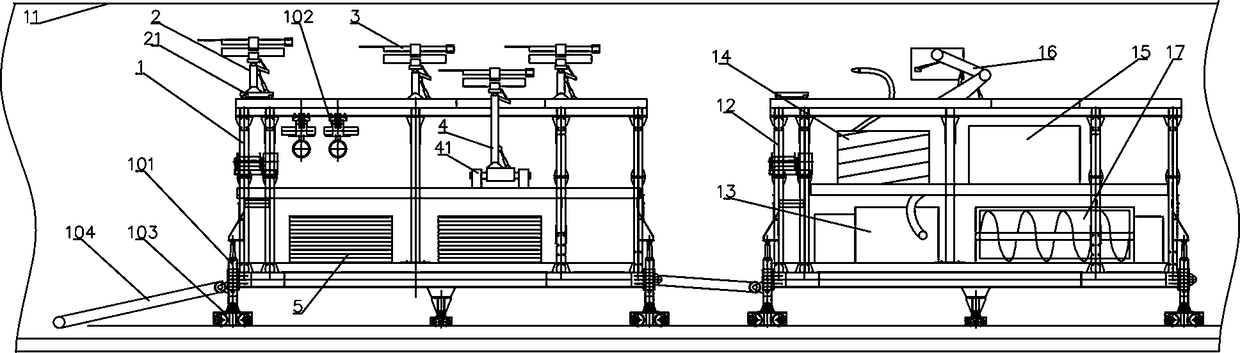

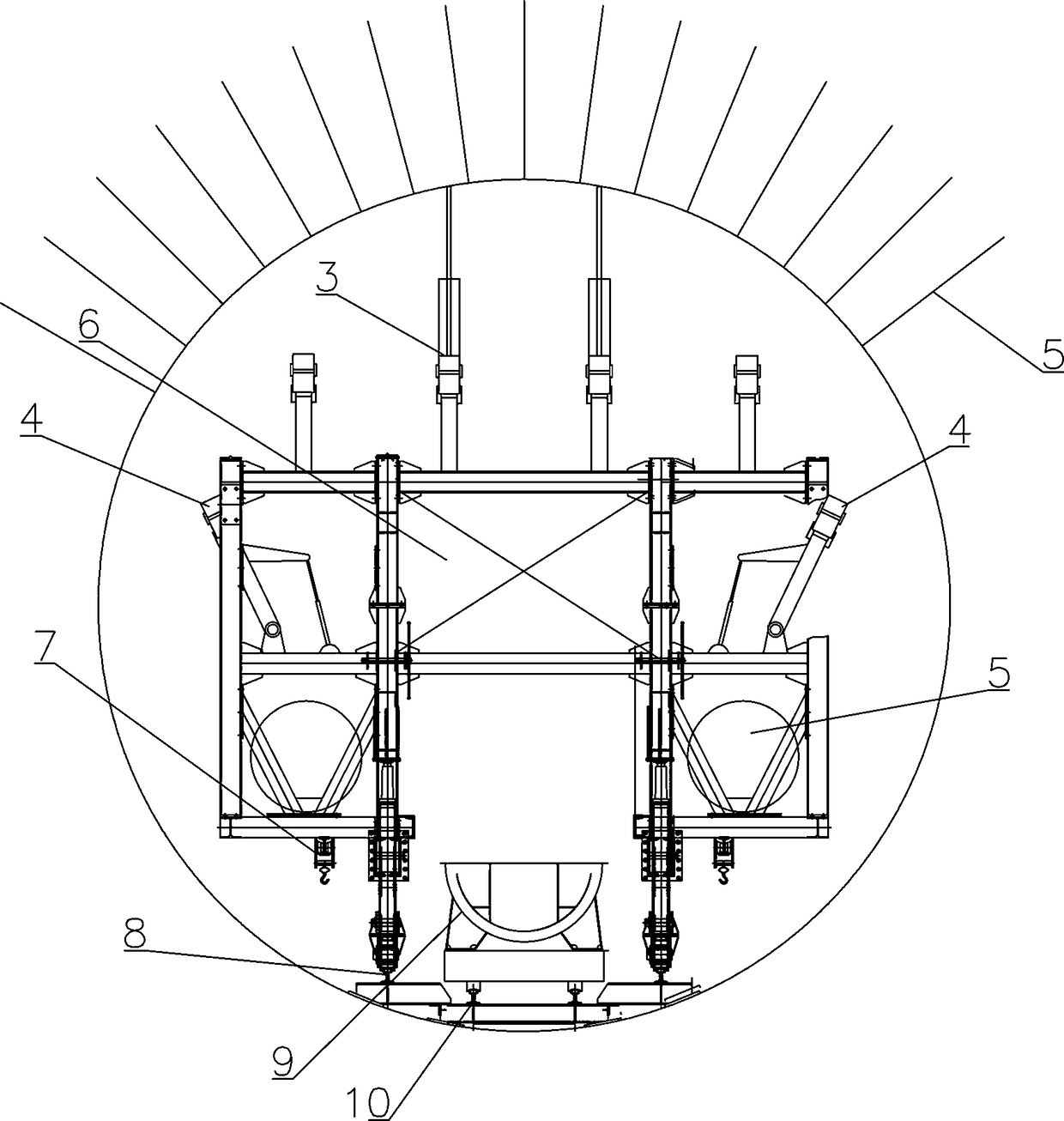

[0038] Such as Figure 1~6 Among them, a trolley for tunnel bolt grouting construction, including a trolley frame 1, on which a plurality of rock bolt drilling rigs are arranged;

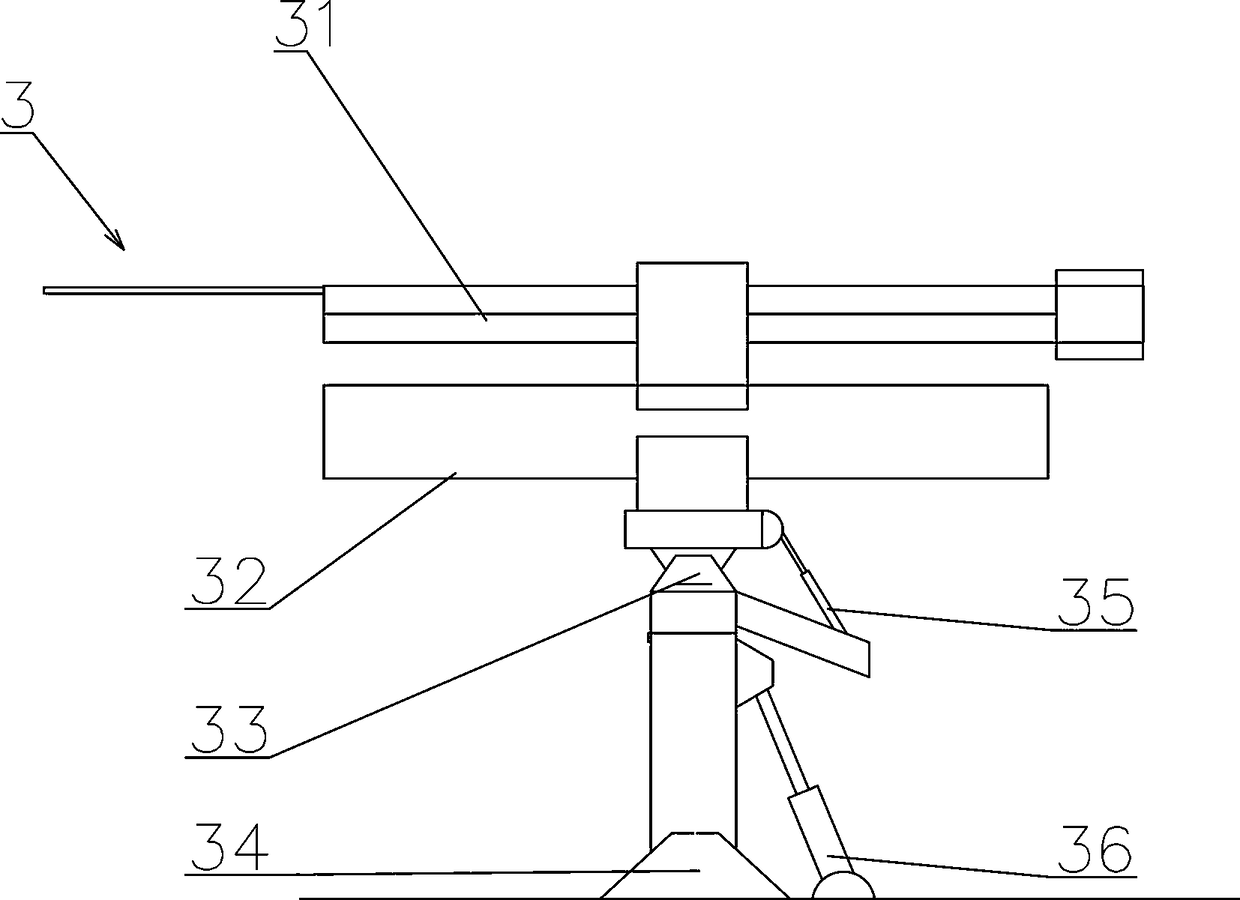

[0039] The rock bolter includes at least a mechanical arm with two joints, and the drilling mechanism 31 is installed on the top of the mechanical arm; since the platform frame is customized according to the size of the tunnel, the mechanical arm with two joints is set, Realizing the pitching operation can satisfy the basic bolt positioning construction. Due to the reduction of the joints, the stiffness of the mechanical arm is also increased correspondingly, which is beneficial to reduce the cost. A joint in this case is a moving part that can move in at least one constrained direction and be constrained in other constrained directions. Such as hinged structure and horizontal rotation structure. The number of joints in this example is preferably no more than 4.

[0040] The rock bolt includes on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com