Material tray supply device for chip recording equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

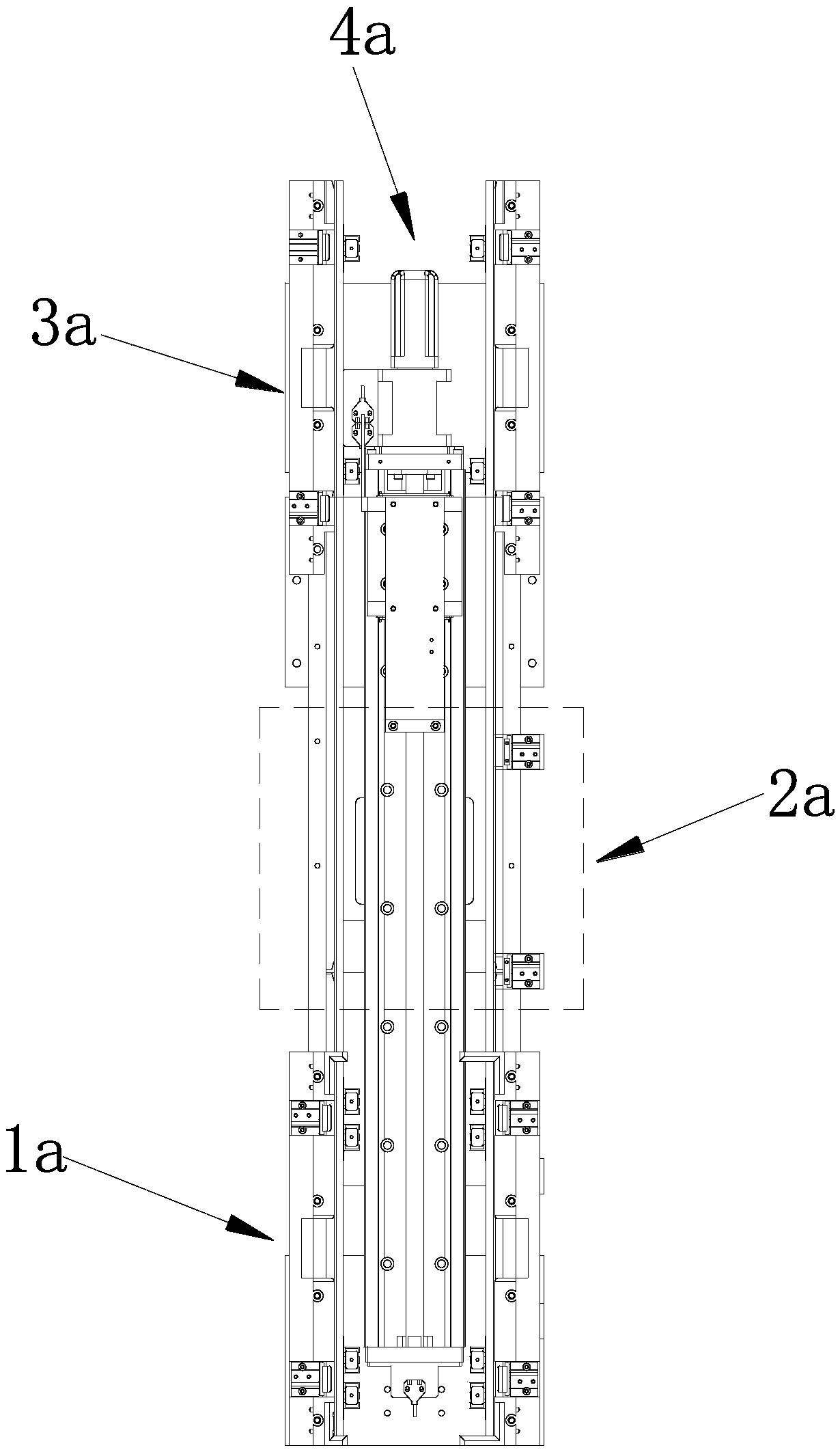

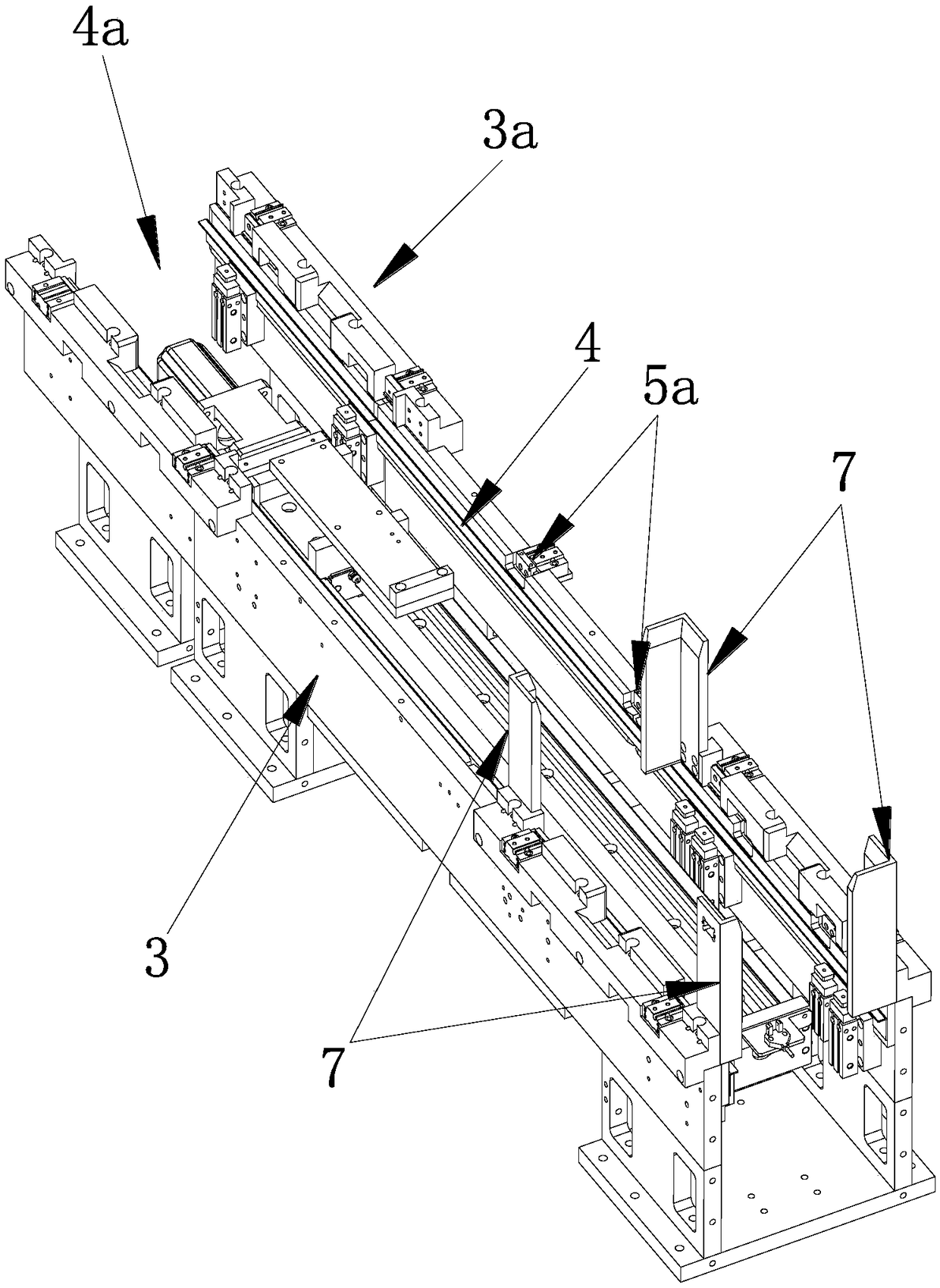

[0035] The tray supply device of the chip programming device in this embodiment includes a fixed frame, a tray sending module, and a tray delivery module; wherein,

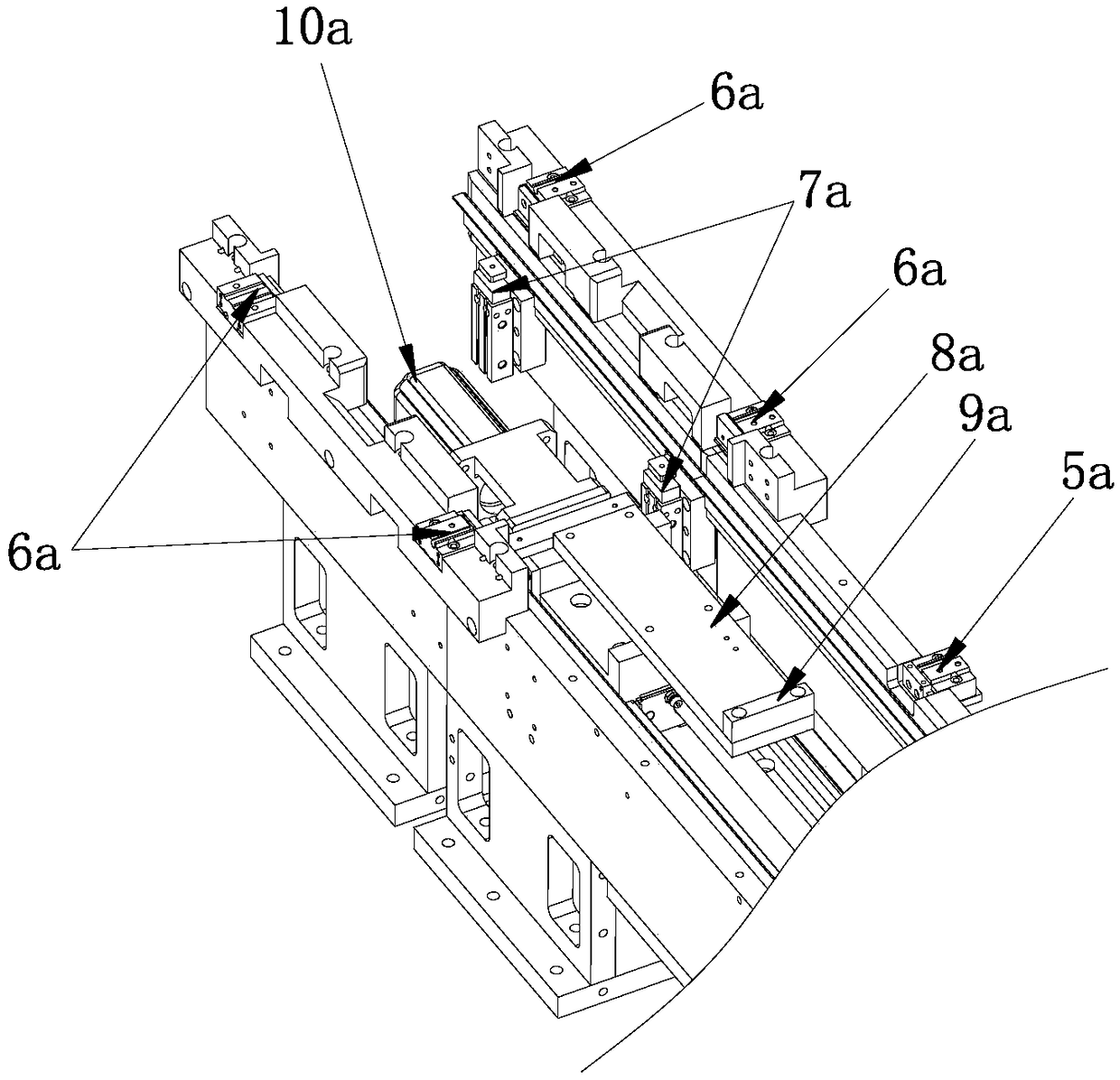

[0036] see Figure 1-Figure 7 , the tray delivery module 1a includes a tray mechanism and a tray distribution mechanism; the tray mechanism includes a pallet 1 and a lateral drive mechanism 2 that drives the pallet 1 to perform telescopic movement, and the chip trays to be sent out are stacked on the tray in turn plate 1; the tray distribution mechanism is arranged below the chip tray, including a support plate and a vertical drive mechanism that drives the support plate to move vertically; during the vertical movement of the support plate, a handover limit Point A and the offer limit point B below the handover limit point A. When the support plate moves to the handover limit point A, the support plate is flush with the pallet 1. When the support plate moves to the offer limit point At position B, the supporting ...

Embodiment 2

[0053]The difference between this embodiment and Embodiment 1 lies in that: the longitudinally moving plate is lower than the limit point of the offer, and higher than the lowest point of the transition plate. When the chip tray to be sent is handed over to the transition plate, the first vertical drive mechanism drives the transition plate to move downward. During the downward movement, the chip tray on the transition plate is transferred to the longitudinal moving plate, and then The longitudinal driving mechanism drives the longitudinal moving plate to move forward to the loading station to complete the supply of the chip tray; when the chips on the chip tray are transported away, the longitudinal driving mechanism drives the longitudinal moving plate to move forward to the collecting station. position, the empty chip trays are collected and processed by the tray collection module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com