Dual Jet System

a dual-jet system and jet pump technology, applied in the direction of jet pumps, charge feed systems, non-positive displacement pumps, etc., can solve the problems of engine hesitation and stop phenomenon of vehicles, fuel is not smoothly filled in the reservoir,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

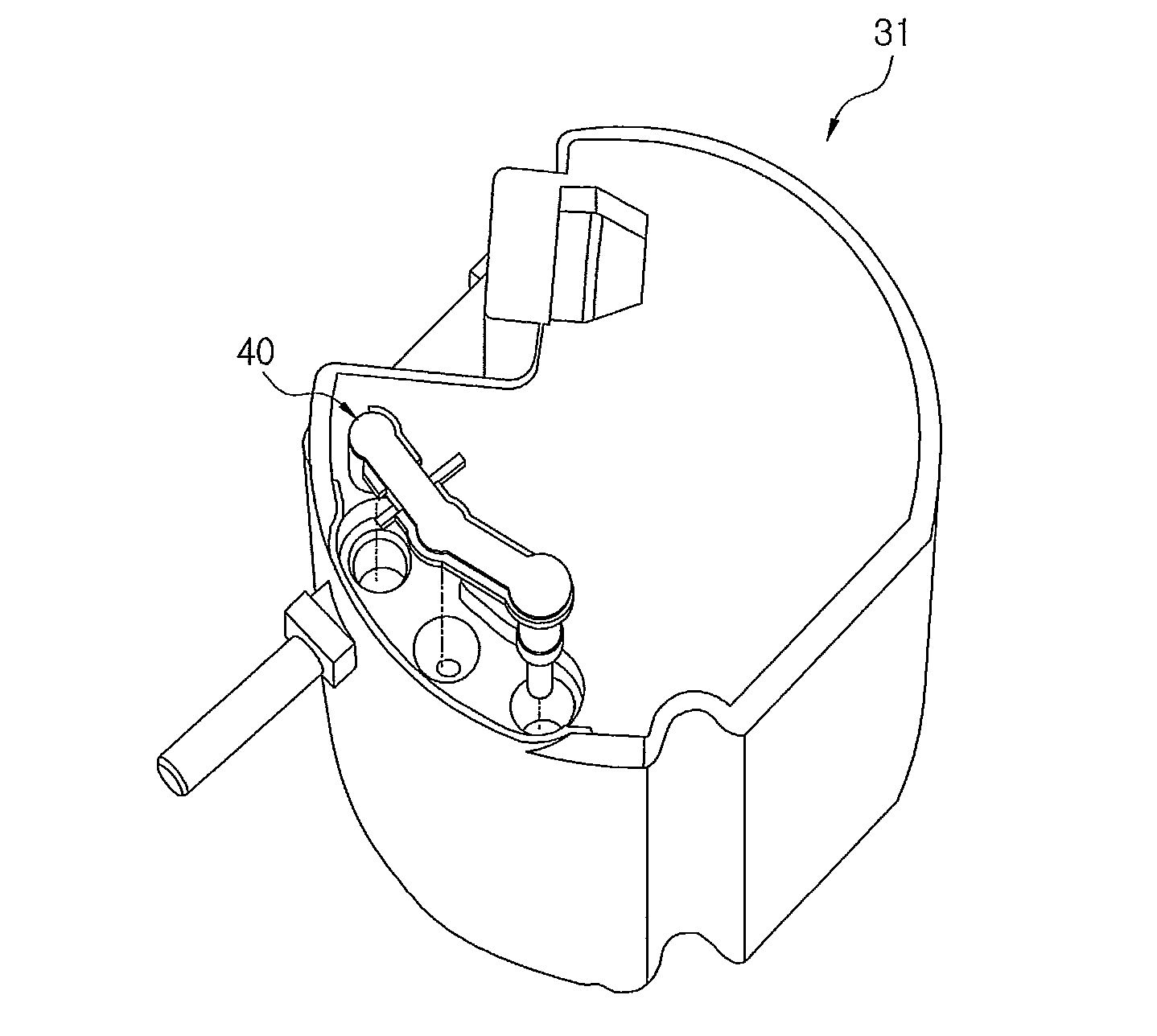

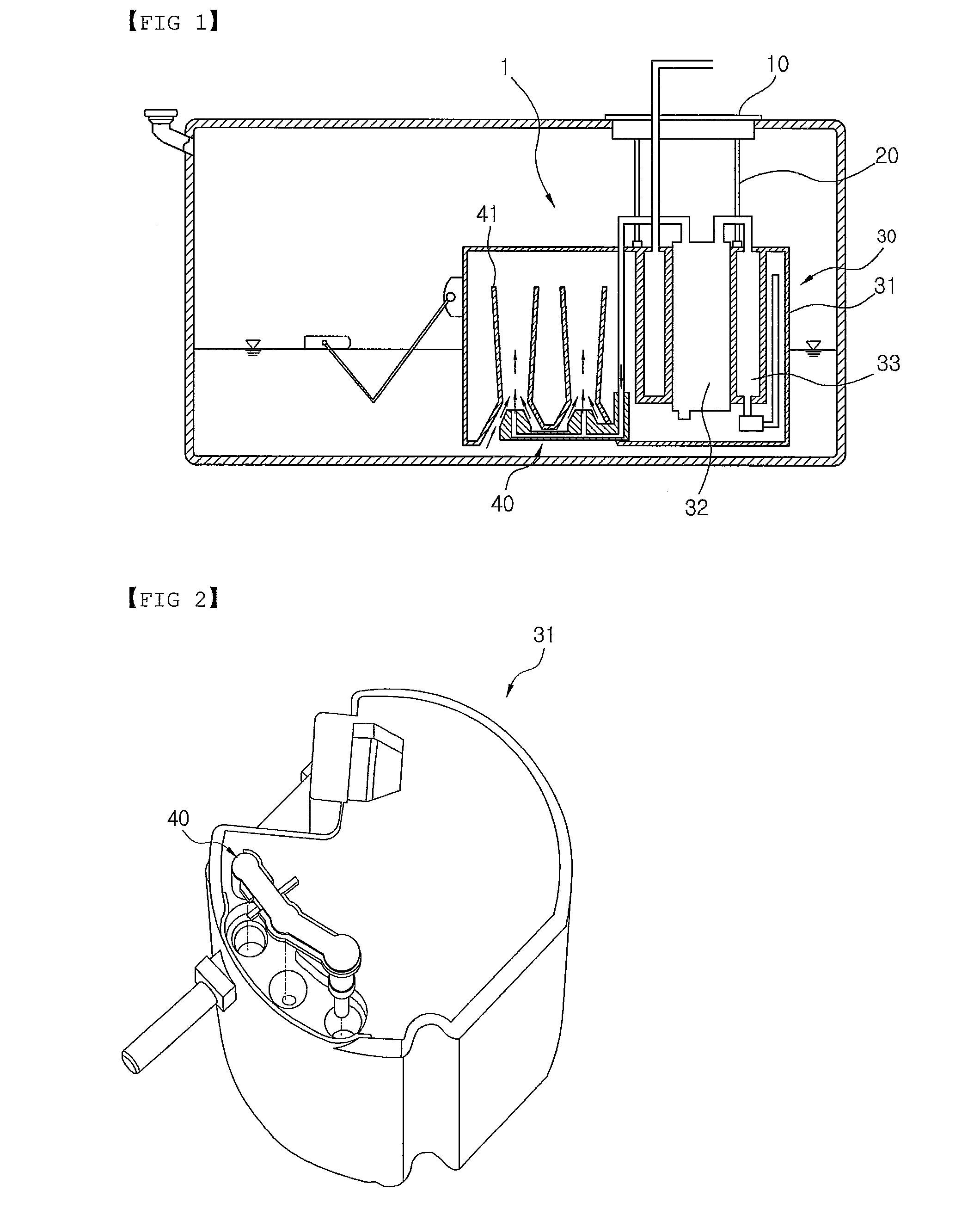

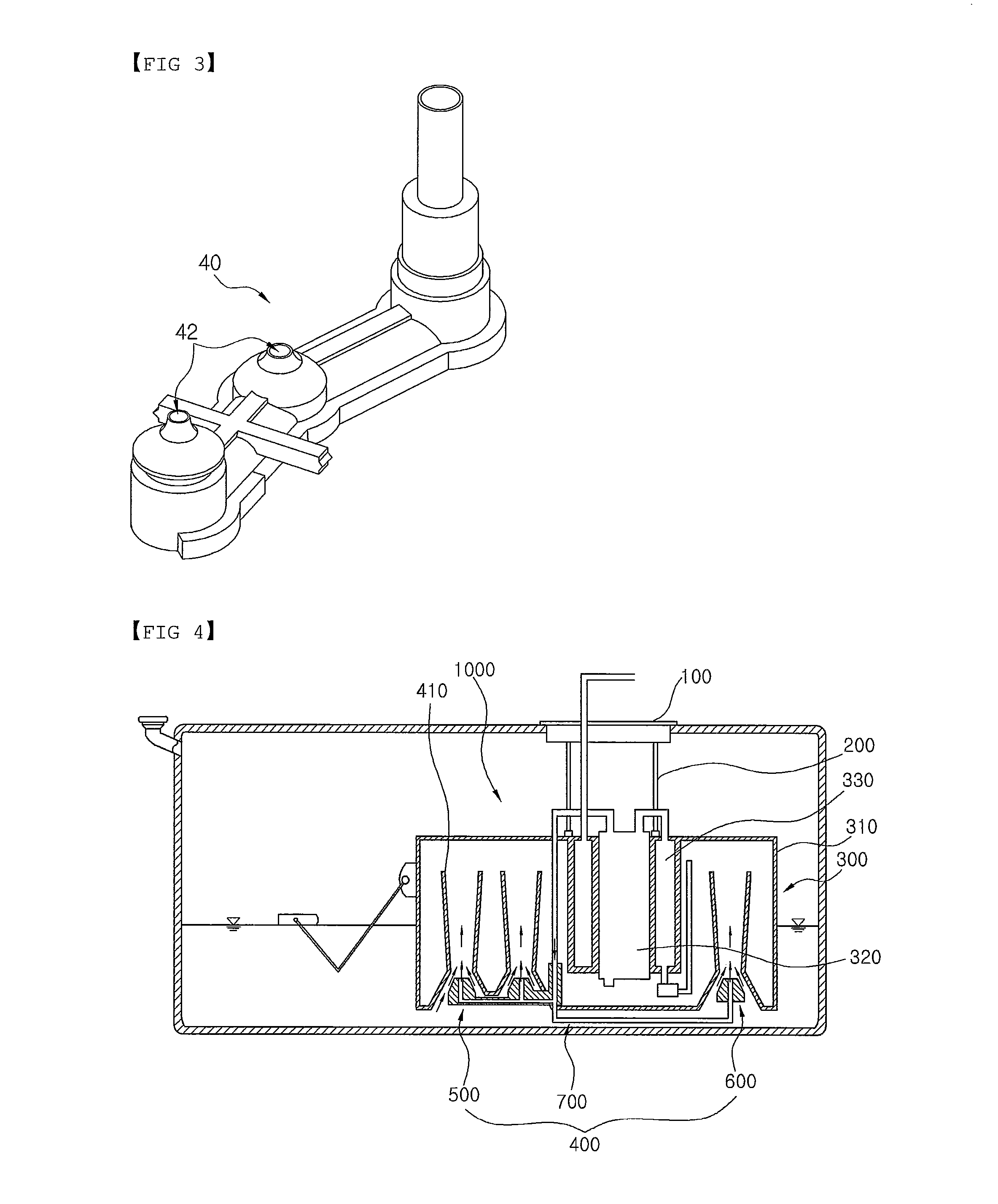

1000: FUEL PUMP MODULE 100: FLANGE ASSEMBLY 200: GUIDE ROD 300: RESERVOIR ASSEMBLY 310: RESERVOIR320: FUEL PUMP 330: INTANK FILTER 400: DUAL JET SYSTEM 410: GUIDE TUBE 500: MAIN JET PUMP 510: MAIN JET PUMP HOUSING520: FIRST JETORIFICE 530: CHECK VALVE SEALING PART540: OUTLET PIPE 550: COMMUNICATING TUBE560: FIRST GAPFORMING PART 570: SECOND GAP FORMING PART571: PROTRUSIONPART 580: ANTI SIPHON CHECK VALVE ASSEMBLY 590: JET PUMP FILTER 600: SUB-JET PUMP 610: SUB-JET PUMP HOUSING620: SECOND JETORIFICE 630: INLET PIPE640: THIRD GAPFORMING PART 700: CONNECTION TUBE 800: COUPLING GROOVE 810: INSERTION GROOVE

DETAILED DESCRIPTION OF EMBODIMENTS

The advantages, features and aspects of the present disclosure will become apparent from the following description of the embodiments with reference to the accompanying drawings, which is set forth hereinafter. The present disclosure may, however, be embodied in different forms and should not be construed as limited to the embodiments set forth herein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com