Automatic-cleaning machine and olive vegetable production process thereof

An automatic cleaning machine and production process technology, applied in application, food processing, food science and other directions, can solve the problems of poor cleaning effect, inability to meet enterprises, low cleaning efficiency, etc., to improve supply efficiency, improve efficiency and clean. effect, increase profit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

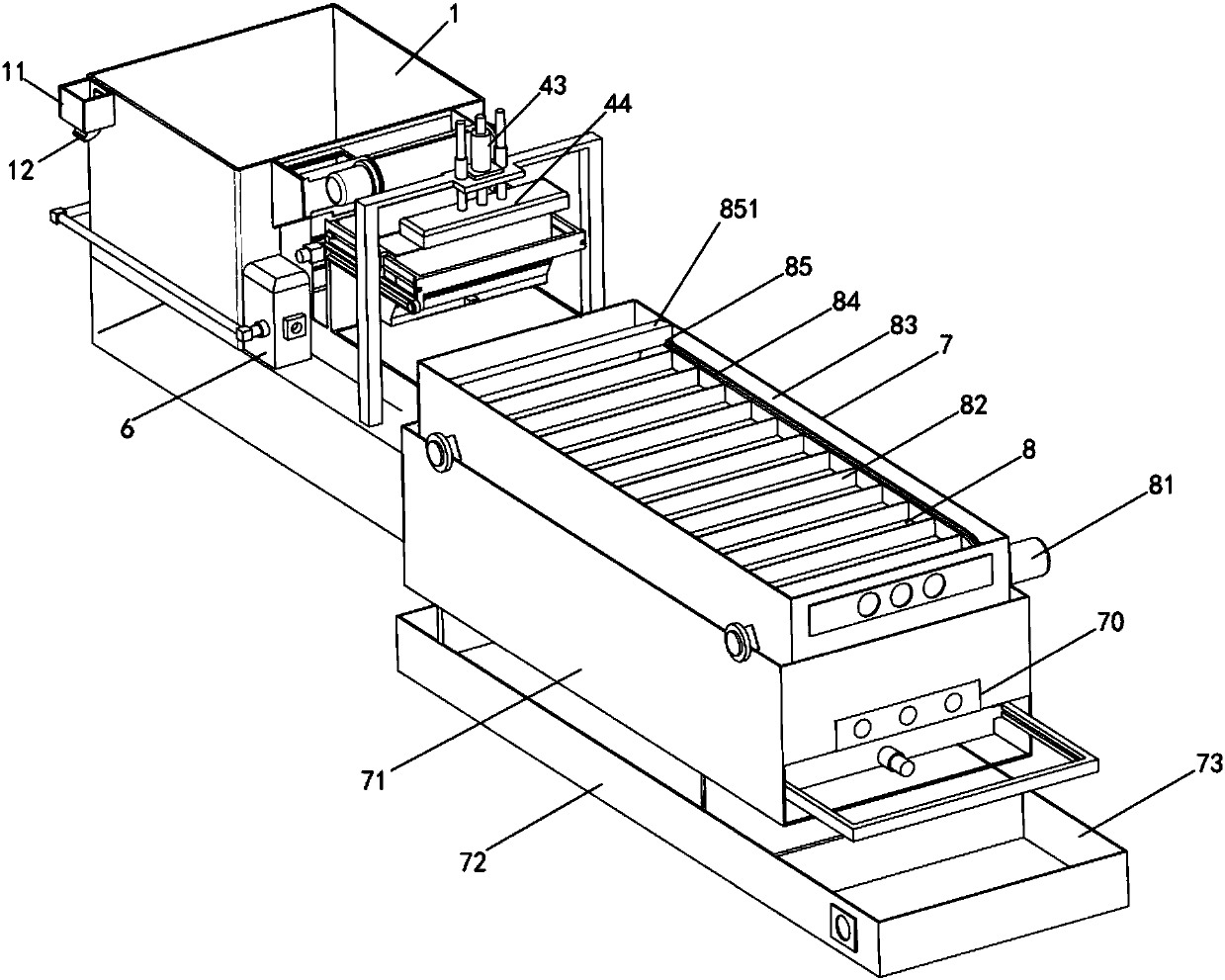

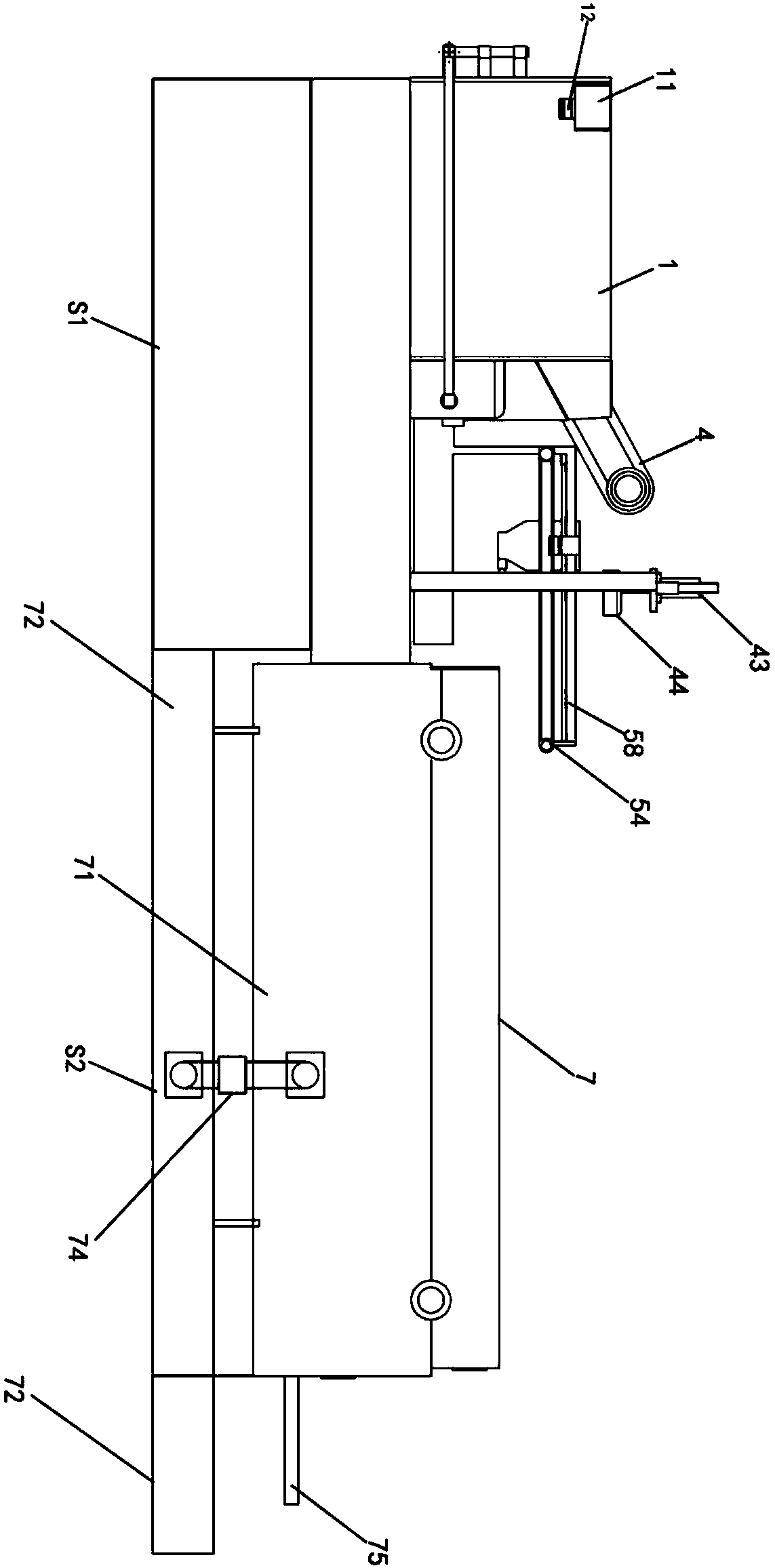

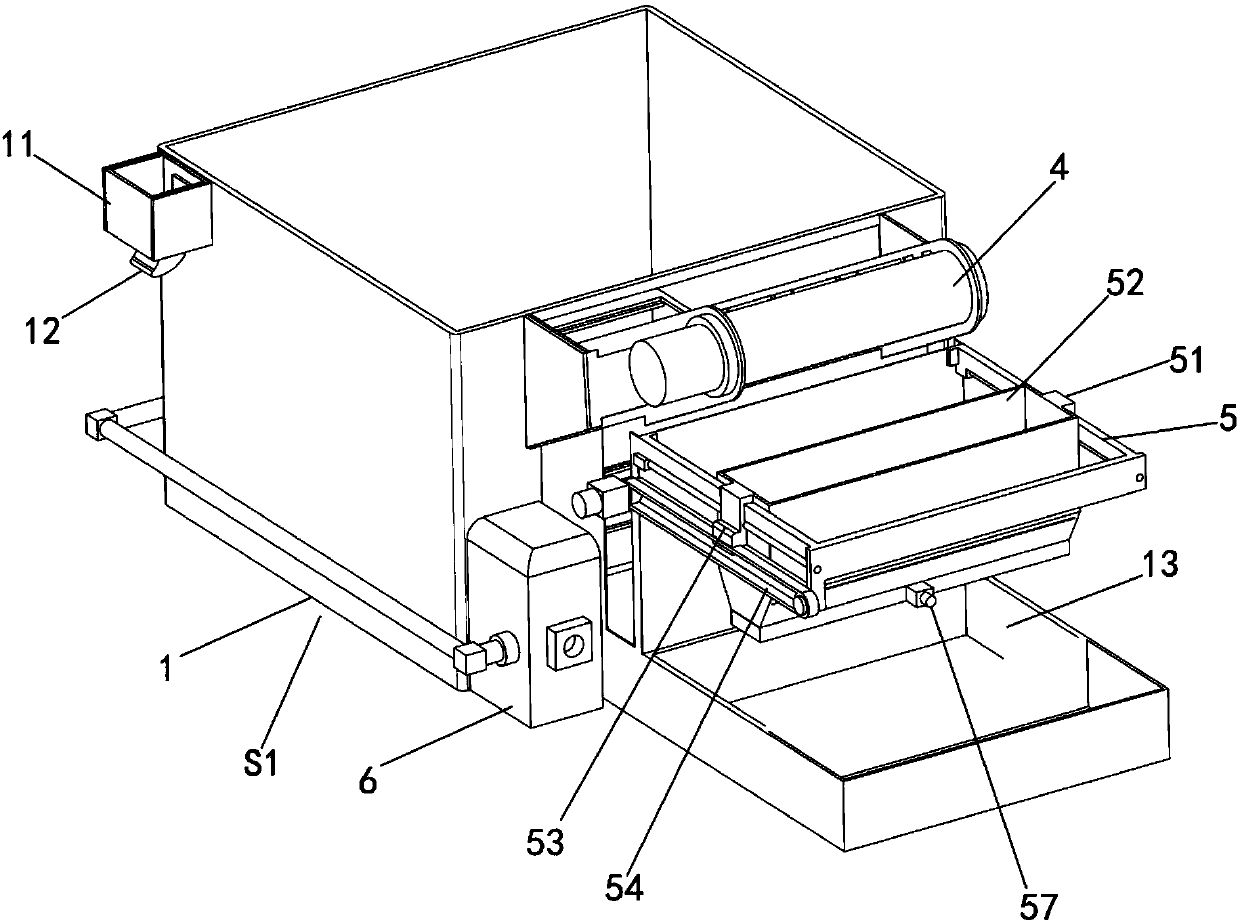

[0029] Embodiment 1: refer to Figure 1-7 , an automatic cleaning machine, at least including a pre-cleaning section S1 and a control circuit arranged at the front of the deep cleaning section S2, the pre-cleaning section S1 includes a pre-cleaning tank body 1 and a second obliquely arranged in the pre-cleaning tank 1 A conveyor belt 4, the first conveyor belt 4 extends obliquely from the bottom of the pre-cleaning tank 1 to the opening of the pre-cleaning tank 1, and the pre-cleaning tank 1 is equipped with a circulating water supply for cleaning water supply output relative to its inner side In the device 6 , several groups of propulsion blades 42 are provided on the outer edge of the first conveyor belt 4 , and the propulsion blades 42 include several groups of propulsion blades perpendicular to the traveling direction of the first conveyor belt 4 .

[0030] In this embodiment, the material is cleaned mustard greens as an example. The material is placed in the pre-cleaning ...

Embodiment 2

[0052] Embodiment 2: a kind of olive dish production technology, comprises the following steps:

[0053] Weigh the following raw materials by weight: 1 part of onion, 2 parts of garlic, 5 parts of olive, 25 parts of edible oil, 10 parts of salt, and 57 parts of mustard greens.

[0054] 1) Pickled mustard greens: add salt to the washed mustard greens and put them in a pickling pool or jar for 85 days;

[0055] 2) Cleaning and cutting of mustard impurities: cleaning, cleaning and cutting the pickled mustard;

[0056] 3) Dehydration of mustard: drying and dehydrating the mustard after cleaning impurities to obtain dehydrated pickled mustard;

[0057] 4) Making onion and garlic oil: put the washed and drained onion and garlic in cooking oil for frying to obtain onion and garlic oil;

[0058] 5) Cook the dehydrated mustard greens and shallot and garlic oil in step 3) and step 4) at a cooking temperature of 5 hours to obtain finished olive vegetables.

[0059] Preferably, in step...

Embodiment 3

[0062] Embodiment 3: a kind of olive vegetable production technology, comprises the following steps:

[0063] The following raw materials are weighed in parts by weight: 0.5 parts of green onion, 1 part of garlic, 4 parts of olive, 20 parts of edible oil, 8 parts of salt, and 40 parts of mustard greens.

[0064] 1) Pickled mustard greens: add salt to the washed mustard greens and put them in a pickling pool or jar for 90 days;

[0065] 2) Cleaning and cutting of mustard impurities: cleaning, cleaning and cutting the pickled mustard;

[0066] 3) Dehydration of mustard: drying and dehydrating the mustard after cleaning impurities to obtain dehydrated pickled mustard;

[0067] 4) Making onion and garlic oil: put the washed and drained onion and garlic in cooking oil for frying to obtain onion and garlic oil;

[0068] 5) Cook the dehydrated mustard greens and shallot and garlic oil in step 3) and step 4), and the cooking temperature is 3.5 hours to obtain the finished olive vege...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com