Button arrangement platform for automatic button feeder

A technology for arranging tables and feeding machines, applied in sewing machine components, textiles and papermaking, sewing equipment, etc., can solve the problems of unsmooth button transmission, inability to perform flexible transmission, and inability to perform precise adjustment, and achieve precise and rapid transmission. , the effect of improving the efficiency of button supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

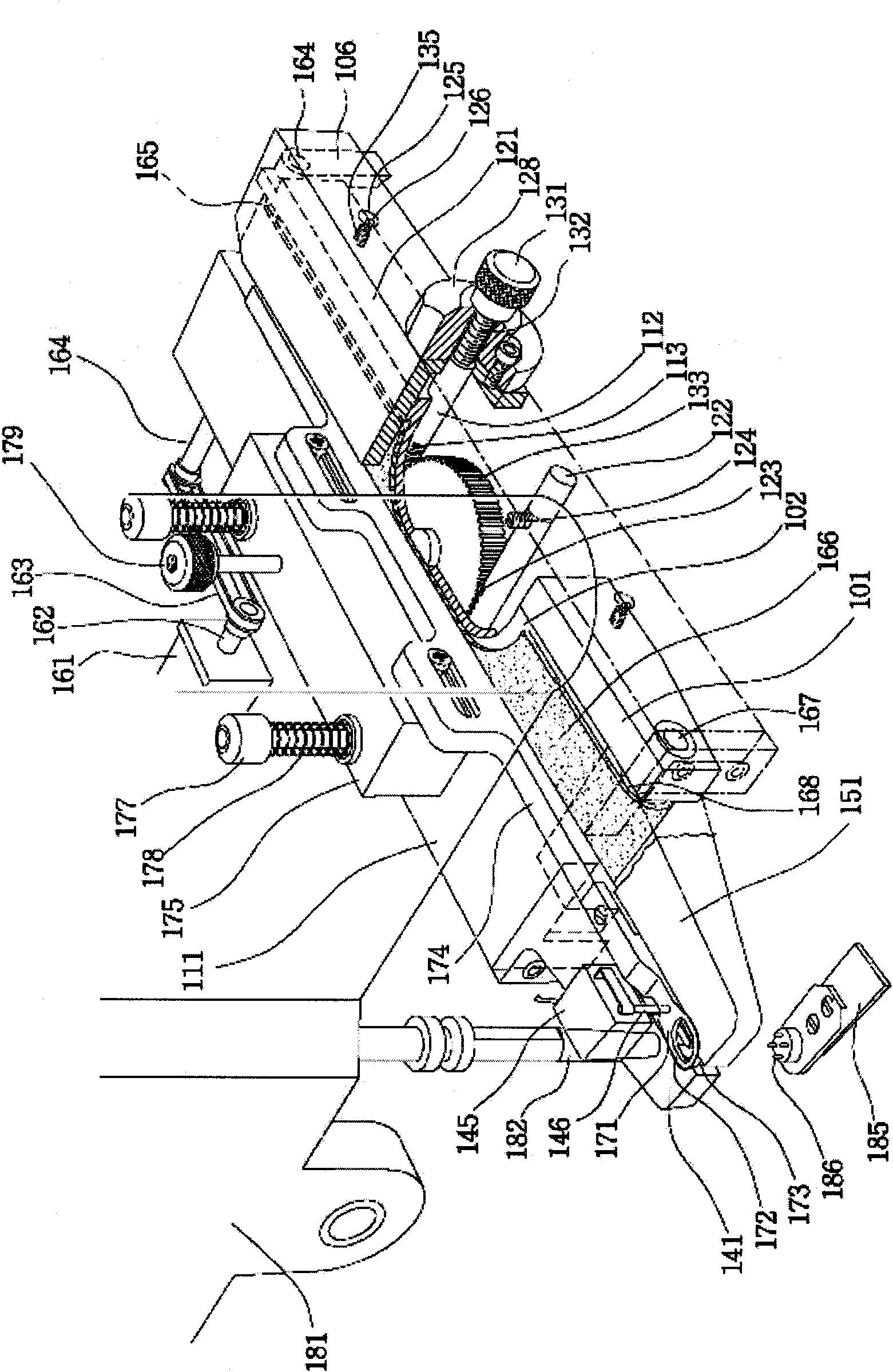

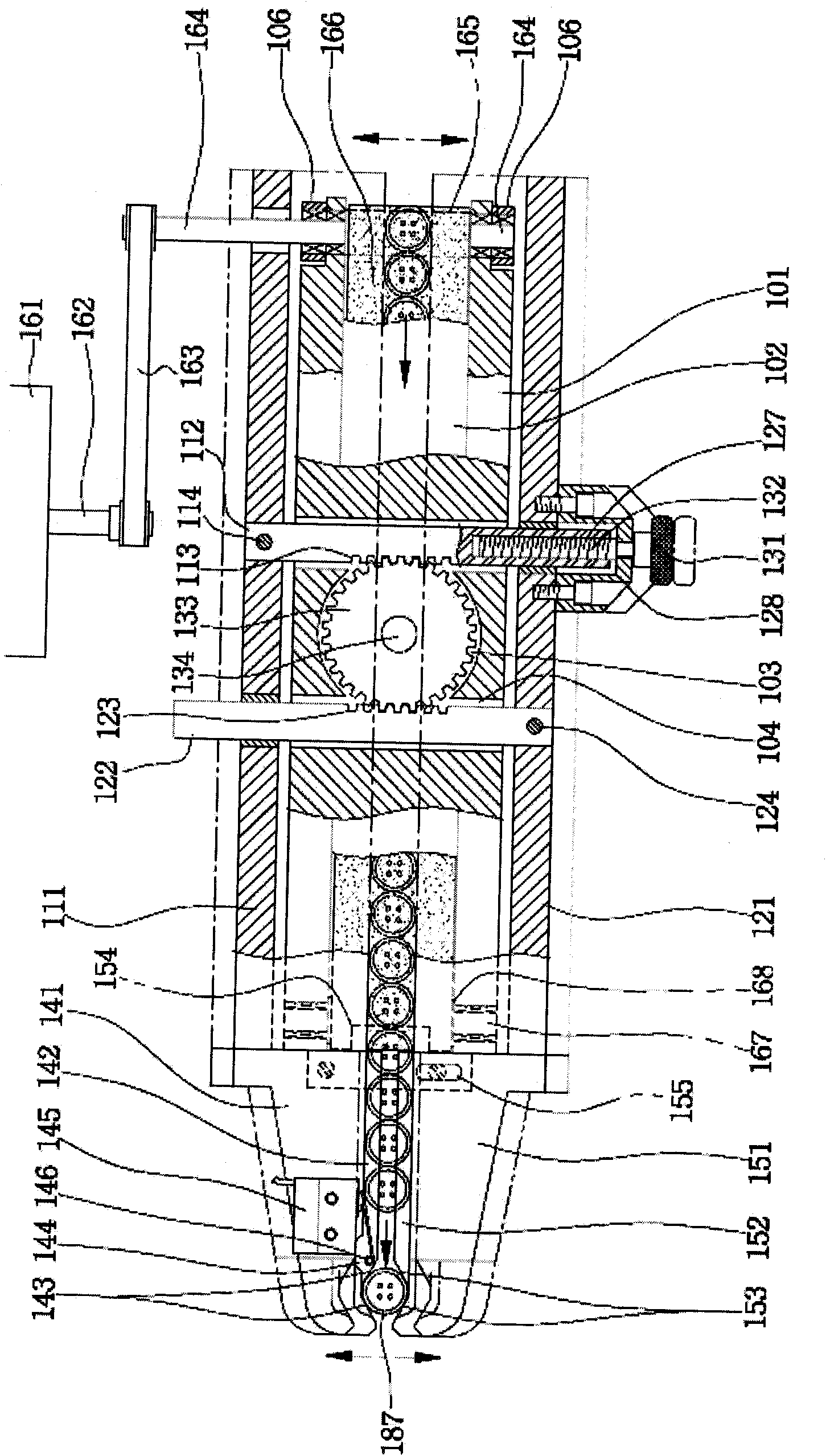

[0058] Hereinafter, the configuration of the present invention will be described in detail with reference to the drawings.

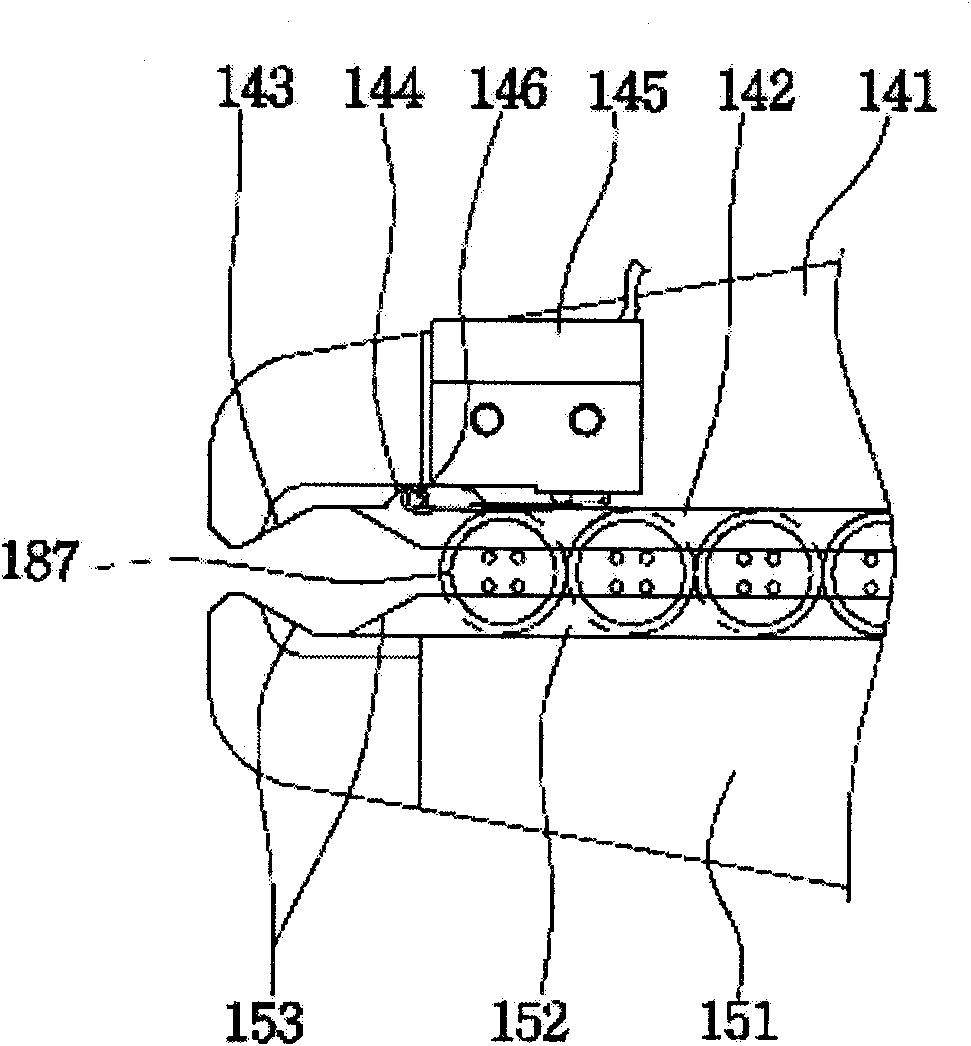

[0059] The button arranging platform has a fixed body 101 that combines one side adjusting platform 111 and the other side adjusting platform 121 side by side on both sides. The other side adjustment platform 121 is used to fix the other side support platform 151 formed with the other side support surface 152,

[0060] The button arranging table has: a conveyor belt 166, which is combined with the guide groove 102 formed in the center of the fixed body 101 to linearly convey the buttons 187 sorted and supplied from the sorting machine;

[0061] a conveyor belt drive mechanism for driving said conveyor belt 166;

[0062] An interval adjustment mechanism, which is used to simultaneously adjust the interval between the one side adjustment table 111 and the other side adjustment table 121 combined with the fixed body 101 both sides according to the size of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com