Unmanned system for automatic food processing and sales

A food processing and automatic technology, applied in the field of unmanned systems, can solve the problems of aggravating the survival pressure of small restaurants, high sales volume, inability to save labor costs, etc., to improve food operation efficiency, reduce operating costs, and occupy a small area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

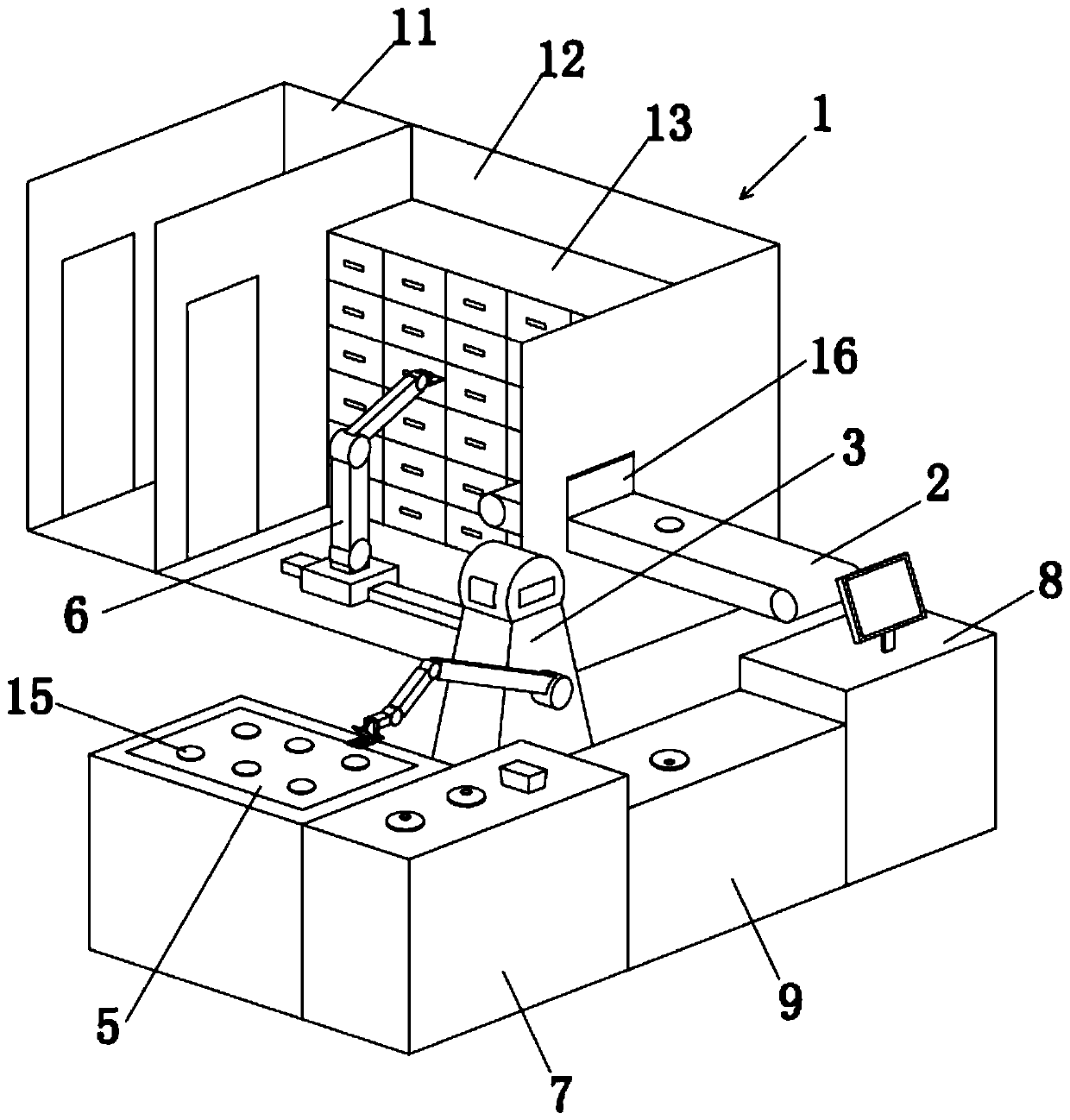

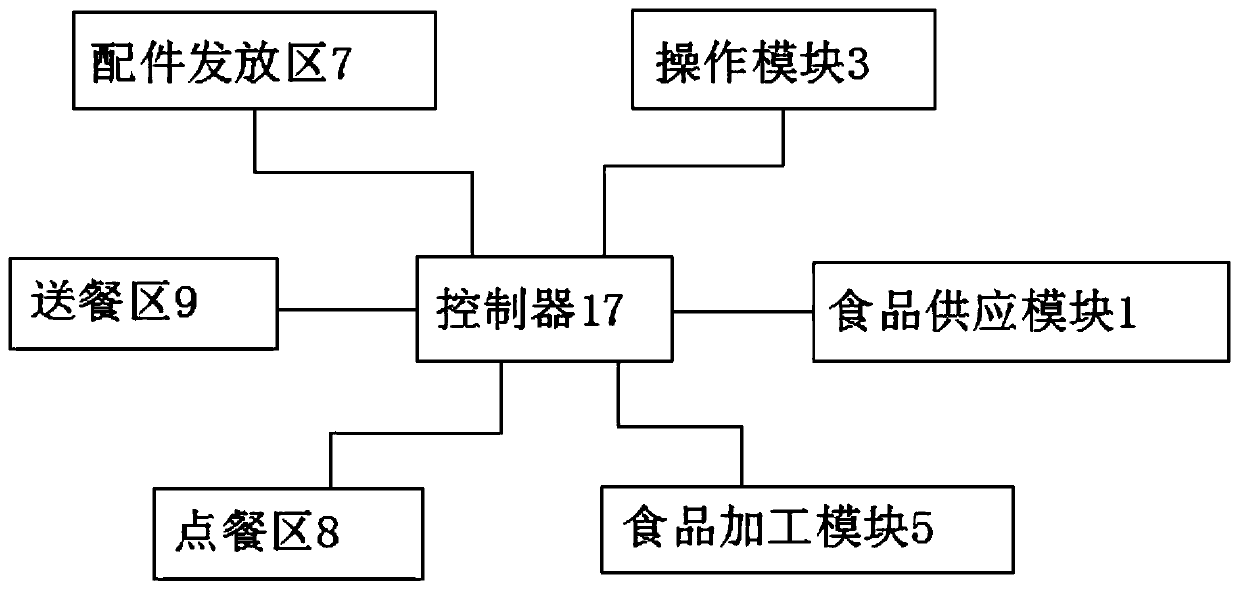

[0046] The specific embodiment of the present invention is as Figure 1 to Figure 8 As shown, an unmanned system for automatic food processing and sales includes an operation module 3 and a food supply module 1 and a food processing module 5 sequentially arranged along the food moving path, and the operation module 3 is located on the side of the food processing module 5 . The unmanned system also includes a controller 17, an ordering area 8 and a meal-taking area, and the meal-taking area is located at one side of the food processing module 5. The controller 17 is signal-connected with the ordering area 8 , the food supply module 1 , the operation module 3 and the food processing module 5 respectively. Wherein, the meal taking area includes an accessory delivery area 7 and a meal delivery area 9 . In the present embodiment, the food supply module 1 is used to supply steak raw materials, and the food processing module is used to process steak 15, and the unmanned system for a...

Embodiment 2

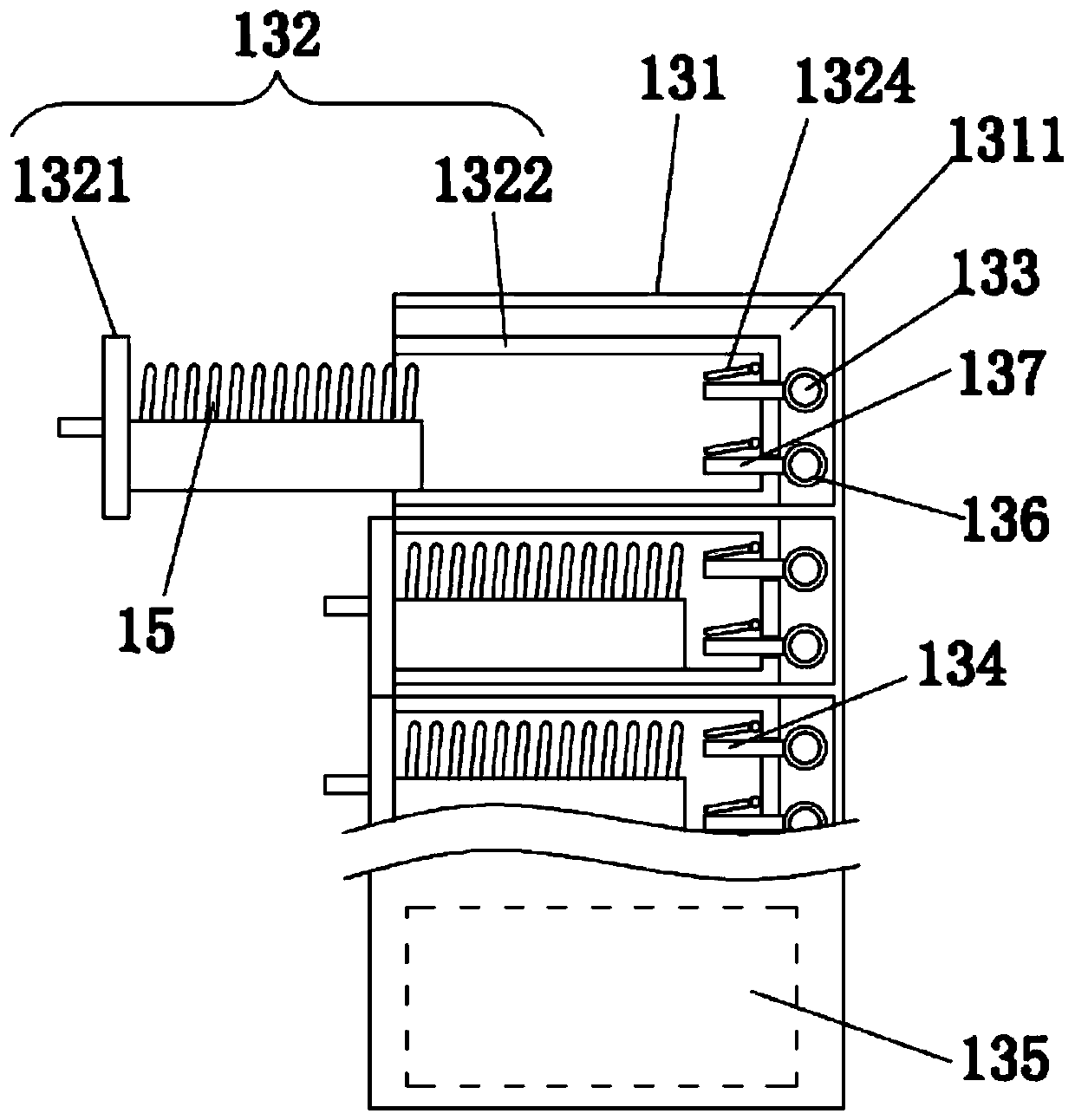

[0067] Such as Figure 9 to Figure 13 As shown, the difference from Embodiment 1 is that the steaks 15 in the cold box unit 132 are placed flat and arranged front and back. The first clamping mechanism 61 of the material storage room manipulator 6 includes a first base 615 connected to the first mechanical arm 62, the first base 615 is provided with a fifth clamping part 611, and the fifth clamping part 611 is hinged above There is a sixth clamping portion 612 , and a fourth cylinder 614 is hinged between the sixth clamping portion 612 and the first base 615 . The steak 15 in the cold box unit 132 is scooped up by the fifth clamping part 611 of the first clamping mechanism 61, and the steak is clamped by the sixth clamping part 612 and the fifth clamping part 611, and then passed through the food storage chamber The manipulator 6 and the first manipulator 62 cooperate to place the steak 15 on the input end of the material transfer mechanism 2 .

[0068] Food material turning...

Embodiment 3

[0074] Such as Figure 14 and Figure 15 As shown, the difference from Embodiment 1 is that the food supply module 1 adopts a horizontal or vertical refrigerator, and the storage room of the refrigerator is provided with movable shelves for placing food materials. There may be no partition between the refrigerator and the food processing area, and there is no need to set up a food conveyor belt mechanism.

[0075] The food processing area can be equipped with one or several food processing modules such as microwave ovens, frying pans, double-sided heating frying clips, electric ovens, ovens, electric steamers, and electric cooking pots. The module processing is completed, and it can also be processed by combining two or more food processing modules.

[0076] The food supply module 1 does not use the material transfer mechanism 2 in Embodiment 1, and only the operation module 3 completes the work of the material storage room manipulator, food material transfer mechanism 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com