Hydraulic control unit

A technology of control unit and pressure control, applied in transmission control, components with teeth, transmission, etc., can solve problems such as C1 clutch response delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

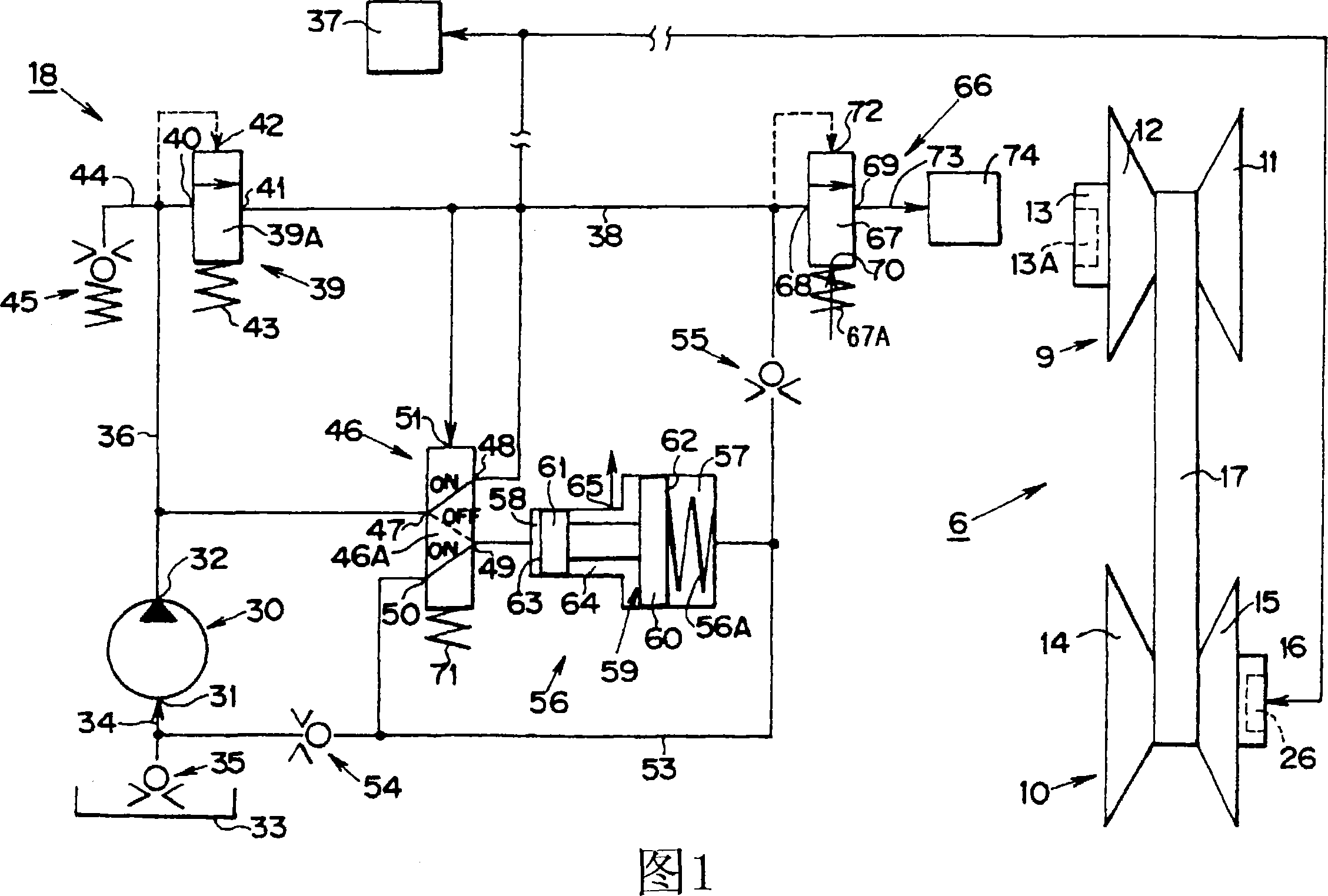

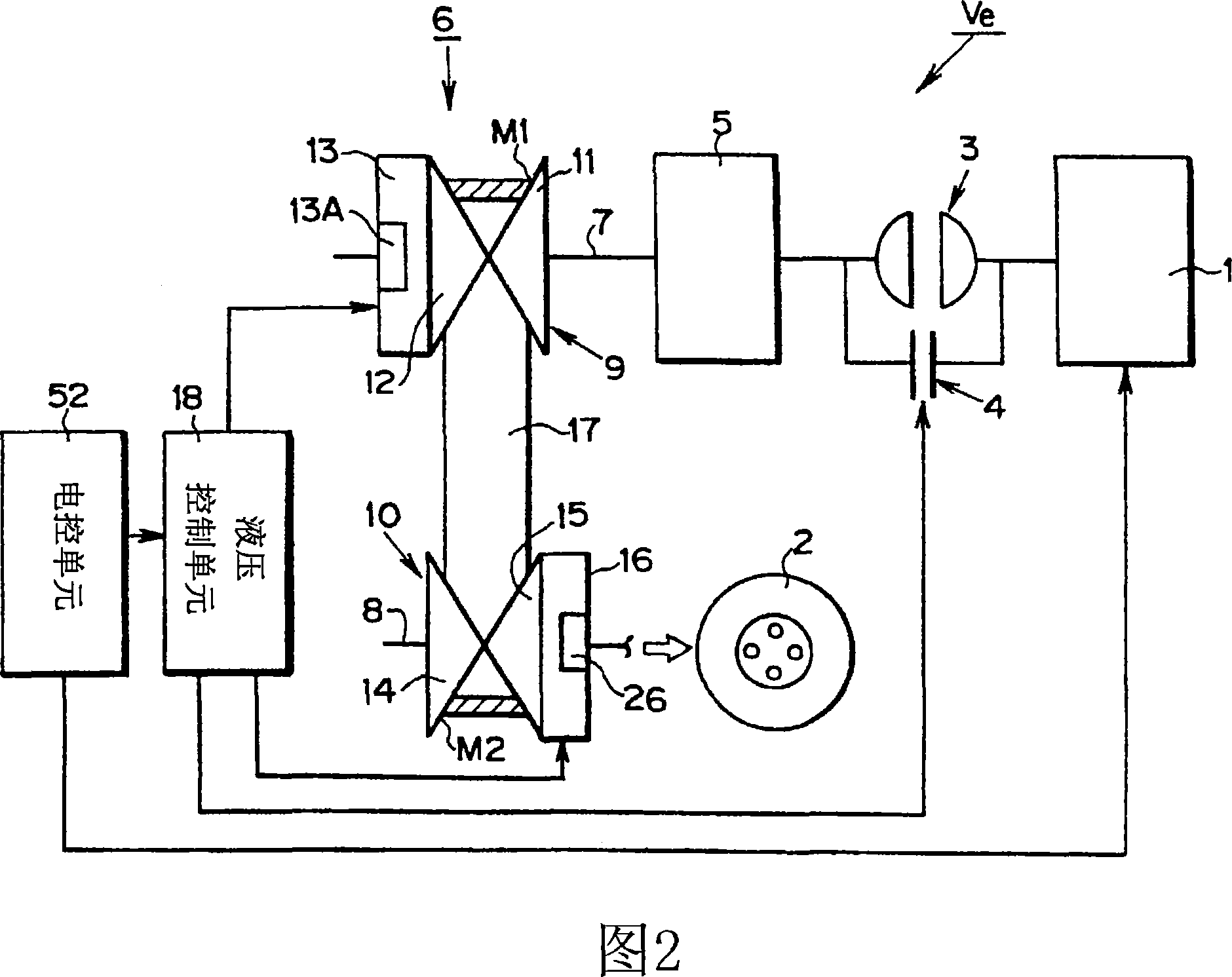

[0047] FIG. 1 shows Example 1 of the hydraulic control unit 18 . The hydraulic control unit 18 has an oil pump 30 driven by the engine 1 . The oil pump 30 has a suction port 31 and a discharge port 32 , and is formed with an oil passage 34 to connect the suction port 31 and an oil pan 33 . A check valve 35 is also provided on the oil passage 34 . The one-way valve 35 allows oil to flow from the oil pan 33 into the oil passage 34 and prevents the oil in the oil passage 34 from flowing back to the oil pan 33 .

[0048] On the other hand, the discharge port 32 is connected to an oil passage 36 . The oil passage 36 communicates with an oil passage 38 that communicates with the hydraulic chamber 26 and the hydraulic chamber 37 of the friction engagement device of the forward / reverse switching mechanism 5 . The frictional engagement devices include a brake and a clutch, and are provided with hydraulic chambers separately, however, for the sake of convenience, the hydraulic chambe...

example 2

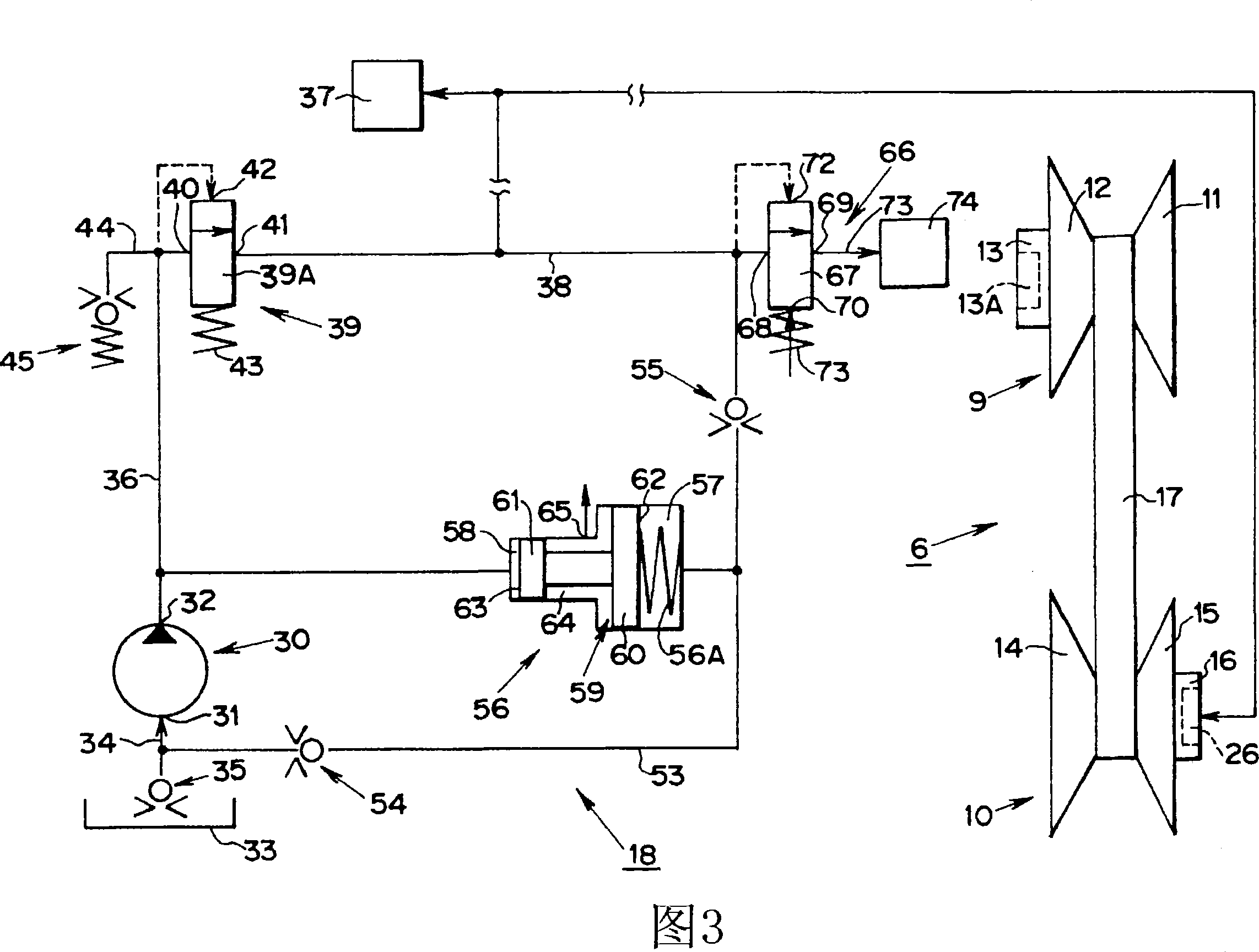

[0074] Hereinafter, Example 2 of the foregoing hydraulic control unit 3 is described with reference to FIG. 3 . In Example 2, the oil passage 36 and the second hydraulic chamber 58 of the accumulator 56 are directly connected to each other, and the aforementioned selection valve 46 is not provided. The rest of the structure of Example 2 is the same as that of Example 1. According to Example 2, when the engine 1 is started, the oil discharged from the oil pump 30 is supplied to the first hydraulic chamber 58 of the accumulator 56 through the oil passage 36 . Then, based on the same principle as in Example 1, the oil in the first hydraulic chamber 57 is supplied to the oil passage 38 through the oil passage 53 . The line pressure control valve 39 supplies the oil of the oil passage 36 to the oil passage 38 through the input port 40 and the drain port 41 before the oil of the first hydraulic chamber 57 is completely supplied to the oil passage 38 .

[0075] Also, according to E...

example 3

[0077] Next, Example 3 of the hydraulic control unit 18 will be described with reference to FIG. 4 . According to Example 3, an oil passage 75 connected to the hydraulic chamber 26 is provided, and the oil pressure of the oil passage 75 is input to the control port 51 of the selection valve 46 . Also, the oil passage 75 and the oil passage 53 are connected to each other with the check valve 55 disposed therebetween. The check valve 55 allows oil to flow from the oil passage 53 into the oil passage 75 and prevents the oil in the oil passage 75 from flowing back into the oil passage 53 .

[0078] On the other hand, an oil passage 76 connected to the oil passage 36 is formed, and a line pressure control valve 77 is arranged between the oil passages 36 and 76 . The line pressure control valve 77 includes a relief valve, and is equipped with a valve element 77A and an elastic element 77C for pressing the valve element 77A against a valve seat 77B. The line pressure control valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com