Semiconductor manufacturing device, semiconductor manufacturing system and substrate processing method

A technology for manufacturing devices and processing methods, which is applied in semiconductor/solid-state device manufacturing, comprehensive factory control, comprehensive factory control, etc., and can solve problems such as huge investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

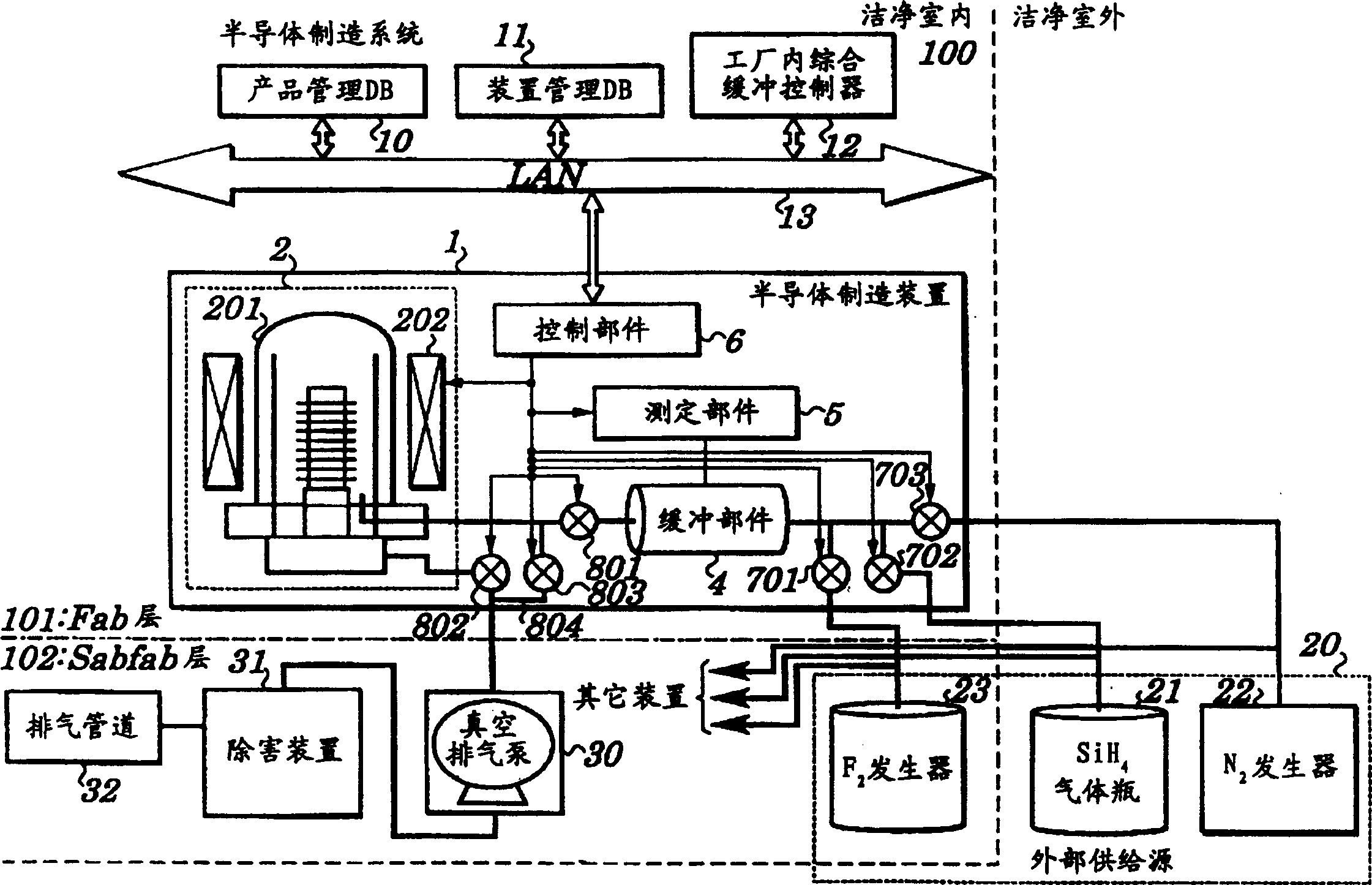

[0047] In a first embodiment of the present invention, an LPCVD apparatus is used as a semiconductor manufacturing apparatus, and the present invention is applied to the semiconductor manufacturing apparatus, a semiconductor manufacturing system composed of the semiconductor manufacturing apparatus, and a substrate processing method used therefor.

[0048] Basic structure of semiconductor manufacturing equipment and semiconductor manufacturing system

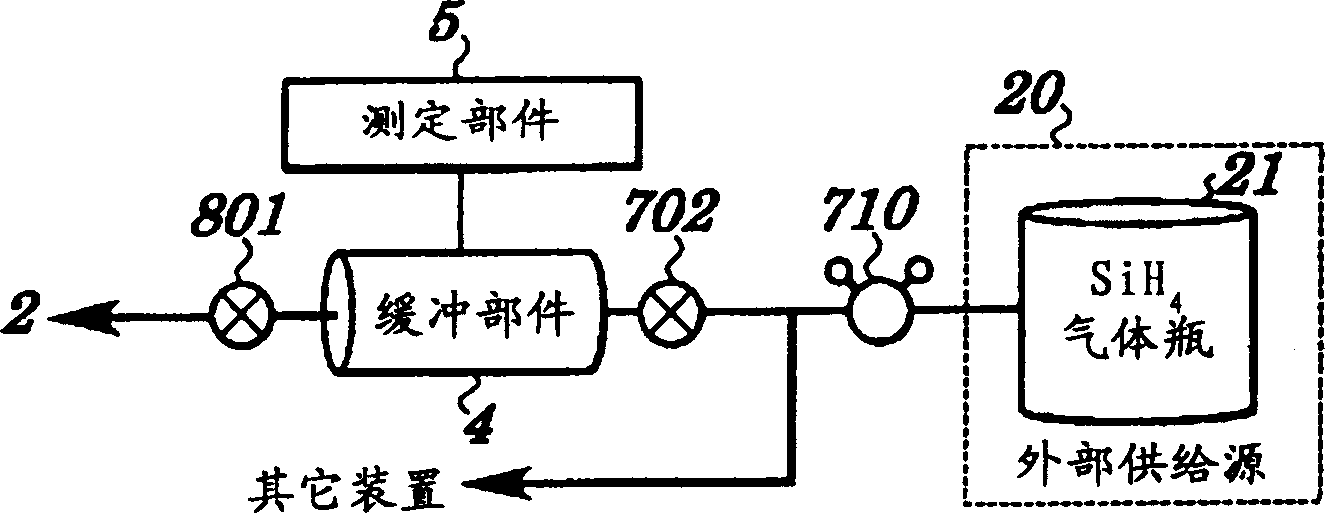

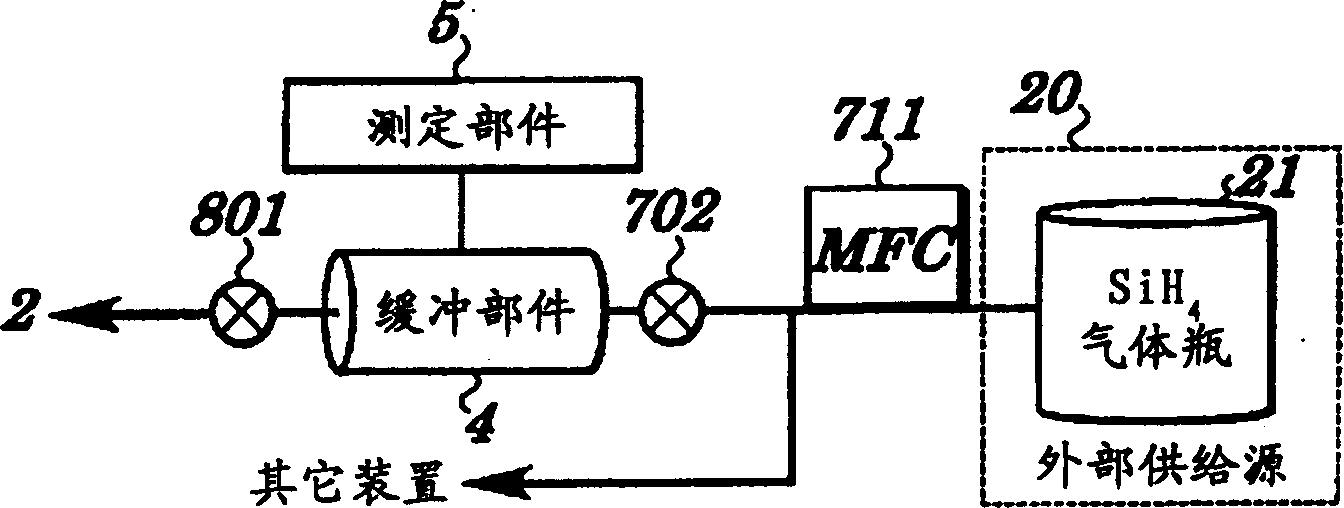

[0049] Such as figure 1 As shown, the semiconductor manufacturing apparatus 1 according to the first embodiment of the present invention is an LPCVD apparatus for forming a polysilicon film on the surface of a semiconductor wafer using monosilane gas as a material gas. That is, the semiconductor manufacturing apparatus 1 includes at least a processing chamber 2 for performing substrate processing, supplies materials necessary for processing from an external supply source 20 to the inside of the processing chamber 2 or the inside...

no. 2 Embodiment approach

[0127] The second embodiment of the present invention is an example in which the buffer member 4 built in the semiconductor manufacturing apparatus 1 constituting the first embodiment of the present invention is described as an external semiconductor manufacturing apparatus.

[0128] Such as Figure 13 As shown, in the semiconductor manufacturing system according to the second embodiment of the present invention, unlike the semiconductor manufacturing apparatus 1 having the processing chamber 2, an additional semiconductor manufacturing apparatus 1A is arranged. The semiconductor manufacturing apparatus 1A includes a buffer member 4 that supplies substances necessary for substrate processing from an external supply source 20 , stores the supplied substances, and supplies the stored substances to the outside, that is, the processing chamber 2 of the semiconductor manufacturing apparatus 1 .

[0129] Further, the semiconductor manufacturing apparatus 1A includes a control unit 6...

no. 3 Embodiment approach

[0133] Third Embodiment of the Present Invention An example in which the present invention is applied to the semiconductor manufacturing apparatus 1 and the semiconductor manufacturing system according to the first embodiment of the present invention will be described in terms of a method for cleaning the inner wall of the reaction tube 201 in the processing chamber 2 of the semiconductor manufacturing apparatus 1 .

[0134] basic cleaning method

[0135] In the reaction tube 201 of the semiconductor manufacturing apparatus 1 according to the first embodiment of the present invention, a polysilicon film is formed by LPCVD according to the previous example, so the method for cleaning the silicon film adhering to the inner wall of the reaction tube 201 will be described here. Also, here, using figure 1 Be explained. Furthermore, the process of forming a silicon film on a semiconductor wafer is a direct substrate process, but the process of cleaning the silicon film adhering to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com