Transmission

A technology of transmission and lubrication mechanism, applied in the direction of toothed elements, gear lubrication/cooling, belt/chain/gear, etc., can solve problems such as material cost or assembler increase, reduction of lubricating oil supply efficiency, and layout space limitation. , to achieve the effect of improving oil supply efficiency, light weight and small layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

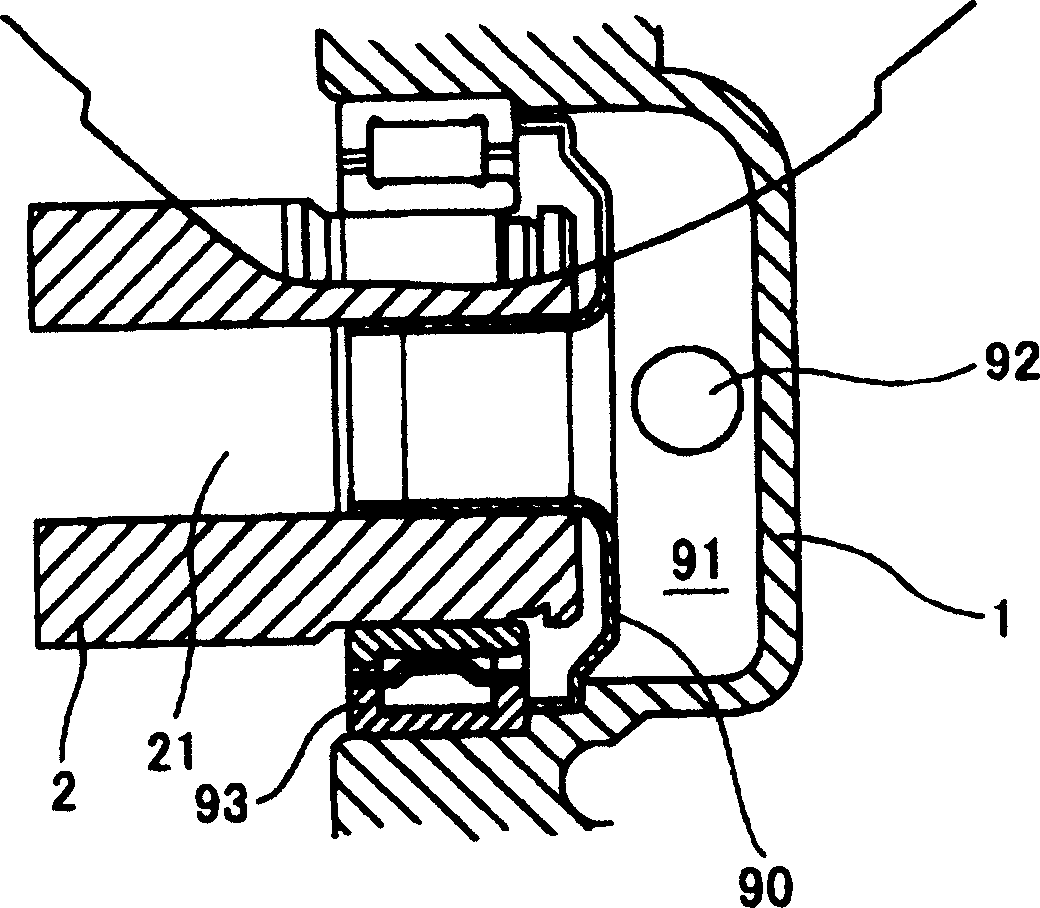

[0025] exist figure 1 The bearing part of the existing transmission and the vicinity of the input shaft 2 are enlarged in the figure. Usually, such as figure 1 As shown, the oil reservoir 91 is formed by a wall 90 coupled near the axial end of the input shaft 2 and separated from the transmission case 1 by a space. Lubricating oil as lubricant is collected by a pan (not shown), and supplied into the oil reservoir 91 through the oil supply port 92 . Then, lubricating oil is supplied to the axial oil passage 21 inside the input shaft 2 . However, in this lubricating structure, lubricating oil leaks from the gap between the wall 90 and the transmission case 1, and / or leaks from the gap between the bearing portion 93 and the transmission case 1, resulting in sometimes reduced oil supply efficiency.

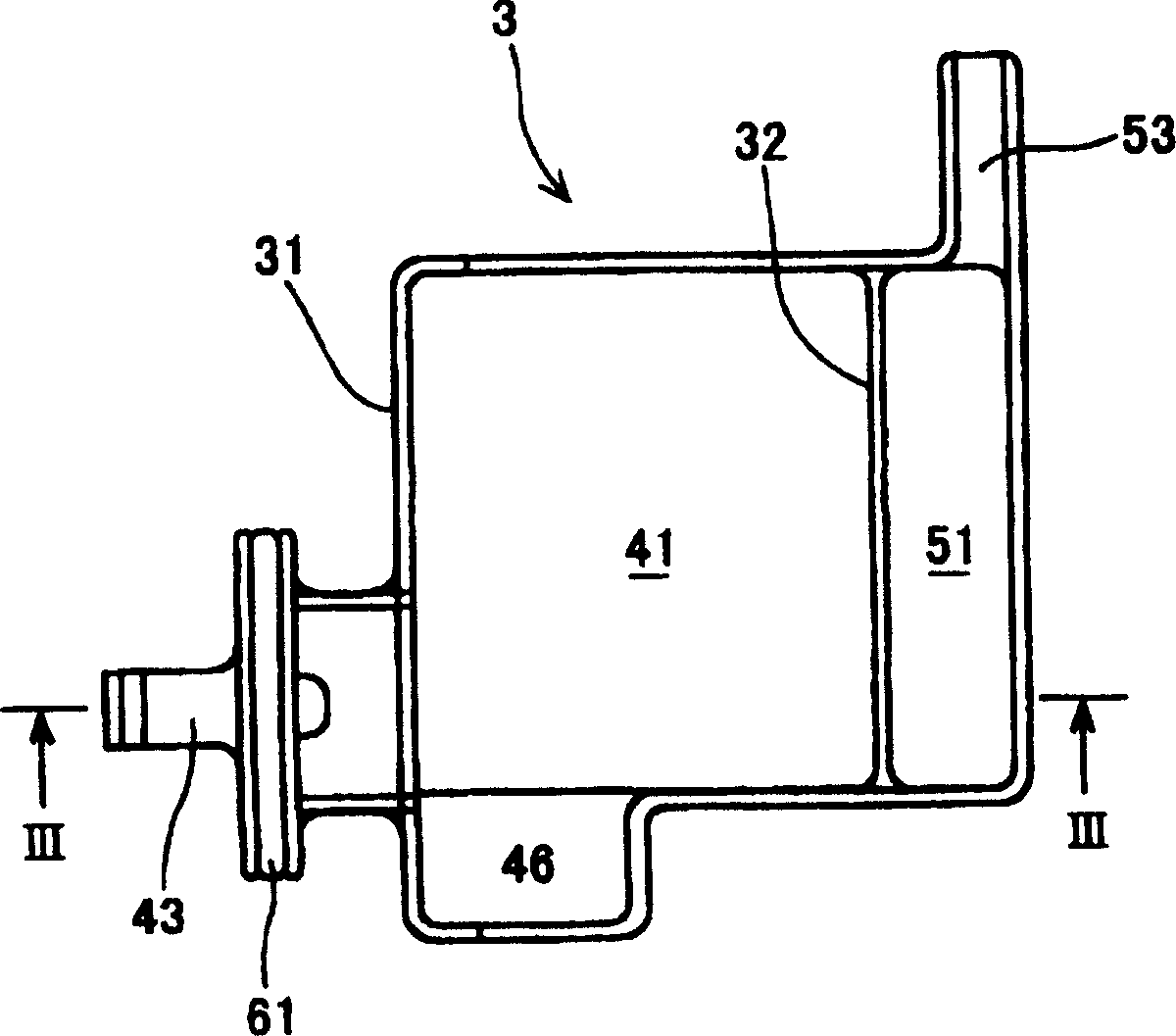

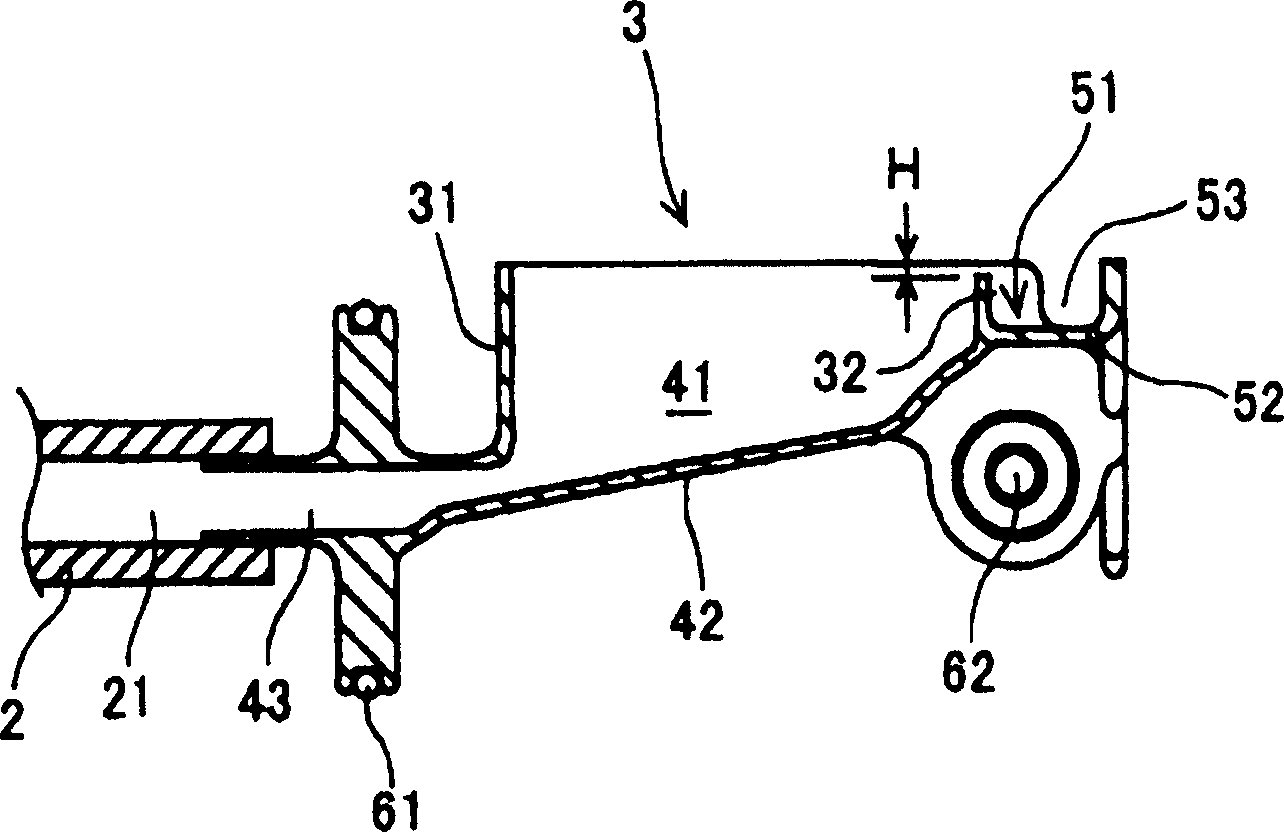

[0026] like figure 2 and 3 As shown, the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com