Horn assembling, dispensing, feeding and discharging automatic machine

An automatic machine, automatic loading and unloading technology, applied in the direction of spraying devices, conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity, high scrap, easy to stick glue, etc., to achieve high degree of automation and low production cost , the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

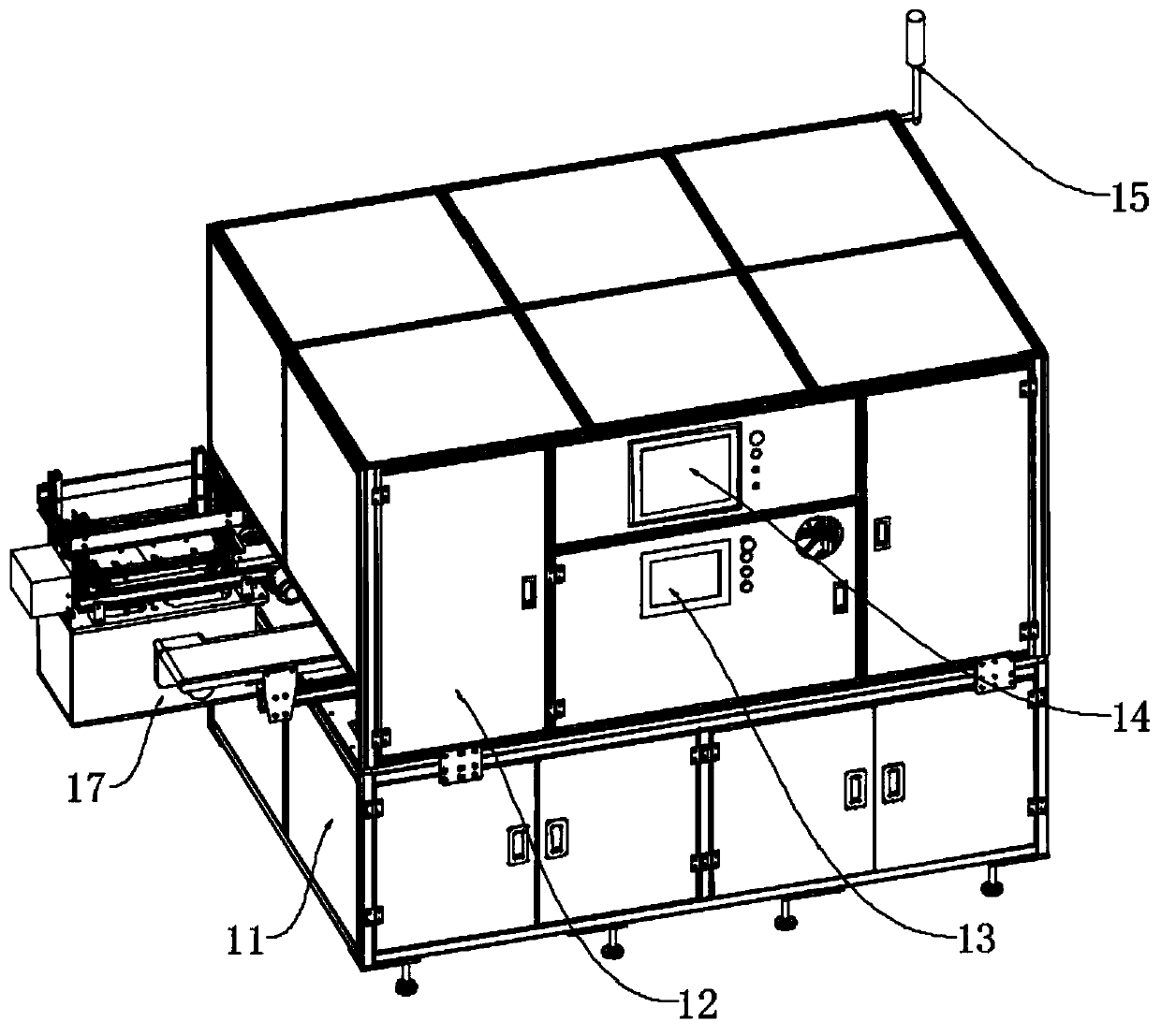

[0099] see Figure 1-17 , the present invention is a kind of speaker assembly dispensing and loading and unloading automatic machine, comprising:

[0100] Frame 11; and the outer cover 12 arranged on the frame 11; and the intake controller 17 and the exhaust module 16 arranged on the frame 11; An emergency stop button 14; and a tricolor warning light 15 arranged on the outer cover 12;

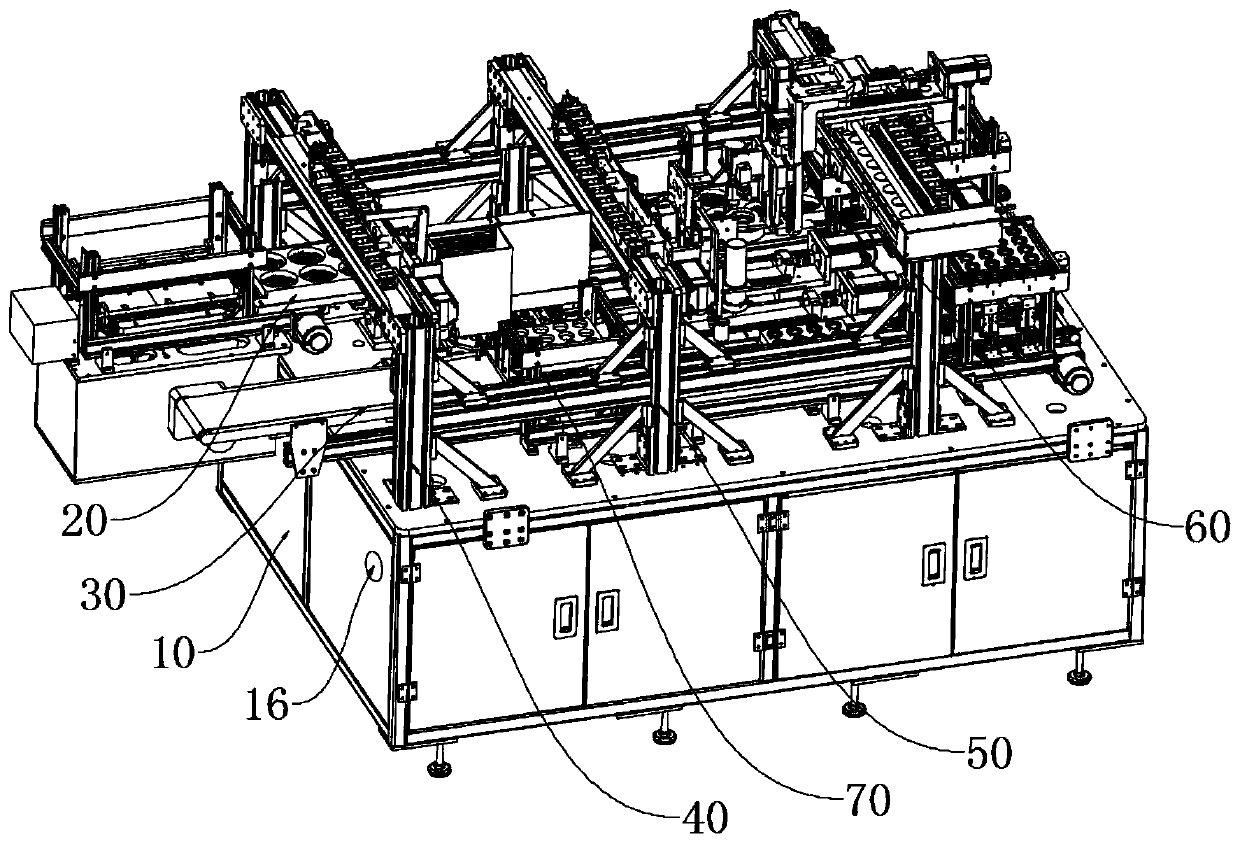

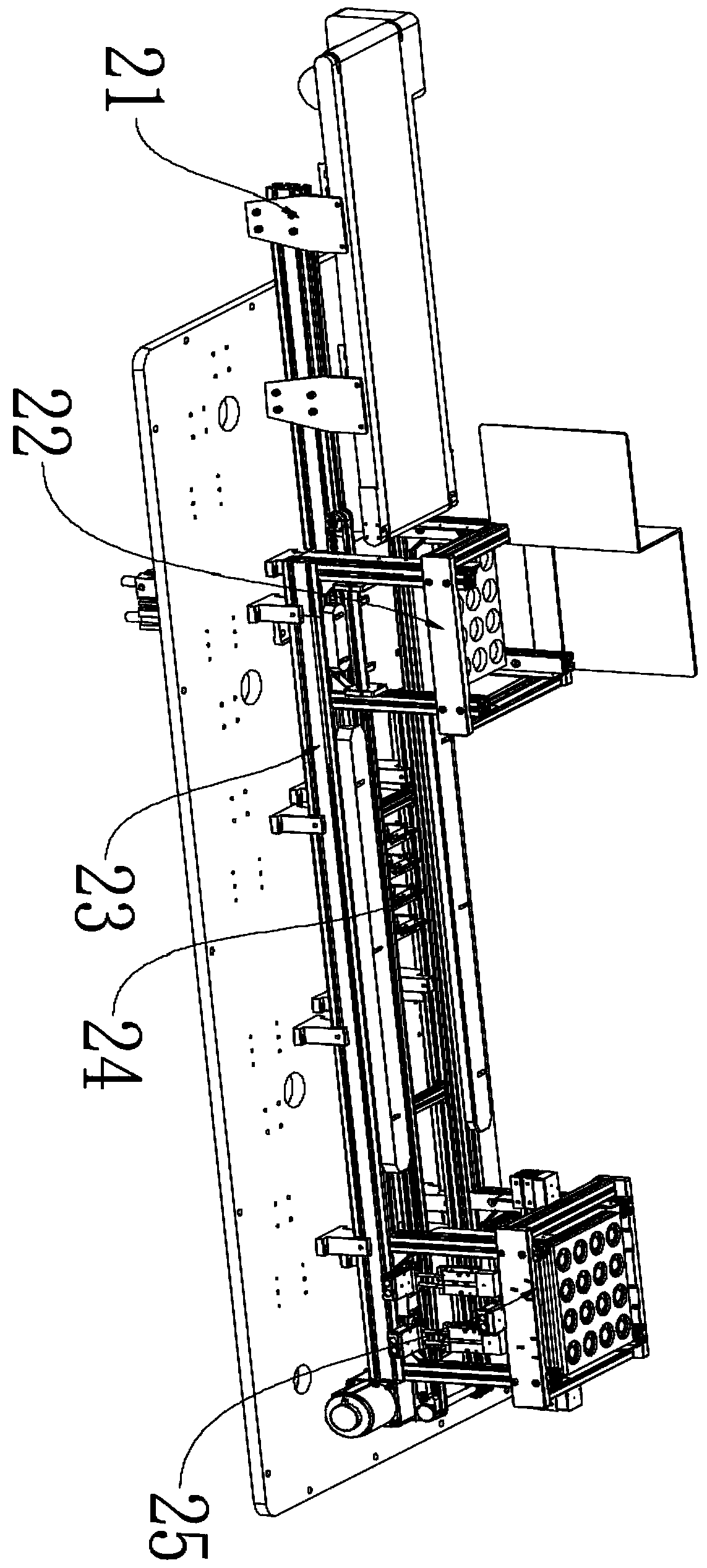

[0101] see image 3 , a kind of speaker assembly dispensing and loading and unloading automatic machine of the present invention should also include a horn automatic loading and unloading module 20; a horn cover loading and unloading module 30; a material grabbing module 40; a glue dispensing module 50; 60 ; carrier module 70 .

[0102] Put the plastic discs with horn products in the first tray module 25 of the horn automatic loading and unloading module 20, stack 20 layers at a time; put the plastic discs with horn cover products on the horn cover for automatic loading and unloading In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com