contact system

A connected system and fine-network technology, applied in the direction of mechanical conveyors, metal processing, conveyor objects, etc., can solve the problems of manpower consumption, material resources, transportation errors, etc., and achieve space saving, high versatility, and easy manufacturing and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0121] The invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

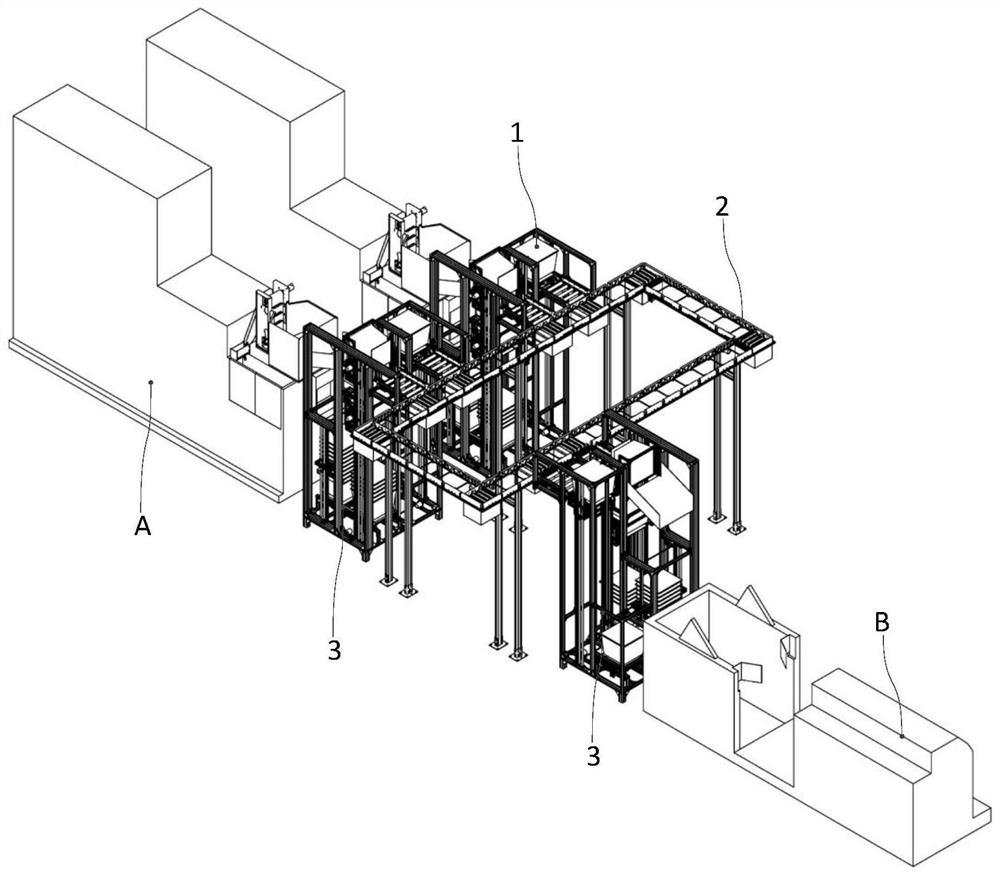

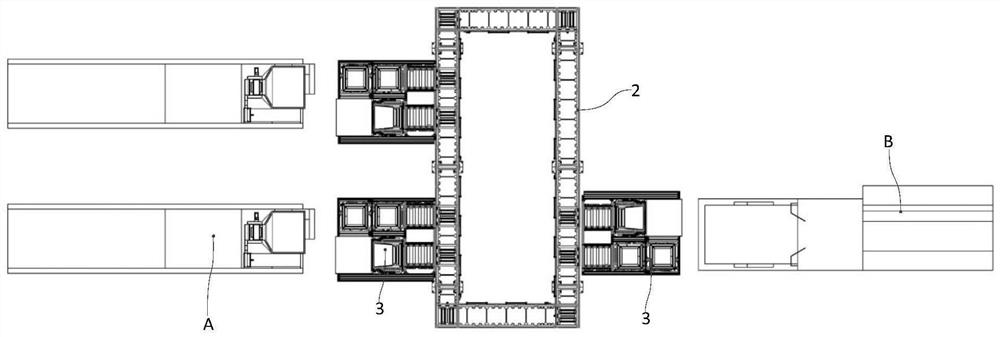

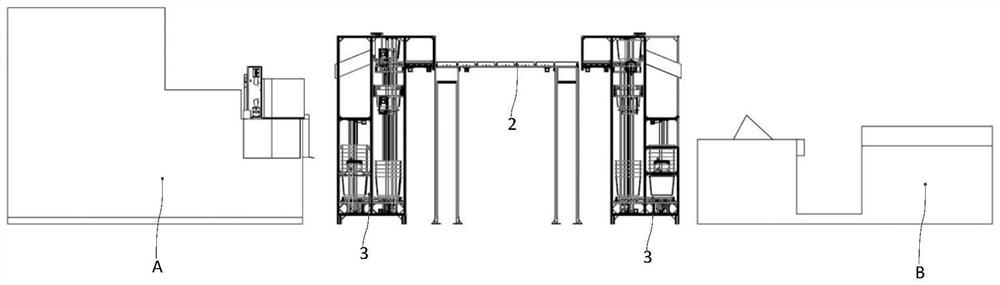

[0122] contact system, such as Figure 1-Figure 3 As shown, the spun yarn produced by the spinning machine group A is sent to the designated machine of the winding machine group B at a fixed point, and the spun yarn bobbin is stored through the yarn basket 1, or the empty bobbin is carried out by the rail conveying system 2 For the fixed-point transportation and transportation of the yarn basket 1, the hoisting system 3 lifts, transports and temporarily stores the yarn basket 1; specifically, the hoisting system 3 lifts the spun bobbin storage basket 1 produced by the spinning machine group A, and enters the to the rail conveying system 2; the rail conveying system 2 transfers the yarn basket 1 to the designated machine station of the corresponding winding machine group B, and then removes the yarn basket 1 by the lifting system 3 of the machine statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com