Bar material conveying system

A conveying system and bar material technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of difficulty in controlling the rhythm and frequency of feeding, low feeding efficiency, and large quantity, so as to reduce labor costs and reduce labor costs. The effect of labor intensity and improving feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

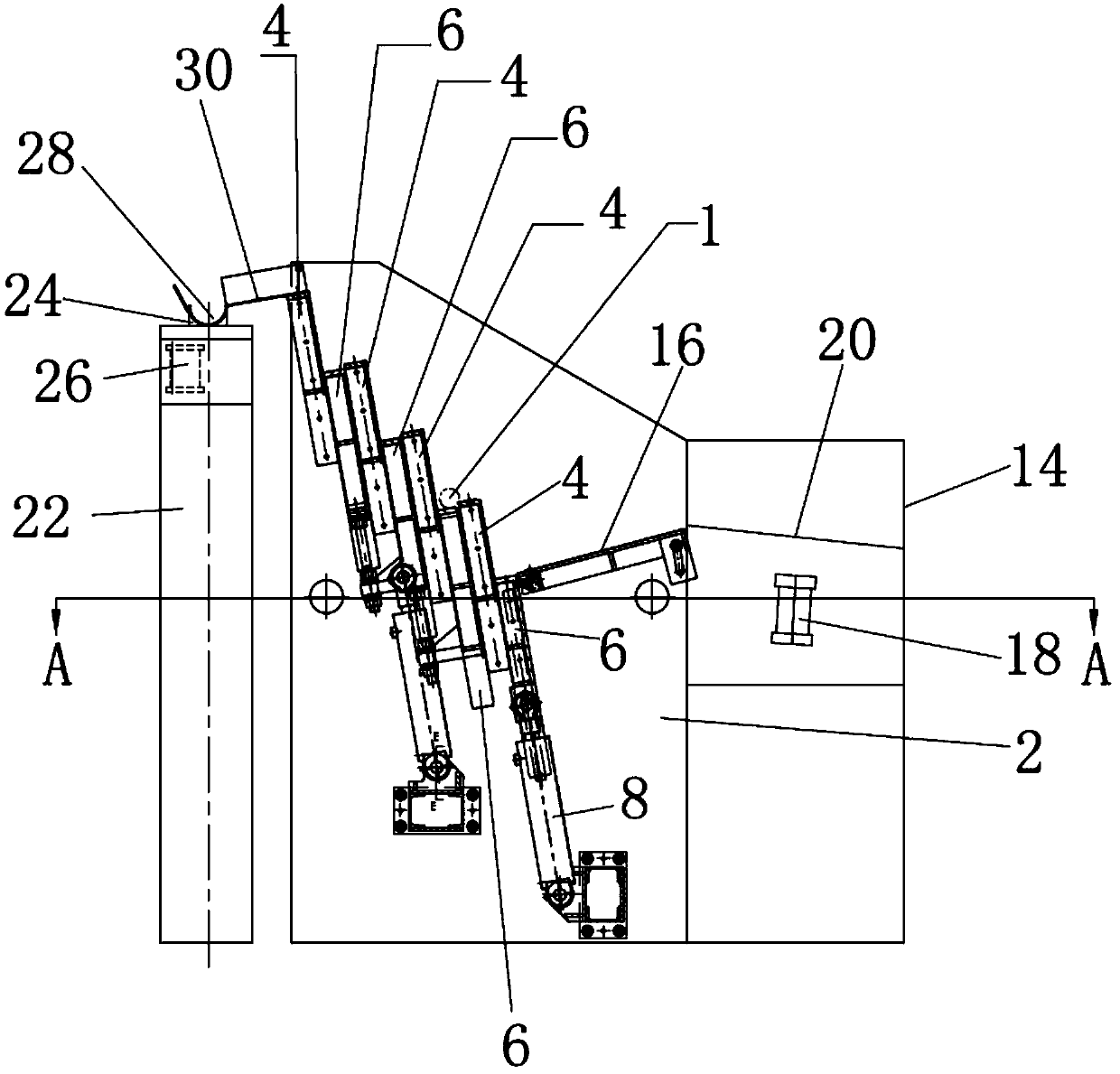

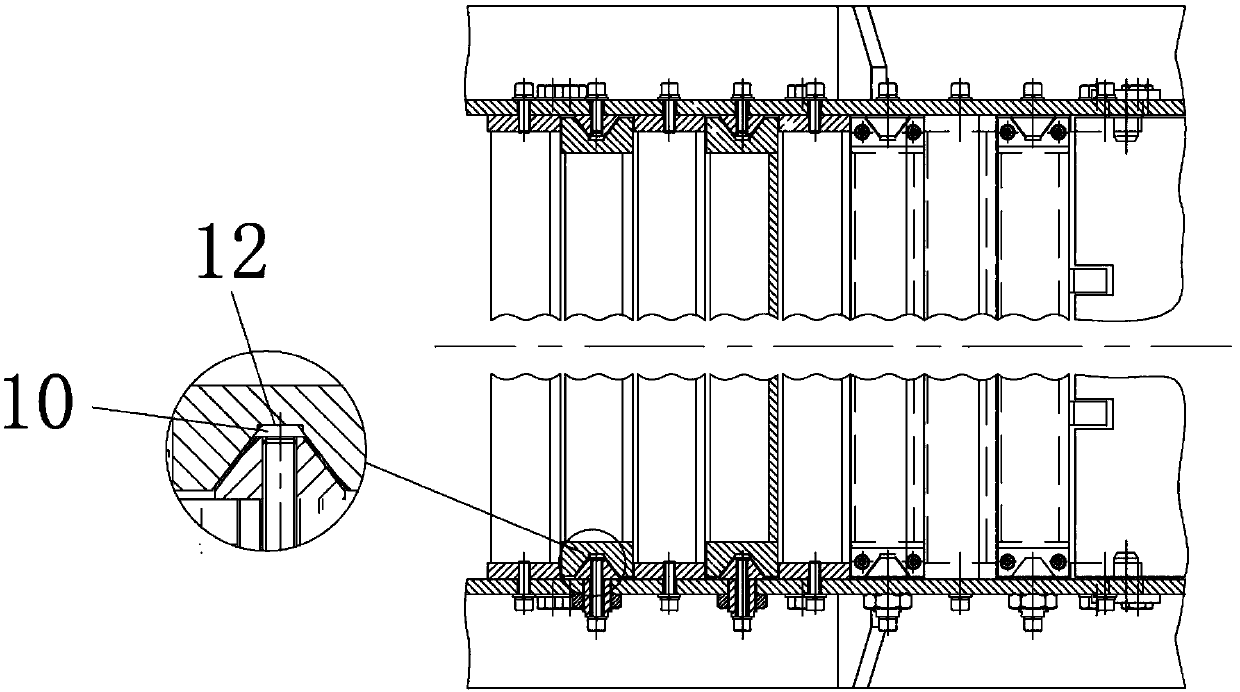

[0020] Such as Figure 1-2 As shown, this embodiment discloses a bar material conveying system, which includes a vibrating feeding device 14, a step lifting feeding device, a vibrating whole material device 22 and a conveyor belt conveyor chain arranged in sequence, and the vibrating feeding device 14 transports the bar material to the step lifting In the feeding device, the ladder-elevating feeding device feeds and sorts the materials while lifting them, and transports the disorderly piled bars to the vibrating whole material device 22, which further arranges the bars to ensure that each bar The material can be transported to the conveyor belt conveyor chain in a regular position and posture. The conveyor belt conveyor chain transports the sorted bar material to the target position to realize the automatic delivery of the bar material. After use, it can improve the feeding efficiency of the bar material and reduce labor costs. and manual labor intensity. The specific structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com