Chain type feeding and conveying device of net rack pipe end circular seam full-automatic welding machine

A conveying device and chain conveying technology, which is applied in the field of fully automatic welding machines for grid pipe end ring seams, can solve problems such as waste of human resources, and achieve the effects of reducing labor intensity, good stability and safety, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

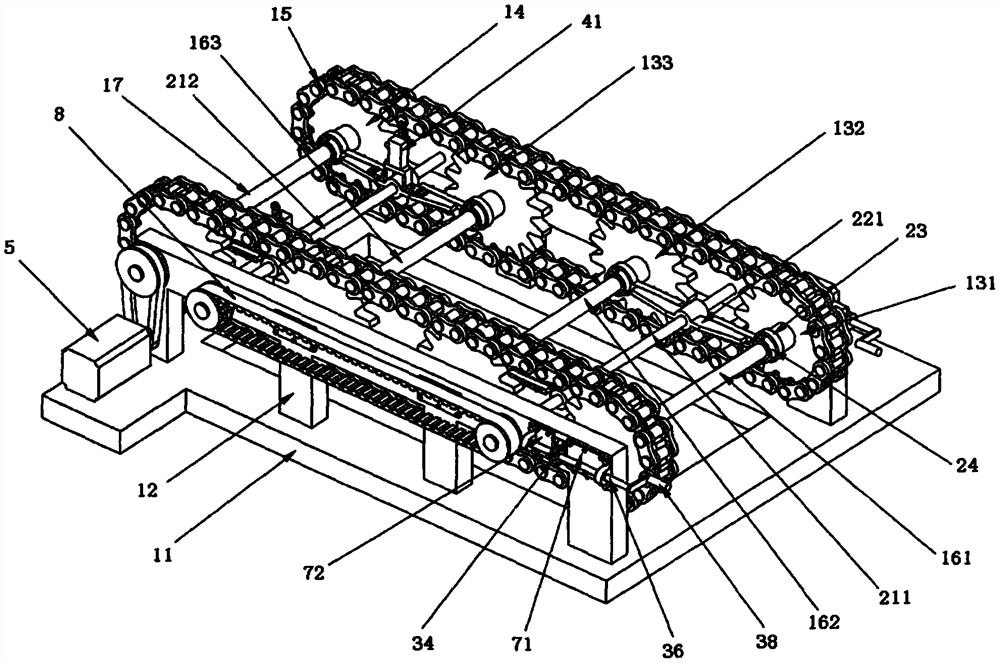

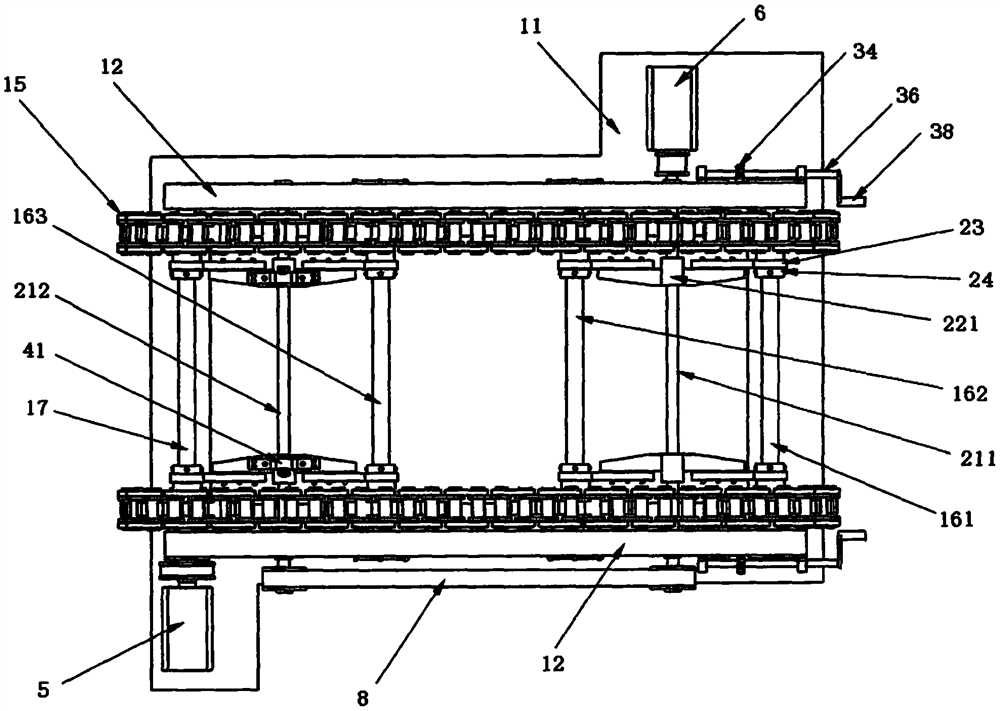

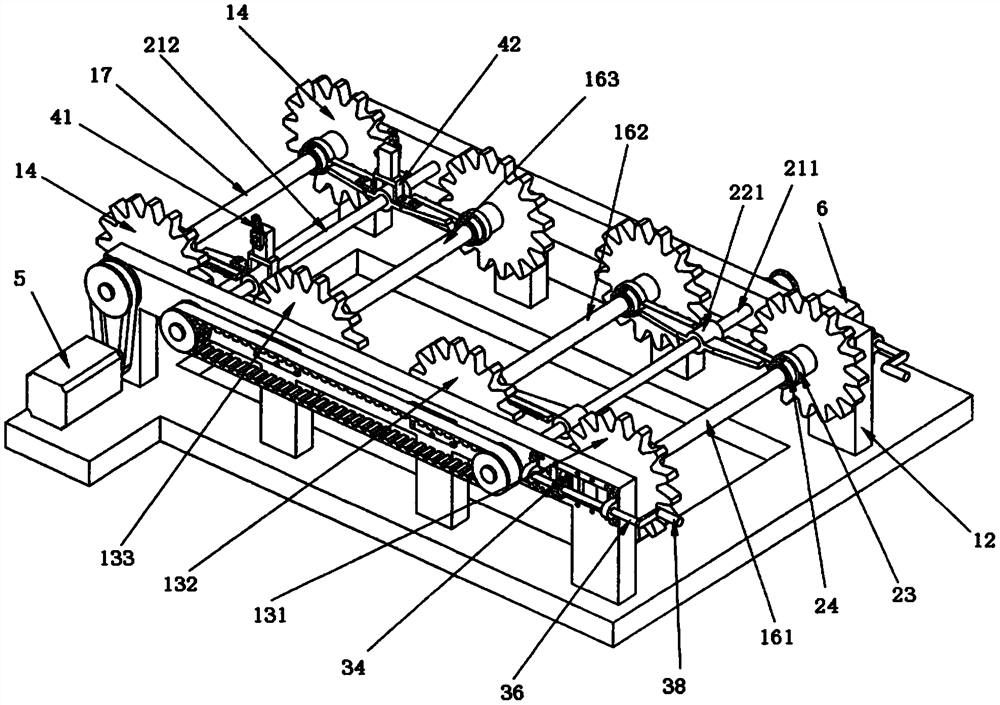

[0039] Such as Figure 1-19 As shown, this specific embodiment adopts the following technical solutions: a chain-type feeding and conveying device for a fully automatic welder for the pipe end ring seam of a network frame, including a chain conveying mechanism 1, a position adjusting mechanism 2, a tension adjusting mechanism 3, a waiting Welded pipe position detection device 4, the input end of the chain conveying mechanism 1 is manually loaded, the output end of the chain conveying mechanism 1 is equipped with a fully automatic welding machine, and the chain conveying mechanism 1 includes a machine base 11 and a frame 12 , driven sprocket 13, driving sprocket 14, transmission chain 15, slide shaft 16, rotating shaft 17, described frame 12 is provided with two, offers chute on the described frame 12, slides in the chute A sliding shaft 16 is installed, and a cylindrical hole is provided on the frame 12, and a rotating shaft 17 and a screw mandrel 21 are respectively rotated i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com