Automatic packaging system for winding cone yarns and method thereof

A bobbin and automatic technology, applied in the field of textiles, can solve the problems of difficulty in production and recruitment of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

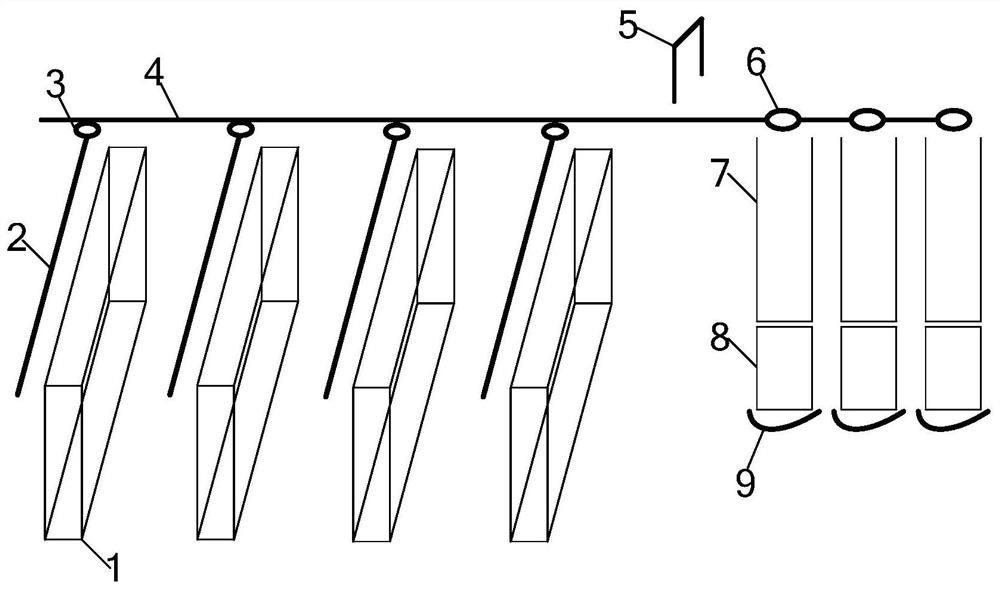

[0012] Winding bobbin yarn automatic packaging system, the packaging system includes a winder 1, the number of winders 1 is between 3-10, the winders 1 are arranged in parallel along the length direction, along the length of the winder 1 The bobbin production system with the same structure is arranged at equal intervals in the direction. The bobbin production system realizes the transformation from at least one small package bobbin to the large bobbin bobbin, and realizes the bobbin on the bobbin during the conversion process. Thick places, fine details, and neps are removed within the preset range, and the prepared bobbin is wound on the bobbin, and the bobbin is stable and easy to unwind in a certain design shape on the bobbin Winding in the same way, and then the number of turns of the prepared bobbin wound on the bobbin along the height direction of the bobbin is gradually reduced, and finally the wound bobbin has the largest number of winding turns and high quality The la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com