Bundled glass tube conveyer

A conveyor and glass tube technology is applied to a bundled glass tube conveyor to transport glass tubes in bundles. It can solve the problems of breakage, secondary scratches of glass tubes, and high labor intensity of workers, and achieve the effect of reducing secondary pollution and labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate those skilled in the art to better understand the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The following is only exemplary and does not limit the protection scope of the present invention.

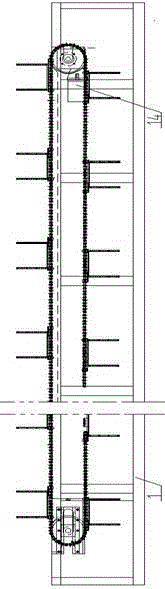

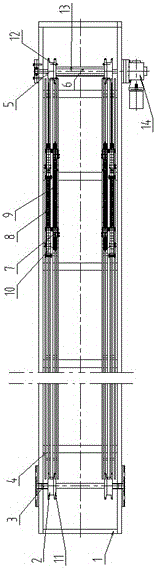

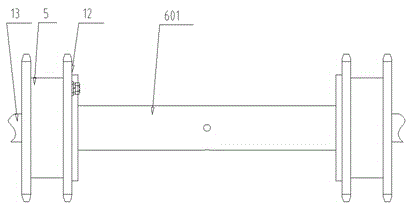

[0018] Reference attached figure 1 and figure 2 , a glass tube bundle conveyor, including a frame 1, a drive unit 14, a driving shaft 13, a driven shaft 3, a fixed conveying unit, an adjusting conveying unit, a plurality of glass tube bundles moving bracket 7, a plurality of bundled glass tubes fixed The bracket 10 and the glass tube bracket spacing adjustment device 6; the frame 1 is a frame structure in which profiles are welded as one; the drive unit 14 is an integrated motor and reducer, fixed on the frame 1; the two ends of the driving shaft 13 are installed through the bearing seat One end on the frame 1, and connected with the drive unit 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com