Full-automatic feeding device of heating furnace

A heating furnace, fully automatic technology, applied in the field of fully automatic feeding device for heating furnace, can solve the problems of empty material, increase labor intensity of workers, safety cannot be guaranteed, etc., to improve stability and safety, and realize orderly progress The effect of giving and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

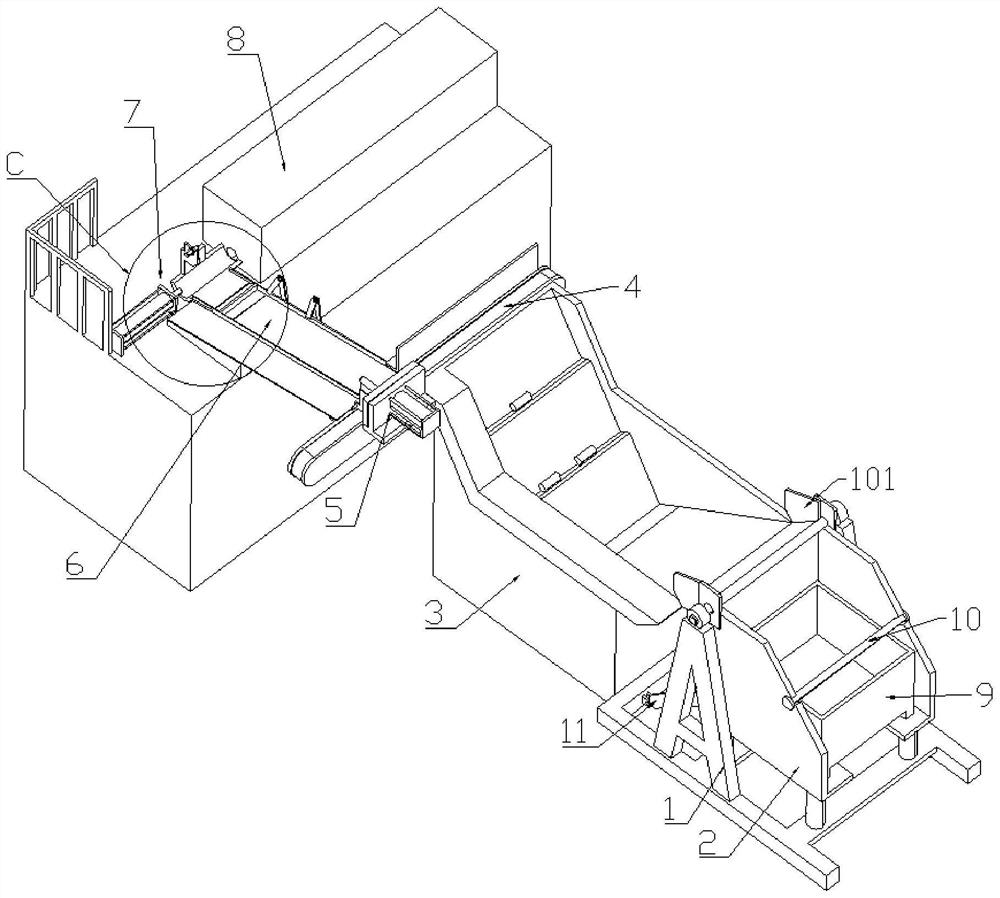

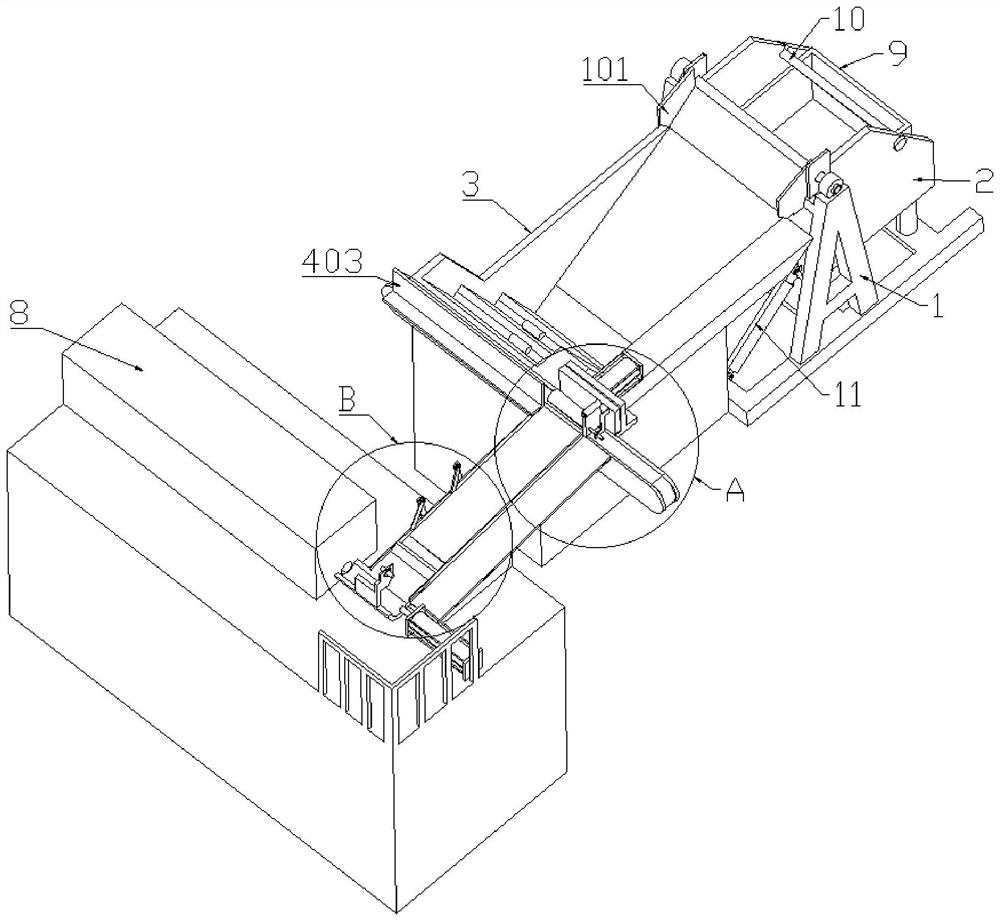

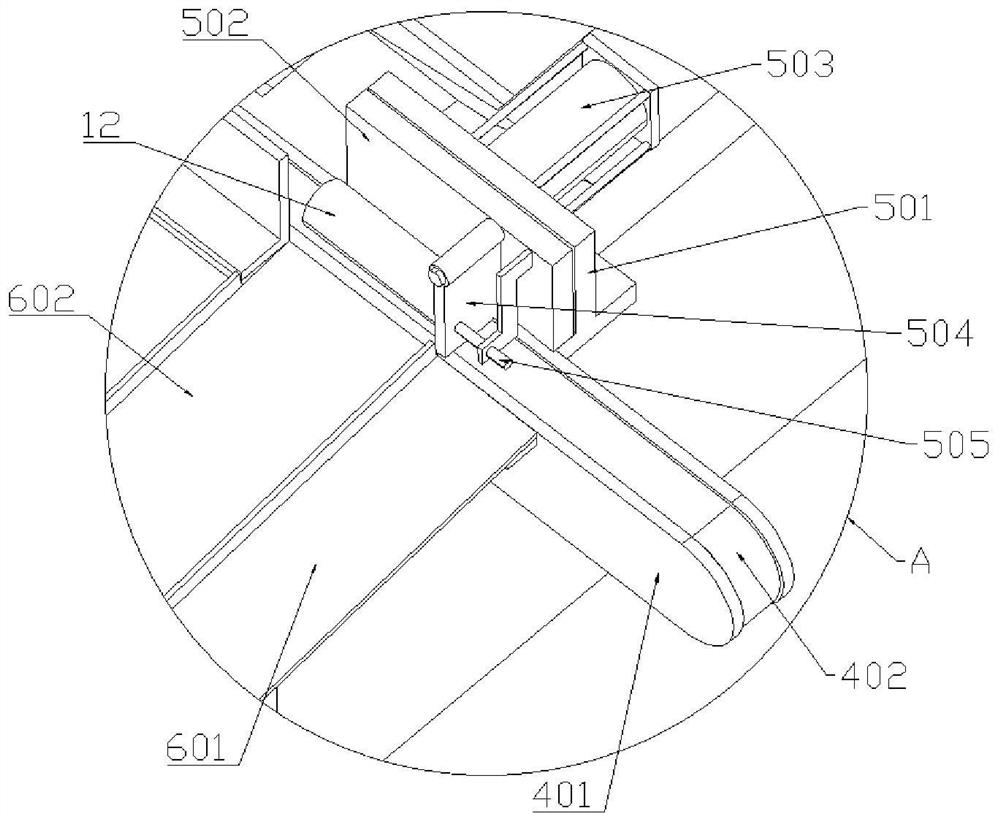

[0028] like Figure 1-Figure 7 As shown, a fully automatic feeding device for a heating furnace includes a turning hopper 2, a feeding bin 3 and an intermediate frequency heating furnace 8. A supporting frame 1 is provided on one side of the feeding bin 3, and the top of the turning hopper 2 is connected to the supporting frame 1. The top end is connected in rotation, and a turning drive device is arranged between the turning bucket 2 and the support frame 1; wherein the turning drive device includes two first hydraulic rods 11 arranged in parallel, and the bottom end of the first hydraulic rod 11 is hinged with the support frame 1, The top end of the first hydraulic rod 11 is hinged with the side of the tipping bucket 2 close to the upper silo 3, and the two first hydraulic rods 11 are externally connected to hydraulic pumps to provide power, and are transformed into the tipping bucket 2 through the telescopic motion of the first hydraulic rods 11. Rotational movement of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com