Frame disassembling system of solar cell

A solar cell and frame technology, applied in the field of solar cells, can solve the problems of component backplane scratches, glass scratches, and impact on battery module production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

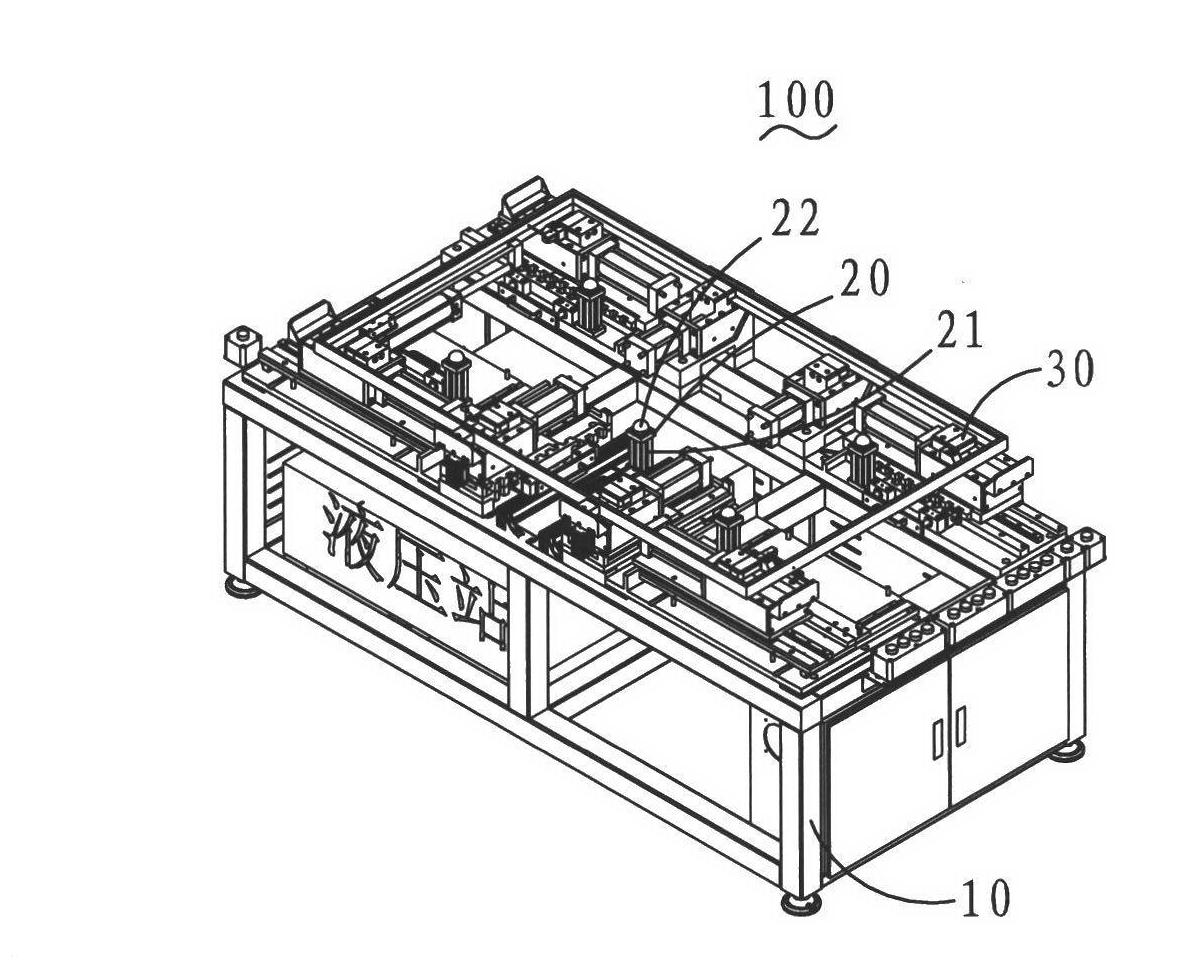

[0021] figure 1 Shown is a preferred embodiment of the solar cell frame disassembly system of the present invention. The solar cell disassembly system 100 includes: a cabinet body 10, a support part 20 and a disassembly device 30, and the support part 20 and the disassembly device 30 are installed on the cabinet body 10 .

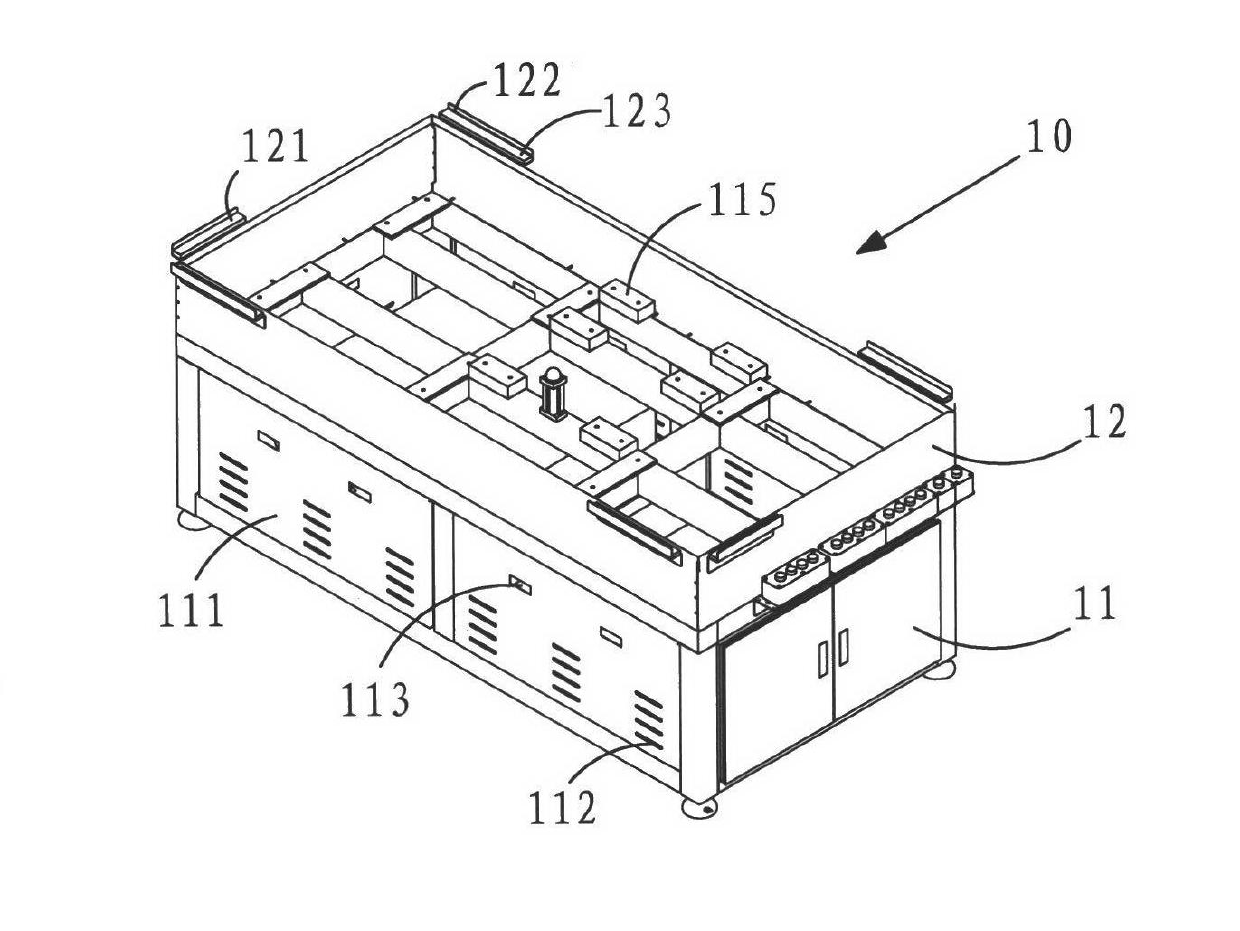

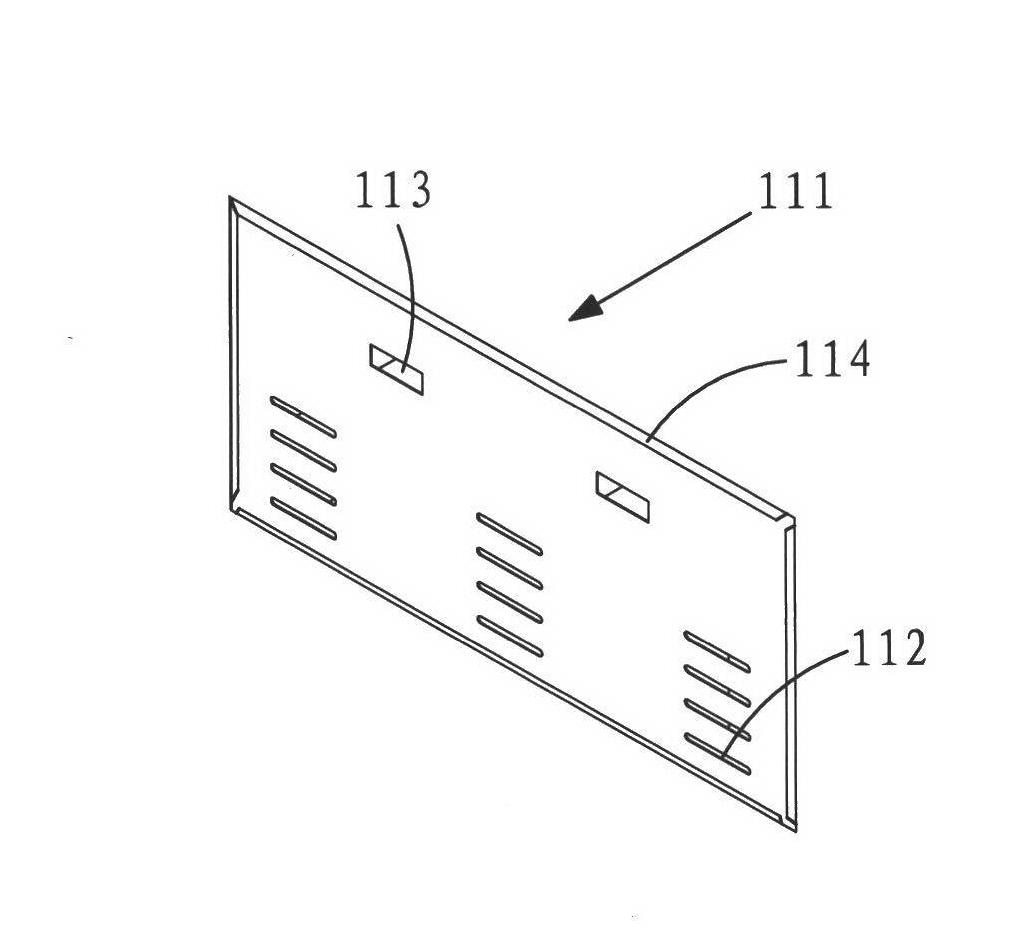

[0022] Please refer to figure 2 As shown, the cabinet body 10 is roughly in the shape of a cuboid, which includes a workbench 11 and a fence 12 arranged on the top of the workbench 11 . A cooling door 111 is provided on the periphery of the workbench 11 for dissipating heat. Please refer to image 3 As shown, the heat dissipation door 111 has a rectangular shape, and a plurality of heat dissipation holes 112 arranged in an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com