Water-jet loom nozzle cluster net disassembly machine

A technology of water jet loom and cluster net, which is applied to looms, textiles, jetting devices, etc., can solve the problems of damaged nozzles and dismantling of the cluster net of nozzle holes, so as to improve production efficiency, improve the success rate of dismantling and dismantling efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

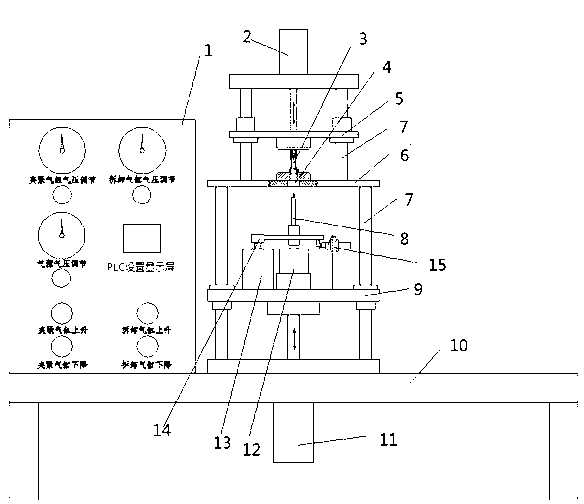

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0013] see figure 1 , the water-jet loom nozzle bundle net removal machine of the present invention is used to disassemble the bundle net from the nozzle 3. , dismantling pull rod 8, stepping motor 13 gear pairs, slewing bearing seat 13, operation panel 1, programmable logic controller and proximity switch 15, the support is composed of 2 pairs of vertical guide columns 7 fixedly connected by three beams, pressing The tightening slide 5 and the dismounting slide 9 are arranged on the guide post 7 and can slide on the guide post 7. The cylinder is divided into a pressing cylinder 2 and a dismounting cylinder 11. The pressing slide 5 and the piston of the pressing cylinder 2 fixed on the upper end of the bracket Rod connection, the dismounting slide plate 9 is connected with the piston rod of the dismounting cylinder 11 fixed on the lower end of the bracket, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com