Material for RFID (Radio Frequency Identification) antenna conductive pattern

A conductive pattern and radio frequency identification technology, applied in the field of RFID antennas, can solve the problems of high cost and large pollution, and achieve the effects of low cost, high conductivity and high oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

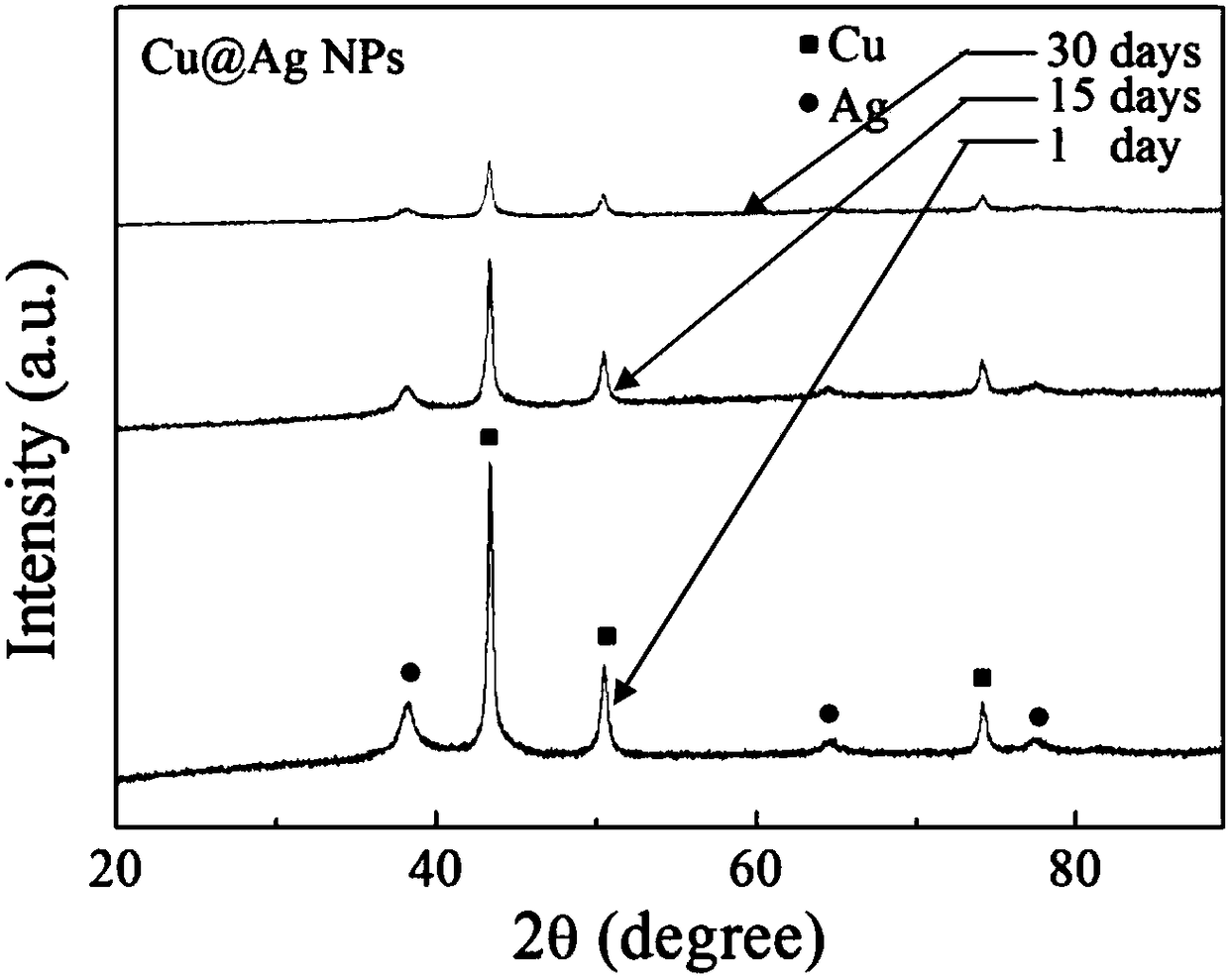

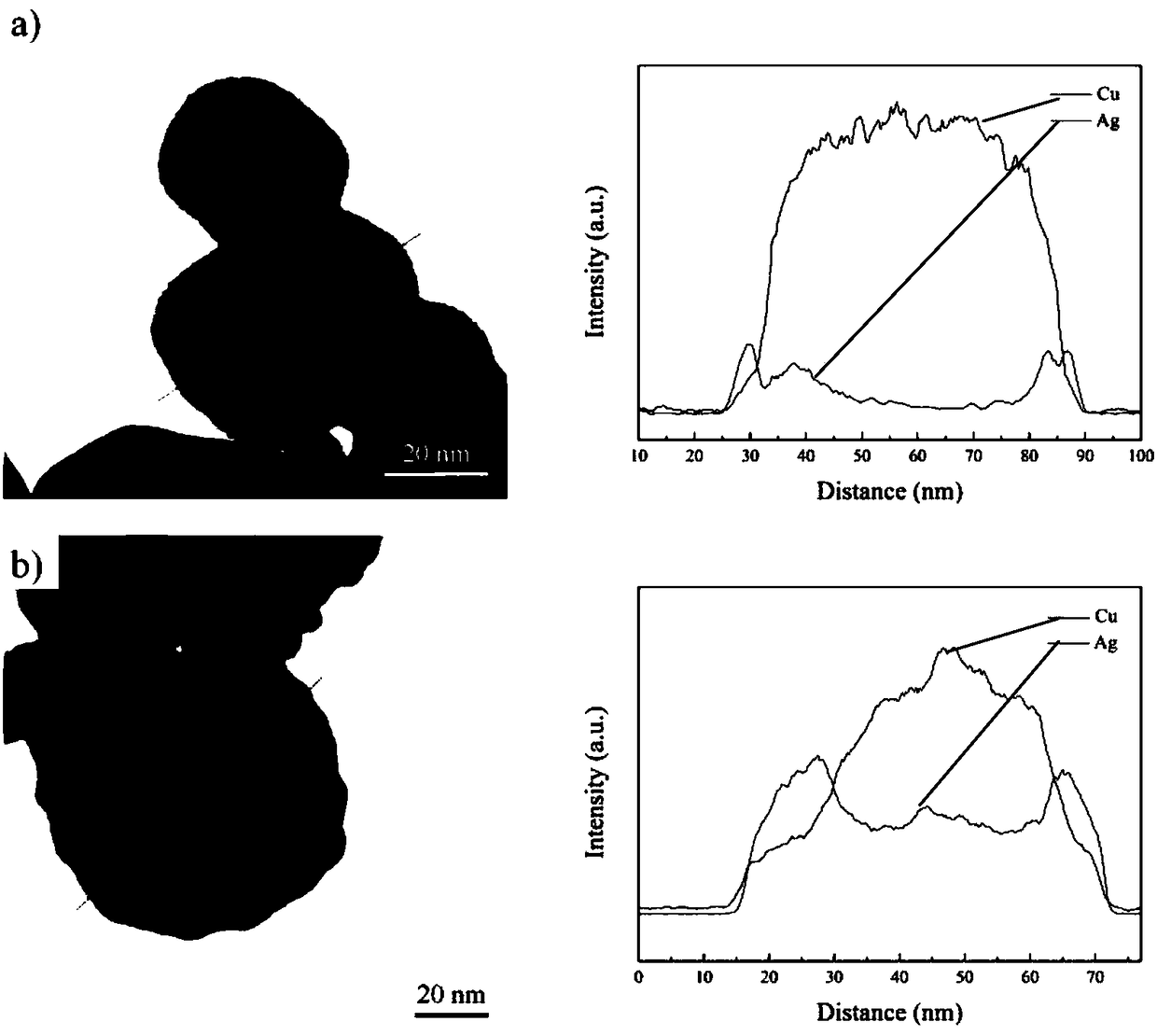

[0058] A preparation of a Cu@Ag core-shell structure nanomaterial for radio frequency identification RFID antenna conductive pattern and manufacturing RFID antenna with the material, specifically comprising the following steps:

[0059] (1) Mix 10g PVP and 10g NaH 2 PO 2 ·H 2 O was dissolved in 160ml of ethylene glycol, and heated to 90°C by magnetic stirring to obtain solution A; 10g of CuSO 4 ·5H 2 O was dissolved in 40ml of ethylene glycol, heated to 90°C by magnetic stirring to obtain solution B, and solution B was poured into solution A, and reacted by magnetic stirring for 10 minutes to obtain a Cu nanoparticle solution; the obtained Cu nanoparticle solution was centrifuged, ethanol Repeatedly washing with deionized water three times to obtain Cu nanoparticles, the preferred particle size is about 50nm.

[0060] (2) 2g Cu nanoparticles and 0.64g trisodium citrate were dissolved in 100ml deionized water to obtain solution C; 0.75gAg 2 SO 4 Dissolve in 250ml deionize...

Embodiment 2

[0069] A preparation of a Cu@Ag core-shell structure nanomaterial for radio frequency identification RFID antenna conductive pattern and manufacturing RFID antenna with the material, specifically comprising the following steps:

[0070] (1) Mix 10g PVP and 10g NaH 2 PO 2 ·H 2 O was dissolved in 160ml ethylene glycol, heated to 70°C with magnetic stirring to obtain solution A; 10g CuSO 4 ·5H 2 O was dissolved in 40ml of ethylene glycol, and heated to 70°C by magnetic stirring to obtain solution B. Pour solution B into solution A and react with magnetic stirring for 10 minutes to obtain a Cu nanoparticle solution; the obtained Cu nanoparticle solution was centrifuged and alcohol Repeated washing with deionized water three times to obtain Cu nanoparticles, with a preferred particle size of about 70nm.

[0071] (2) 2g Cu nanoparticles and 0.64g trisodium citrate were dissolved in 100ml deionized water to obtain solution C; 0.75gAg 2 SO 4Dissolve in 250ml deionized water to o...

Embodiment 3

[0074] A preparation of a Cu@Ag core-shell structure nanomaterial for radio frequency identification RFID antenna conductive pattern and manufacturing RFID antenna with the material, specifically comprising the following steps:

[0075] (1) Mix 10g PVP and 10g NaH 2 PO 2 ·H 2 O was dissolved in 160ml ethylene glycol, heated to 70°C with magnetic stirring to obtain solution A; 10g CuSO 4 ·5H 2 O was dissolved in 40ml of ethylene glycol, heated to 70°C by magnetic stirring to obtain solution B, and solution B was poured into solution A, and reacted by magnetic stirring for 10 minutes to obtain a Cu nanoparticle solution; the Cu nanoparticle solution obtained in (1) After repeated washing with centrifugation, alcohol and deionized water three times, Cu nanoparticles are obtained, with a preferred particle size of about 70nm.

[0076] (2) 2g Cu nanoparticles and 0.64g trisodium citrate were dissolved in 100ml deionized water to obtain solution C; 0.75gAg 2 SO 4 Dissolve in 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com