Metallographic corrosive for super austenitic stainless steel and corrosion method

An austenitic stainless steel, metallographic corrosion technology, applied in the field of metallographic structure analysis, can solve the problems of easy scratching of the sample surface, difficult to handle, over-corrosion corrosion, etc., to promote timely separation from the sample surface, accurate voltage and corrosion resistance. Corrosion time, the effect of accelerating metallographic corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] (1) Corrosive preparation

[0061] At room temperature, add 6g of oxalic acid, 30mL of deionized water and 120mL of concentrated hydrochloric acid (38%) into the beaker successively, stir continuously with a glass rod, and let it stand for 1.5h after the oxalic acid is completely dissolved.

[0062] (2) Metallographic sample preparation

[0063] Cut the sample to be tested with a size of 10mm×10mm×5mm from the super austenitic stainless steel 654SMO ingot, mount the sample with a sample mounting machine, and use 120 mesh, 240 mesh, 400 mesh, 800 mesh, 1200 mesh, 1500 mesh in sequence Roughly grind and finely grind the inlaid sample with 2000-mesh water sandpaper, and then polish the sample with 3.5 μm and 2.5 μm polishing paste in turn, until the surface of the sample is bright without any scratches, pits, or stains After waiting for defects, wash with absolute ethanol and blow dry.

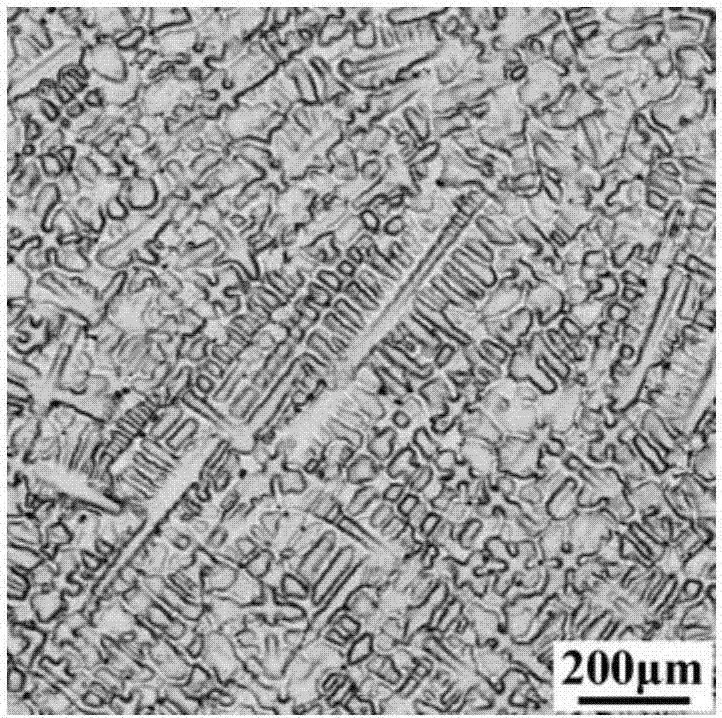

[0064] (3) metallographic corrosion

[0065] A, do anode with the sample after step...

Embodiment 2

[0080] (1) Corrosive preparation

[0081] At room temperature, add 10g of oxalic acid, 10mL of deionized water and 150mL of concentrated hydrochloric acid (38%) into the beaker successively, stir continuously with a glass rod, and let it stand for 2 hours after the oxalic acid is completely dissolved.

[0082] (2) Metallographic sample preparation

[0083] Homogenize the super austenitic stainless steel 654SMO ingot at 1280°C for 20 hours, cut out a sample to be tested with a size of 10mm×10mm×5mm on the ingot, mount the sample with a sample mounting machine, and sequentially use 120 mesh and 240 mesh , 400 mesh, 800 mesh, 1200 mesh, 1500 mesh and 2000 mesh water sandpaper to coarsely grind and finely grind the inlaid sample, and then polish the sample with 3.5μm and 2.5μm polishing paste in turn. After the surface is bright without any scratches, pits, stains and other defects, clean it with absolute ethanol and dry it.

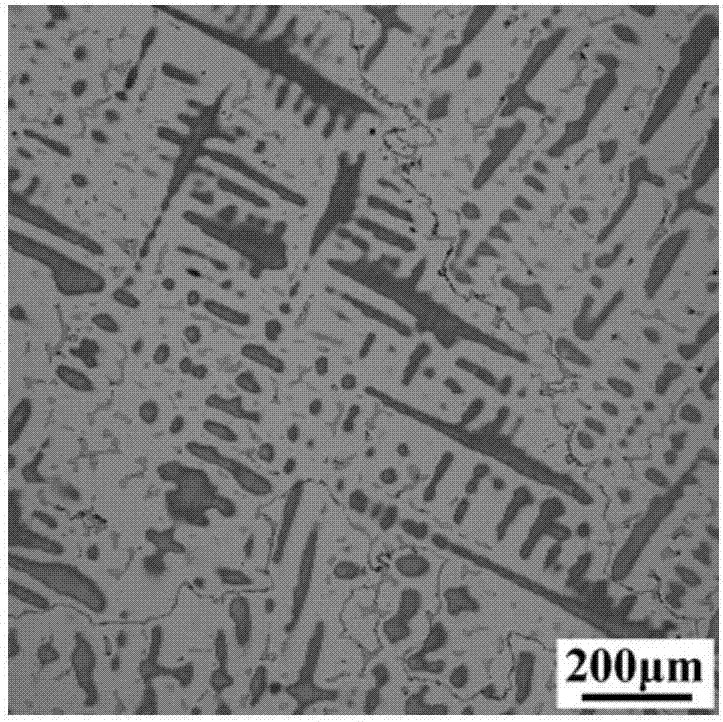

[0084] (3) metallographic corrosion

[0085] A, do ...

Embodiment 3

[0100] (1) Corrosive preparation

[0101]At room temperature, add 3g of oxalic acid, 40mL of deionized water and 100mL of concentrated hydrochloric acid (37%) into the beaker successively, stir continuously with a glass rod, and let it stand for 1 hour after the oxalic acid is completely dissolved.

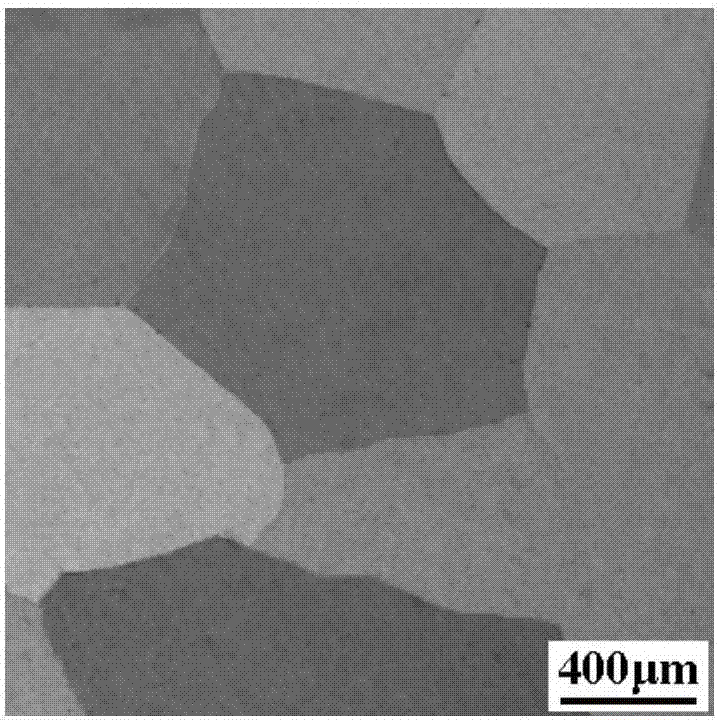

[0102] (2) Metallographic sample preparation

[0103] The homogenized super austenitic stainless steel 654SMO ingot is hot-rolled at 1150-1250°C into a 5mm rolling plate, and a sample to be tested with a size of 10mm×10mm×5mm is cut from the rolling plate, and the sample mounting machine is used for testing. Mount the sample, use 120 mesh, 240 mesh, 400 mesh, 800 mesh, 1200 mesh, 1500 mesh and 2000 mesh water sandpaper to rough and finely grind the mounted sample, and then use 3.5μm and 2.5μm polishing Polish the sample with paste, and after the surface of the sample is bright without any defects such as scratches, pits, stains, etc., clean it with absolute ethanol and dry it. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com