Container prefabricated house assembling type steel reinforced concrete single-double-column foundation and construction method thereof

A container-type, prefabricated house technology, applied in infrastructure engineering, construction, etc., can solve the problems of unenvironmental protection of cast-in-place foundation, inability to quickly adjust the site at any time, low construction efficiency, etc., to improve the reuse rate and light structure , the effect of reducing construction waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

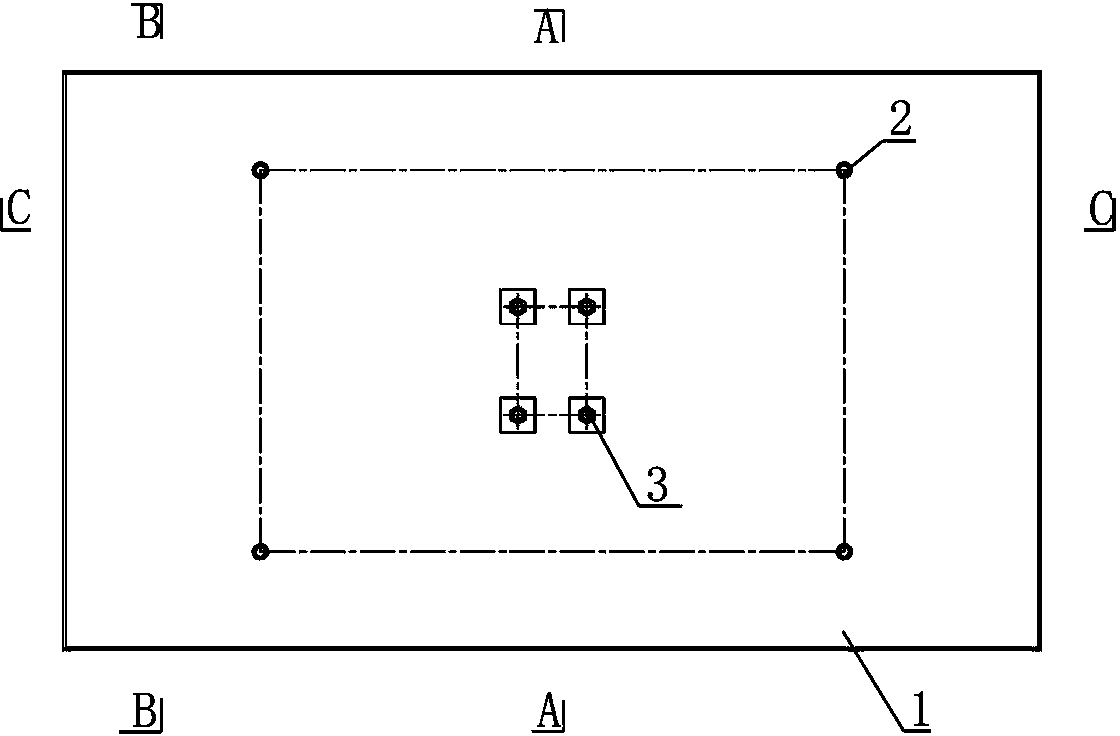

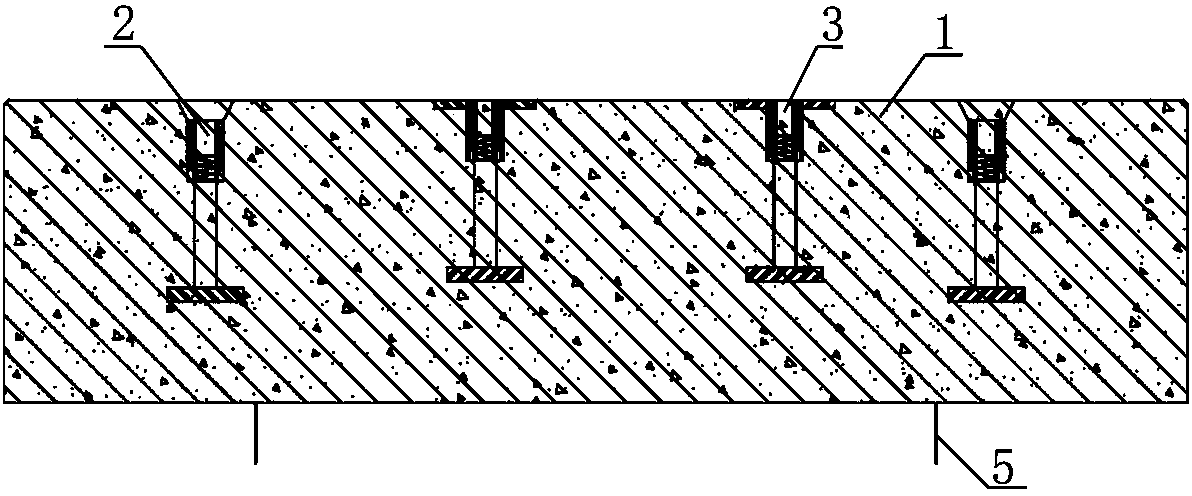

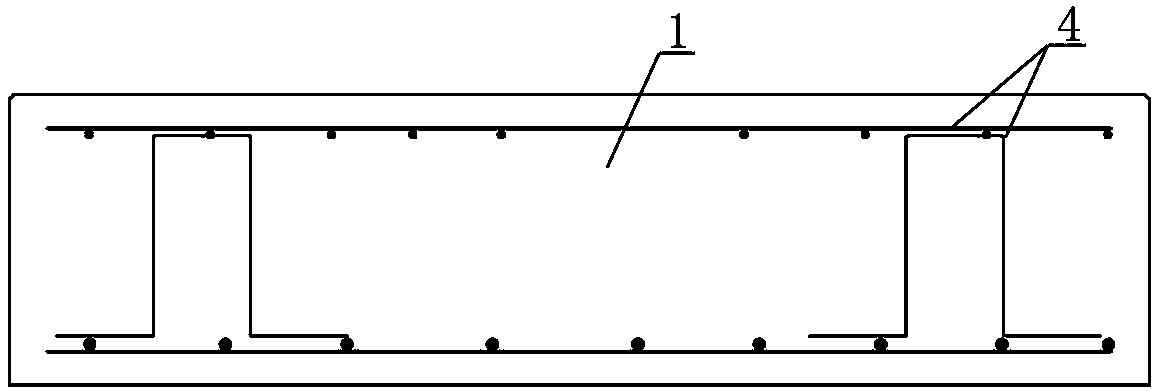

[0047] Examples see Figure 1 to Figure 4 and Figure 12 As shown, a prefabricated prefabricated base plate 1 and H-shaped steel column foot 6 is a prefabricated prefabricated base plate 1 with four pre-buried in the center of the upper surface of the prefabricated base plate 1. The asymmetric I-shaped embedded part 3 is pre-embedded with four T-shaped embedded parts 2 in a rectangular distribution near the edge of the upper surface of the prefabricated foundation floor 1, and the H-shaped steel column foot 6 is located at the center of the upper surface , and insert the asymmetric I-shaped embedded part 3 through the bolt 7 and fix it with the prefabricated base plate 1, and the upper flange of the H-shaped steel column foot 6 is provided with a connecting bolt hole 9.

[0048] A suspension ring 5 is pre-embedded on the lower surface of the prefabricated base plate 1 .

[0049] The T-shaped embedded part 2 refers to Figure 5 and Figure 6, consisting of an internally thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com