Cross-direction supporting pipe fixing device

A fixed device and cross-directional technology, which is applied in the direction of construction and building construction, can solve the problems of difficulty in ensuring the radian at the end of the support pipe, affecting work efficiency, and long construction period, so as to ensure construction speed, improve work efficiency, and reduce The effect of the difficulty of warping error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

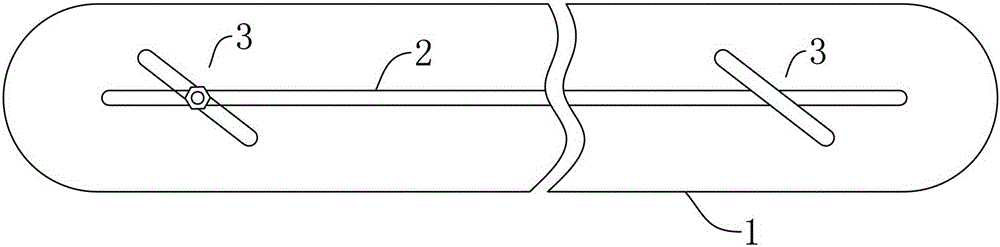

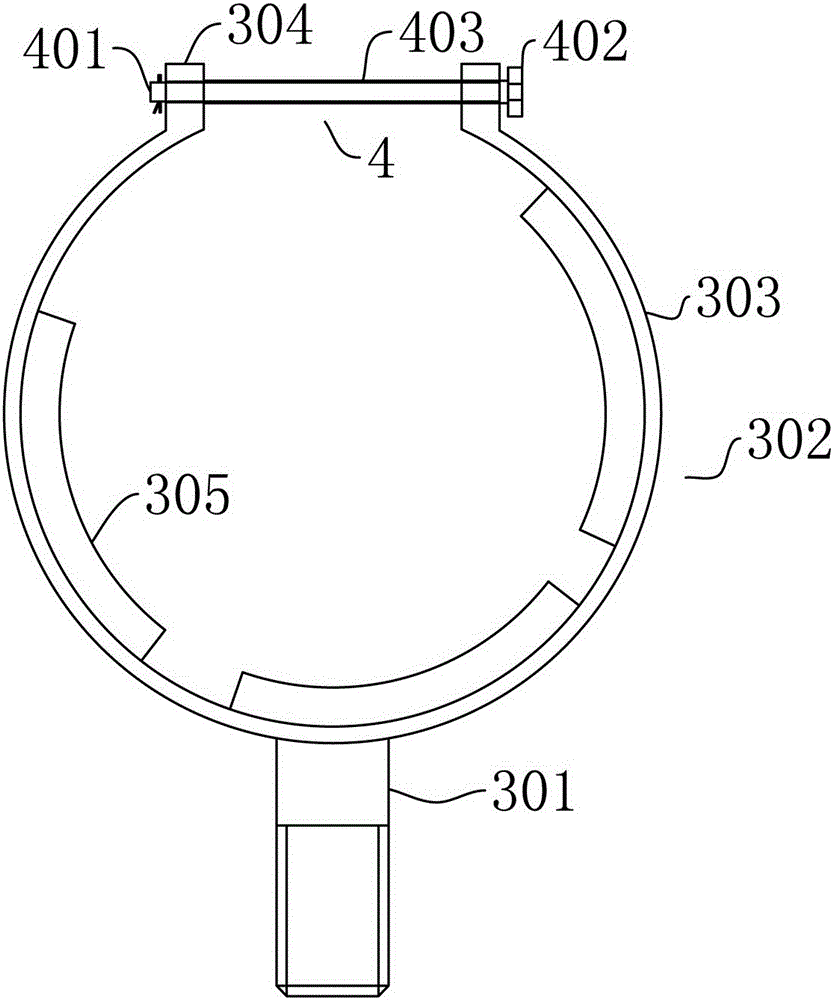

[0011] Embodiment one: if figure 1 with figure 2 As shown, the cross-direction supporting pipe fixing device includes a rigid fixing part 1, and the fixing part 1 is provided with a chute 2 in the middle along its length direction, and the chute 2 is connected with a plurality of fixing seats 3 in rotation and sliding, and the fixing seats 3 includes a slide block 301 that cooperates with the chute 2. An annular hoop 302 is provided on the slide block 301. The hoop 302 includes an outer ring 303 made of elastic material located on the outer ring. The upper end of the outer ring 303 is provided with Opening, the two ends of the opening extend outwards respectively to be provided with lugs 304, between the two lugs 304 is provided with an adjusting bolt 4, one end of the adjusting bolt 4 is rotationally and fixedly connected with a lug 304, the other end of the adjusting bolt 4 is connected with the other One lug 304 is screwed together to form a structure in which the adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com