Supporting and retaining device for open excavation construction of comprehensive pipe gallery and construction method thereof

A technology of integrated pipe gallery and construction method, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of prolonging the construction period, reducing the construction efficiency, affecting the surrounding environment, etc., to improve the degree of mechanization, reduce construction investment, The effect of reducing environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

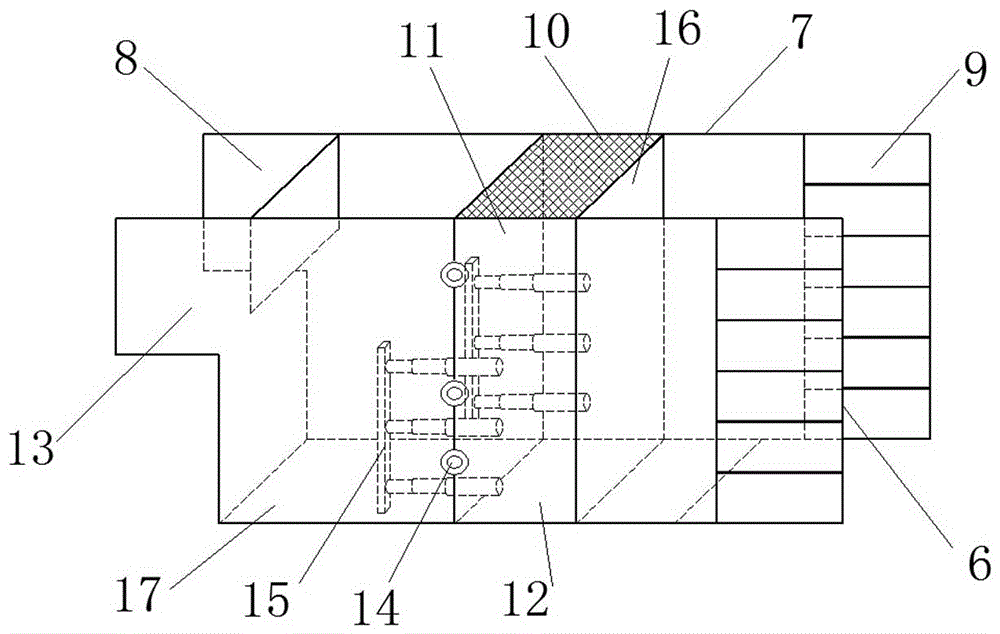

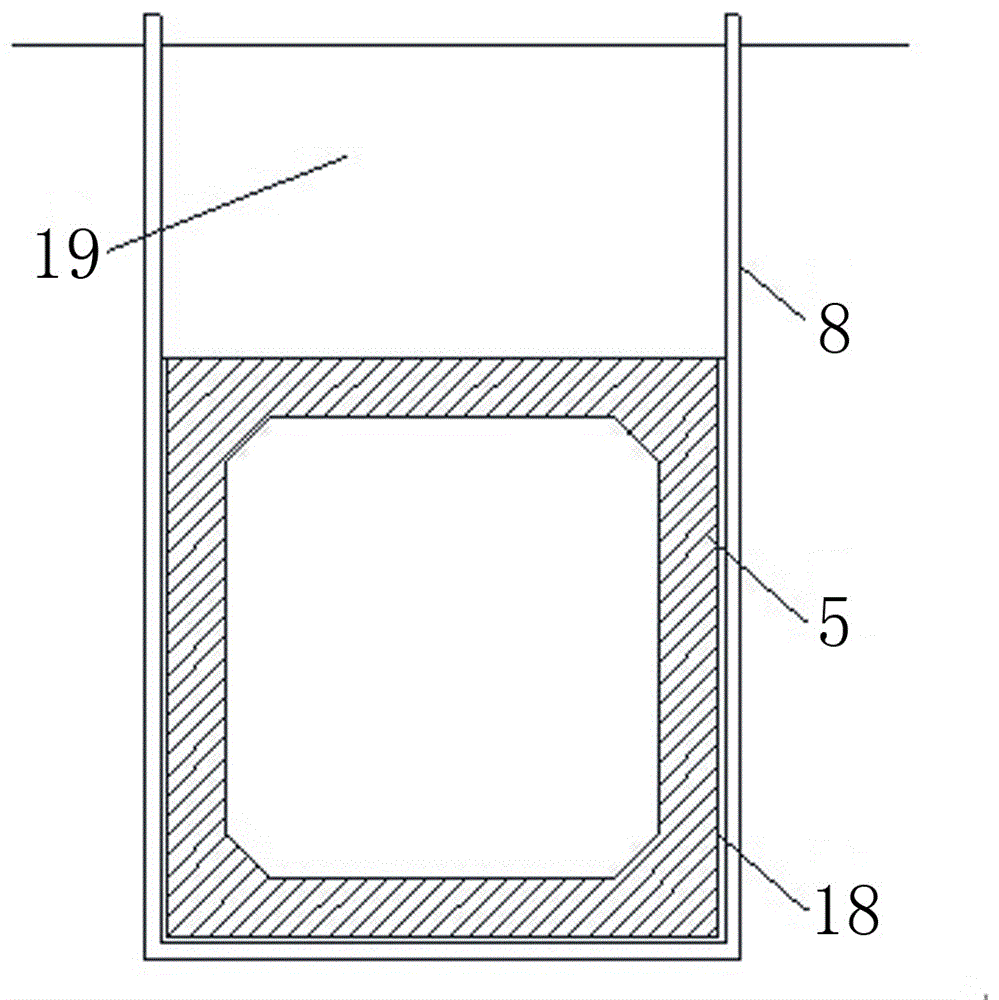

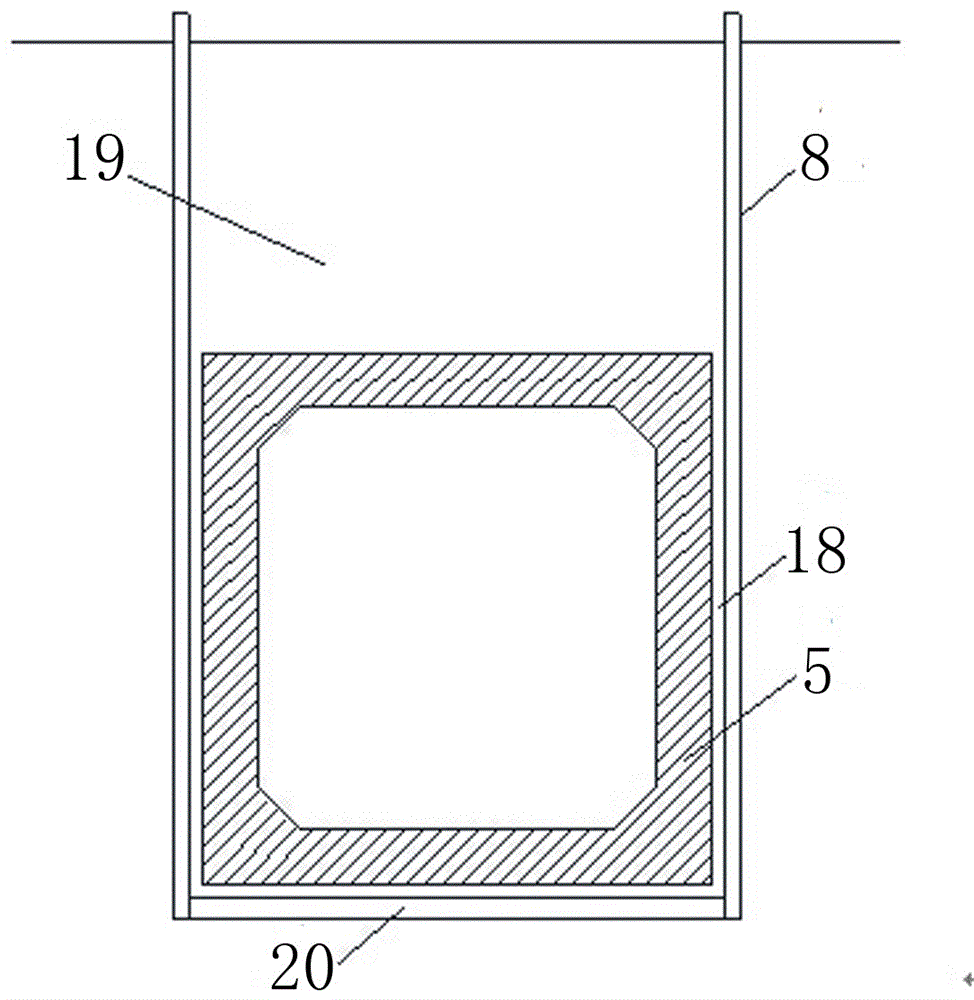

[0031] Embodiment one: if Figure 1~4 As shown, a support device for open-cut construction of a comprehensive pipe gallery is provided, which is mainly a mobile support device composed of a front support 6, a middle support 7 and a tail support 8. The front support of the device is composed of It is composed of telescopic blocks 9 arranged on both sides of the front support, and the middle support is arranged at the rear end of the front support, which is mainly composed of a top plate 10, a side plate 11 and a bottom plate 12. The support is mainly composed of tail side plates 13, the middle support and the tail are connected by a hinged oil cylinder 14, and a propulsion device 15 is also arranged between the tail support and the middle support. The front end of the propulsion device and the middle support The block is connected, and the rear end is connected with the tail support block.

[0032] A partition 16 is arranged inside the middle support.

[0033] A tail bottom p...

Embodiment 2

[0044] Example 2: Take the construction of a single-cabin comprehensive pipe gallery with a section size of 4m wide and 3m high as an example. The pipe gallery is covered with 2m of soil and has a total length of 800m. It is planned to be built under the central green belt of the urban road. Slope excavation, and the use of the traditional enclosure structure will increase the project cost, the construction of the present invention can complete the construction task economically and quickly, in the specific application, first construct the starting work well and the receiving work well of the mobile support device; According to the site and design conditions, the underground comprehensive pipe gallery to be constructed is divided into two sections, each section is 400m in length, and the shield launching shaft and receiving shaft are set at both ends of each section. The two sections connected end to end will be constructed later. The first section can use the receiving well of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com