Construction method for prefabricated box culvert above running subway shield interval structure

A technology for subway shield tunneling and construction methods, which is applied in basic structure engineering, underwater structures, artificial islands, etc., can solve the problems of long construction time and low construction efficiency, and can ensure construction quality, reduce friction, and avoid floating. and deformation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

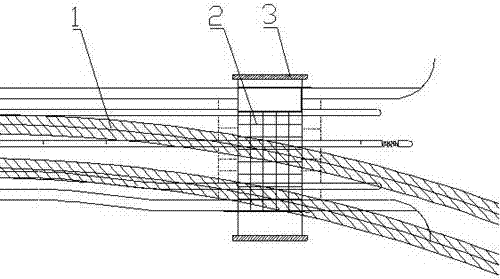

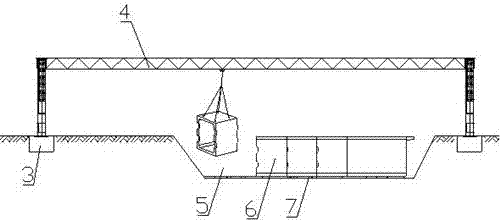

[0033] Such as Figure 1-4 Shown, a kind of porous prefabricated box culvert construction method above the subway shield section structure is characterized in that: the construction method is specifically as follows:

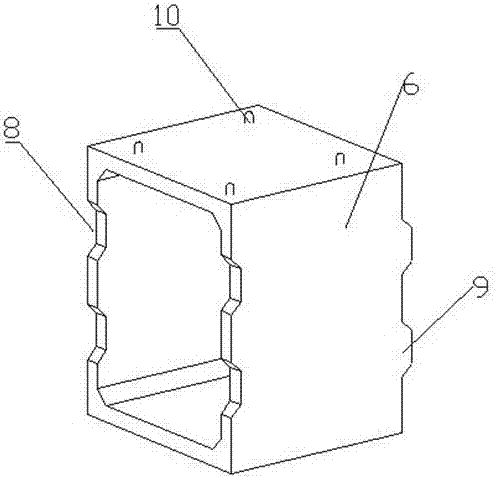

[0034] (1) Prefabricated box culvert 2: The box culvert 2 includes 5*10 assembled single warehouse boxes 6 with an overall size of 20m*40m. The single warehouse box 6 is formed by casting molds, and the interior is equipped with a steel skeleton , the overall shape is a rectangular parallelepiped structure with two ends open, and the open sides of the two sides have a number of concave cavities 8 and several convex blocks 9 nested with the concave cavities 8 on the sides of the adjacent single warehouse box body 6. The end face is provided with several lifting lugs 10;

[0035] (2) Prefabricated site: In this embodiment, the selected site is above the subway shield section structure, the ground elevation is 2.3m, the top elevation of the track structure 1 is -8...

Embodiment 2

[0042] The only difference between this embodiment and Embodiment 1 is that in step (4), the method of prefabricating the cushion layer can be used, and the steel plate is embedded on the side of each cushion layer, and the staggered seam is arranged for assembly, and the steel plate on the side is welded during assembly. Fixed, this method is very suitable in rainy days, and can also ensure construction efficiency; at the same time, the method of combining prefabricated cushion and cast-in-place cushion can be used to further improve the construction progress and reduce the impact on the track structure below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com